Lifting hook clamp for four-split wires of carbon fiber plates for 500 kV hot-line work

A technology of carbon fiber board and live work, applied in layered products, load hanging components, transportation and packaging, etc., can solve the problem of easy oxidation of metal fixtures, and achieve simple and practical structure, high strength, and high fatigue resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

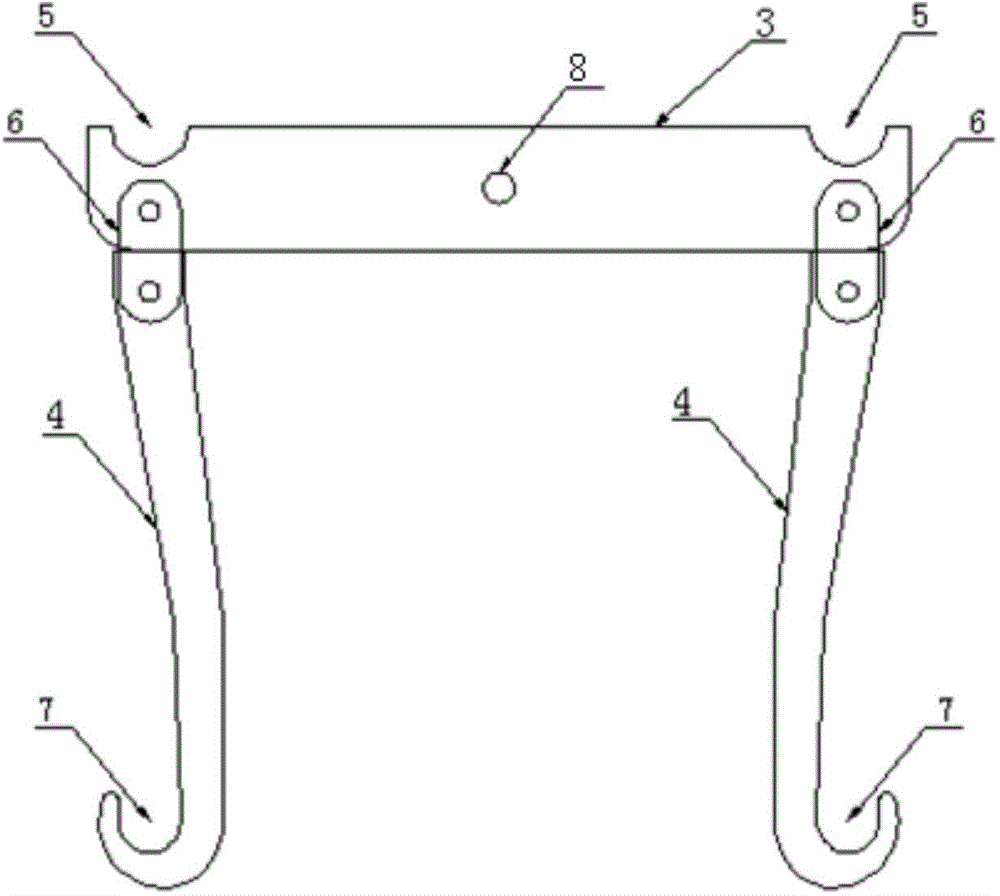

[0033] Such as figure 1 As shown, the four-split wire lifting hook fixture for live work of the present invention includes a horizontal clamping body 3 and two vertical clamping bodies 4, and the two ends of the horizontal clamping body 3 are respectively connected to the two vertical clamping bodies through an aluminum alloy connecting plate 6. One end of body 4 is connected, and the other end of two vertical card bodies 4 is provided with wire hook 2 7, and the two ends of horizontal card body 3 are provided with wire hook 1 5, and the middle part of horizontal card body 3 is provided with connecting hole 8, when using The insulating rod is directly fixed with the connection hole 1, and the whole set of clamps is placed directly below the four split wires, and the clamps are lifted upwards so that the four wires fall into the first wire hook 5 and the second wire hook 7.

[0034] The four-split wire lifting hook fixture of the present invention is made of carbon fiber sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com