High-potential gradient zinc oxide voltage piezo-resistor material and preparation method thereof

A varistor, zinc oxide technology, applied in the field of high potential gradient zinc oxide varistor materials and its preparation, can solve the problems of restricting product export and application range, and can not meet the requirements, and achieve good flow capacity and energy tolerance Ability, reduced size, and strong combined wave resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

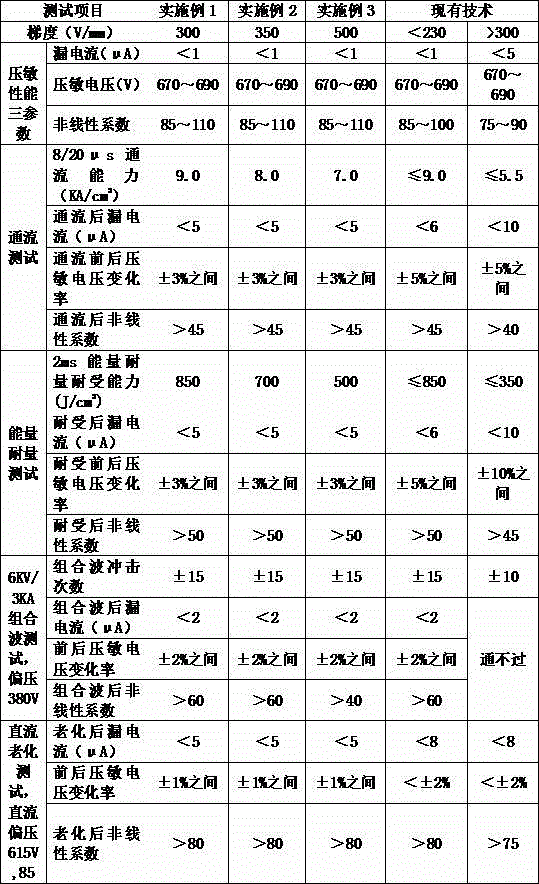

Examples

Embodiment 1

[0025] A preparation method of a high potential gradient zinc oxide varistor is carried out according to the following steps:

[0026] 1. First, accurately weigh 57.12 grams of analytically pure raw material with a purity ≥ 99% 2 o 3 , 1.5 g B 2 o 3 , 0.8g Ag 2 O, 0.4 g Al 2 o 3 , 6.92 grams of SiO 2 , 8.56 g ZrO 2 , 15.5 g SnO 2 , 7 grams of MgO, 2.2 grams of K 2 CO 3 , put it into a ball mill jar, add 400 grams of zirconium balls and 200 grams of deionized water, and mix it with a planetary ball mill for 4 hours at a speed of 100 rpm, then quickly dry it in an oven at 140°C until it is completely dried;

[0027] 2. Crush the dried powder in step 1, put it into an alumina crucible, preheat the alumina crucible in a muffle furnace at 400°C for 45 minutes, and then transfer it to a high temperature muffle furnace at 1100°C to keep it warm After 60 minutes, a uniform and clear glass liquid was formed.

[0028] 3. Quickly pour the molten glass melted in step 2 into 70...

Embodiment 2

[0038] A preparation method of a high potential gradient zinc oxide varistor is carried out according to the following steps:

[0039] 1. First, accurately weigh 57.644 grams of Bi, an analytically pure raw material with a purity ≥ 99% 2 o 3 , 1.606 g B 2 o 3 , 0.6 g Ag 2 O, 0.3 g Al 2 o 3 , 7.6467 grams of SiO 2 , 6.2733 g ZrO 2 , 17.26 g SnO 2 , 6.67 grams of MgO, 2 grams of K 2 CO 3 , put it into a ball mill jar, add 400 grams of zirconium balls and 200 grams of deionized water, and mix it with a planetary ball mill for 4 hours at a speed of 100 rpm, then quickly dry it in an oven at 140°C until it is completely dried;

[0040] 2. Crush the dried powder in step 1, put it into an alumina crucible, preheat the alumina crucible in a muffle furnace at 300°C for 30 minutes, and then transfer it to a high temperature muffle furnace at 1050°C to keep it warm After 60 minutes, a uniform and clear glass liquid was formed.

[0041] 3. Quickly pour the molten glass melted ...

Embodiment 3

[0051] A preparation method of a high potential gradient zinc oxide varistor is carried out according to the following steps:

[0052]1. First, accurately weigh 53.3711 grams of analytically pure raw material with a purity ≥ 99% 2 o 3 , 1.8 g B 2 o 3 , 0.7 g Ag 2 O, 0.5 g Al 2 o 3 , 8.5468 g SiO 2 , 6.5821 g ZrO 2 , 19.55 grams of SnO 2 , 7.45 grams of MgO, 1.5 grams of K 2 CO 3 , put it into a ball mill jar, add 400 grams of zirconium balls, 200 grams of deionized water, and mix it with a planetary ball mill for 4 hours at a speed of 100 rpm, then quickly dry it in an oven at 120°C until it is completely dried;

[0053] 2. Crush the dried powder in step 1, put it into an alumina crucible, preheat the alumina crucible in a muffle furnace at 300°C for 60 minutes, and then transfer it to a high temperature muffle furnace at 1050°C to keep it warm After 60 minutes, a uniform and clear glass liquid was formed.

[0054] 3. Quickly pour the molten glass melted in step 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com