Polymer aqueous asphalt colloid and preparation method thereof

A technology of polymer and asphalt, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problem that the colloid cannot be used alone, achieve good emulsification effect, prolong the demulsification time, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

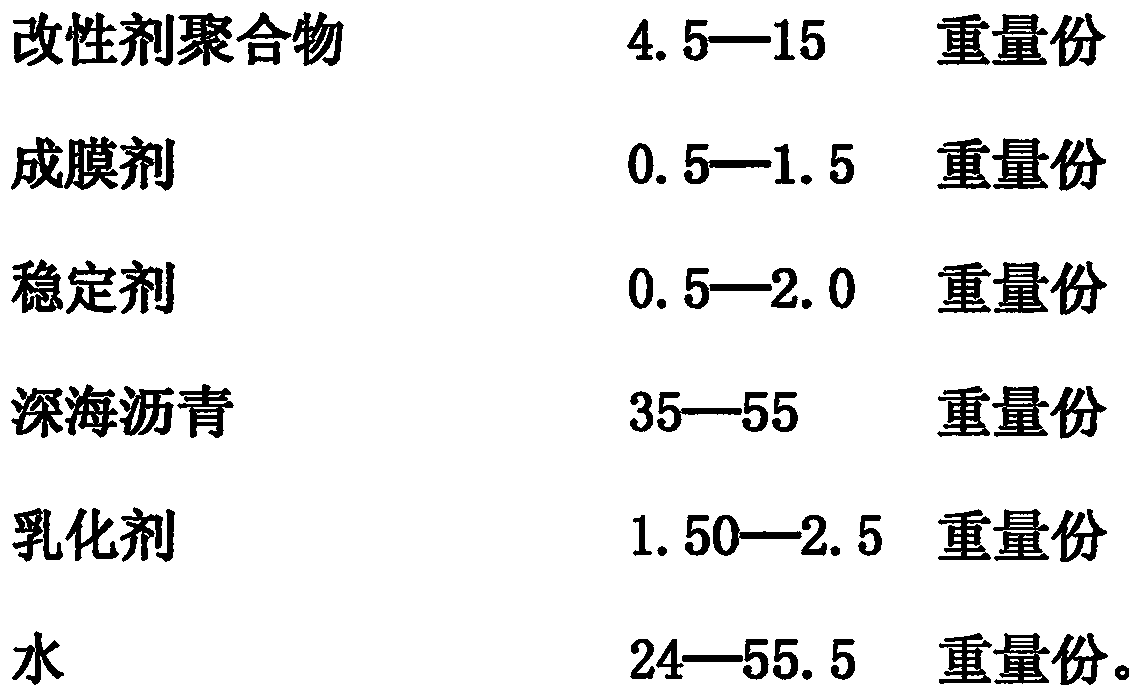

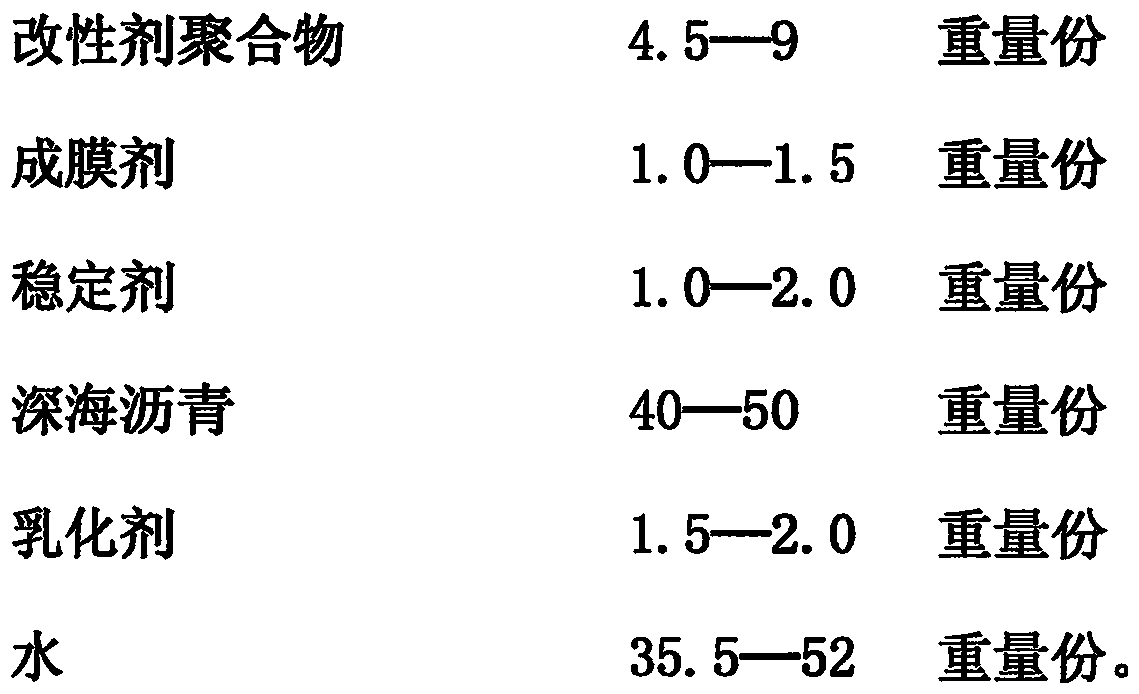

Method used

Image

Examples

Embodiment 1

[0043] Get 80 grams of clean water, add 15 grams of slow-cracking and quick-drying type RC-SMRHJ804 (commercially available) emulsifier in the water, add 60 grams of SBR latex, 5 grams of vinylpyrrolidone / vinyl acetate copolymer, polyethylene glycol fat After 7.5 g of the acid ester was stirred evenly, when the temperature reached 65° C., the stirring was continued and the temperature was maintained. Take 272.5 grams of AH-70# deep-sea asphalt A, heat it to 145°C, stir it evenly, then add it to a shearing machine and a colloid mill for grinding twice at a speed of 4900 rpm, and process for 5 minutes to obtain the polymer to be prepared. Water-based asphalt colloid. The test results (see Table 2) show that the various indicators are relatively ideal, the residual amount on the sieve is small, the storage stability is good, the softening point is high, the viscosity is good, and the aging performance is good.

Embodiment 2

[0052] Get 135 grams of clean water, add 7.5 grams of polyoxyethylene alkyl quaternary ammonium salt emulsifier, 1.5 grams of sodium methylene bis-naphthalene sulfonate, 10 grams of graft copolymers of polyorganosiloxane and polyols in the water Stabilizer, stir well and heat to 65°C, then add 30 grams of acrylonitrile-butadiene-styrene resin copolymer latex, mix well, keep warm for later use, and take 310 grams of deep-sea bitumen C, heat to 145°C, heat After uniformity, enter the colloid mill for grinding together with the prepared solution at the same time, and the speed is 4900 rpm. After shearing and grinding for 5 minutes, the qualified polymer water-based asphalt colloid was obtained. The analysis results show (see Table 3), the viscosity of the colloid, the remaining amount on the sieve, and the evaporation residue content reach the specified standards, the storage stability is only 0.06 in 24 hours, the low temperature storage stability has no particles, no agglomerat...

Embodiment 3

[0055] Take 155 grams of clean water, add 9 grams of RC-CO5 emulsifier, 6 grams of vinylpyrrolidone homopolymer film-forming agent, and 10 grams of Sasobid stabilizer, stir well, heat to 65°C, and then add 5 grams SBS latex copolymer, continue to stir the mixture to maintain the temperature evenly for use, and take 305 grams of deep-sea AH-100# asphalt, and heat it to 145°C. After being heated evenly, slowly add it into the prepared solution and stir evenly, then shear and grind for 5 minutes in a shearing machine and a colloid mill at a speed of 3900 rpm to obtain qualified asphalt colloid (see Table 3 for its properties). The colloid has high viscosity, good stability, no coarse particles and agglomerates in low temperature storage, high softening point, strong viscosity and toughness, which is conducive to the maintenance of micro-surfaces. The original roadbed of Qianrong Line in Wuxi City is still good, but the road surface is damaged, cracked, and pitted Groove, use the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com