Insulation board, preparation method and application thereof

A thermal insulation board and inorganic thermal insulation technology, applied in thermal insulation, climate change adaptation, building components, etc., can solve the problems of poor thermal insulation effect, high thermal conductivity, and easy damage of straw thermal insulation products, and achieve convenient material acquisition, good thermal insulation performance, and promote The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

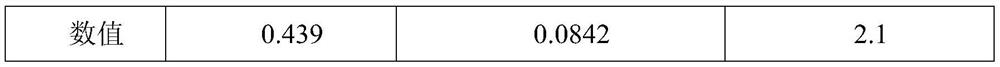

Embodiment 1

[0055] An insulation board made of straw fragments, inorganic insulation particles, and waste plastics, its components and proportions are shown in Table 1.

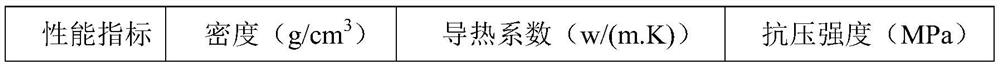

[0056] Table 1 Insulation board components and ratio

[0057] materials straw debris expanded perlite waste plastic Proportion (wt%) 20 20 60 Character description Wheat Straw Fragments 3-6mm closed cell perlite Waste polyethylene

[0058] The preparation process of the insulation board is as follows:

[0059] (1) Preparation of wheat straw fragments: Put the wheat straw produced in the current year into the straw grinder from the feeding port, after high-speed shearing and beating, it will be output from the feeding pipeline by wind pressure, and the wheat straw will be obtained after screening. Straw fragments. The length of the wheat straw fragments is 5mm-30mm, and the width of the wheat straw fragments is 1mm-5mm.

[0060] (2) Mix the straw fragments in (1) with 3-6mm closed-...

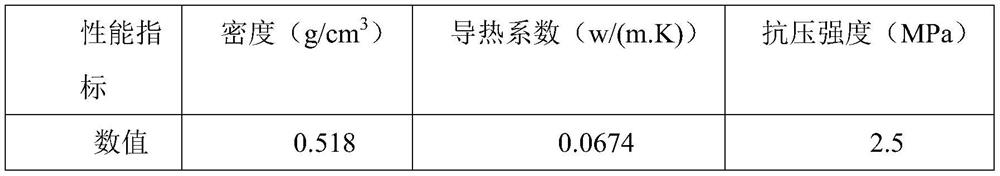

Embodiment 2

[0069] An insulation board prepared by using straw fragments, inorganic insulation particles, and waste plastics, its components and proportions are shown in Table 3.

[0070] Table 3 Insulation board components and ratio

[0071] materials straw debris expanded perlite waste plastic Proportion (wt%) 30 25 45 Character description Wheat Straw Fragments 3-6mm closed cell perlite Waste polyethylene

[0072] The preparation process of the insulation board is as follows:

[0073] (1) Preparation of wheat straw fragments: Put the wheat straw produced in the current year into the straw grinder from the feeding port, after high-speed shearing and beating, it will be output from the feeding pipeline by wind pressure, and the wheat straw will be obtained after screening. Straw fragments. The length of the wheat straw fragments is 5mm-30mm, and the width of the wheat straw fragments is 1mm-5mm.

[0074] (2) Mix the straw fragments in (1) with 3-6...

Embodiment 3

[0083] An insulation board made of straw fragments, inorganic insulation particles, and waste plastics, its components and proportions are shown in Table 5.

[0084] Table 5 Insulation board components and ratio

[0085] materials straw debris Expanded Vermiculite waste plastic Proportion (wt%) 20 20 60 Character description Wheat Straw Fragments 1-2mm expanded vermiculite Waste polyethylene

[0086] The preparation process of the insulation board is as follows:

[0087] (1) Preparation of wheat straw fragments: Put the wheat straw produced in the current year into the straw grinder from the feeding port, after high-speed shearing and beating, it will be output from the feeding pipeline by wind pressure, and the wheat straw will be obtained after screening. Straw fragments. The length of the wheat straw fragments is 5mm-30mm, and the width of the wheat straw fragments is 1mm-5mm.

[0088] (2) Mix the straw fragments in (1) with 1-2mm ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com