Assembly type magnesium-based cement foaming light board and preparation method thereof

A technology of cement foaming and cement foaming layer, which is applied in the field of preparation of prefabricated magnesium-based cement foaming lightweight panels, can solve the problems of insufficient hydration and low strength, and achieve good thermal insulation and sound insulation effects, and anti-corrosion Good impact performance and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

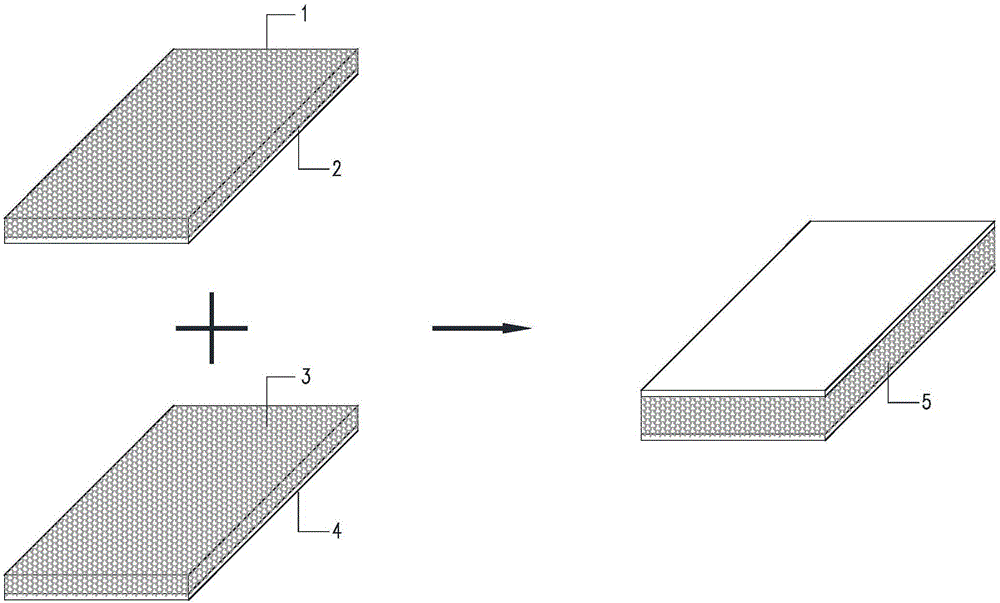

Image

Examples

Embodiment 1

[0035] A method for preparing a prefabricated magnesium-based cement foamed lightweight board, the method specifically includes the following steps:

[0036] (a) Preparation of magnesium-based foamed cement

[0037] 65 kg of magnesia salt cement, 3 kg of foam stabilizer and 5 kg of foaming agent, add water according to the water-cement ratio of 0.45, and stir to make magnesium-based cement foam slurry. The foam stabilizer is silicone amide; the foaming agent is sodium lauryl sulfate.

[0038] The preparation method of the magnesia salt cement is as follows: 100-200 mesh MgO, 100-200 mesh MgSO 4 and H 2 O, the three are mixed according to the ratio of the amount of substances of 9:1:25, and then add the inducer, the addition of the inducer is MgO, MgSO 4 and H 2 O 1 wt% of the total mass of the three, stirring for more than 24 hours, drying, grinding, and passing through a 200-mesh sieve to obtain magnesia salt cement.

[0039] The preparation method of the inducer is as f...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is:

[0050] The inducer is composed of A component and B component, and the preparation method of A component is as follows: 200-400 mesh talcum powder is added to the vinegar-acrylic emulsion, and the mass ratio of the talc powder to the vinegar-acrylic emulsion is 8:27, Stir, be heated to 60 ℃ and keep 4 hours, filter and dry; Join in the tannic acid aqueous solution in the obtained solid product, the massfraction of tannic acid in the tannic acid aqueous solution is 10wt%, the mass ratio of solid product and tannic acid aqueous solution The ratio is 1:30, heated to 100°C and kept for 5 hours, filtered, dried and pulverized, and passed through a 100-mesh sieve to obtain component A; the preparation method of component B is as follows: add 200-400-mesh fly ash to three In the ethanolamine aqueous solution, the mass fraction of the triethanolamine aqueous solution is 5wt%, the mass ratio of the fly ash to the trie...

Embodiment 3

[0053] The difference between this embodiment and embodiment 2 is:

[0054] (a) Preparation of magnesium-based foamed cement

[0055] 65 kg of magnesia salt cement, pre-treated fly ash, 3 kg of foam stabilizer and 5 kg of foaming agent, add water according to the water-cement ratio of 0.45, and stir to make magnesium-based cement foam slurry. The amount of fly ash after pretreatment is 10wt% of the mass of MgO used in the preparation of magnesia salt cement.

[0056] The preparation method of the fly ash after the pretreatment is as follows: 200-400 mesh fly ash is added in the triethanolamine aqueous solution, the mass fraction of the triethanolamine aqueous solution is 3wt%, and the mass ratio of the fly ash and the triethanolamine aqueous solution is 1: 12. Stir, heat to 70°C and keep for 12 hours, filter and dry; add the obtained solid product to the silane coupling agent solution, the mass ratio of the solid product to the silane coupling agent solution is 1:16, silane c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com