Organic fireproof foaming composite of water tank of solar water heater

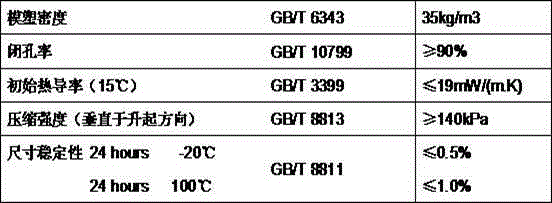

A technology for a solar water heater and a foaming composition, which is applied in the field of polyurethane rigid foam organic fire-proof thermal insulation materials, can solve the problems of non-flammability, uneven mixing, foam cracking, etc., achieve stable thermal insulation performance, avoid water tank deformation, and reduce shrinkage rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 5 parts of glycerol polyether resin, 5 parts of glycol ether resin, 0.2 part of foam stabilizer water-soluble silicone oil, 0.2 part of catalyst N, N-dimethylcyclohexylamine, 0.3 part of curing agent dilaurel Acetate dibutyltin, 0.2 part of water, after mixing, form raw material all-water type combination polyether, then add 3 kilograms of dimethyl ethers, 4 kilograms of chitosan of 500,000-800,000 molecular weight according to 80 kilograms of all-water type combination polyethers (with 3% acetic acid dissolved) and 7 kg of center hole expanded perlite, add brominated flame retardant pentabromotoluene, mix uniformly to form a polyether composition, and then mix with isocyanate at a mass ratio of 1:1.4 and pour into the cavity of the solar water heater tank The organic fireproof foam insulation layer of the solar water heater water tank of the present invention can be obtained after high temperature curing.

Embodiment 2

[0041] Take the polyether produced by Huizhou Foam King Products Co., Ltd., add 4 kg of dimethyl ether, 3 kg of chitosan with a molecular weight of 500,000-800,000 (dissolved with 3% acetic acid) and expanded perlite with a center hole 8 kg, add 3 kg of decabromodiphenyl ether, mix evenly to form a polyether composition, and then mix it with diphenylmethane diisocyanate (MDI) at a mass ratio of 1:1.3 and pour it into the cavity of the solar water heater for foaming. After curing at high temperature, the organic fireproof foaming insulation layer of the solar water heater water tank of the present invention can be obtained.

Embodiment 3

[0043] Weigh 6 parts of glycerol polyether resin, 4 parts of glycol ether resin, 0.3 part of foam stabilizer water-soluble silicone oil, 0.3 part of catalyst N, N-dimethylcyclohexylamine, 0.2 part of curing agent dilaurel Acetate dibutyltin, 0.3 part of water, after mixing, form raw material all-water type combination polyether, then add 4 kilograms of dimethyl ether, 5 kilograms of chitosan of 500,000-800,000 molecular weight according to 80 kilograms of all-water type combination polyethers (with 3% acetic acid dissolved) and 8 kg of center hole expanded perlite, or tetrabromobisphenol. Mix evenly to form a polyether composition, then mix with toluene diisocyanate (TDI) at a mass ratio of 1:1.3 and pour it into the cavity of the solar water heater tank for foaming, and after high temperature curing, the solar water heater tank of the present invention can be obtained Organic fireproof foam insulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com