A novel prefabricated detachable and repairable aseismic bridge column structure system and implementation method thereof

A seismic bridge and column structure technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of poor traffic environment and natural environment, and achieve the effect of shortening construction period, improving seismic performance and improving ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

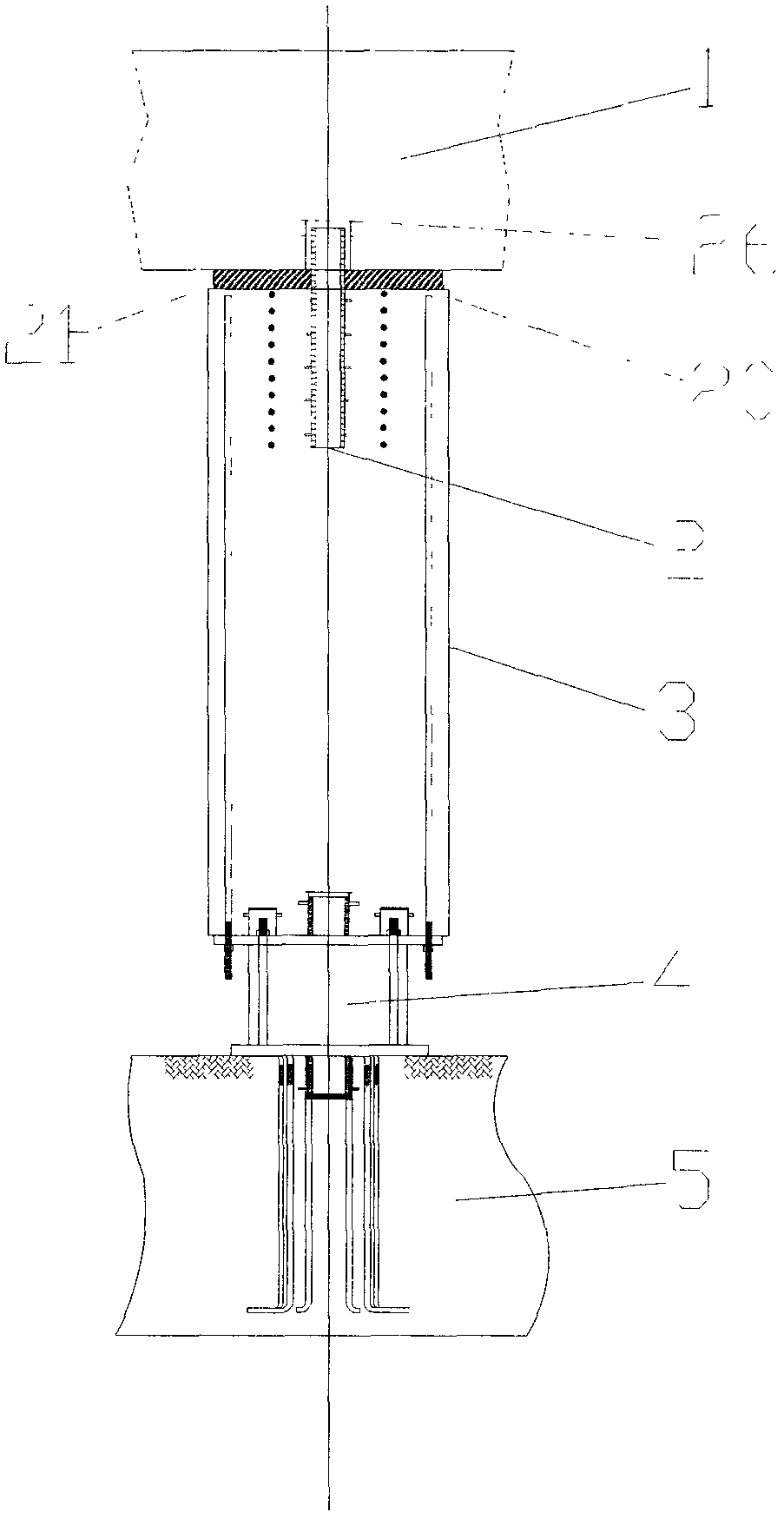

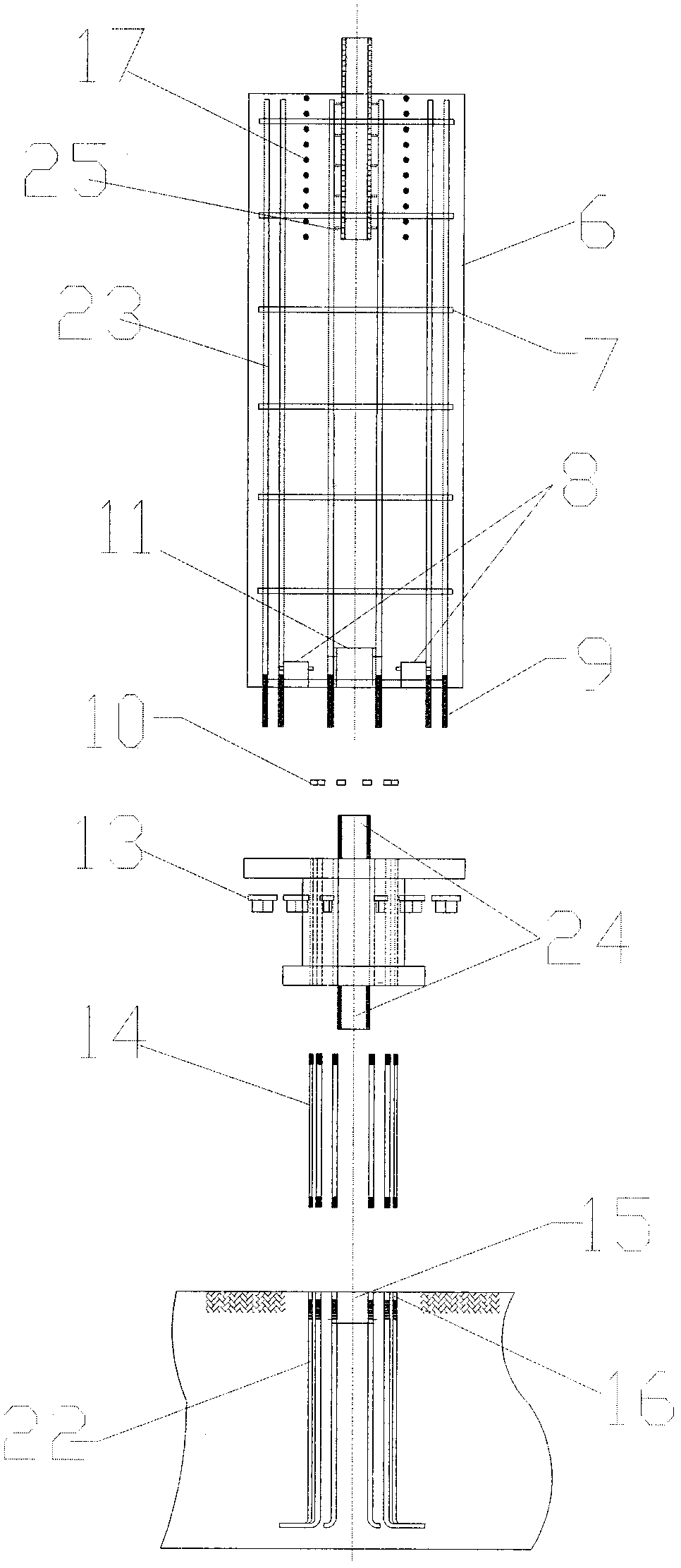

[0025] Such as Figure 1-4 As shown, a new type of prefabricated detachable and repairable seismic bridge column structure system, the structure system includes cover beam 1, ultra-high performance concrete (UHPC) steel pipe 2, bridge column 3, SMA plastic hinge device 4 and cap 5.

[0026] The platform 5 is composed of a pre-embedded steel pipe 22 , a reserved hole 15 and a coupling nut 16 . The outside of the reserved hole 15 is inlaid with a steel sheet, which is used to insert the embedded steel pipe 24, and the coupling nut 16 is used to lock the SMA pipe 14 inside the SMA plastic hinge device 4. The existence of the coupling nut 16 and the reserved hole 15 makes the upper SMA The plastic hinge device 4 and the platform 5 are tightly engaged together, and the strong energy dissipation capacity of the SMA plastic hinge device is well exerted.

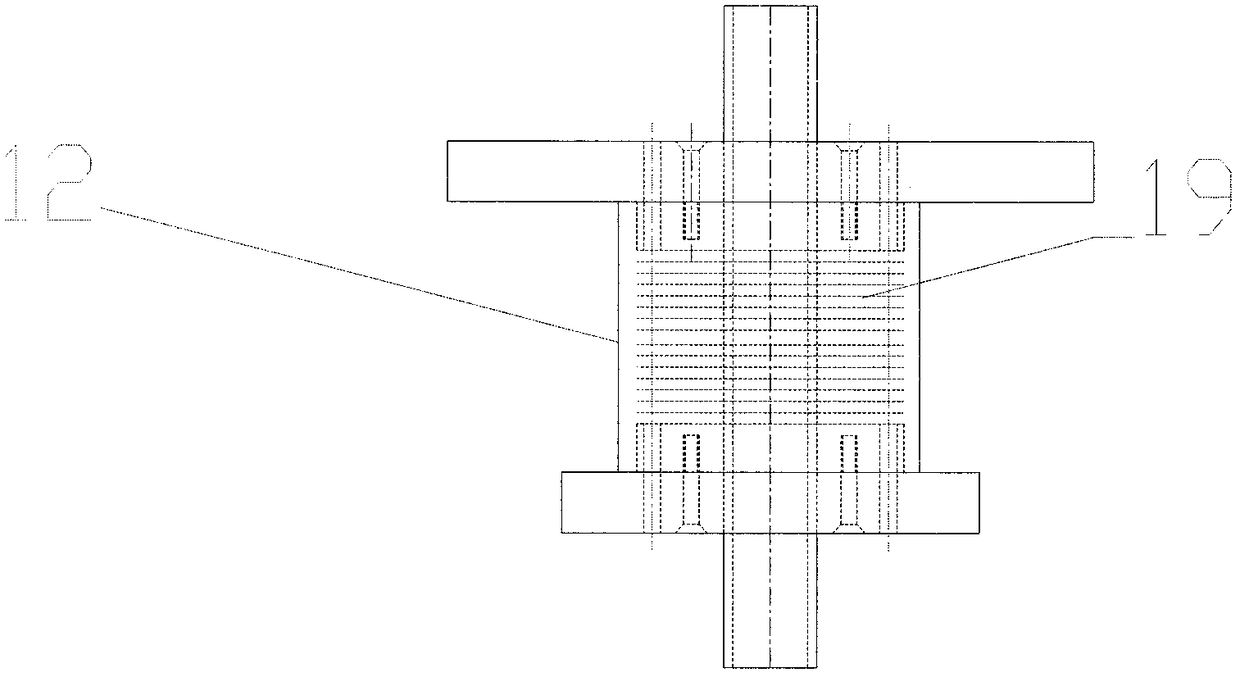

[0027] The SMA plastic hinge device 4 is composed of an ECC outer layer 12, a spiral steel ring 19, an embedded steel pipe 24, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com