HCM glue powder polyphenyl particle external wall thermal insulation system

A technology of rubber powder polystyrene particles and external wall insulation, which is applied in the direction of walls, building components, covering/lining, etc., can solve the problems of unsuitable veneer bricks, high construction difficulty, poor air permeability and crack resistance, etc., and achieve convenient construction, The effect of high softening number and low drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: The outer layer is paint

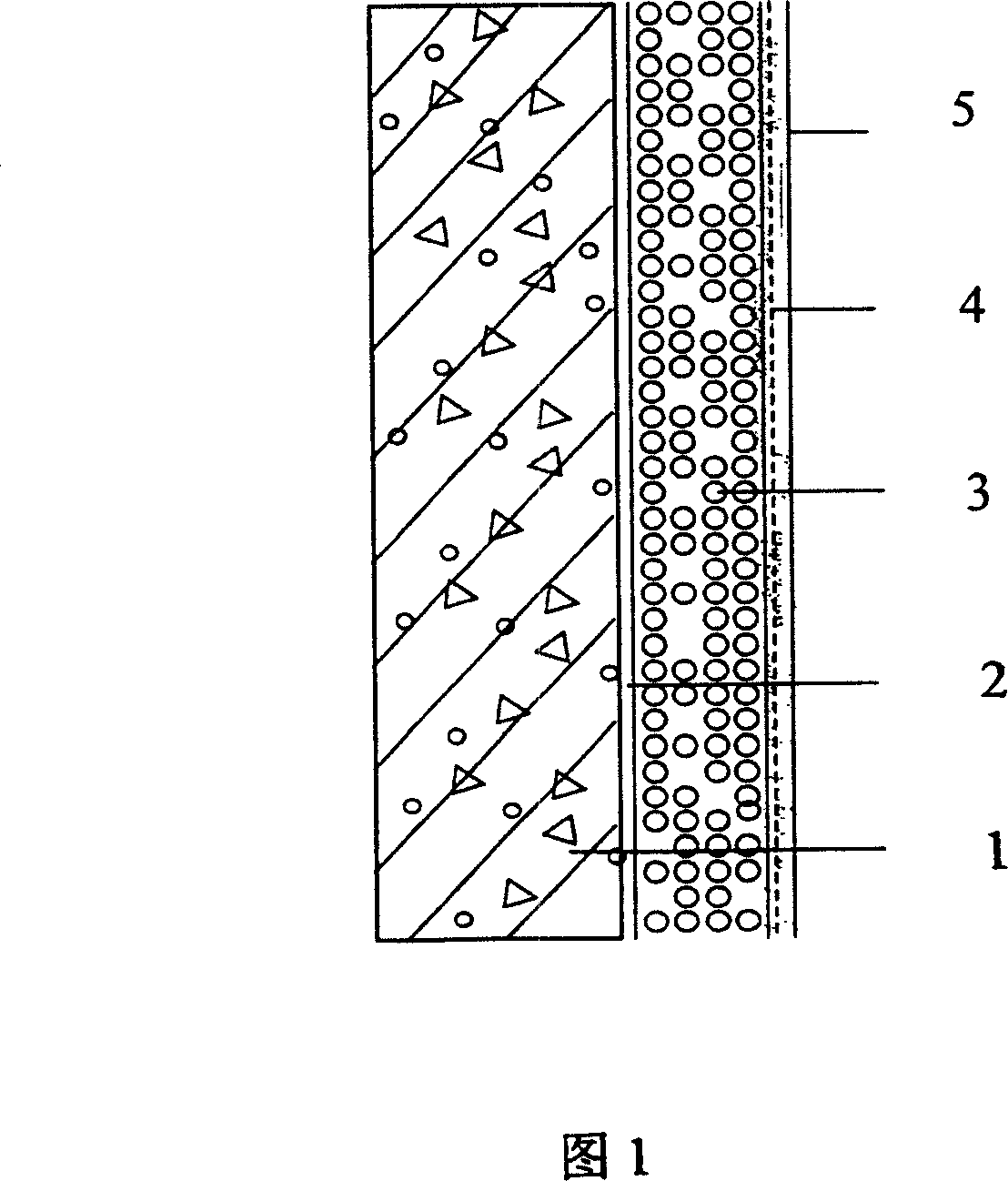

[0038] As shown in Figure 1, it is a schematic diagram of the coating structure for the outer layer, and the described a kind of HCM rubber powder polyphenylene particle external wall insulation system consists of a base wall body 1, an HCM interface layer 2, and an HCM rubber powder polyphenylene particle insulation layer 3 , armor layer 4, and outer layer 5, an HCM interface layer 2 is provided between the base wall body 1 and the HCM rubber powder polystyrene particle insulation layer 3, and an HCM rubber powder polystyrene particle insulation layer 3 and the outer layer 5 are provided. There is a face protection layer 4, the face protection layer 4 is composed of two layers of HCM cement mortar anti-cracking layer, and HCM is coated with alkali-resistant glass fiber mesh cloth, and the outer layer 5 is made of HCM polymer emulsion waterproof Elastic primer, composed of scraping HCM anti-crack flexible water-resistant putty and t...

Embodiment 2

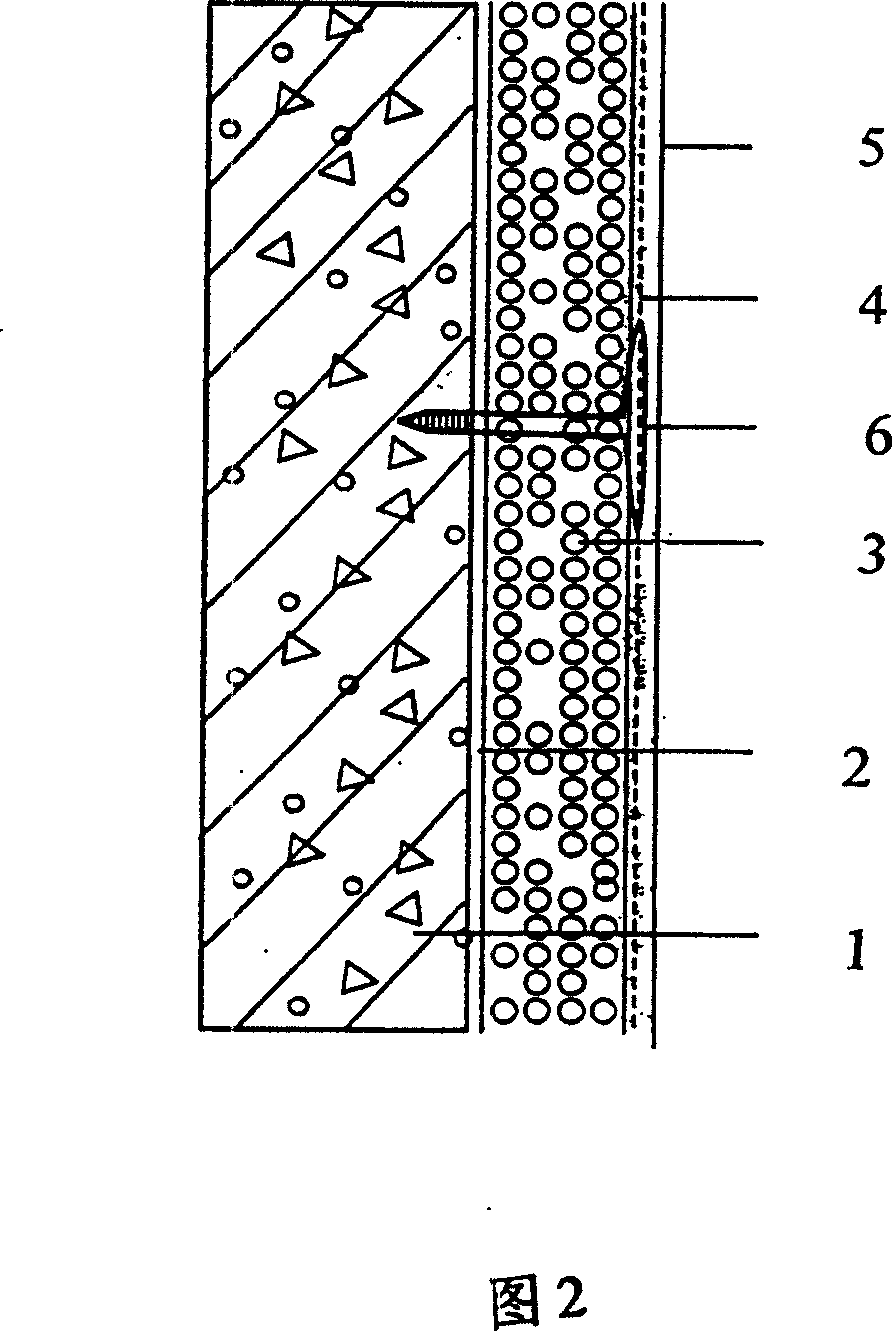

[0047] Embodiment 2: the outer layer is facing brick

[0048] As shown in Figure 2, it is a schematic diagram of the structure of the outer layer as a face brick, and the described protective layer 4 is composed of anchor nails 6 embedded in the back of the hot-dip galvanized steel mesh between the two layers of HCM cement mortar anti-cracking layers; the outer layer 5 Consists of a special adhesive layer for HCM thermal insulation wall bricks, a special jointing agent for HCM thermal insulation wall bricks, and an external facing brick. The facing bricks are made of stone or schist, and the others are the same as in Example 1.

[0049] The outer layer is the surface brick HCM rubber powder polystyrene particles The construction method of the external wall external insulation system:

[0050] Step 4: Apply HCM cement mortar anti-cracking agent, bury hot-dip galvanized steel wire mesh, and nail anchor nails 6;

[0051]Step 5: Apply the HCM cement mortar anti-cracking agent for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com