A method of manufacturing an integral vacuum insulation box

A technology of vacuum insulation and production method, which is applied to packaging under vacuum/special atmosphere, household refrigeration devices, lighting and heating equipment, etc., can solve problems such as the decline of thermal insulation performance, and achieve the reduction of product breakage rate, stable thermal insulation performance, and avoidance of breakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The manufacturing method of the overall vacuum insulation box described in this embodiment comprises the following steps:

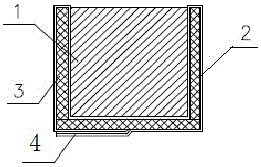

[0049] (1) Prepare a small barrier bag with an opening at one end and a large barrier bag with two ends open. The large and small barrier bags are made of barrier film. Insert the small barrier bag 7 into the large barrier bag 6, with the upper port flush and centered , the outside of the upper port of the small barrier bag 7 is heat-sealed with the inner surface of the upper port of the large barrier bag 6, and the seal is 5 to form an inner jacket barrier bag, such as figure 1 shown;

[0050] (2) Make a model, the outer dimensions of model 1 are the same as the inner dimensions of the insulation box;

[0051] (3) Stretch the opening of the barrier bag of the inner jacket made in step (1), and put the model 1 into the small barrier bag 7;

[0052] (4) Put the heat-insulating core material 3 from the other pocket of the large barrier bag into the...

Embodiment 2

[0058] A method for manufacturing an integral vacuum insulation box described in this embodiment includes the following steps:

[0059] (1) Make model 1 with the same size as the required box;

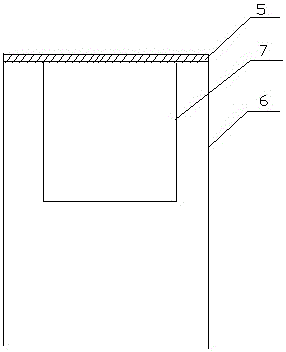

[0060] (2) In the atmospheric environment, put the model into a barrier bag, which is a bag made of barrier film 2, and make the barrier bag fit the surface of model 1 through shaping;

[0061] (3) Wrap the heat insulation core material 3 with the same size as that of each side of the model on the outer side and bottom of the barrier bag, such as image 3 shown;

[0062] (4) Wrap the insulation core material 3 inside the barrier bag and fix it;

[0063] (5) Send it into the vacuum sealing box to vacuumize and seal the barrier bag;

[0064] (6) Move the product to the atmosphere, fold and reshape the barrier bag, such as Figure 4 shown;

[0065] (7) Take out the model.

[0066] In the overall vacuum insulation box described in this embodiment, the box body is wrapped by the same ba...

Embodiment 3

[0068] A method for manufacturing an integral vacuum insulation box described in this embodiment includes the following steps:

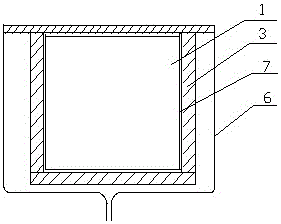

[0069] (1) The heat insulation core material 3 is made into a box shape with one end open by pressing, pouring, and splicing, such as Figure 5 shown;

[0070] (2) In the atmospheric environment, put the barrier film 2 into the box that has been made, and spread the barrier film 2 evenly on the inner and bottom surfaces of the box, such as Image 6 shown;

[0071] (3) Turn the barrier film 2 outward along the opening of the box to wrap the outer side and bottom of the box, such as Figure 7 shown;

[0072] (4) Send it into the vacuum sealing box to evacuate and seal the barrier film;

[0073] (5) Move the product to the atmosphere, and fold and shape the barrier film 2 .

[0074] In the overall vacuum insulation box described in this embodiment, the box body is made first, and the box body is wrapped by the same barrier film 2, and the heat insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com