Lightweight composite wall panel

A wallboard, lightweight technology, applied in building components, building materials, buildings, etc., can solve the problems of not meeting the production of larger blocks, pure gypsum blocks are prone to mildew, and the promotion and use are limited, etc., and achieve energy-saving and environmental protection construction. Simple and efficient, increase the usable area of the house, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiment of the present invention is illustrated below in conjunction with accompanying drawing:

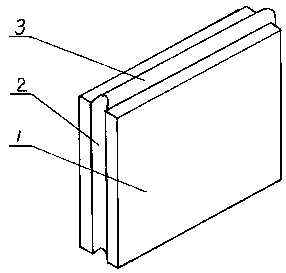

[0013] The shape of the wallboard is a rectangular slab with a length of 666mm, a width of 500mm and a thickness of 100mm. On the four side surfaces of the wallboard 1, grooves 2 or ribs 3 are respectively processed, and the grooves 2 and the ribs 3 are oppositely arranged, that is, one side surface is processed with a groove 2, and the corresponding other side The surface is processed with ribs 3 . The thickness of the wall panels can be 120mm or 150mm as required. The wall panel used at the bottom beam of the wall or the lintel of the door and window can be a long rectangular column, such as 2000mm in length, 200mm in width, and 100mm in the rear.

[0014] The material composition of making wallboard 1 is by weight ratio: sludge ceramsite 70%, cement 15%, gypsum 15%; The weight of water accounts for 75% of cement plus gypsum weight; Yes, high iron powder 1‰, cellulo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com