Preparation method of silicon dioxide-boron trioxide low melting point glass combined with hollow glass microsphere insulation material

A technology of hollow glass microspheres and low melting point glass, which is applied in the field of thermal insulation materials, can solve problems such as high density, decreased strength of microspheres, and defects in product strength, and achieve the effects of low thermal conductivity, light weight, and superior thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

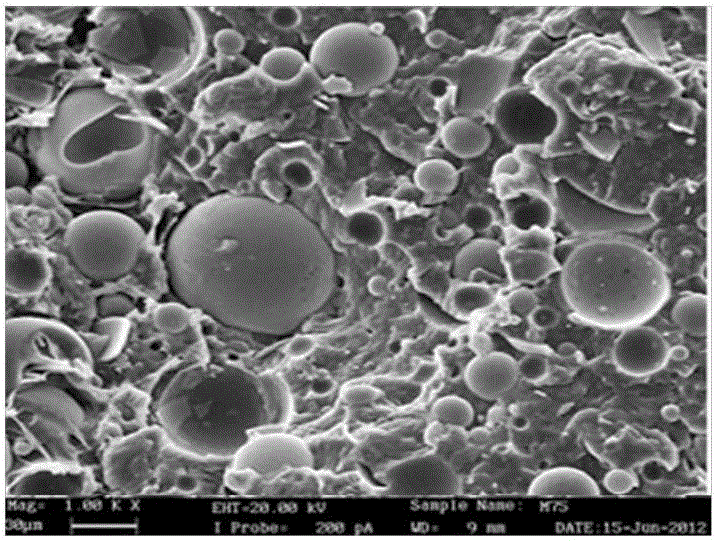

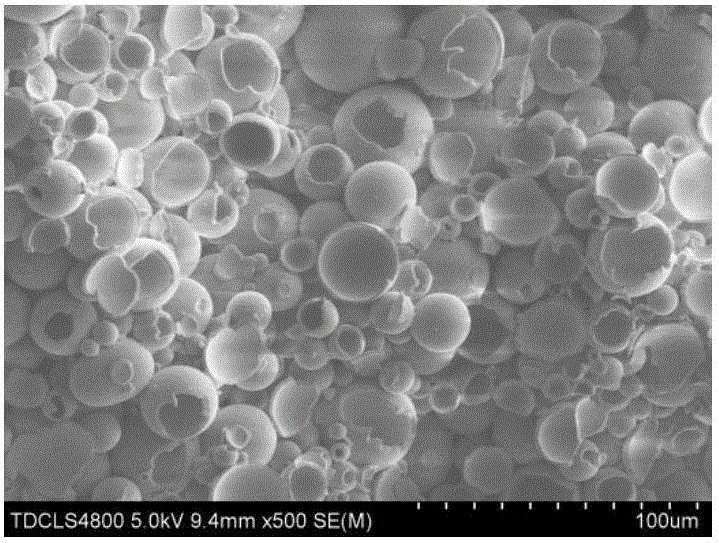

Image

Examples

Embodiment 1

[0017] In the specific embodiment of the present invention, B in the sol solution that adopts in the lightweight high-strength thermal insulation material 2 o 3 / SiO 2 The molar ratio is 0.56, and the sintering temperature is 650°C.

[0018] The preparation method of the lightweight high-strength thermal insulation material in this embodiment comprises the following steps:

[0019] (1) Preparation of sol solution: tetraethyl orthosilicate as SiO 2 The precursor, ethanol as a solvent, and deionized water are added to promote the hydrolysis of ethyl orthosilicate, and the three are configured according to the molar ratio (1:5:3). Adjust the pH of the solution with ammonia water to 7, and magnetically stir the solution at room temperature for 20 minutes as solution S1; boric acid as B 2 o 3 The precursor of boric acid was dissolved in ethanol to prepare a boric acid ethanol solution with a concentration of about 0.02mol / L, which was magnetically stirred at room temperature f...

Embodiment 2

[0025] In the specific embodiment of the present invention, B in the sol solution that adopts in the lightweight high-strength thermal insulation material 2 o 3 / SiO 2 The molar ratio is 0.56, and the sintering temperature is 700°C.

[0026] The preparation method of the lightweight high-strength thermal insulation material in this embodiment comprises the following steps:

[0027] (1) Preparation of sol solution: tetraethyl orthosilicate as SiO 2 The precursor, ethanol as a solvent, and deionized water are added to promote the hydrolysis of ethyl orthosilicate, and the three are configured according to the molar ratio (1:5:3). Adjust the pH of the solution with ammonia water to 7, and magnetically stir the solution at room temperature for 20 minutes as solution S1; boric acid as B 2 o 3 The precursor of boric acid was dissolved in ethanol to prepare a boric acid ethanol solution with a concentration of about 0.02mol / L, which was magnetically stirred at room temperature f...

Embodiment 3

[0033] In the specific embodiment of the present invention, B in the sol solution that adopts in the lightweight high-strength thermal insulation material 2 o 3 / SiO 2 The molar ratio is 0.56, and the sintering temperature is 780°C.

[0034] The preparation method of the lightweight high-strength thermal insulation material in this embodiment comprises the following steps,

[0035] (1) Preparation of sol solution: tetraethyl orthosilicate as SiO 2 The precursor, ethanol as a solvent, and deionized water are added to promote the hydrolysis of ethyl orthosilicate, and the three are configured according to the molar ratio (1:5:3). Adjust the pH of the solution with ammonia water to 7, and magnetically stir the solution at room temperature for 20 minutes as solution S1; boric acid as B 2 o 3 The precursor of boric acid was dissolved in ethanol to prepare a boric acid ethanol solution with a concentration of about 0.02mol / L, which was magnetically stirred at room temperature for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com