Enamel heat-insulation tube

A thermal insulation pipe and enamel technology, which is applied in the direction of heat preservation and protection of pipes and pipes through heat insulation, can solve the problems of high cost, difficult production, and easy deformation of thermal insulation pipes, and achieves low price, good heat absorption, and easy deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

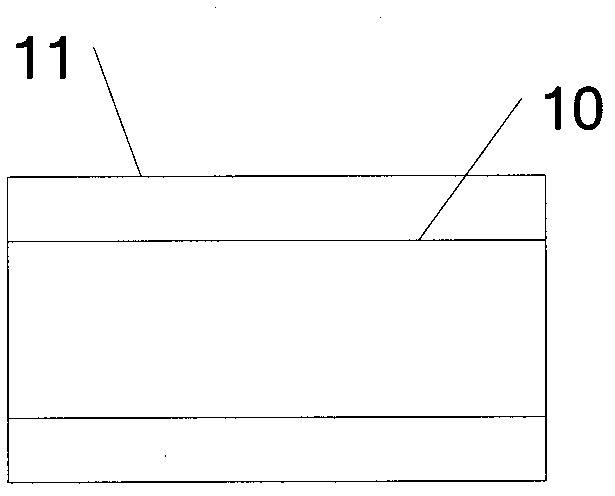

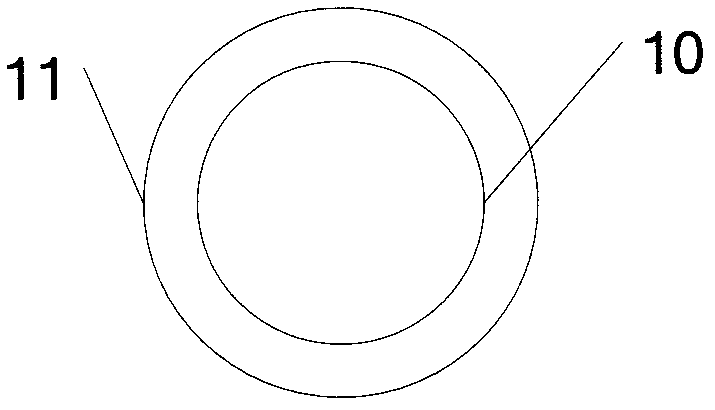

[0012] First, please refer to figure 1 , figure 1 It is a sectional view of the enamel insulation pipe of the present invention, from figure 1 It can be seen that the present invention proposes an enamel insulation pipe, comprising an inner tube 10 and an outer tube 11. The material of the inner tube 10 is metal, and the material of the outer tube 11 is enamel. Due to the chemical properties of the enamel It is stable and has high hardness, so it is not easy to undergo chemical changes and deformations, and effectively protects the inner tube 10 from damage. In order to further improve the heat preservation effect, an air condensation tube can be installed between the inner tube 10 and the outer tube 11. glue. The surface of the enamel 11 is coated with black paint. The material of the inner tube 10 is aluminum alloy.

[0013] Next, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com