Hot-melt pressure sensitive adhesive for adhesive tapes, and preparation method thereof

A technology of hot-melt pressure-sensitive adhesives and tapes, applied in the direction of pressure-sensitive films/sheets, adhesives, heat-activated films/sheets, etc., which can solve the problems of poor bonding strength, poor aging performance of tapes, and inability to combine them at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

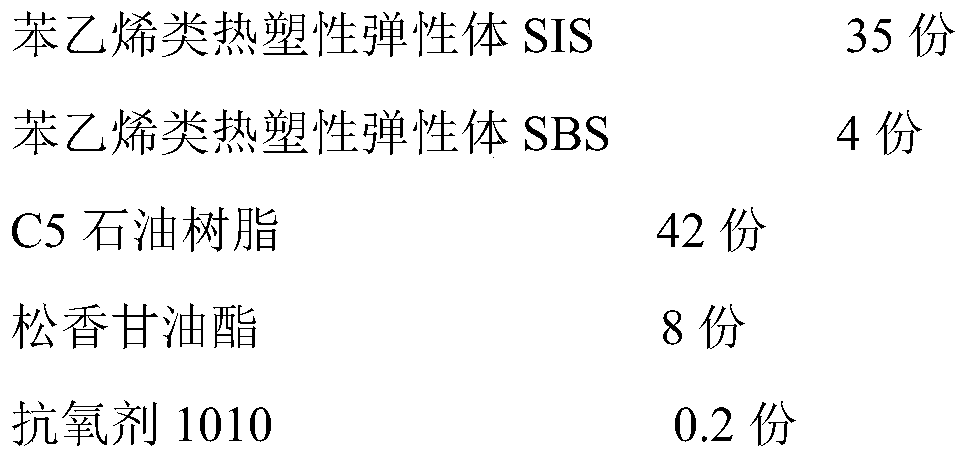

[0033] A hot-melt pressure-sensitive adhesive for tapes, comprising the following components in parts by weight:

[0034]

[0035]

[0036] The preparation method of the hot-melt pressure-sensitive adhesive is as follows:

[0037] (1) According to Example 1, styrene-based thermoplastic elastomers (SIS, SBS), petroleum resin, rosin glyceride, antioxidant 1010, antioxidant 168, and naphthenic oil were weighed.

[0038] (2) Put a stirring bar, a thermometer and a softener into a washed and dried three-neck flask, the heating temperature is 130° C., and the stirring rate is 100 r / min.

[0039] (3) Add petroleum resin and primary and secondary antioxidants in step (2), fill with nitrogen, evacuate, heat up to 165°C, the stirring rate is the same as that of step (1), and the heating time is 40min.

[0040] (4) add rosin glyceride in step (3) reaction vessel, temperature is maintained on about 165 ℃, and stirring rate is identical with step (2), after petroleum resin is all me...

Embodiment 2

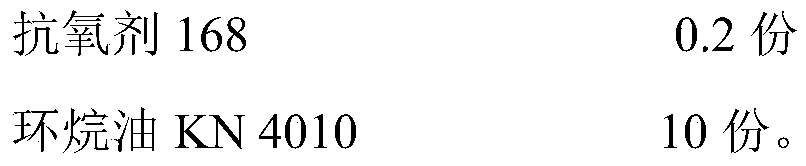

[0046] A hot-melt pressure-sensitive adhesive for tapes, comprising the following components in parts by weight:

[0047]

[0048] The preparation method of the hot-melt pressure-sensitive adhesive is as follows:

[0049] (1) According to Example 2, styrene-based thermoplastic elastomers (SIS, SBS), petroleum resin, rosin glyceride, antioxidant 1010, antioxidant 168, and naphthenic oil were weighed.

[0050] (2) Put a stirring rod, a thermometer, and a softener into a washed and dried three-neck flask, the heating temperature is 120° C., and the stirring rate is 100 r / min.

[0051] (3) Add petroleum resin and primary and secondary antioxidants in step (2), fill with nitrogen, evacuate, heat up to 160°C, the stirring rate is the same as in step (1), and the heating time is 38min.

[0052] (4) add rosin glyceride in step (3) reaction vessel, temperature is maintained on about 165 ℃, and stirring rate is identical with step (2), after petroleum resin is all melted to each com...

Embodiment 3

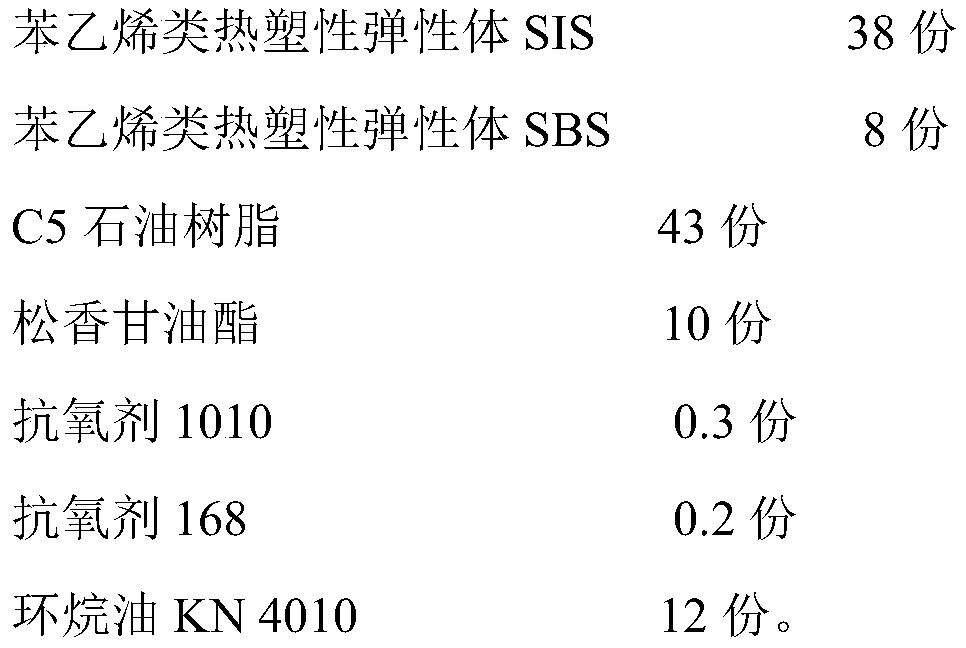

[0058] A hot-melt pressure-sensitive adhesive for tapes, comprising the following components in parts by weight:

[0059]

[0060] The preparation method of the hot-melt pressure-sensitive adhesive is as follows:

[0061] (1) According to Example 3, styrene-based thermoplastic elastomer (SIS, SBS), petroleum resin, rosin glyceride, antioxidant 1010, antioxidant 168, and naphthenic oil were weighed.

[0062] (2) Put a stirring rod, a thermometer, and a softener into a washed and dried three-neck flask, the heating temperature is 120° C., and the stirring rate is 100 r / min.

[0063] (3) Add petroleum resin and primary and secondary antioxidants in step (2), fill with nitrogen, evacuate, heat up to 160°C, the stirring rate is the same as in step (1), and the heating time is 40min.

[0064] (4) add rosin glyceride in step (3) reaction vessel, temperature is maintained on about 165 ℃, and stirring rate is identical with step (2), after petroleum resin is all melted to each comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com