Cast-in-site rigid bone self-heat-preservation wall body, building blocks and wall building method

A technology of self-insulating blocks and cast-in-place rigid bones, which is applied to walls, building materials, and building components, and can solve problems such as cumbersome processes, low production capacity, and low compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

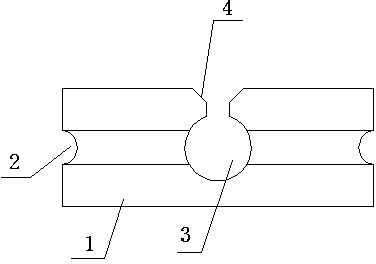

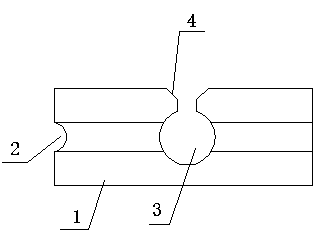

[0035] by attaching figure 1 , 2 , 7 It can be seen that a block for cast-in-place rigid-frame self-insulating walls of this scheme includes a concrete self-insulating block body 1, and grooves are arranged on the upper and lower parts of the concrete self-insulating block body 1 2. Both ends of the concrete self-insulating block body 1 are provided with grooves 2, and a through hole 3 penetrating through the concrete self-insulating block body 1 is provided in the middle of the concrete self-insulating block body 1, and the side wall of the through hole has Opening 4. The opening 4 is V-shaped, and the distance between the side of the opening 4 away from the through hole 3 is greater than the distance between the side of the opening 4 and the side close to the through hole 3 .

[0036] The thermal conductivity of the concrete self-insulating block body 1 is less than 0.041. The concrete self-insulating block body 1 is a polyphenylene granular concrete self-insulating block...

specific Embodiment approach 2

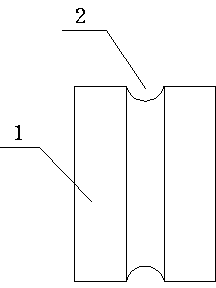

[0042] by attaching image 3 , 4 , 7 It can be seen that the difference between this embodiment and Embodiment 1 is that the upper and lower parts of the concrete self-insulating block body 1 are provided with grooves 2, and one end of the concrete self-insulating block body 1 is provided with grooves 2 .

[0043] The method for building a cast-in-place rigid frame self-insulation wall by using the above-mentioned concrete self-insulation blocks is characterized in that it comprises the following steps:

[0044] a. Pre-set criss-cross rigid frame support, which is a support composed of steel bars and wire ropes at the same time, and the vertical rigid frame interval distance is the same as the length of the concrete self-insulating block;

[0045] b. Lay prefabricated concrete self-insulation blocks 1 on the rigid frame support, one end of all concrete self-insulation blocks 1 with the groove 2 faces the same side, and the vertical rigid frame enters the through hole through...

specific Embodiment approach 3

[0047] by attaching Figure 5 , 6 , 7 It can be seen that the difference between this embodiment and Embodiment 1 is that the upper or lower part of the concrete self-insulating block body 1 is provided with a groove 2, and both ends of the concrete self-insulating block body 1 are provided with grooves 2.

[0048]The method for building a cast-in-place rigid frame self-insulation wall by using the above-mentioned concrete self-insulation blocks is characterized in that it comprises the following steps:

[0049] a, preset criss-cross rigid frame supports, the rigid frame supports are bamboo pole supports, and the vertical rigid frame spacing distance is the same as the length of the concrete self-insulation block;

[0050] b. Prefabricated concrete self-insulation blocks 1 are laid on the rigid frame support, and all the concrete self-insulation blocks 1 have grooves 2 on the upper or lower part at the same time downward or upward, and the vertical rigid frame passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com