Cast-in-place rigid concrete self-insulation wall composed of openings and opening and closing blocks and wall-building method

A self-insulating block and self-insulating technology, which is applied to walls, building components, building structures, etc., can solve problems such as cumbersome process, low production capacity, and low compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

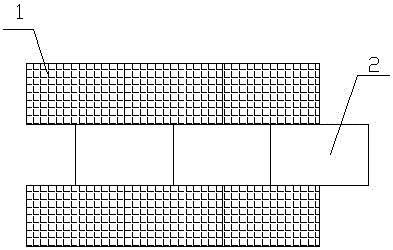

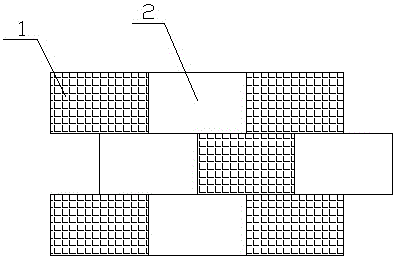

[0038] by attaching figure 1 , 3 , 4, 9, and 10, it can be seen that the cast-in-situ rigid concrete self-insulation wall composed of openings and opening and closing blocks in this scheme, the insulation wall includes concrete self-insulation opening blocks 1 and concrete self-insulation openings staggered combined block 2;

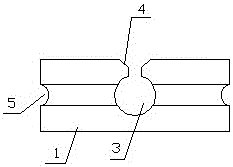

[0039] The concrete self-insulation opening block 1 is provided with a groove 5, and a through hole 3 penetrating through the concrete self-insulation opening block is arranged in the middle of the concrete self-insulation opening block, and the side wall of the through hole has an opening 4;

[0040] The concrete self-insulating opening and closing block 2 includes two concrete blocks 7, a groove 5 is arranged on the concrete block 7, and a groove 6 is arranged in the middle of the concrete block 7, and the groove 6 and the The grooves 5 are all arranged on one side of the concrete block 7, and the grooves 7 of the two concrete blocks 7 correspond to ...

specific Embodiment approach 2

[0046] by attaching figure 1 , Figure 5 , Figure 6 , Figure 11 , Figure 12 It can be seen that the difference between this embodiment and Embodiment 1 is that one end of the concrete self-insulating open block body 1 is provided with a groove 5 instead of grooves at both ends, and the upper or lower part of the concrete block 7 is provided with Grooves 5, instead of all grooves, both ends of the concrete block 7 are provided with grooves 5.

[0047] When building a wall, 1) preset criss-cross rigid frame supports; 2) lay concrete thermal insulation blocks on the rigid frame supports, so that the concrete self-insulation opening blocks form a layer, and the concrete self-insulation opening blocks form a layer. There is a groove between the concrete self-insulation opening block layer and the concrete self-insulation opening and closing block layer for passing through the rigid bone; and the adjacent concrete self-insulation blocks in the concrete self-insulation opening...

specific Embodiment approach 3

[0048] pass figure 1 , 7 , 8, 13, 14 It can be seen that the difference between this specific embodiment and the specific embodiment one is that the upper or lower part of the concrete self-insulating open block body 1 is provided with grooves 5 instead of having grooves, and the concrete blocks 7 The upper or lower part of the concrete block 7 is provided with grooves 5 instead of all grooves, and one end of the concrete block 7 is provided with grooves 5 instead of both ends.

[0049] When building a wall, 1) preset criss-cross rigid frame supports; 2) lay concrete thermal insulation blocks on the rigid frame supports, so that the concrete self-insulation opening blocks form a layer, and the concrete self-insulation opening blocks form a layer. There is a groove between the concrete self-insulation opening block layer and the concrete self-insulation opening and closing block layer for passing through the rigid bone; and the adjacent concrete self-insulation blocks in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com