Graphene oxide-based insulating mortar and preparation method thereof

A thermal insulation mortar and graphene-based technology, applied in the field of construction, can solve the problems of poor thermal performance and durability of thermal insulation mortar, and achieve the effects of remarkable technological progress, good mechanical properties and durability, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

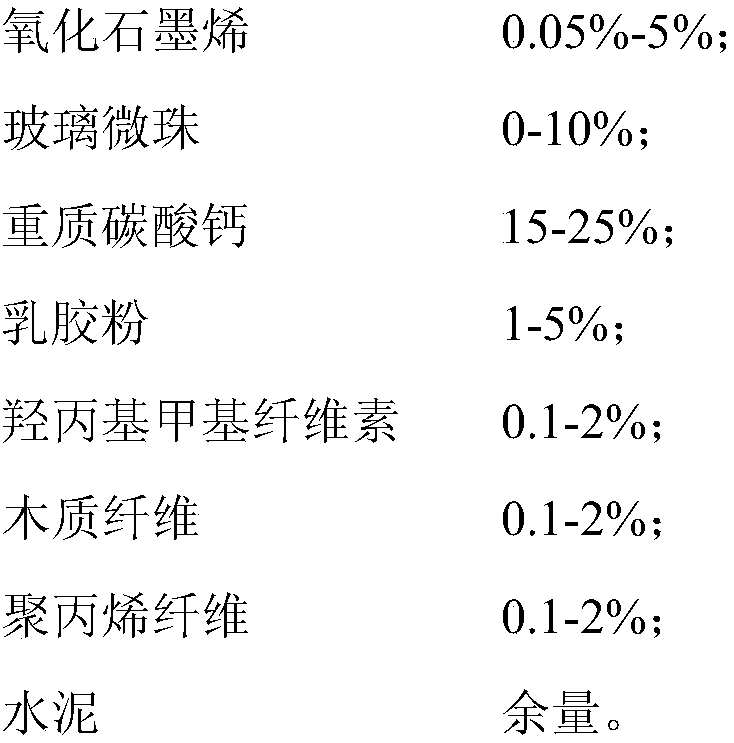

Image

Examples

Embodiment 1

[0020] Preparation of graphene oxide-based thermal insulation mortar:

[0021] Disperse 0.5% graphene oxide in water equal to the total dry weight of mortar, and then prepare dry powder according to the following mass percentage raw materials: cement 70%, heavy calcium carbonate 24%, rubber powder 2%, hydroxypropyl methylcellulose 1 %, wood fiber 1.0%, polypropylene fiber 1.5%. Add the mixed dry powder to the graphene oxide dispersion, and stir at a constant speed for 5-10 minutes to obtain a graphene oxide-based thermal insulation mortar, which can be applied to the wall.

Embodiment 2

[0023] Preparation of graphene oxide-based thermal insulation mortar:

[0024] Disperse 1% graphene oxide in water equal to the total dry weight of mortar, and then prepare dry powder according to the following mass percentage raw materials: cement 70%, heavy calcium carbonate 24%, rubber powder 2%, hydroxypropyl methylcellulose 1 %, wood fiber 1%, polypropylene fiber 1%. Add the mixed dry powder to the graphene oxide dispersion, and stir at a constant speed for 5-10 minutes to obtain a graphene oxide-based thermal insulation mortar, which can be applied to the wall. The graphene oxide-based thermal insulation mortar prepared in embodiment 2 is inspected as follows after hardening:

[0025] Test items

Embodiment 3

[0027] Preparation of graphene oxide-based thermal insulation mortar:

[0028] Disperse 5% graphene oxide in water equal to the total dry weight of mortar, and then prepare dry powder according to the following mass percentage raw materials: glass microspheres 5%, cement 60%, heavy calcium carbonate 24%, rubber powder 2%, hydroxypropyl 1% methyl cellulose, 1% wood fiber, 2% polypropylene fiber. Add the mixed dry powder to the graphene oxide dispersion, and stir at a constant speed for 5-10 minutes to obtain a graphene oxide-based thermal insulation mortar, which can be applied to the wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com