Patents

Literature

31results about How to "Accurate and reliable location" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for locating magnetic implant by source field

InactiveUS7010338B2Accurate and reliable locationSurgeryDiagnostic recording/measuringPower flowSource field

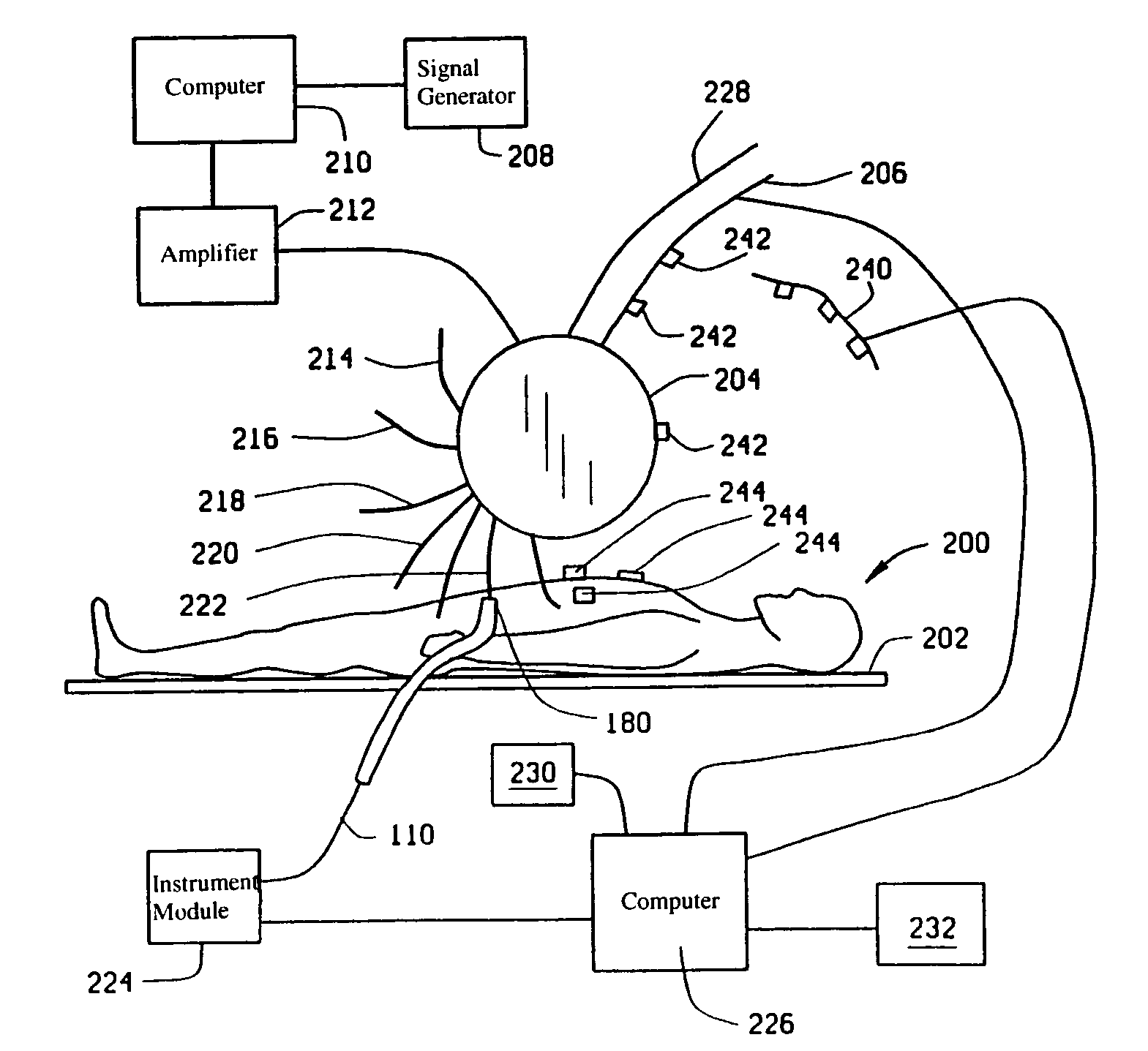

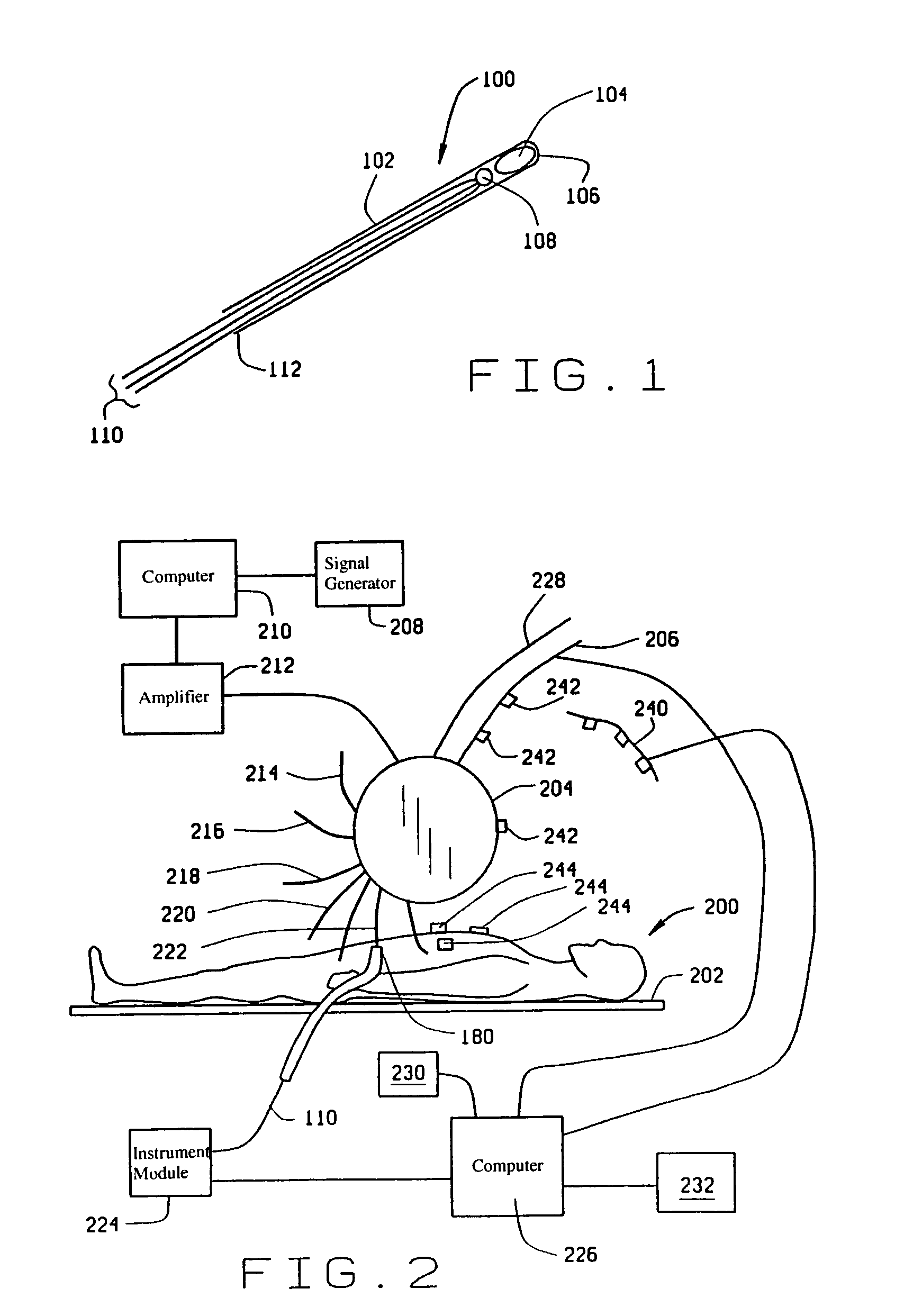

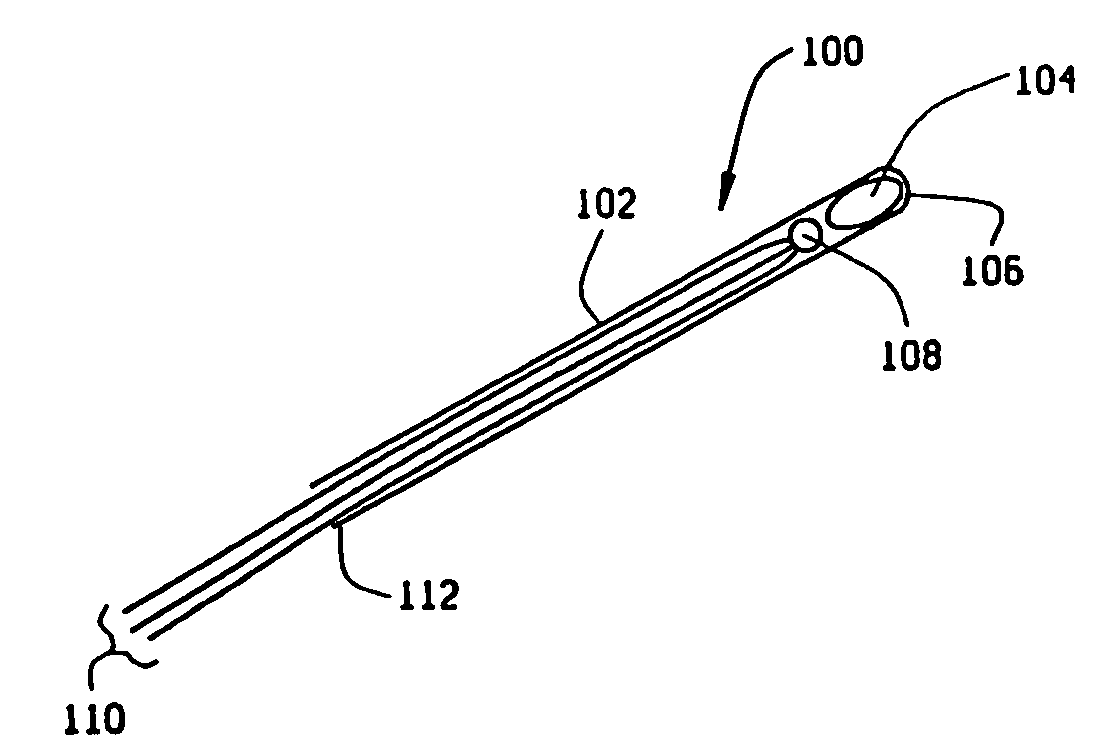

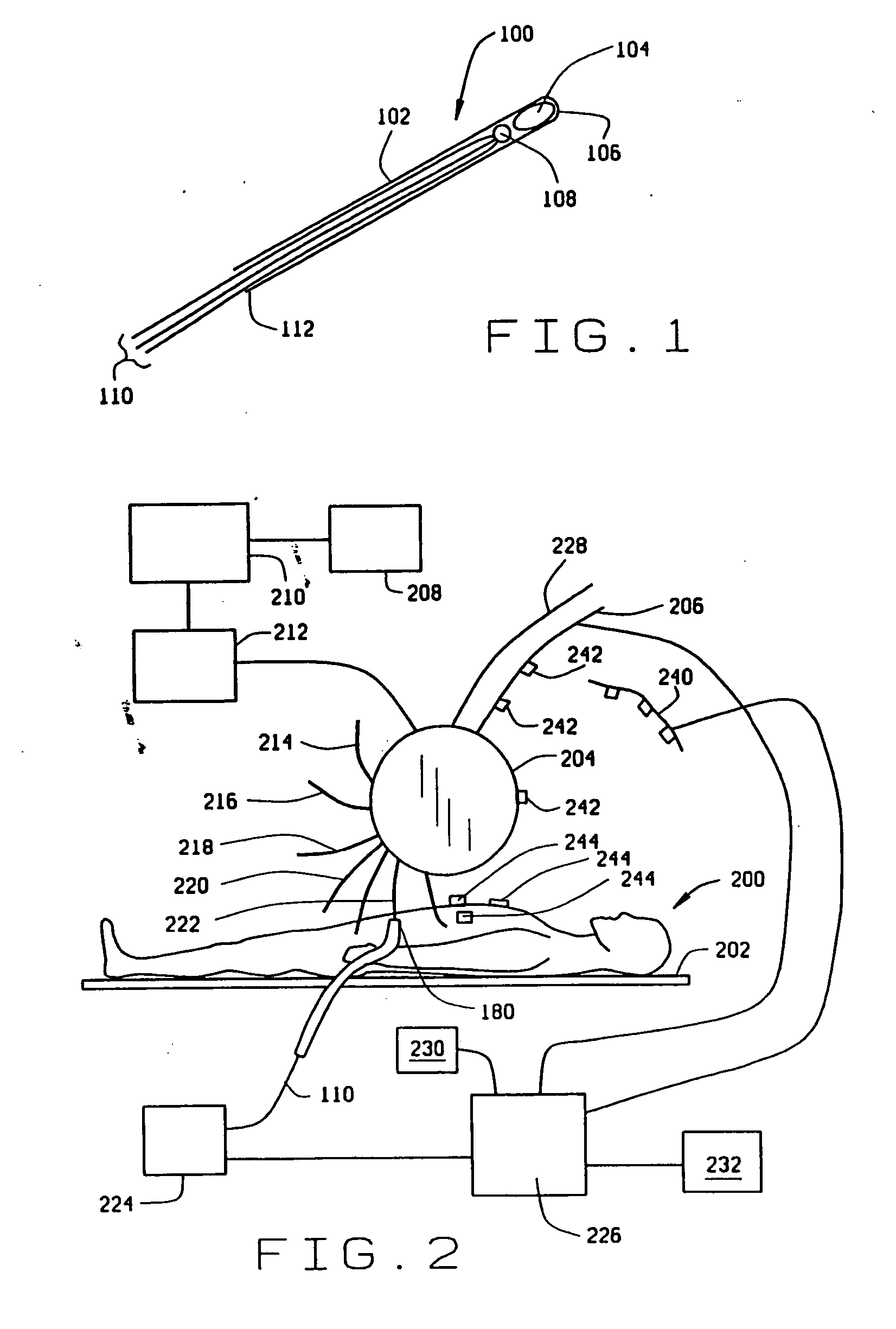

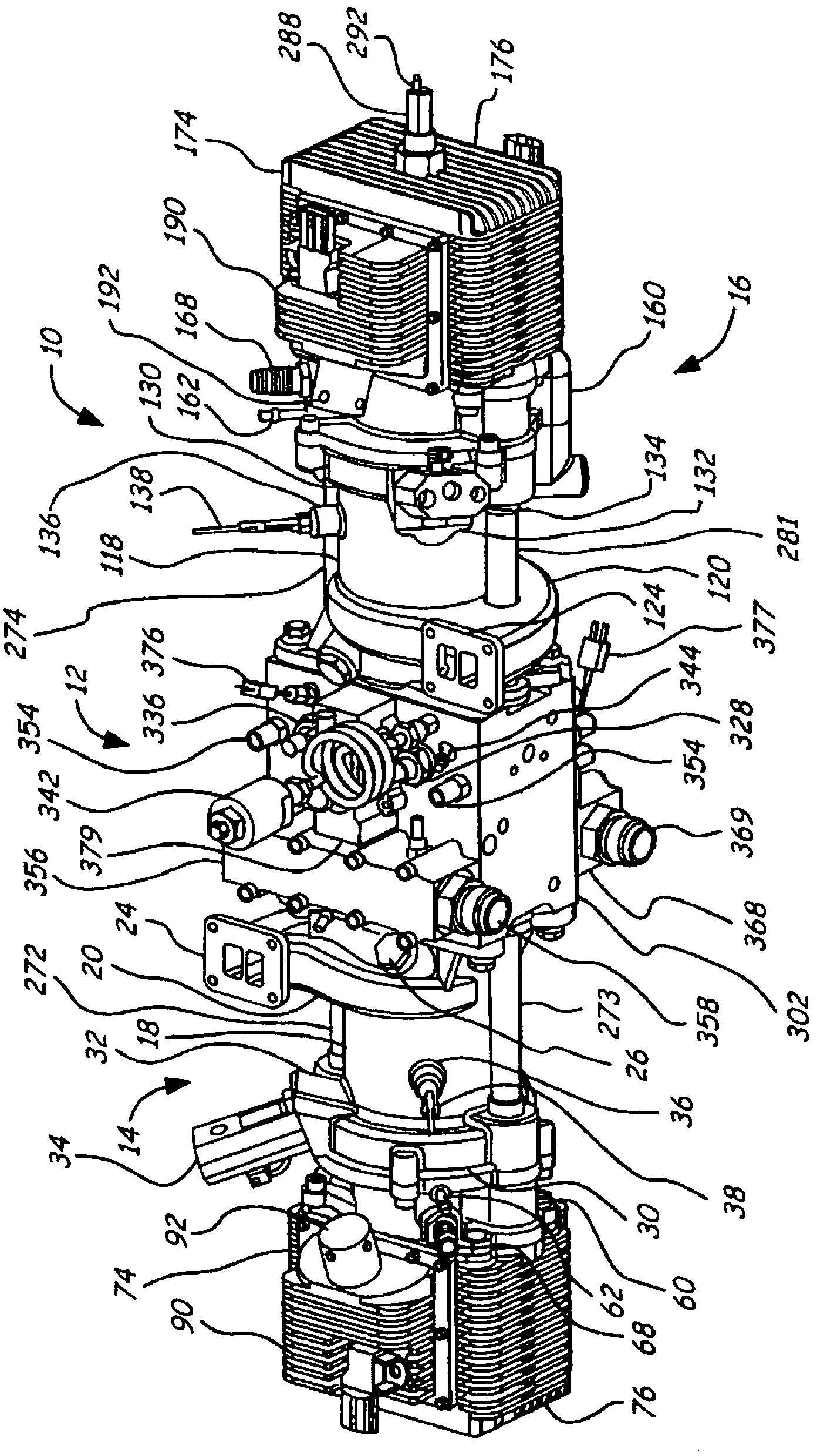

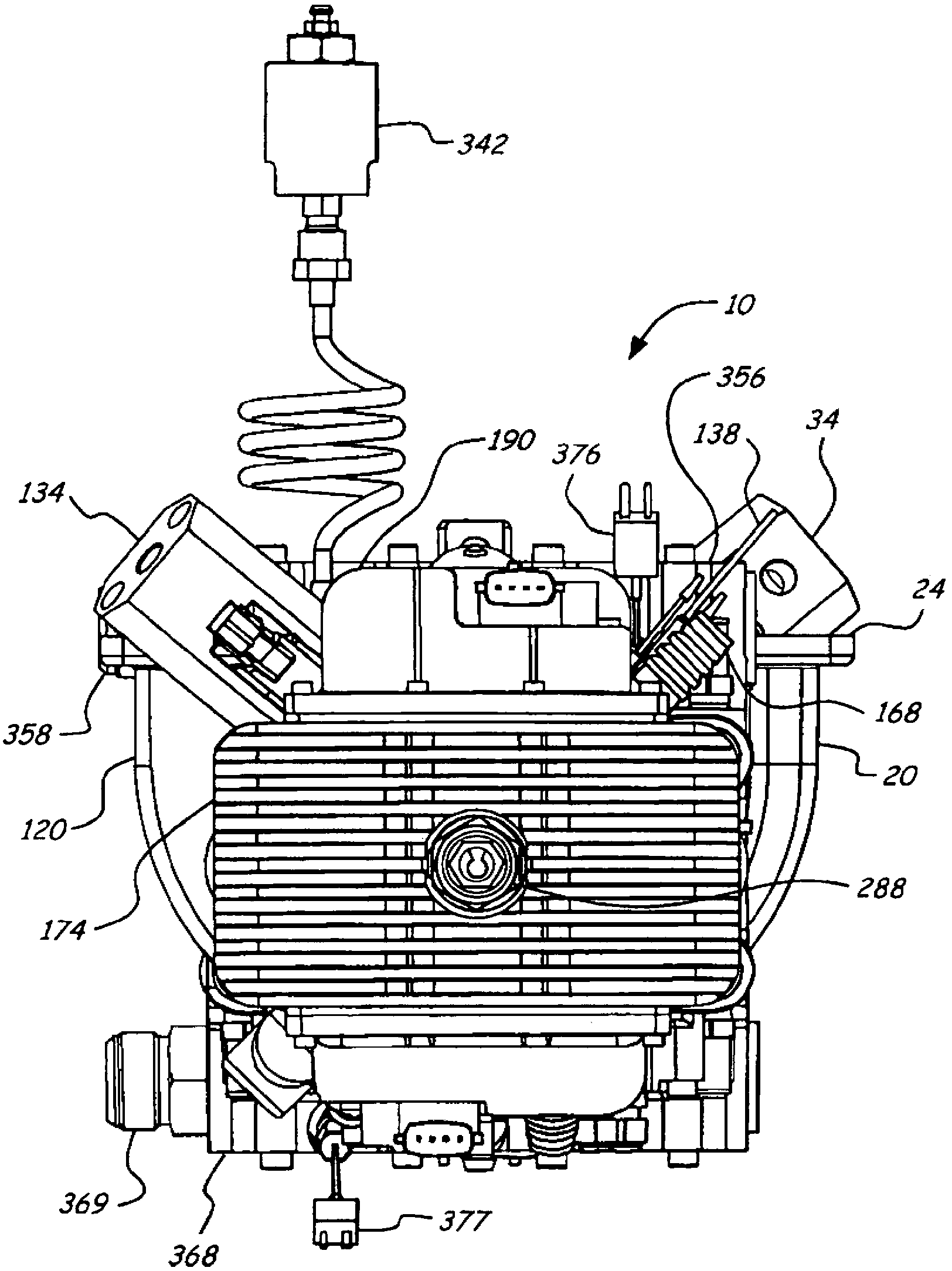

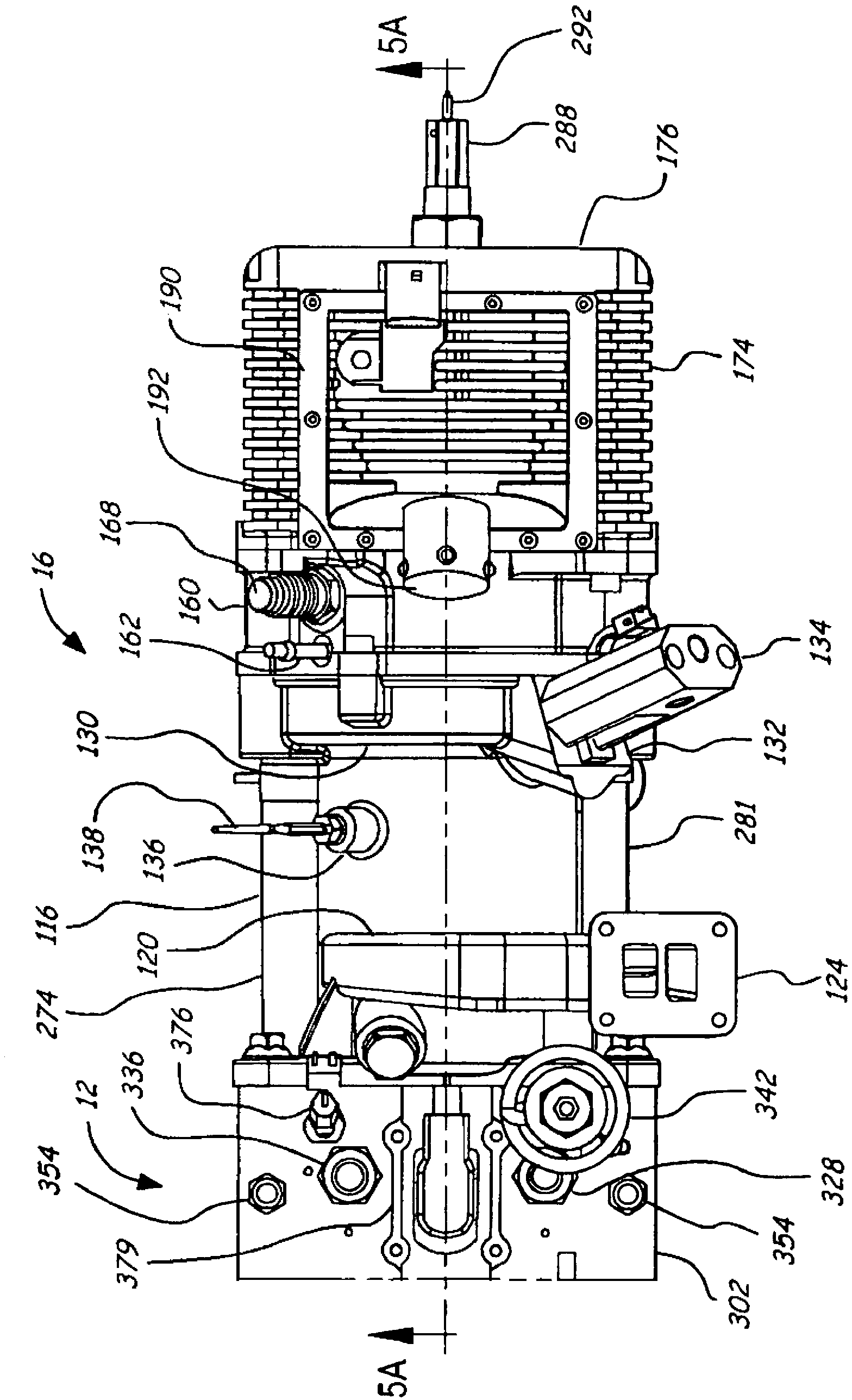

An apparatus and method for locating a magnetic implant in a surgical application using the field of a source magnet for the implant guiding field. The source magnet is an electromagnet having a separate calibrated magnetic field component in addition to the guiding field, so that both the magnitude and orientation of the magnetic field as a function of position around the magnet are known. A magnetic implant is provided with a sensor, such as a three-axis Hall effect sensor, to provide an indication of the magnitude and orientation of an applied magnetic field when the implant is surgically implanted in a patient. After implantation, the source magnet is energized with a current having a modulated component. The modulated component is received and filtered from the signal received from the Hall effect sensor in the implant, and provided to a processor that computes the location of the implant.

Owner:STEREOTAXIS

Method and device for locating magnetic implant source field

InactiveUS20070038074A1Accurate and reliable locationDiagnostic recording/measuringSensorsSource fieldDisplay device

An apparatus and method for locating a magnetic implant in a surgical application using the field of a source magnet for the implant guiding field. The source magnet is an electromagnet having a separate calibrated magnetic field component in addition to the guiding field, so that both the magnitude and orientation of the magnetic field as a function of position around the magnet are known. A magnetic implant is provided with a sensor, such as a three-axis Hall effect sensor, to provide an indication of the magnitude and orientation of an applied magnetic field when the implant is surgically implanted in a patient. After implantation, the source magnet is energized with a current having a modulated component. The modulated component is received and filtered from the signal received from the Hall effect sensor in the implant, and provided to a processor that computes the location of the implant relative to the electromagnet based upon the detected magnitude and orientation of the modulated component of the magnetic field, and the location and orientation of the electromagnet. Localizers may be used to supply the relative locations of the patient and the electromagnet to the processor. A display may be provided to display a representation of the location of the implant in the patient, which may also be superimposed over a preoperative image of the patient.

Owner:RITTER ROGERS C +3

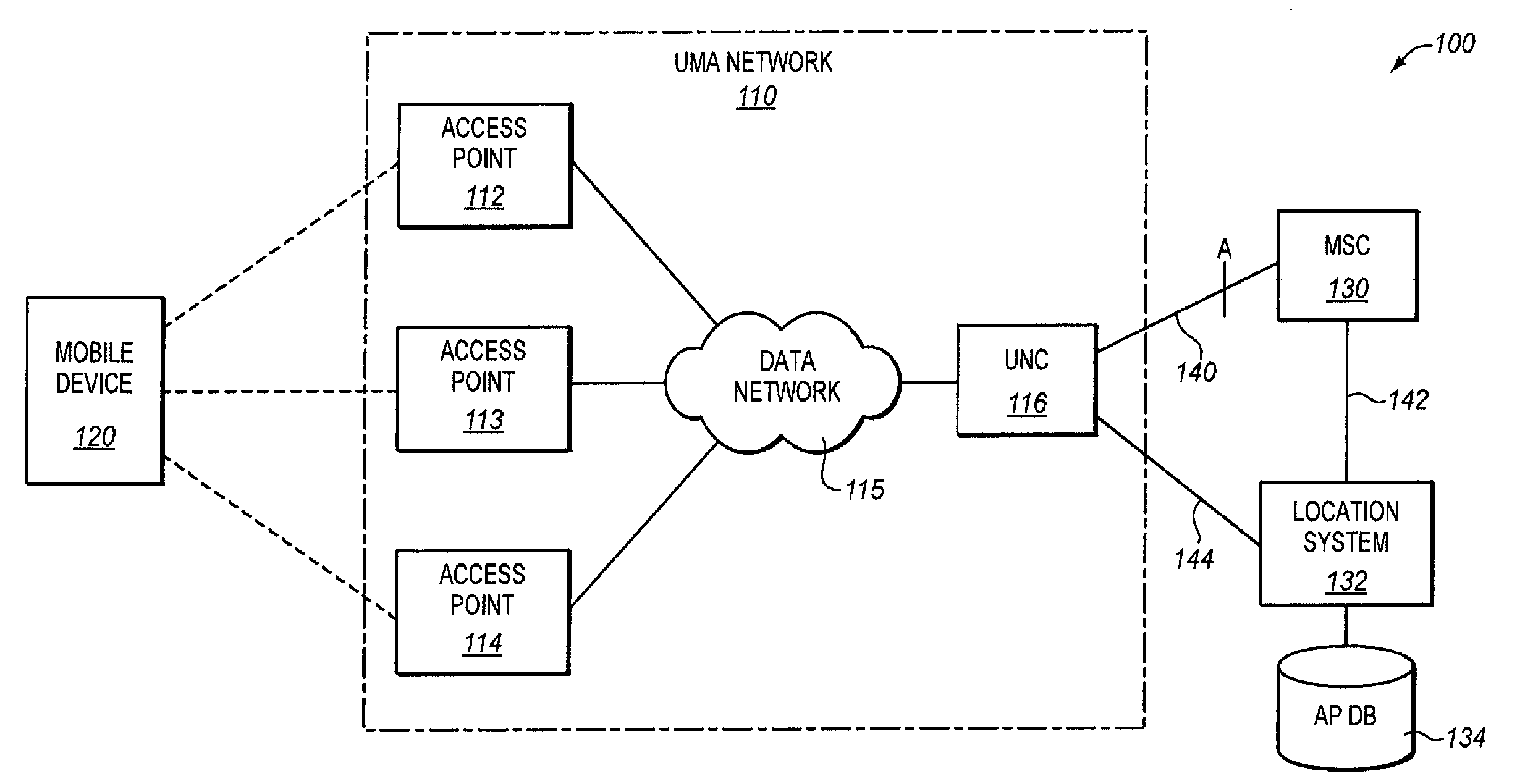

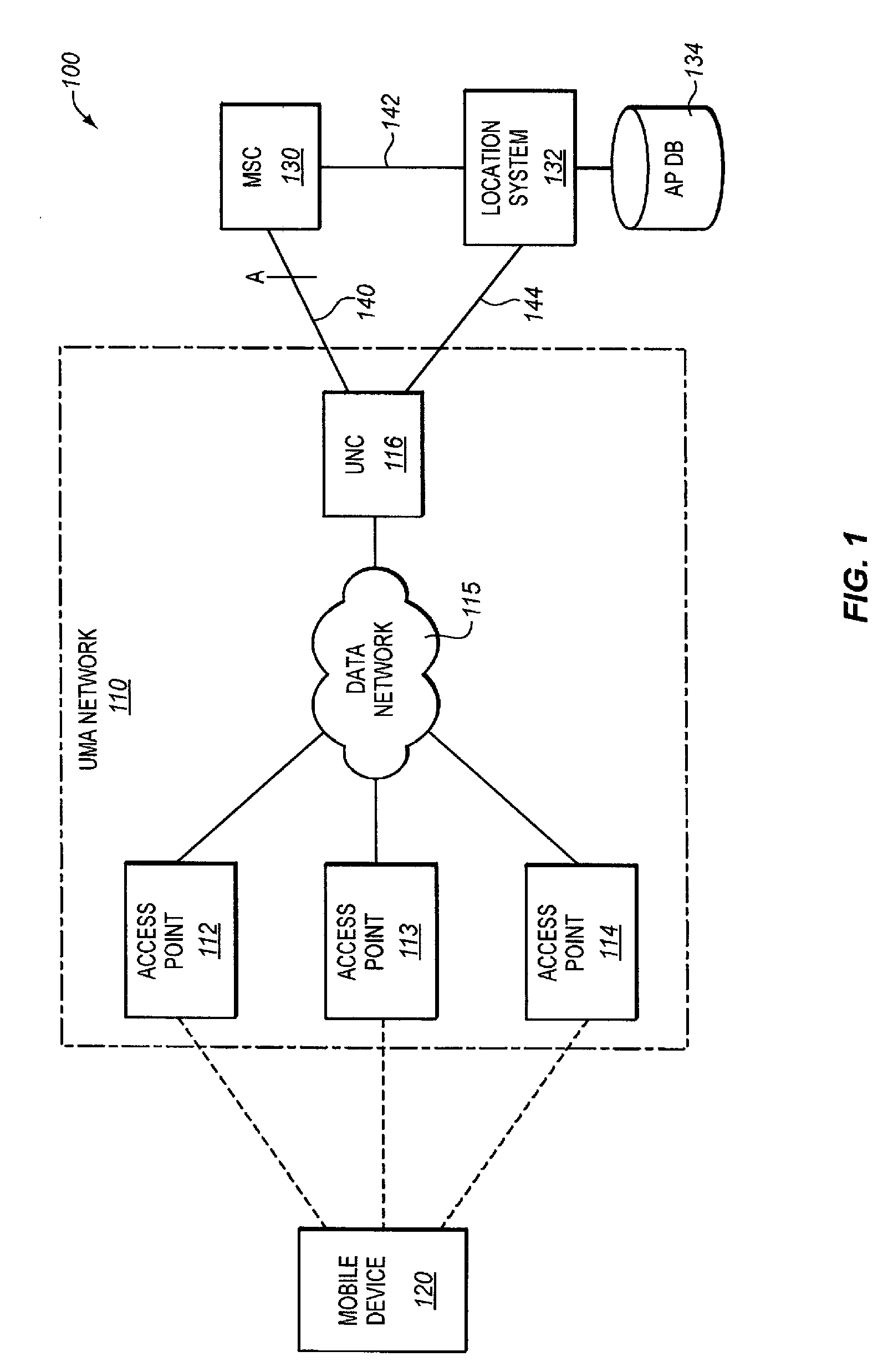

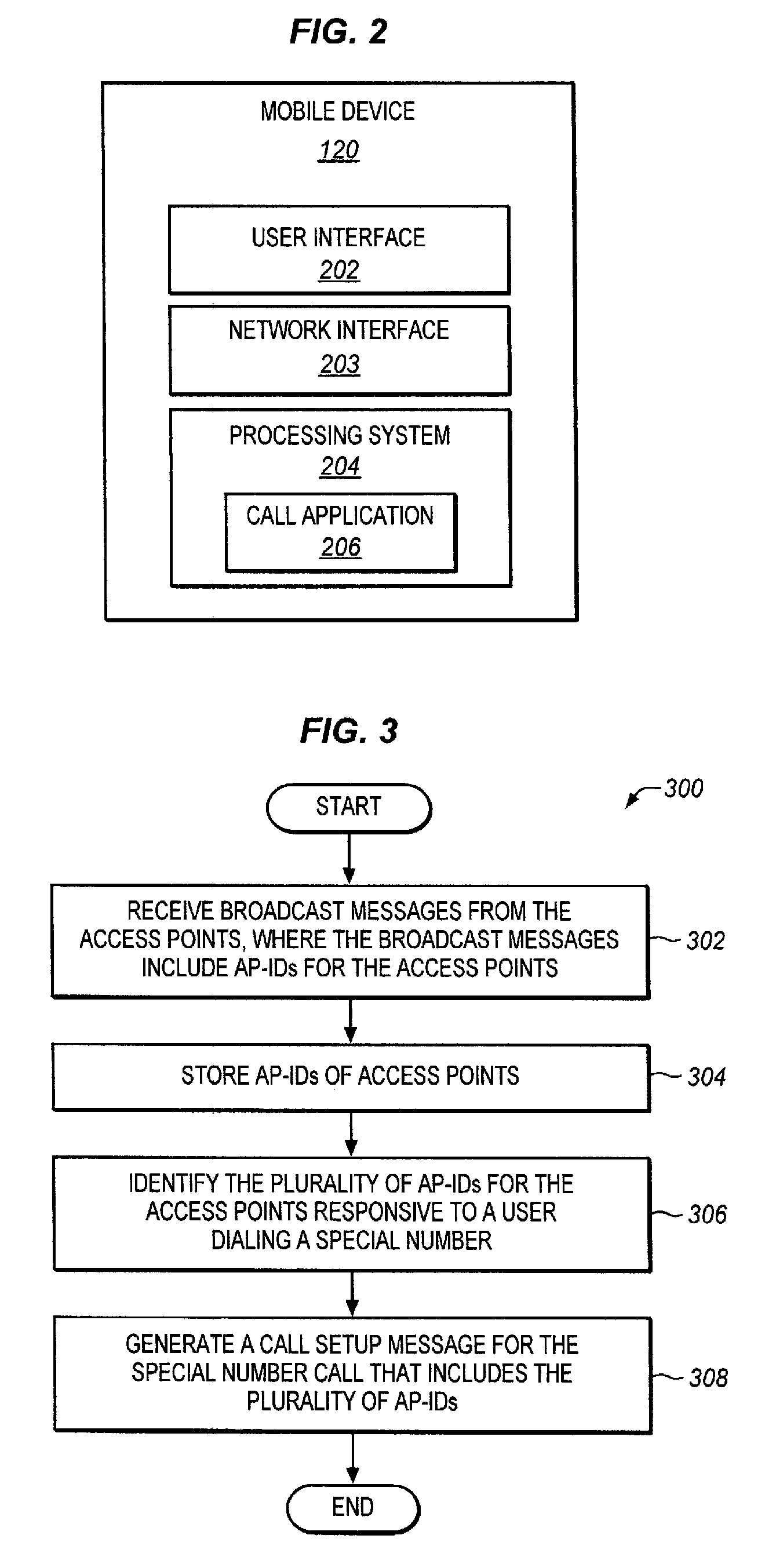

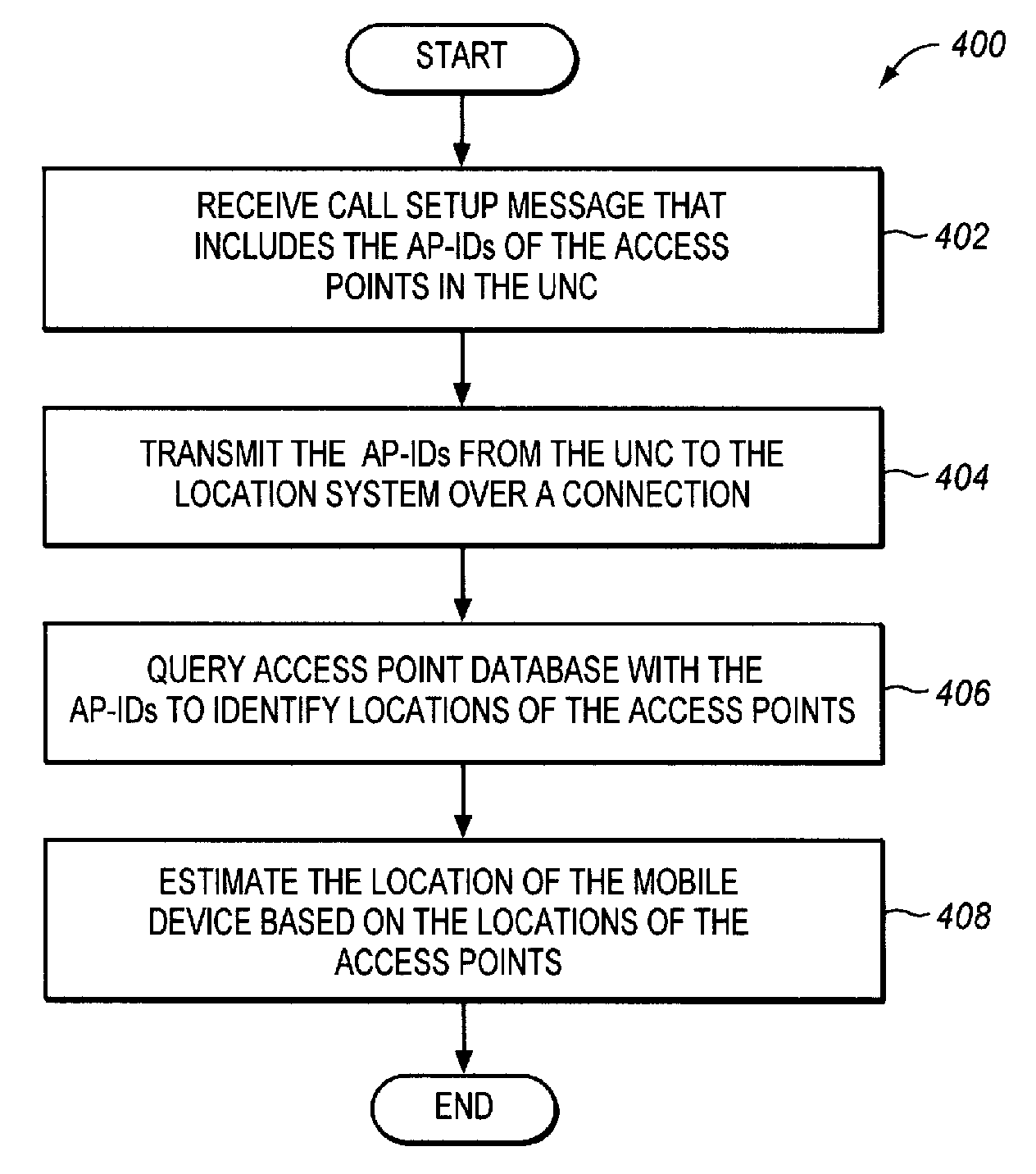

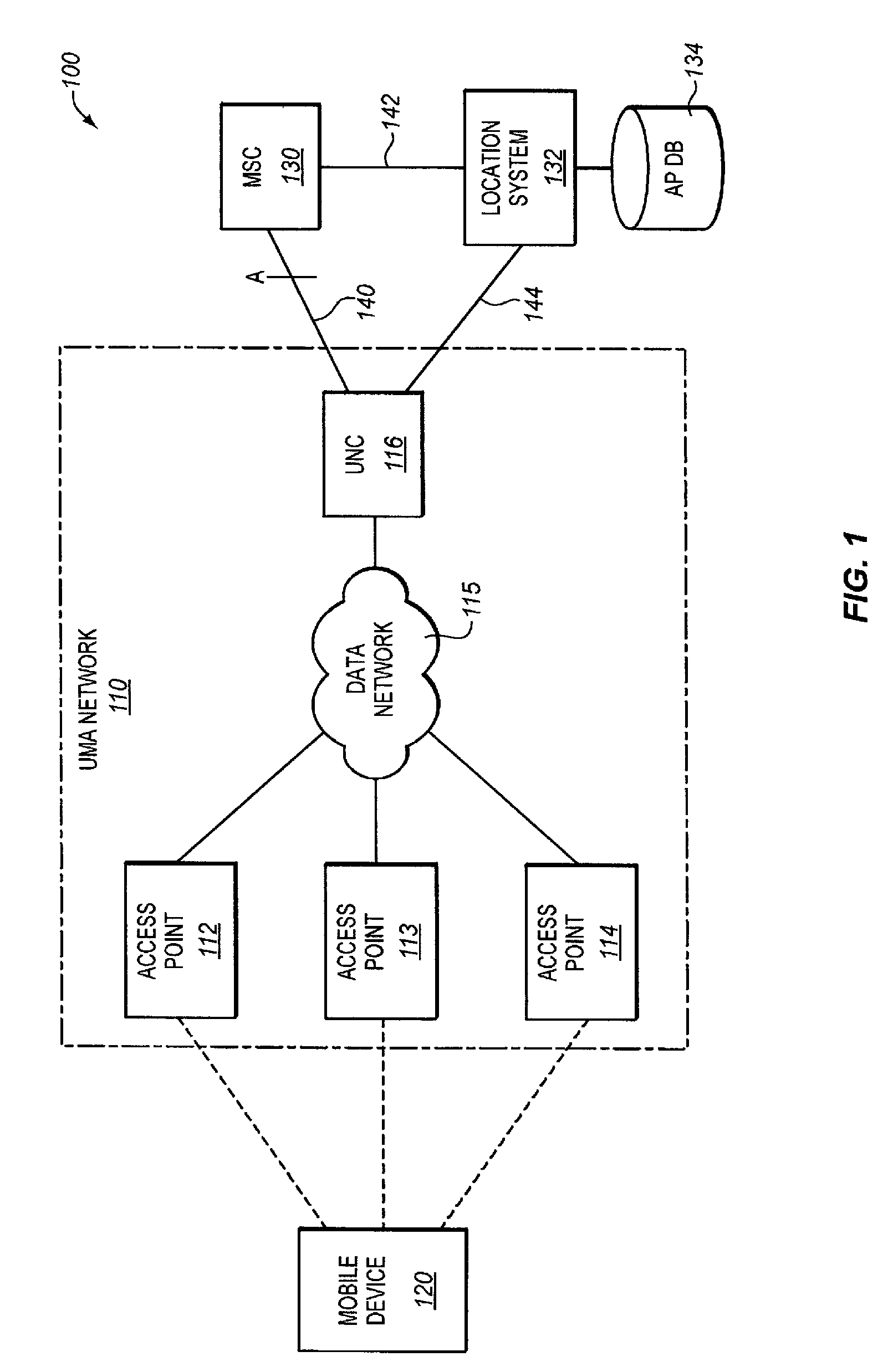

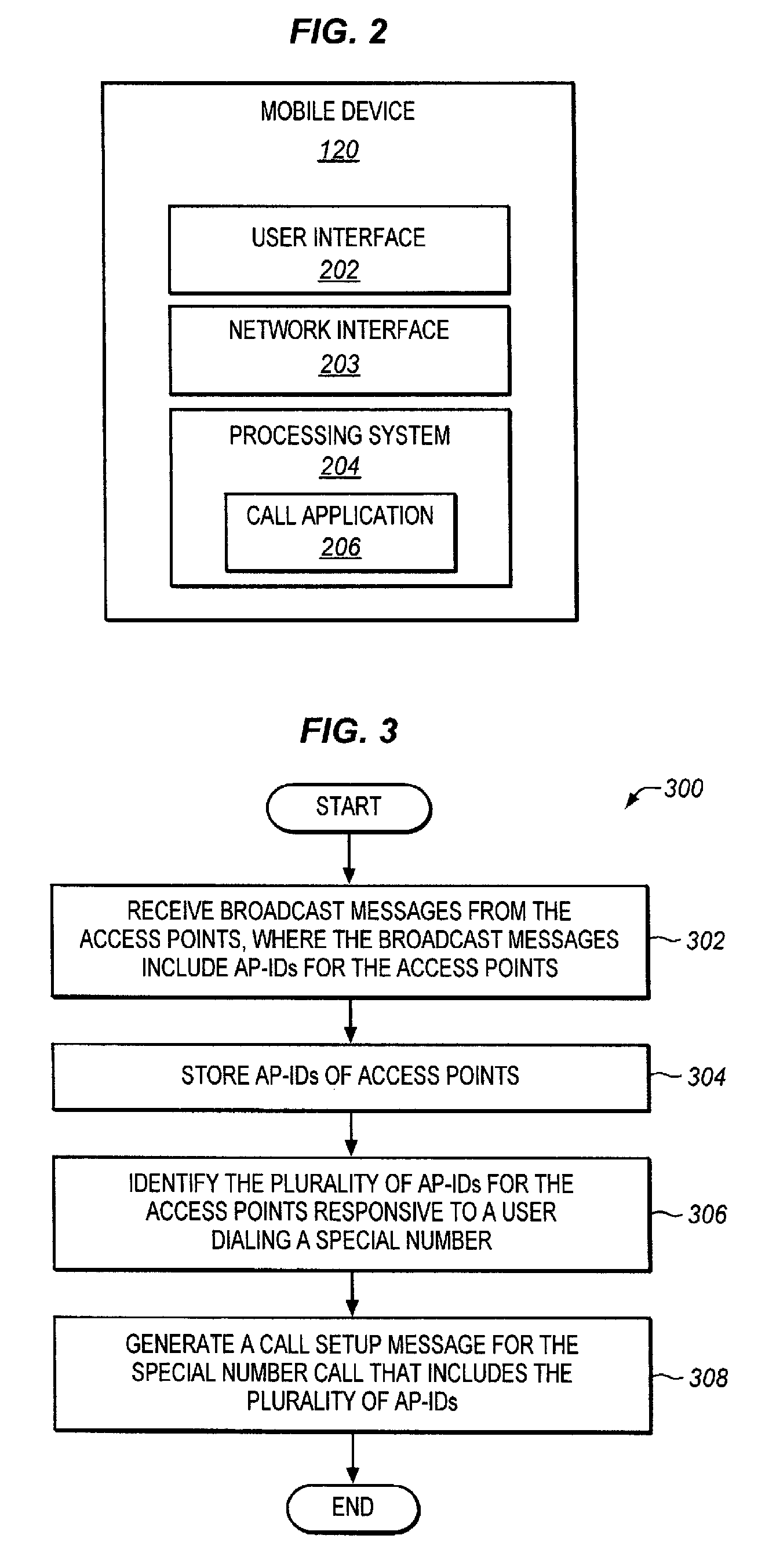

Uma network controller that provides access point identifiers to a location system

InactiveUS20070213071A1Improve accuracyImproving location estimatesEmergency connection handlingNetwork topologiesMobile devicePositioning system

Networks and methods are disclosed for accurately determining the location of a mobile device for a UMA network. When placing a special number call, such as a 9-1-1 call, the mobile device transmits access point identifiers (AP-ID) for a plurality of the access points accessible to the mobile device. A UNC in the UMA network receives the plurality of AP-ID's from the mobile device. The UNC is connected to a location system and transmits the AP-ID's to the location system over the connection. The location system receives the AP-ID's over the connection and queries an access point database that stores a location for each access point registered in the database. The location system then identifies a plurality of locations for the plurality of access points from the access point database, and estimates the location of the mobile device based on the plurality of locations identified for the plurality of access points.

Owner:WEST CORPORATION

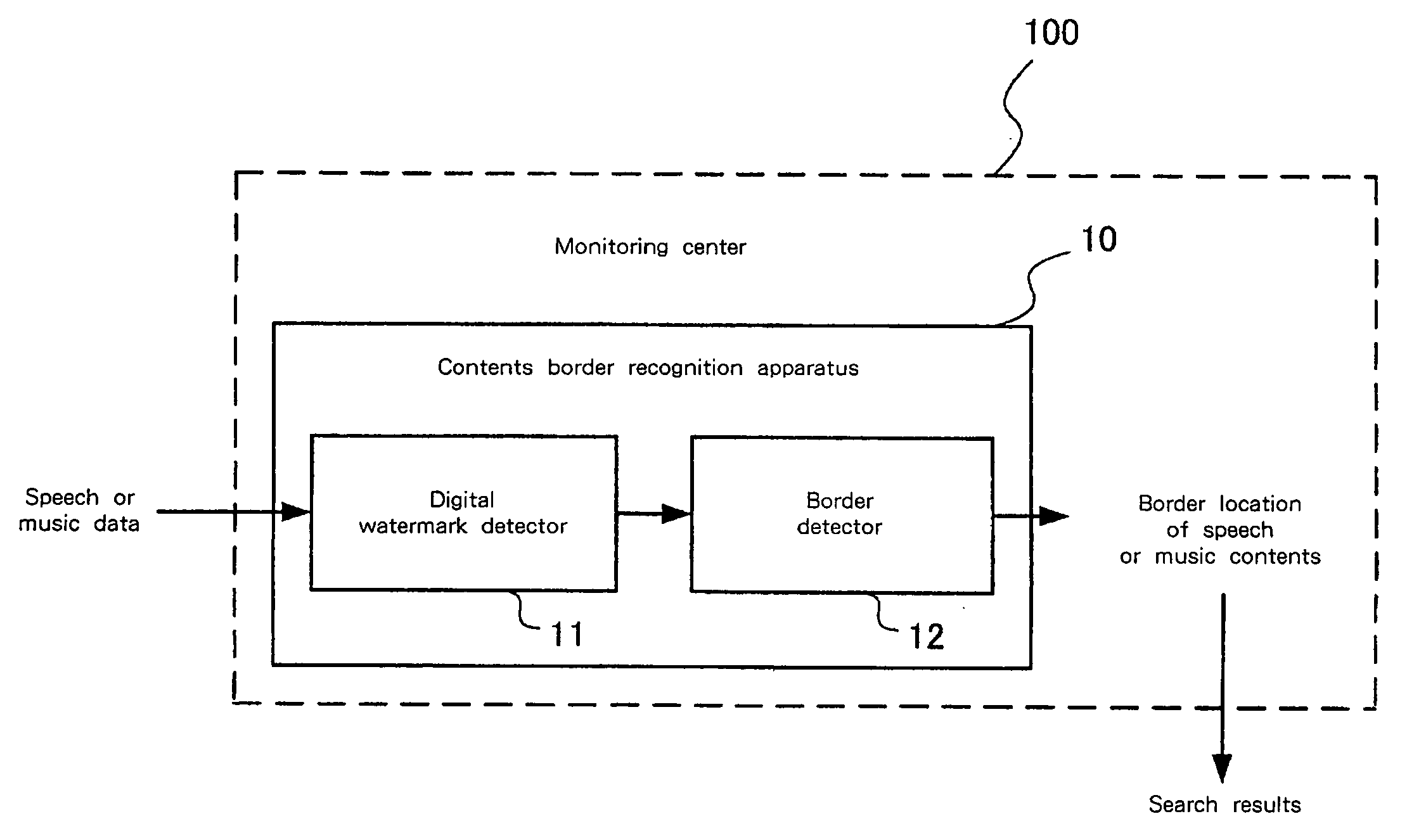

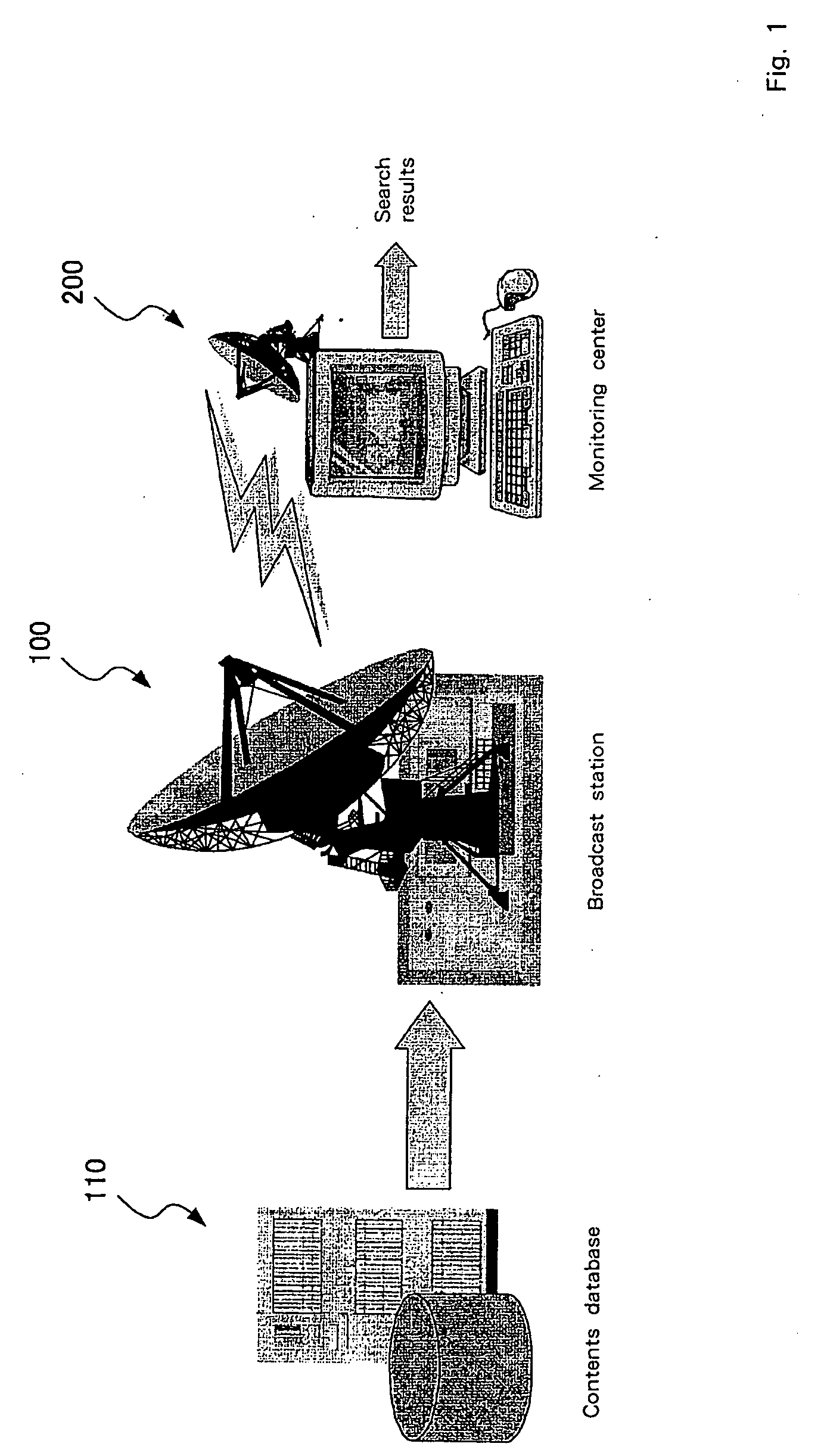

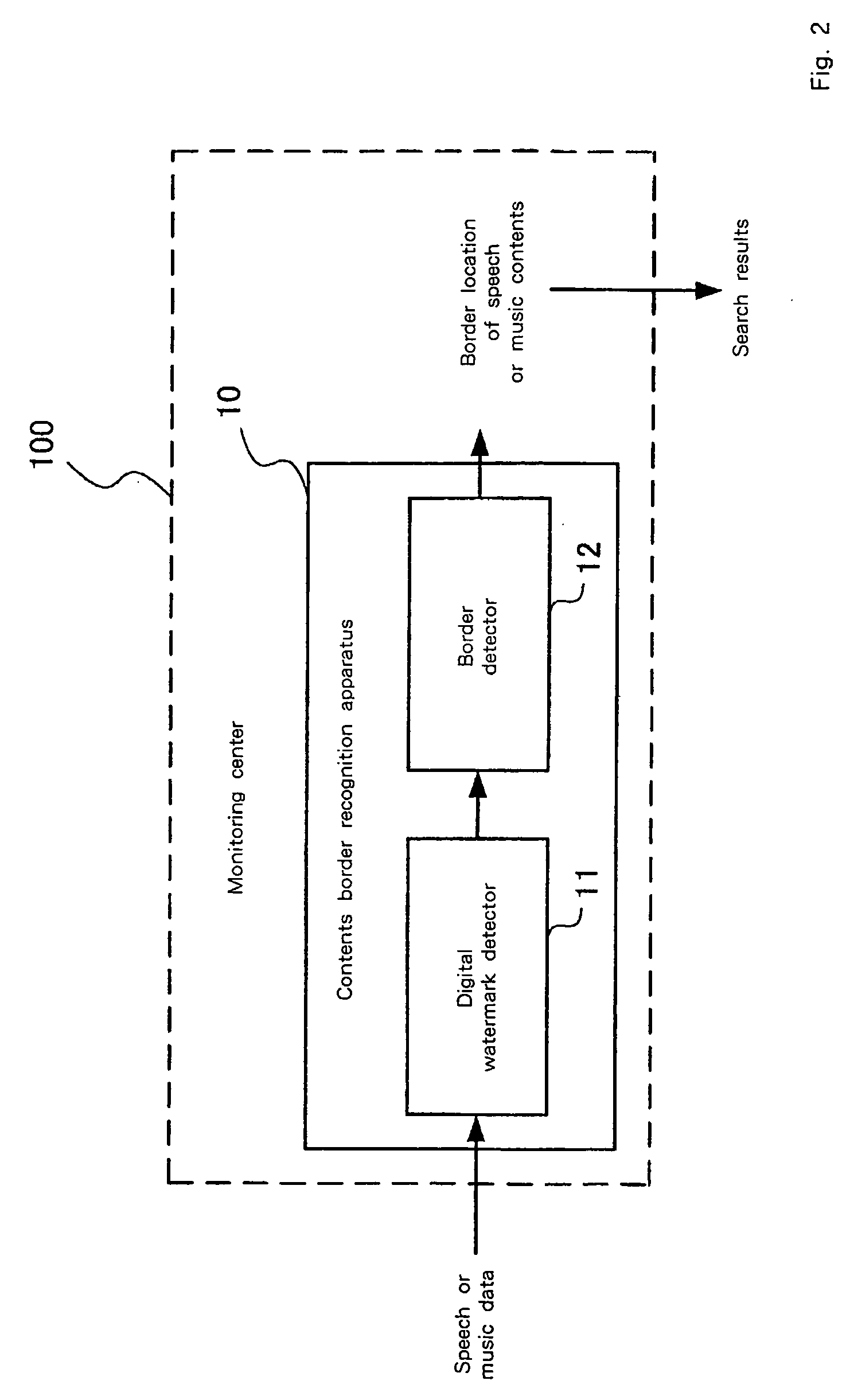

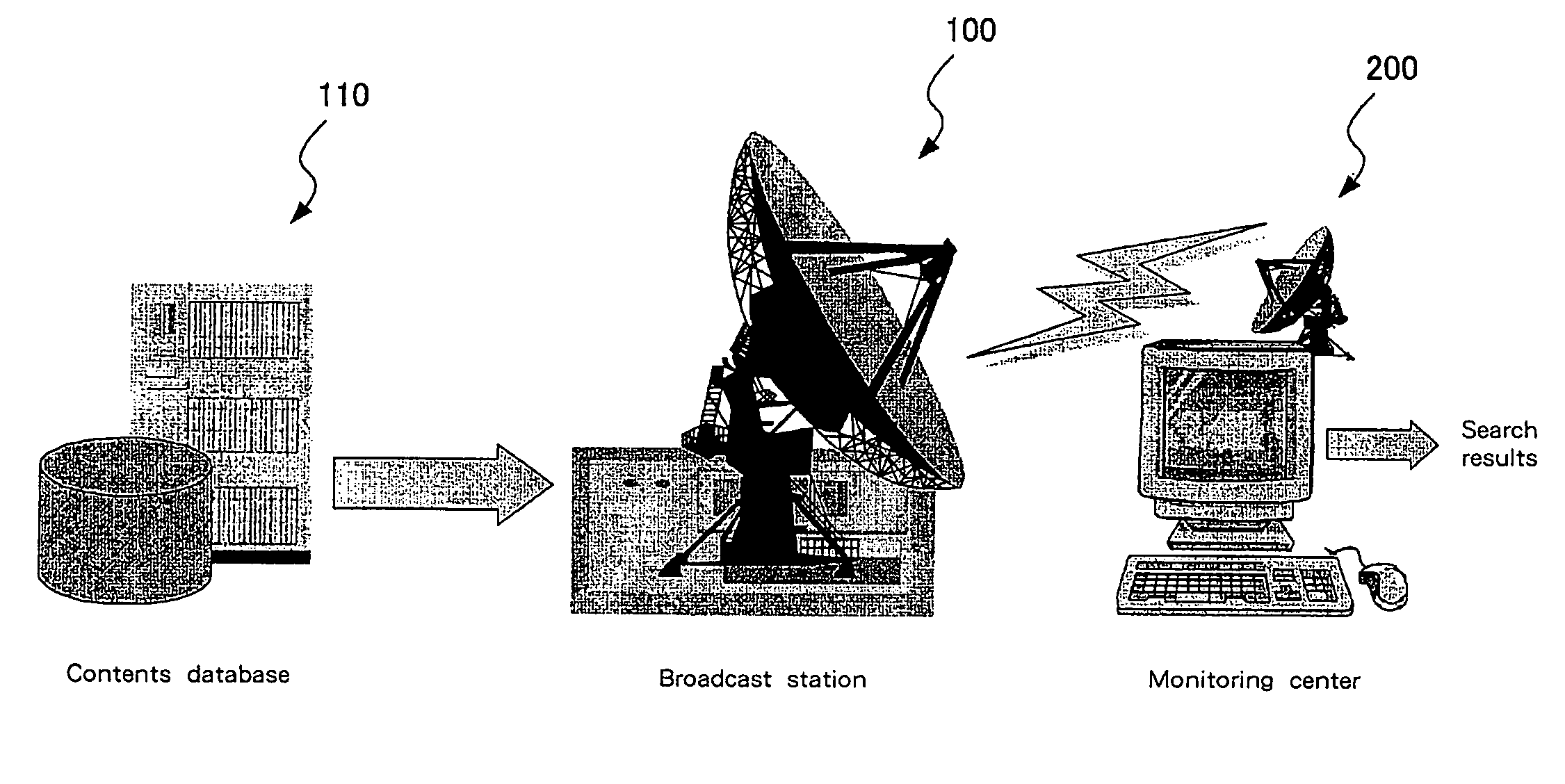

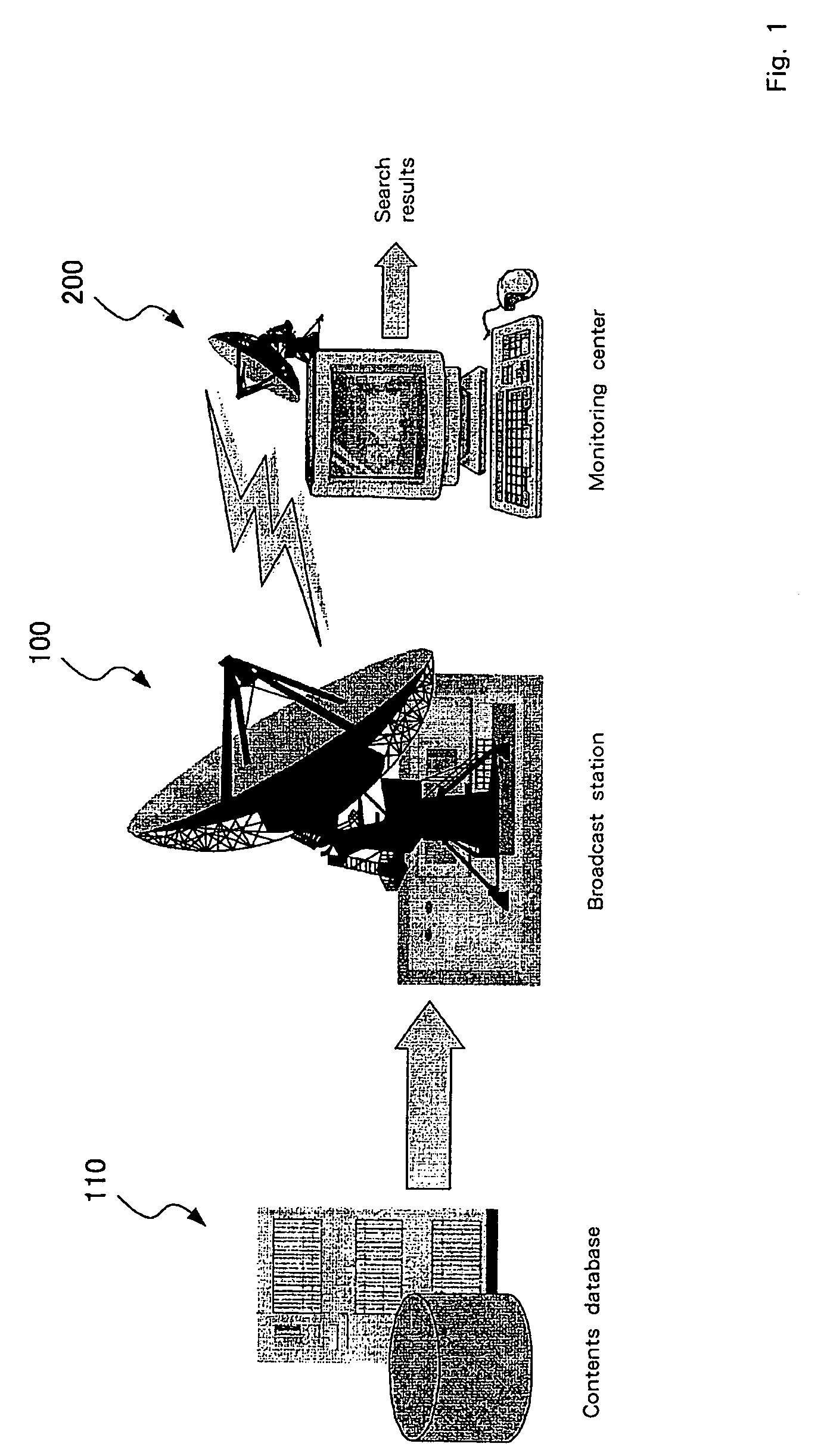

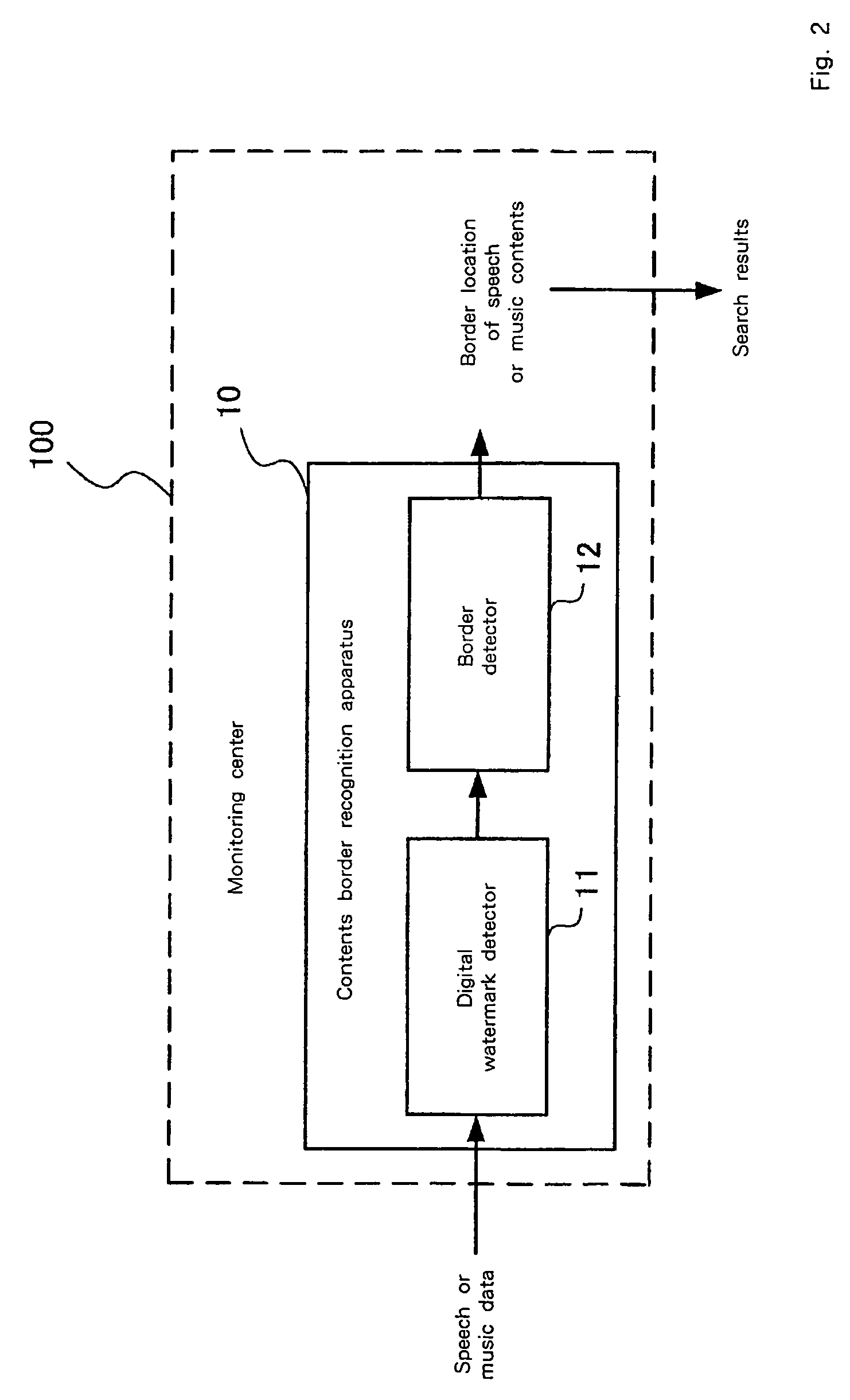

Contents Border Detection Apparatus, Monitoring Method, and Contents Location Detection Method and Program and Storage Medium Therefor

InactiveUS20080052516A1Location specificationAccurate and reliable locationPublic key for secure communicationMultimedia data retrievalBoundary detectionWatermark embedding

It is one object of the present invention to employ multiple methods for identifying contents borders based on a digital watermark detected in contents, so as to provide both high reliability and precision for the identification of contents border locations.A contents border detection apparatus comprises: a digital watermark detector 11, for detecting a digital watermark embedded in contents for which a time element is provided; and a border detector 12, for detecting border locations for the contents corresponding to the state of the digital watermark detected by the digital watermark detector 11, wherein the border detector 12 includes first border specification means, for specifying the border locations for the contents based on information, written in the digital watermark, that is detected by the digital watermark detector 11, and second border specification means, for specifying the border locations for the contents based on bit patterns embedded as the digital watermark, wherein the border locations for the contents are detected by using the process results obtained both by the first and the second border specification means.

Owner:IBM CORP +1

UMA network controller that provides access point identifiers to a location system

InactiveUS8483718B2Improve accuracyGood estimateNetwork topologiesConnection managementMobile devicePositioning system

Networks and methods are disclosed for accurately determining the location of a mobile device for a UMA network. When placing a special number call, such as a 9-1-1 call, the mobile device transmits access point identifiers (AP-ID) for a plurality of the access points accessible to the mobile device. A UNC in the UMA network receives the plurality of AP-ID's from the mobile device. The UNC is connected to a location system and transmits the AP-ID's to the location system over the connection. The location system receives the AP-ID's over the connection and queries an access point database that stores a location for each access point registered in the database. The location system then identifies a plurality of locations for the plurality of access points from the access point database, and estimates the location of the mobile device based on the plurality of locations identified for the plurality of access points.

Owner:WEST CORPORATION

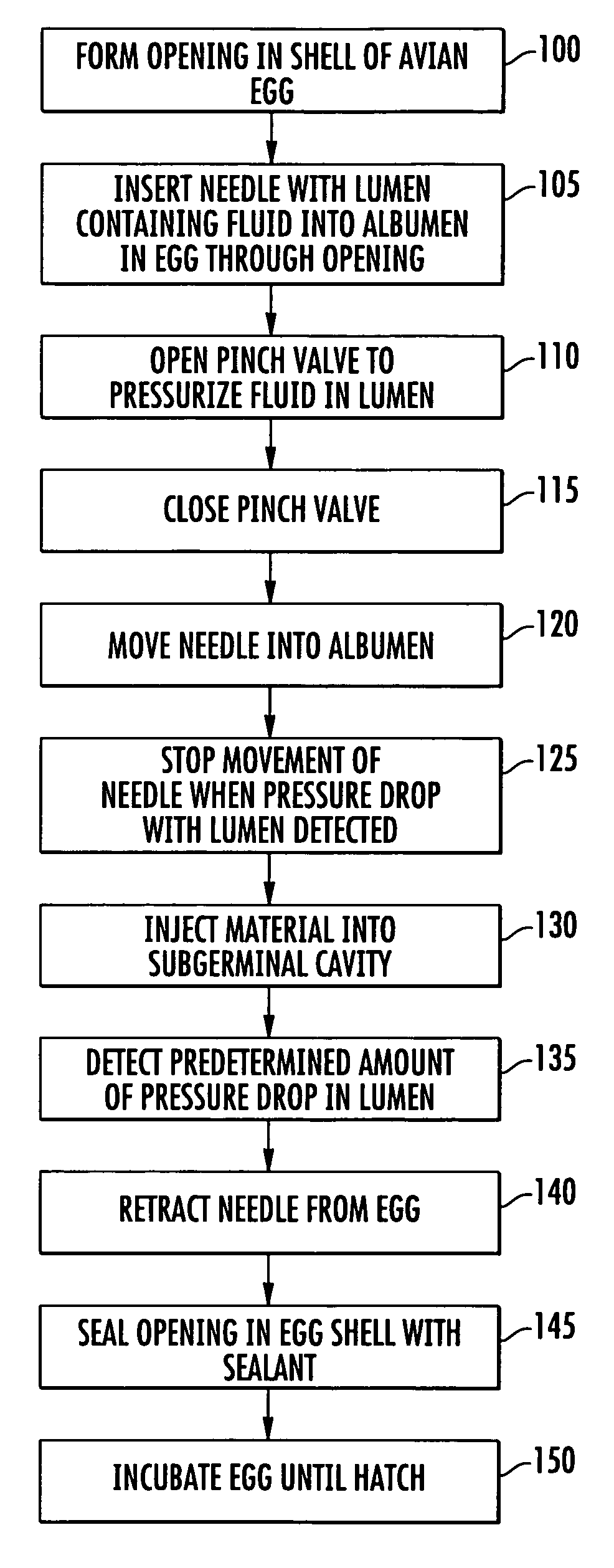

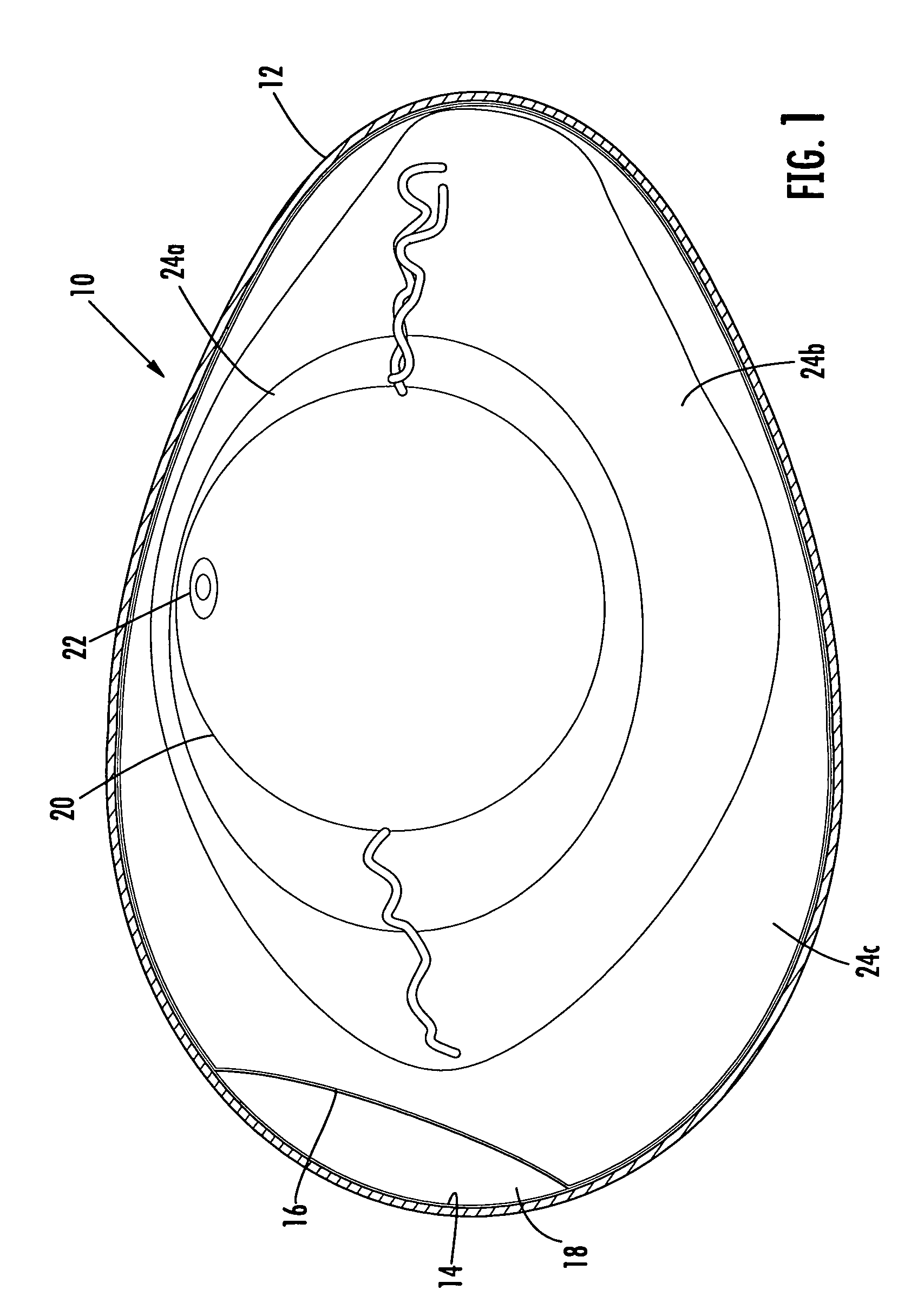

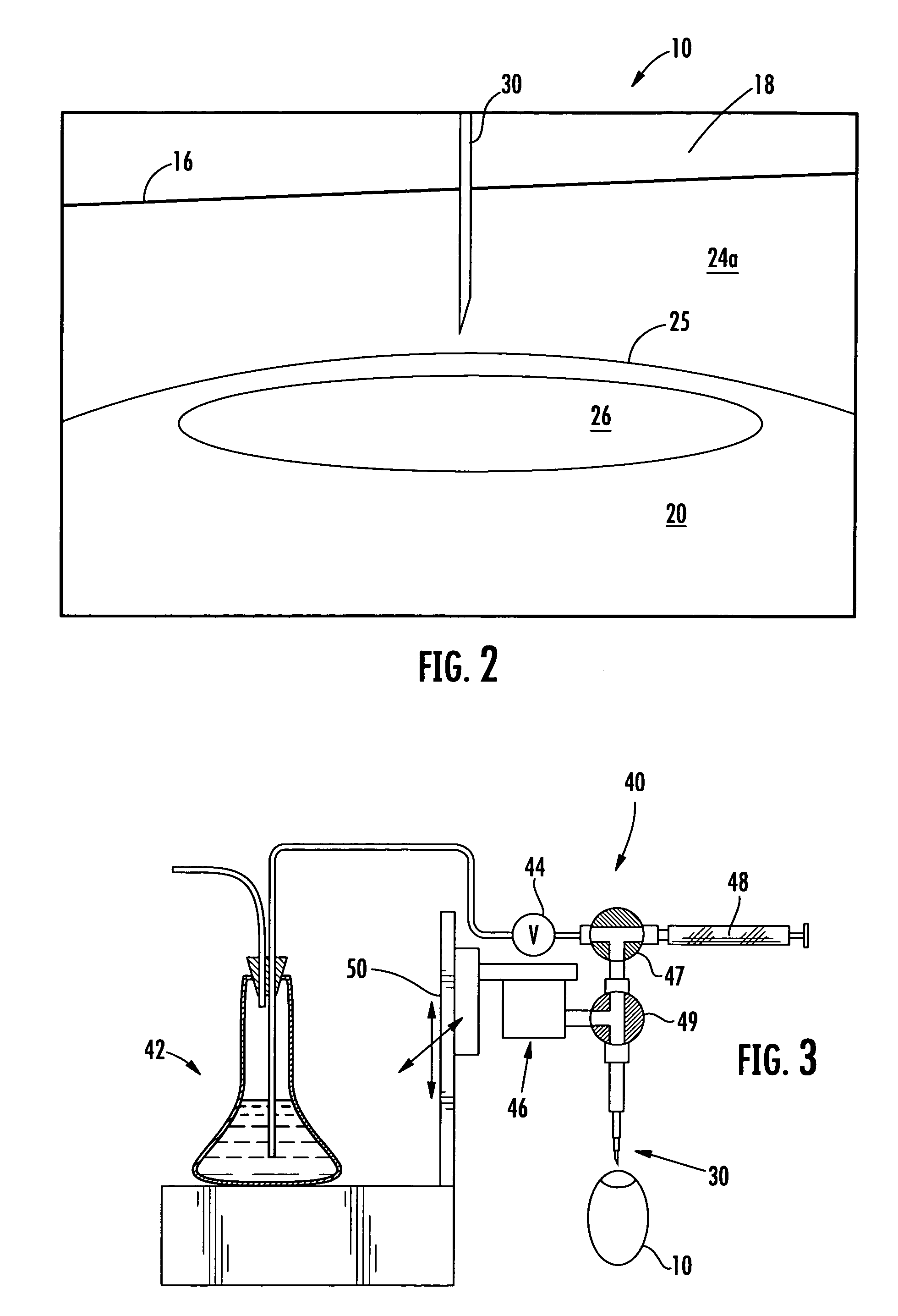

Methods and apparatus for accurately positioning a device within the subgerminal cavity of avian eggs

Owner:ZOETIS SERVICE LLC

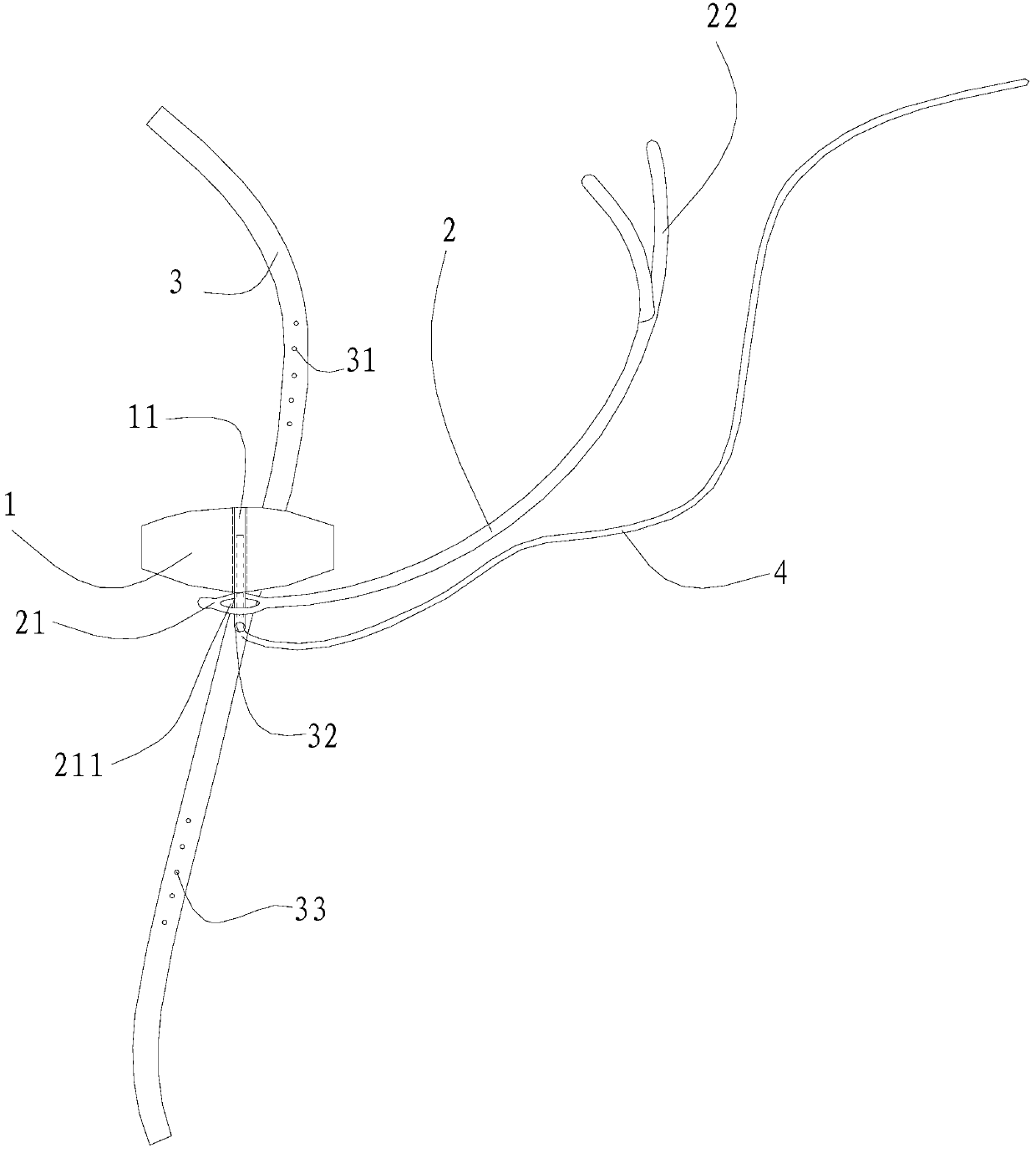

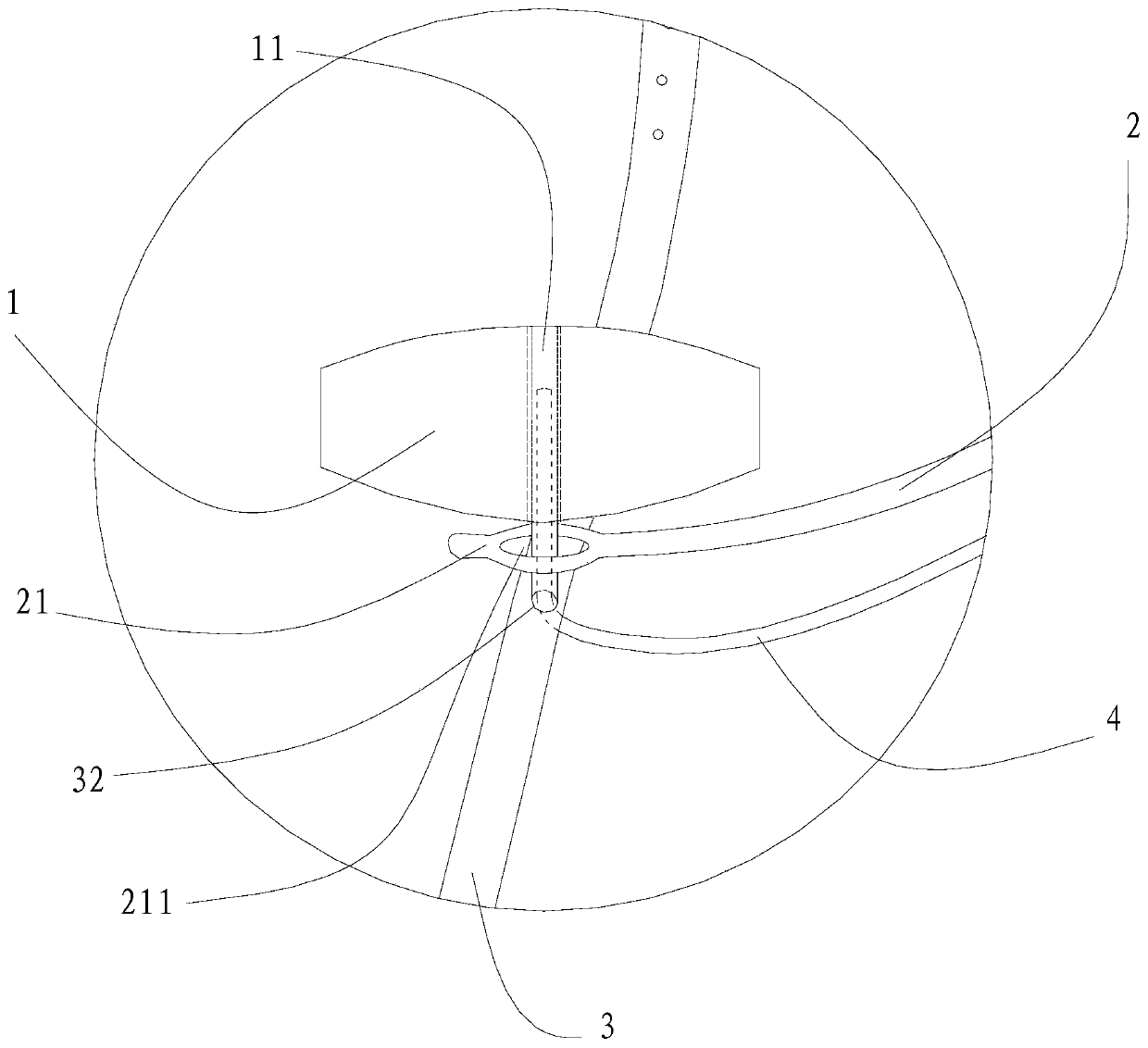

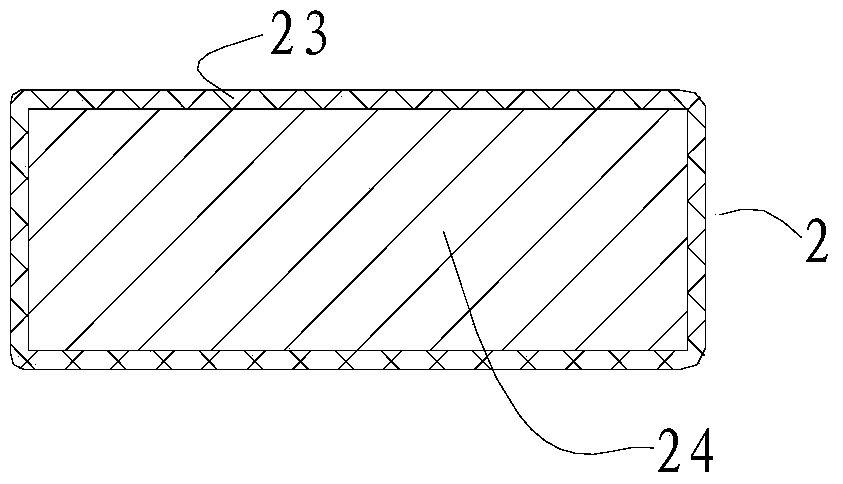

Surgical device for ophthalmic surgery

ActiveCN105125341AAchieve the desired effectSimple and convenient to completeEye surgerySurgical operationFiber

The invention provides a surgical device for ophthalmic surgery. The surgical device comprises a jacking material, a light guiding fiber, a traction strip and an arc-shaped support. The jacking material and the traction strip are arranged on the inner side and the outer side of one end of the arc-shaped support respectively. A hollow channel is formed in the middle of the jacking material. A through hole is formed in the portion, corresponding to the hollow channel, of the arc-shaped support. A hollow region is formed on the traction strip. The joint of the traction strip and the arc-shaped support can freely rotate. One end of the light guiding fiber sequentially penetrates through the hollow region and the through hole to be embedded into the hollow channel. When the surgical device is used, the jacking material can be aligned with the macula lutea center region through the light guiding fiber, the jacking height can be adjusted through the traction strip, the suture position of the arc-shaped support is adjusted through relative rotation between the traction strip and the jacking end, the implantation position of the jacking material can be accurate and reliable, an implant is stable for a long time, surgical operation is simple, side effects are fewer, and the surgical device is suitable for treating high myopia degree progressive increase and posterior scleral staphyloma related complications.

Owner:广州瑞其纳医疗科技有限公司

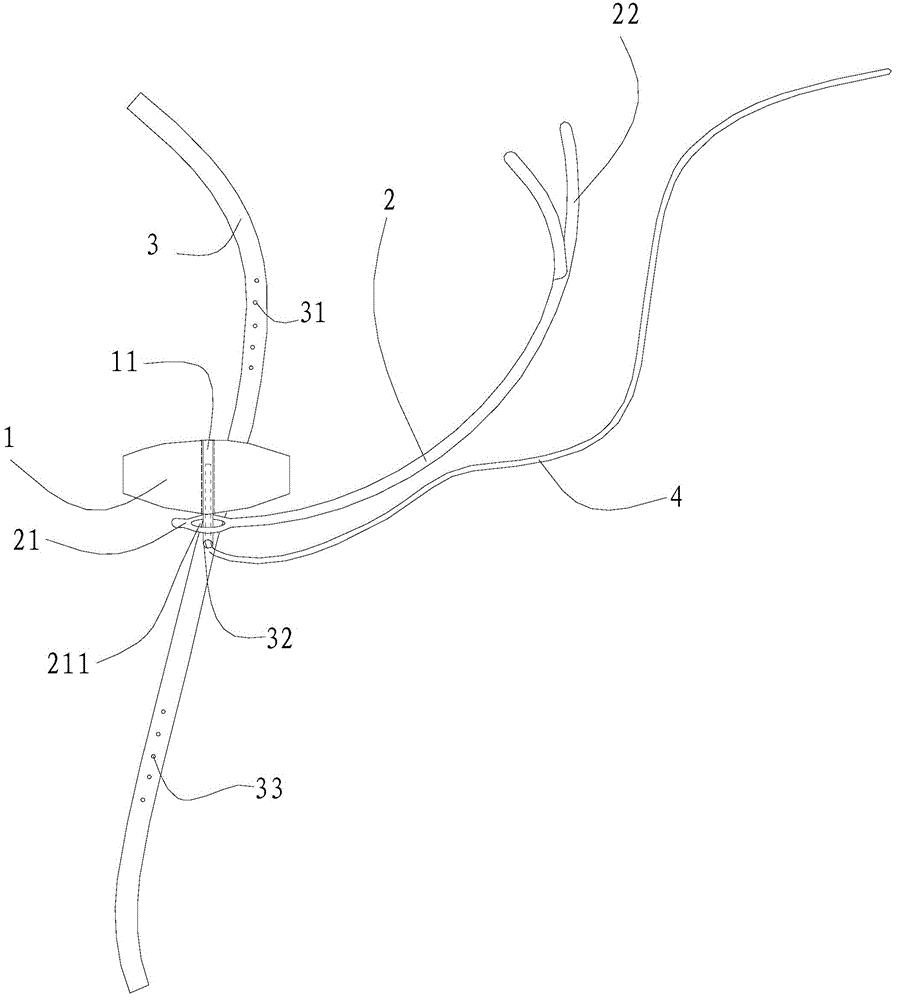

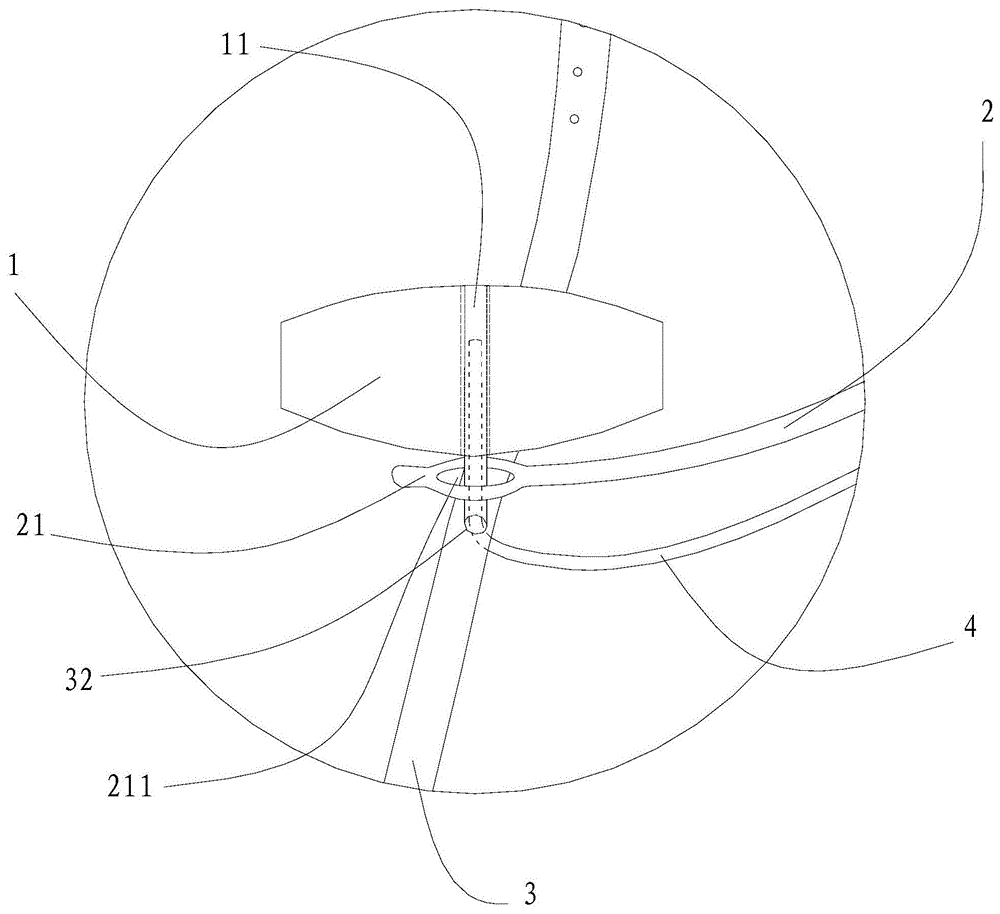

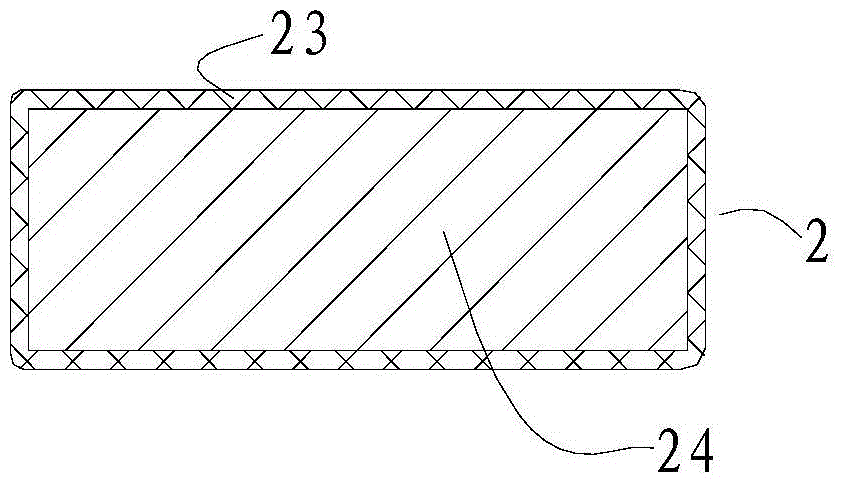

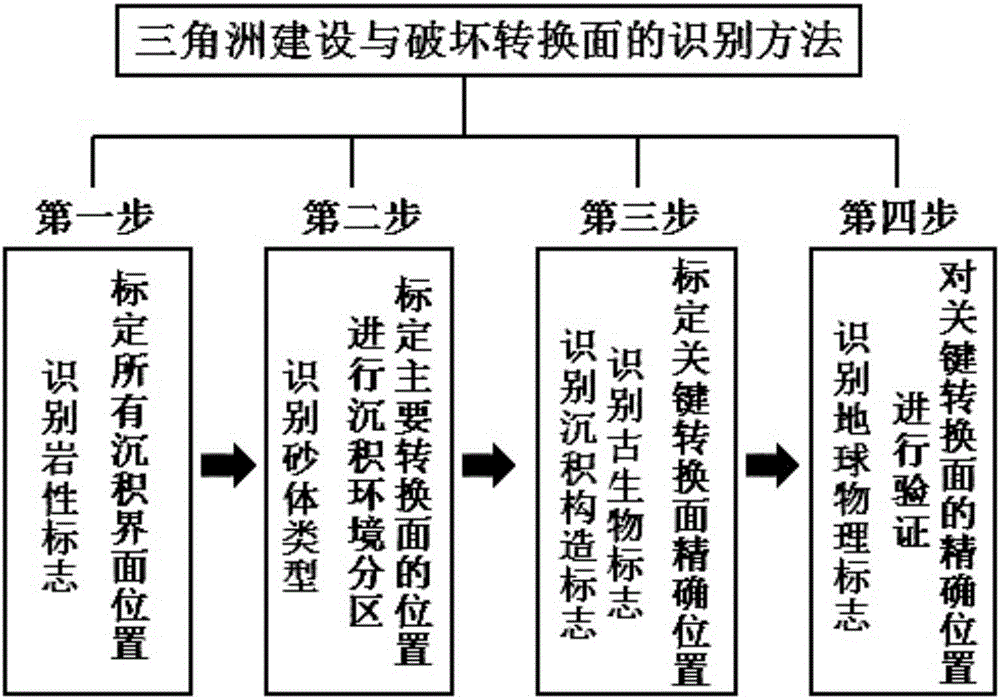

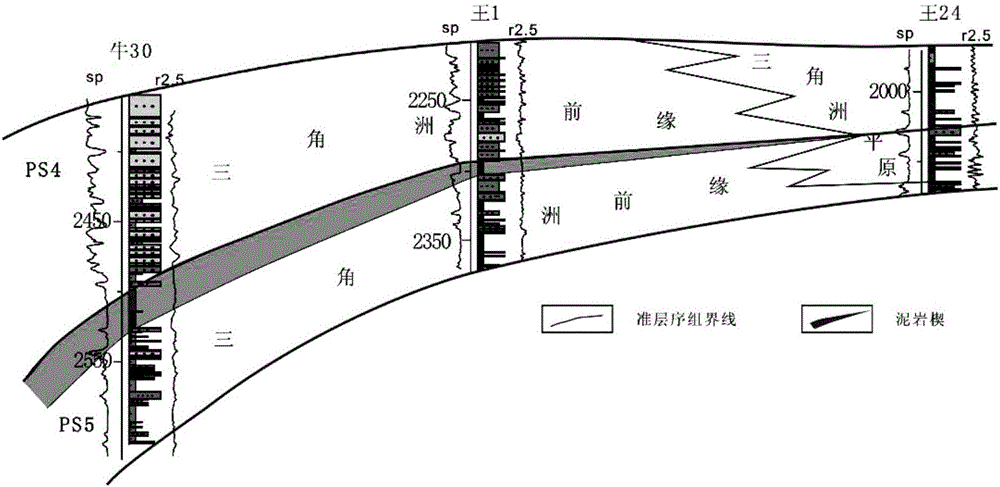

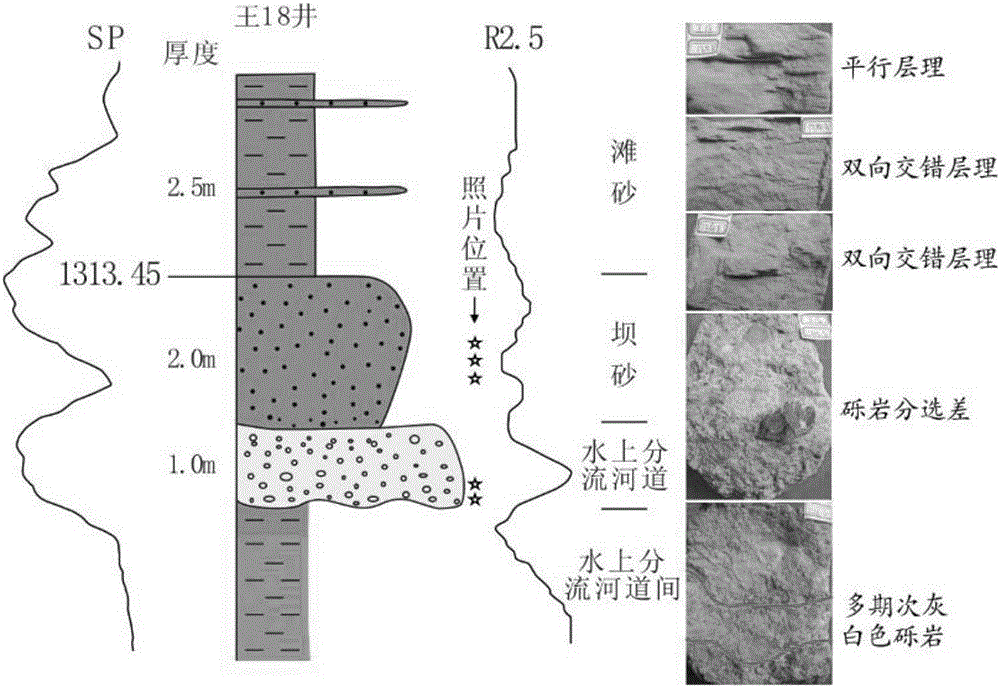

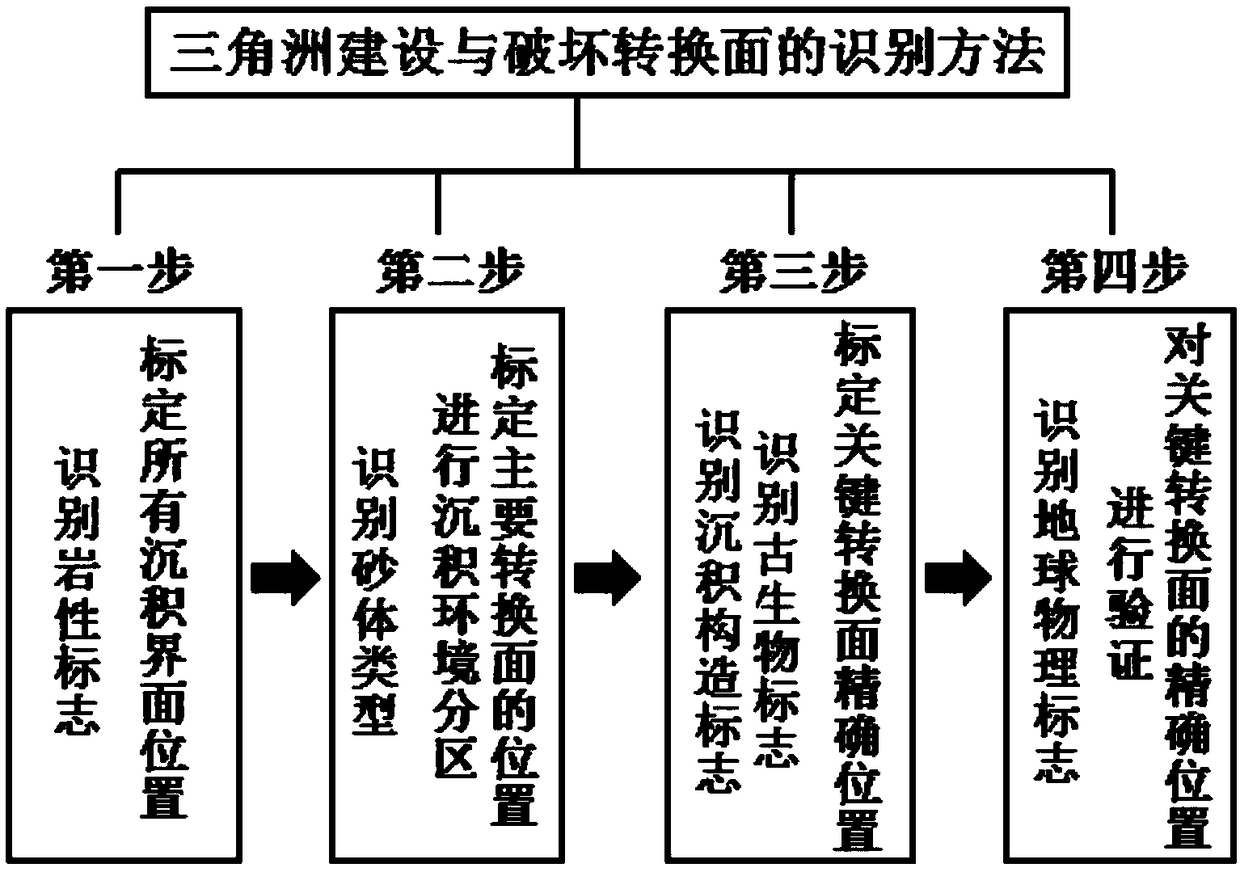

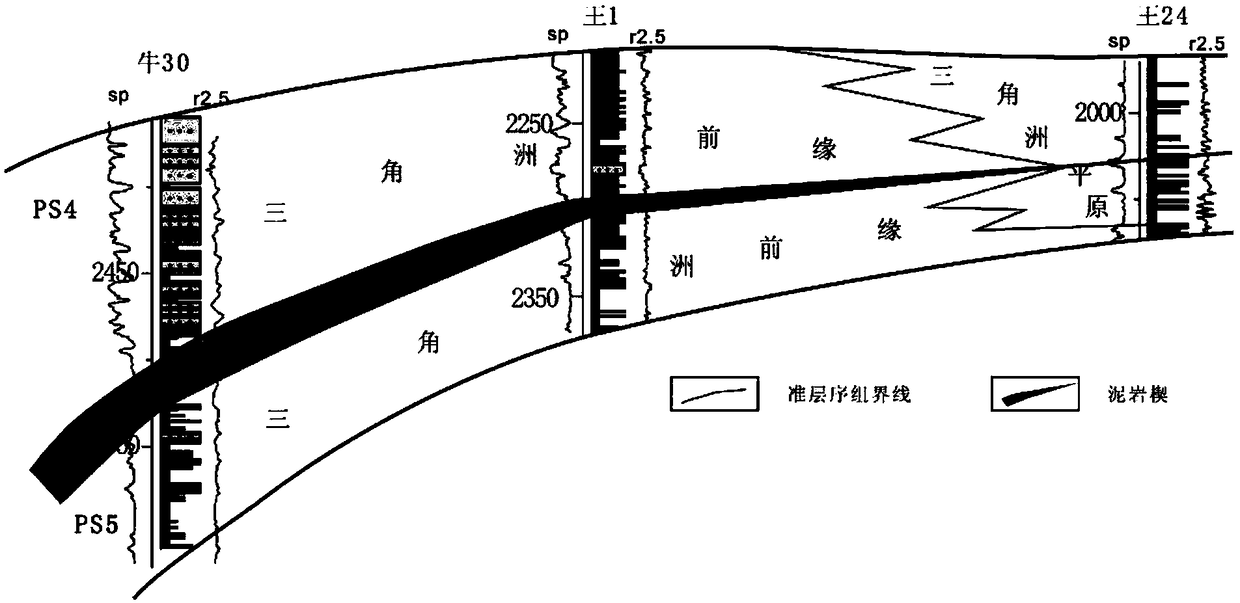

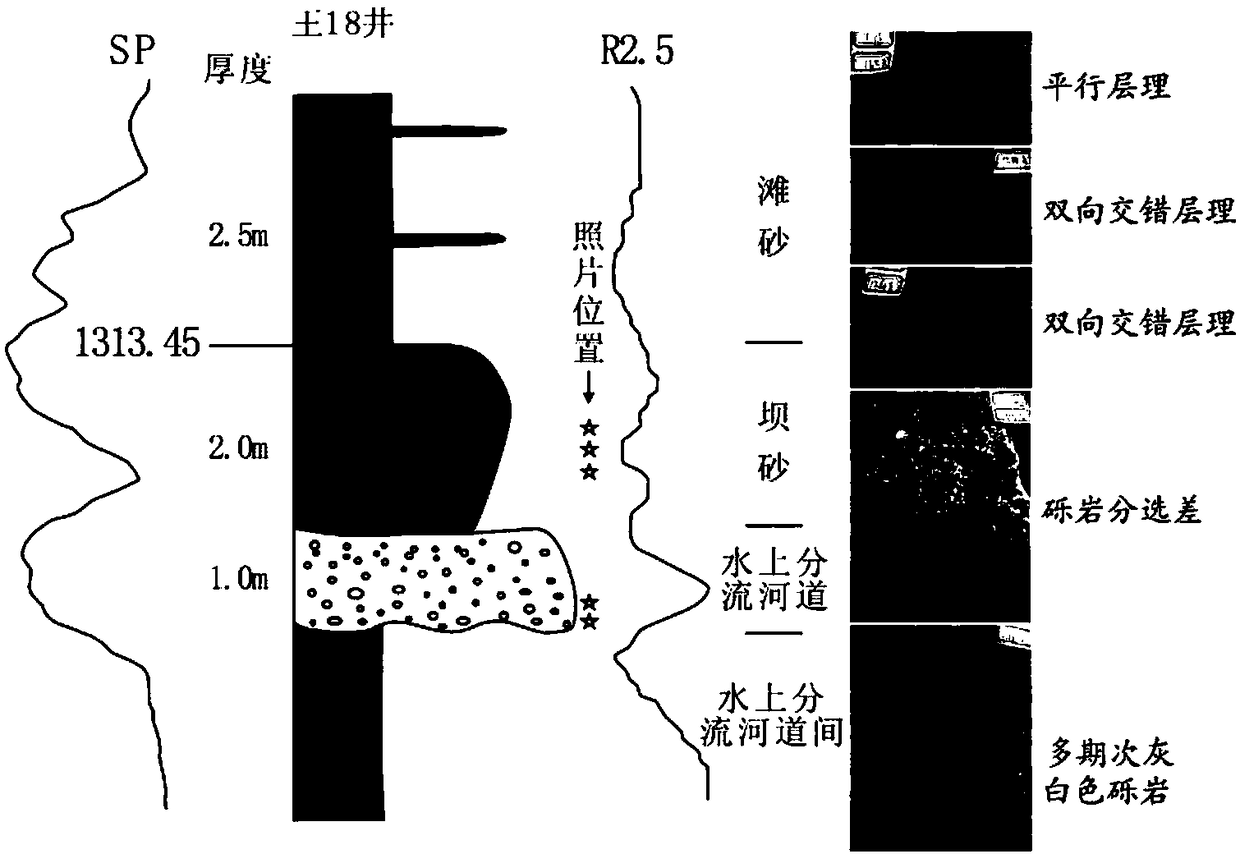

Method for identifying main transform plane of delta construction and destruction

The invention provides a method for identifying a main transform plane of delta construction and destruction. Identification is carried out from perspectives of lithology, sand body types, sedimentary tectonics, paleontology, and geophysics and a precise position of a key transform plane of delta construction and destruction is determined. The method is characterized in that a main transform plane of delta construction and destruction is put forward firstly; and the sedimentary period of the delta is divided into a delta construction period and a delta destruction period based on the delta sedimentary effect for the first time. On the basis of the core, welllogging, logging, and seismic data, precision improvement is realized step by step; the position of the main transform plane of delta construction and destruction is determined comprehensively; and the data reliability and precision are high.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

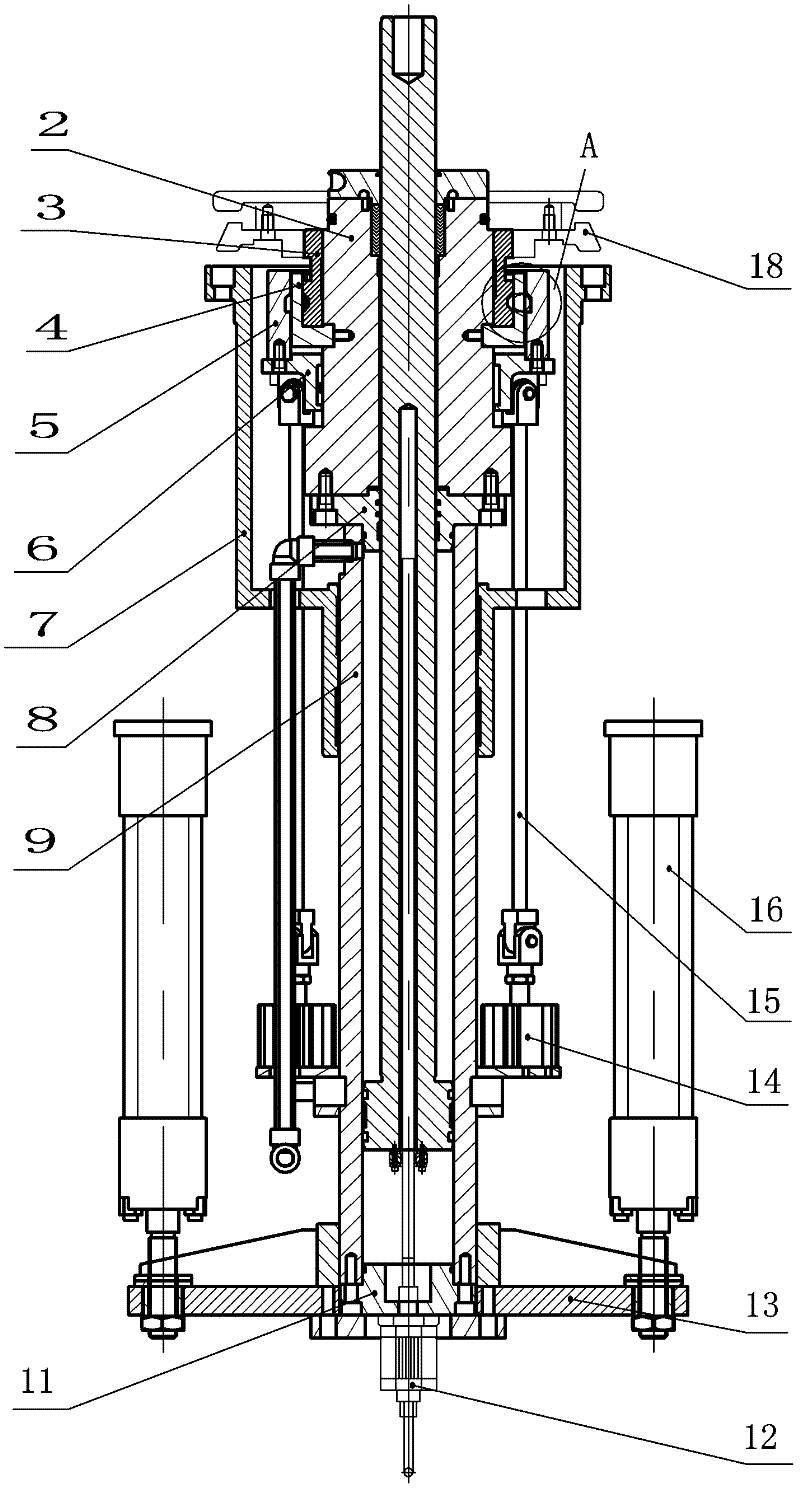

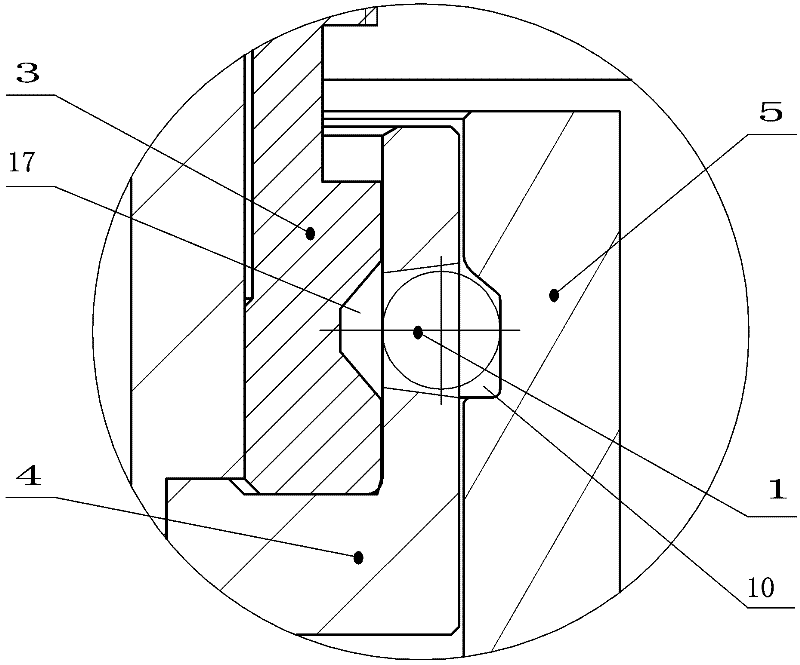

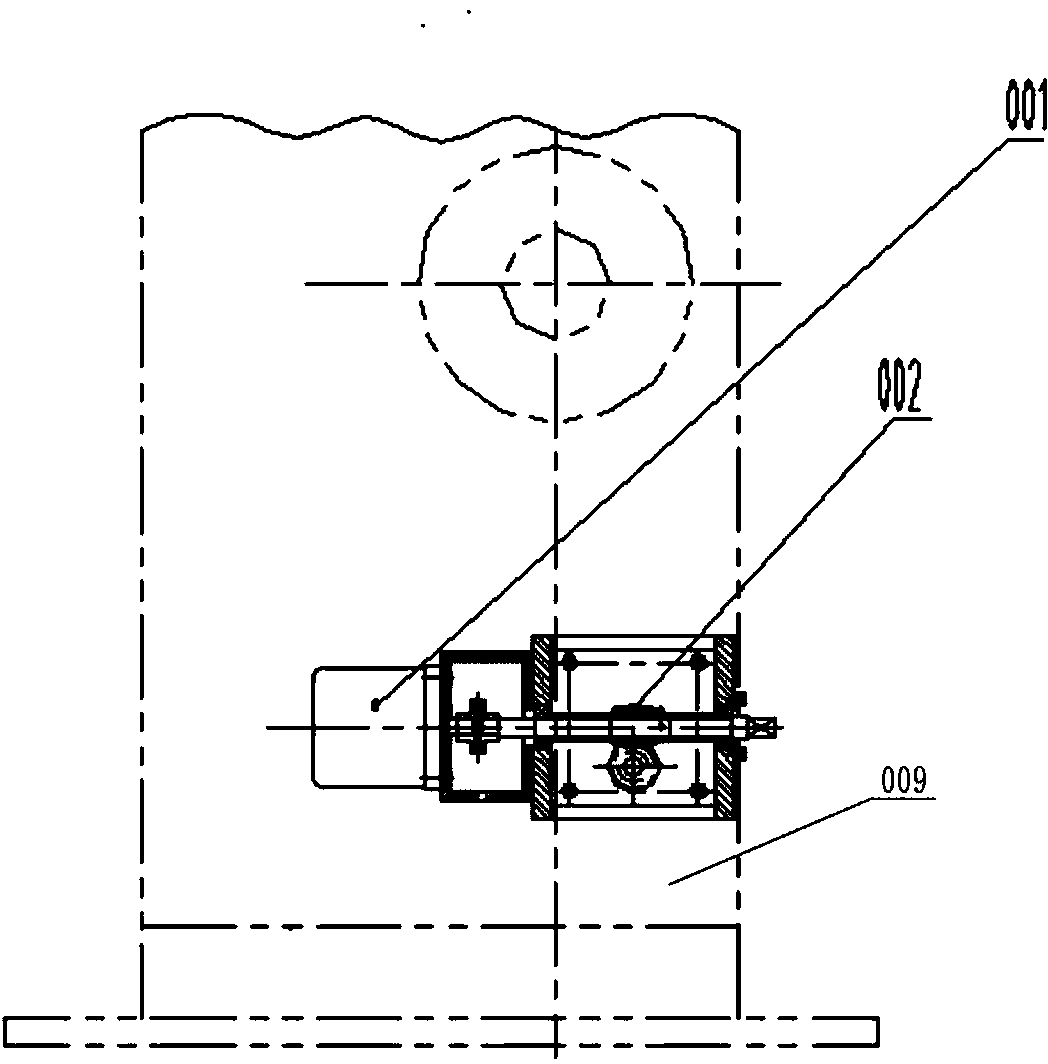

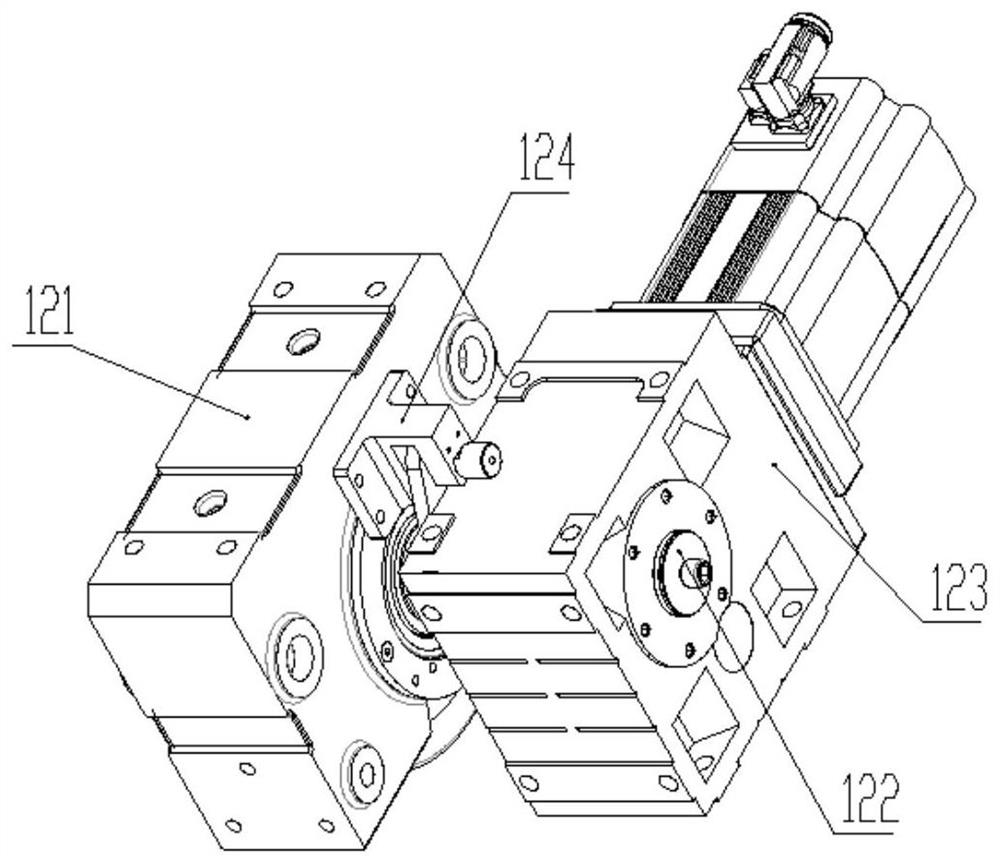

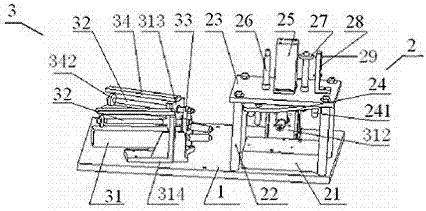

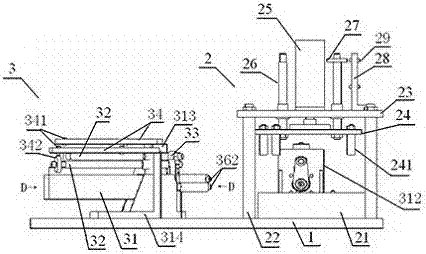

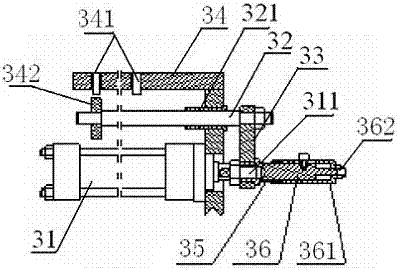

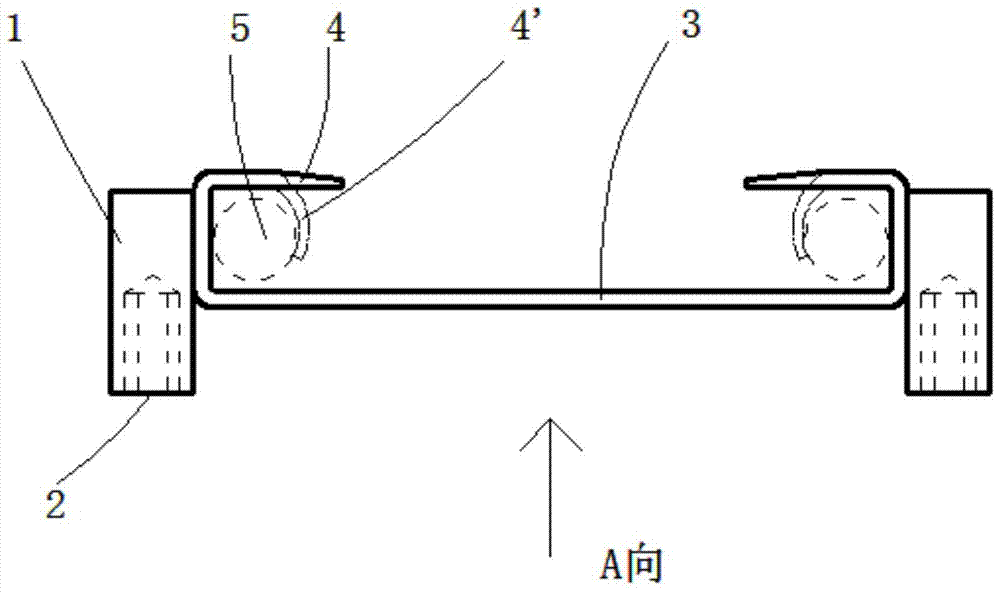

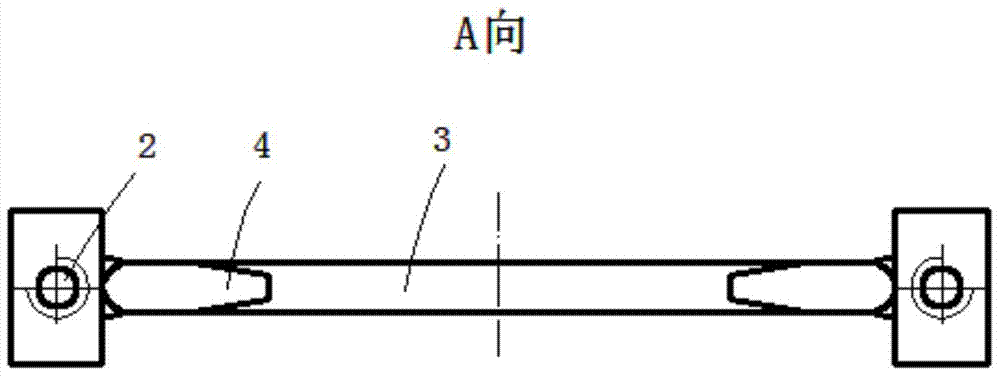

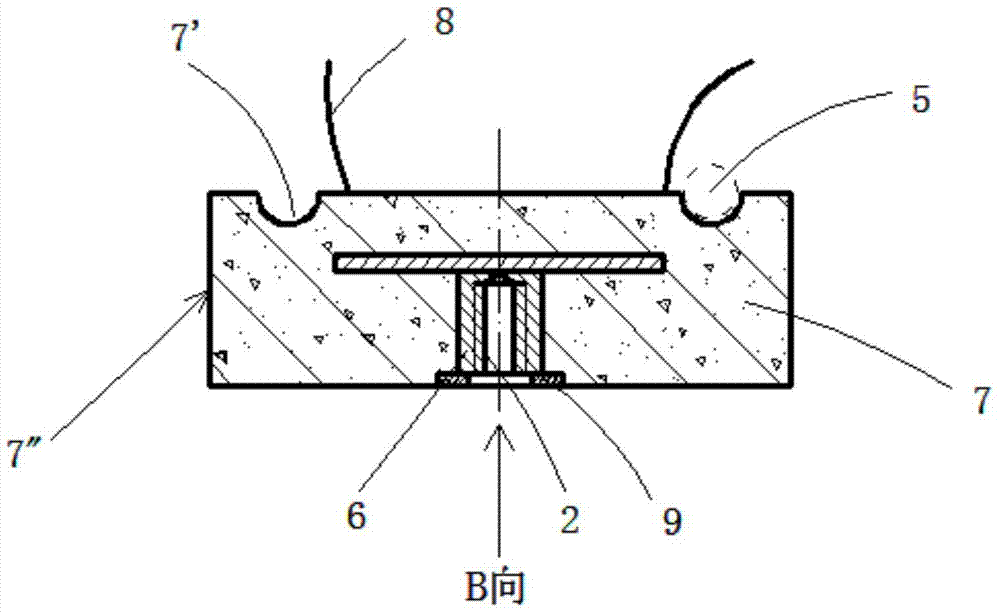

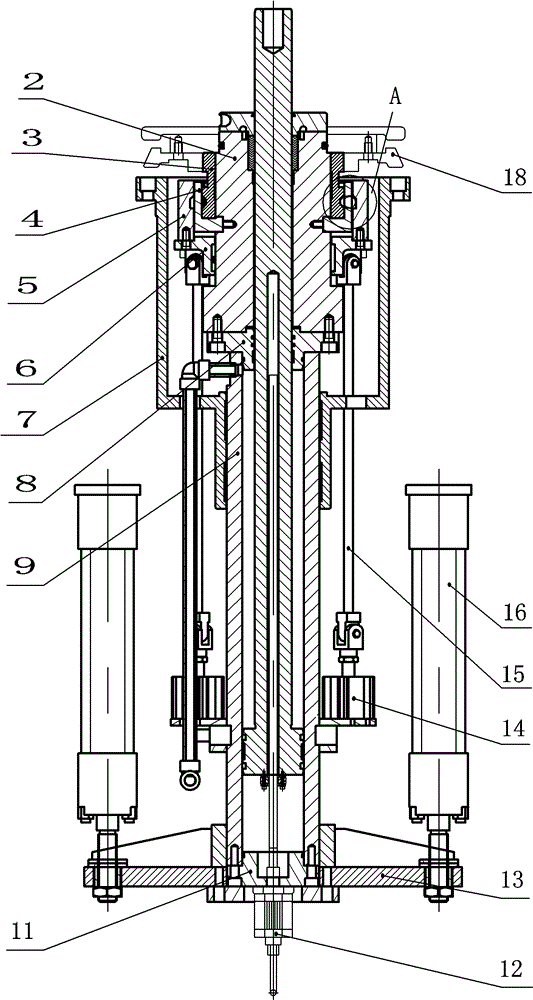

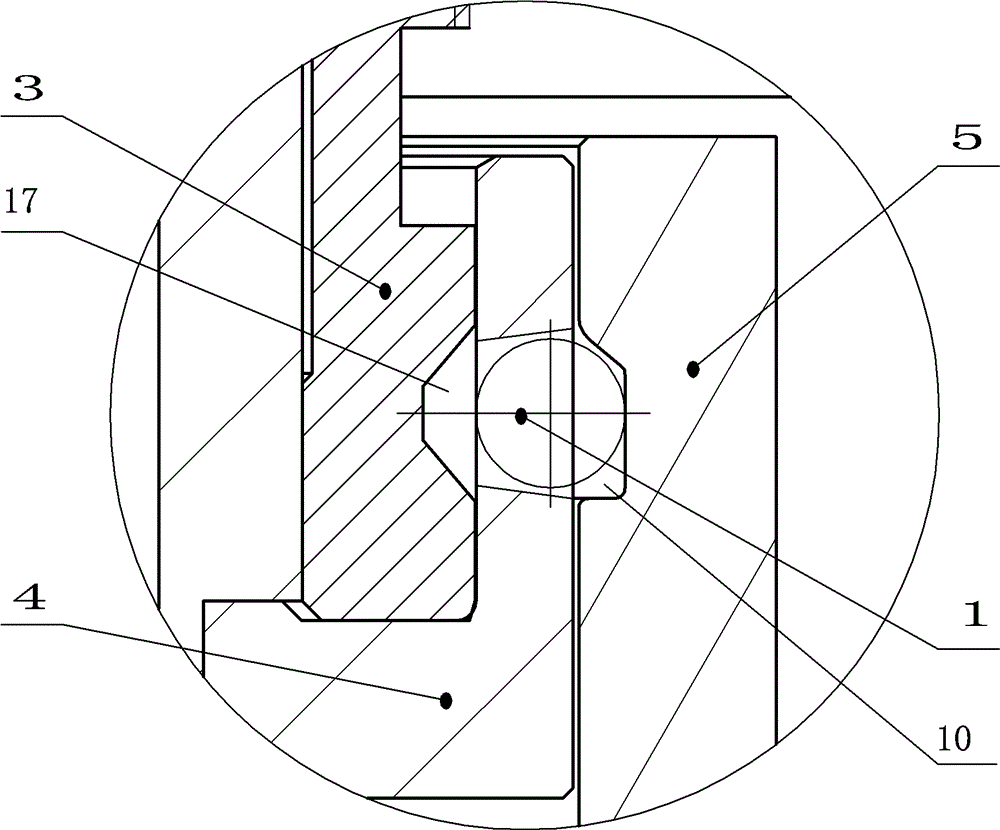

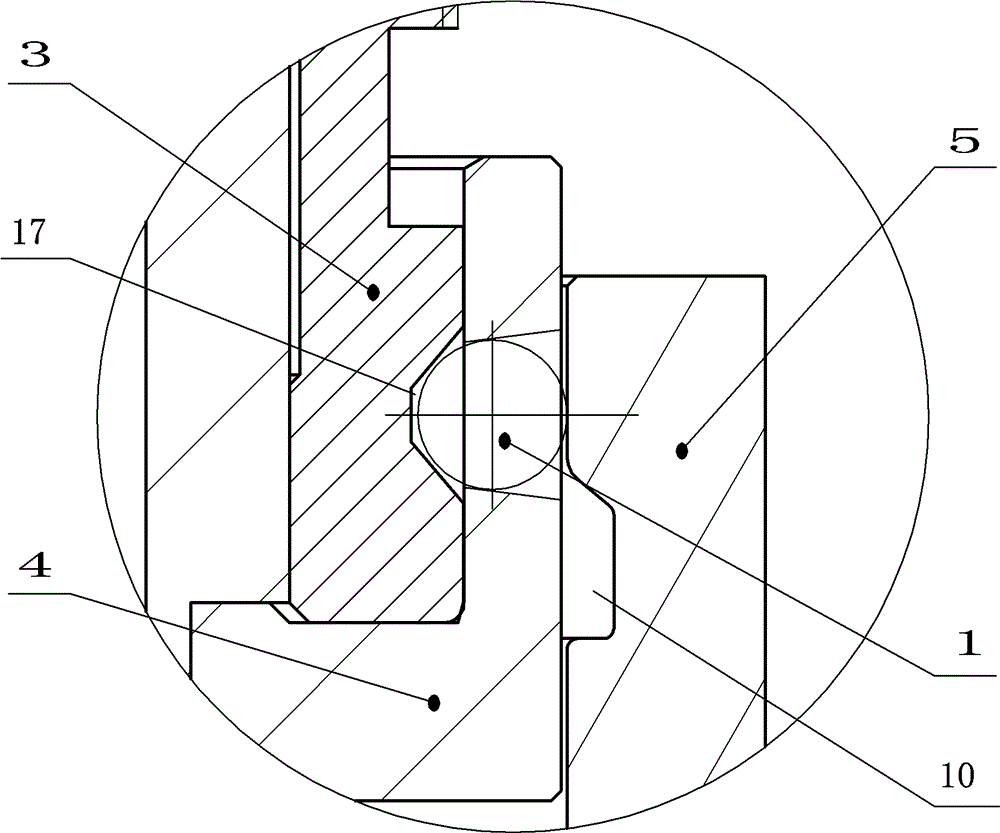

Quick capsule replacing center mechanism for tire vulcanizer

The invention discloses a quick capsule replacing center mechanism for a tire vulcanizer. A quick chuck replacing mechanism consisting of a steel ball retaining ring, a locking ring, a steel ball, a connecting rod and a locking cylinder can quickly replace a capsule and a sealing ring, time is saved, and the work efficiency of the vulcanizer is improved; an upper ring lifting water cylinder is separated from a ring seat and has an independent structure, so that processing and installation difficulty is reduced, internal pressure superheated water can be prevented from leaking and entering the water cylinder, and the service life of the sealing ring of the water cylinder is prolonged; and the water cylinder has a single-piston structure and is provided with a built-in displacement sensor, so that the straightening height and forming height of the capsule can be accurately controlled.

Owner:BRIDGESTONE CORP

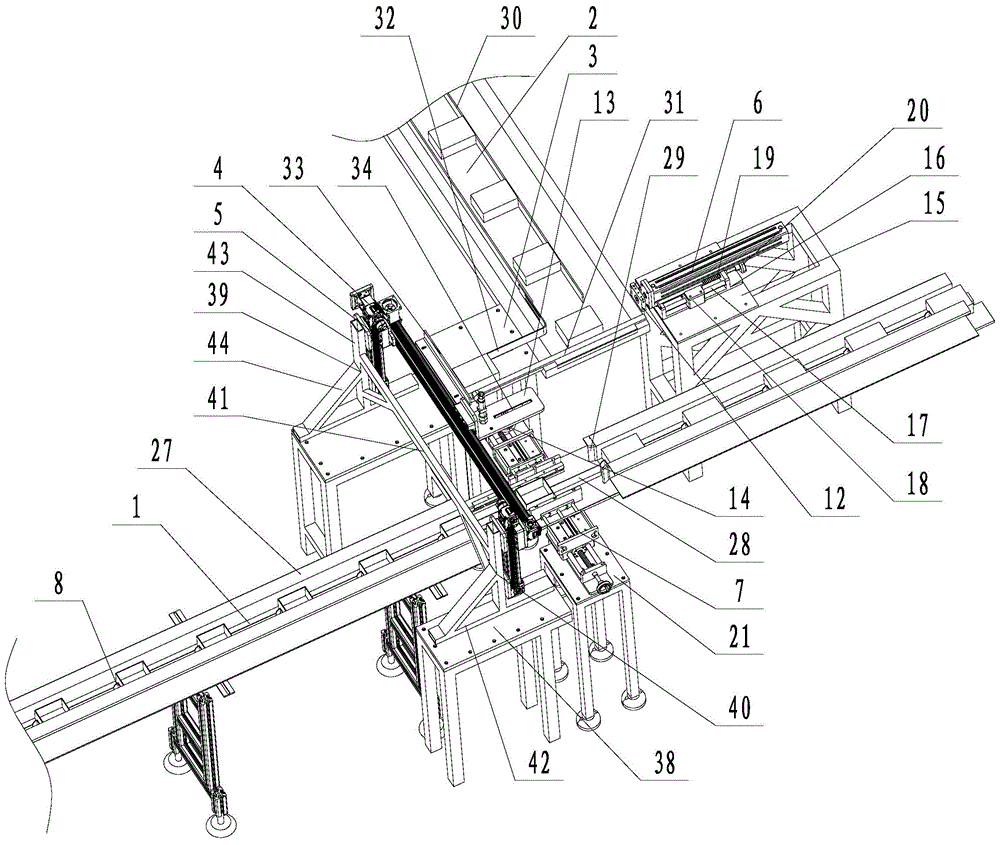

Universal full-automatic box covering mechanism

InactiveCN105347278ASimple structureOpen structureCapsClosure using capsEngineeringMechanical engineering

The invention discloses a universal full-automatic box covering mechanism in order to overcome the defects that during packaging and covering of boxes, the work efficiency is low, labor intensity is high, the covering positions are prone to being inaccurate, and a special box covering machine is complex in structure, high in equipment investment, inconvenient to maintain and poor in universality. The universal full-automatic box covering mechanism comprises a box conveying line, a box cover conveying line, a box cover buffering platform, a transverse linear module, vertical linear modules, a push piston cylinder and pre-tightening piston cylinders, wherein a plurality of shifting rods are arranged on the box cover conveying line; telescopic rods of the two pre-tightening piston cylinders are both connected with connecting plates; the inner sides of the two connecting plates are connected with movable plates in a lifting mode; the inner sides of the movable plates are connected with pre-tightening rods, and the rear ends of the pre-tightening rods are of an L-shaped structure; a telescopic rod of the push piston cylinder is connected with a push plate; the two ends of the transverse linear module are connected with the two vertical linear modules in a lifting mode, and the transverse linear module is connected with a moving plate in a sliding mode; the moving plate is connected with a sucker, and the connecting position of the sucker on the moving plate is adjustable.

Owner:BEILUN SCI & ART EXPERIMENT CENT INST OF AUTOMATION CHINESES ACADEMY OF SCI

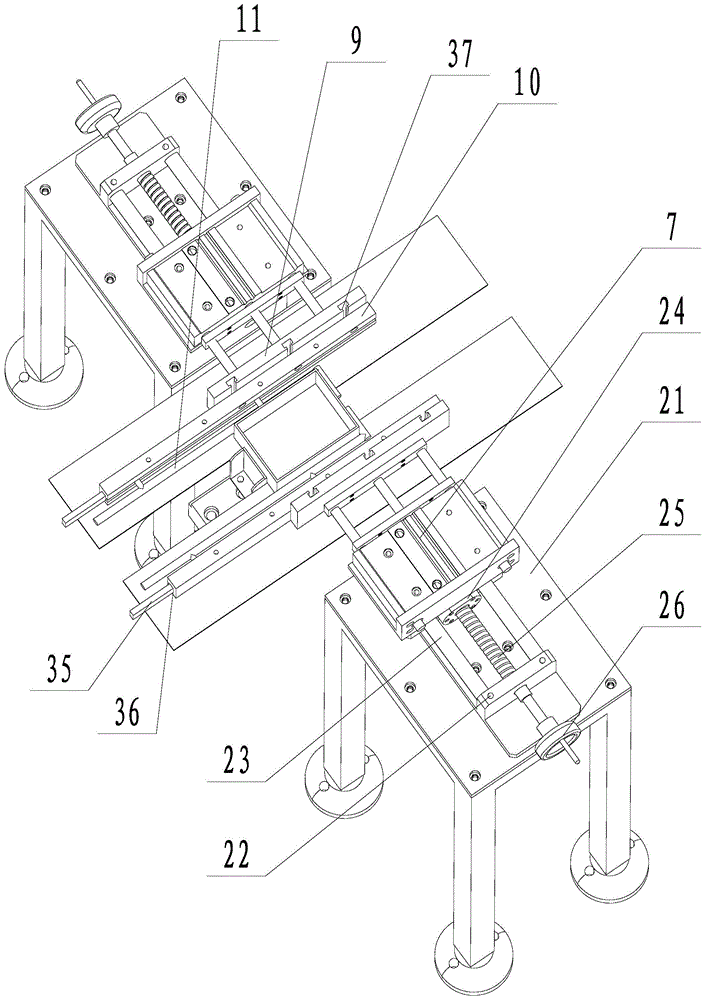

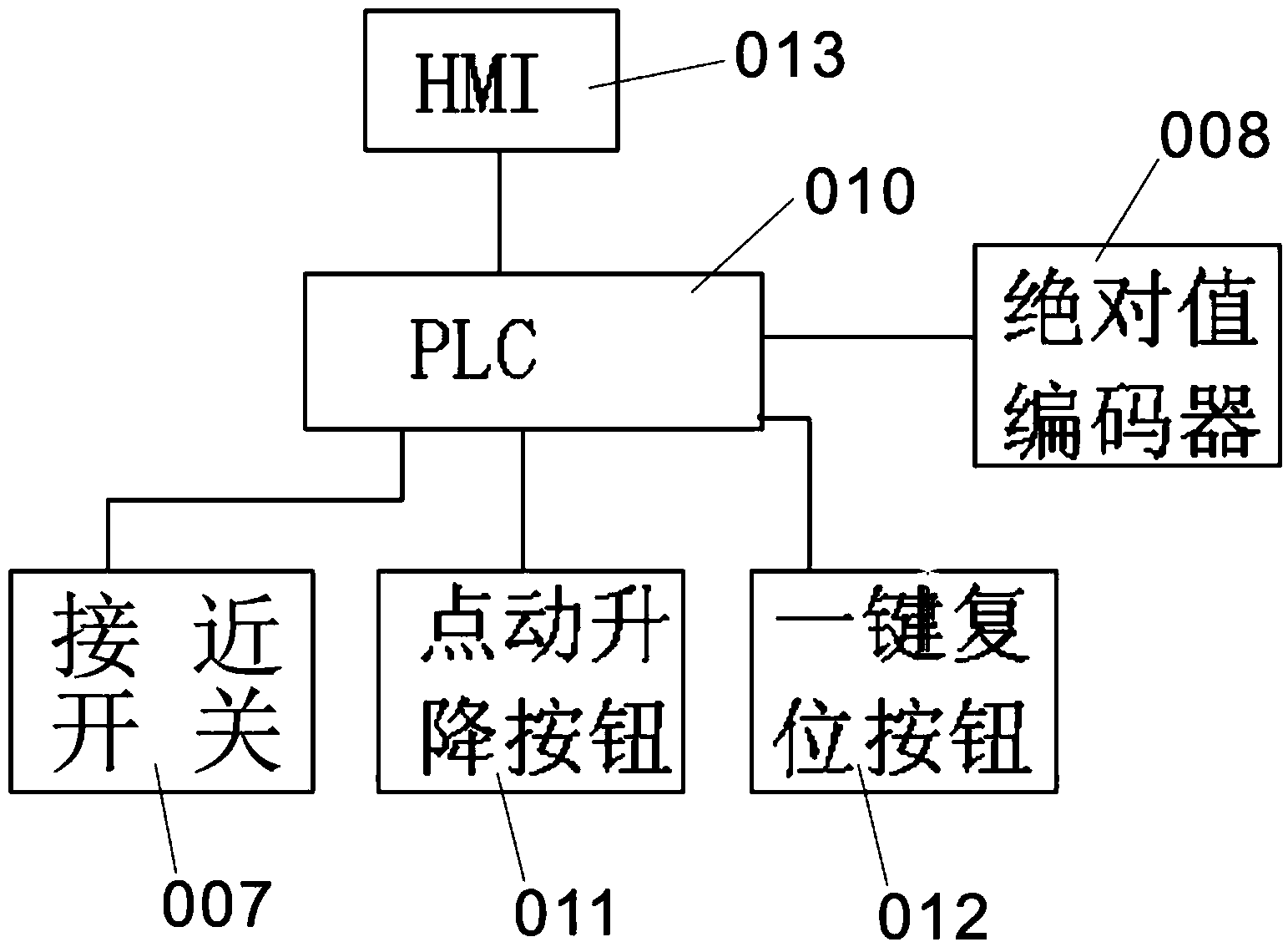

Ink fountain reset device for gravure printing machine and control method thereof

ActiveCN103707636AAccurate and reliable locationStable positionPrinting press partsSynchronous motorEngineering

The invention discloses an ink fountain reset device for a gravure printing machine. The ink fountain reset device comprises a gear installed on a machine frame; a rack meshed with the gear is installed at the gear and is vertically arranged; a worm wheel perpendicular to the rack is further installed on the machine frame and is meshed with the gear; one side of the machine frame is fixedly connected with a synchronous motor, and the rotor end of the synchronous motor is connected with a worm meshed with the worm wheel; a proximity switch and an absolute value encoder are installed on the other side of the machine frame; the absolute value encoder is connected with a PLC through a signal cable; the PLC is further connected with the proximity switch, an inching lifting button, a one-key reset button and an HMI through signal cables. According to the ink fountain reset device for the gravure printing machine, manpower can be greatly saved, the burden of an operator is relieved, meanwhile, order replacement time of workers can be greatly saved, and work efficiency is improved.

Owner:SHAANXI BEIREN PRINTING MACHINERY

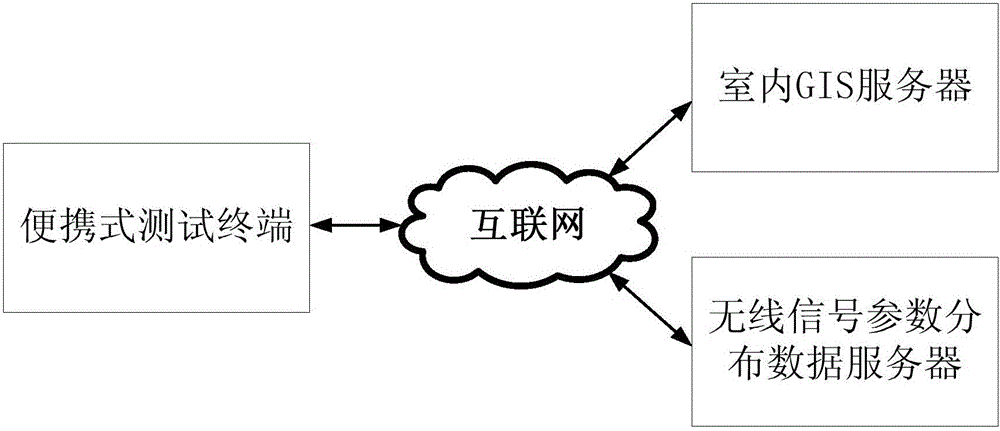

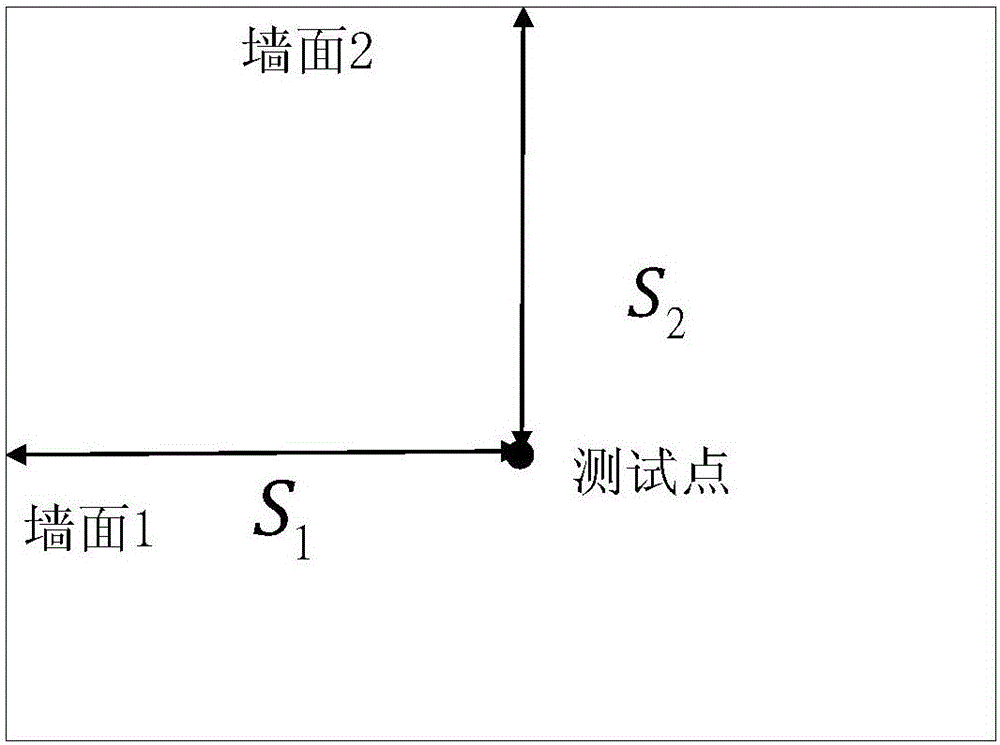

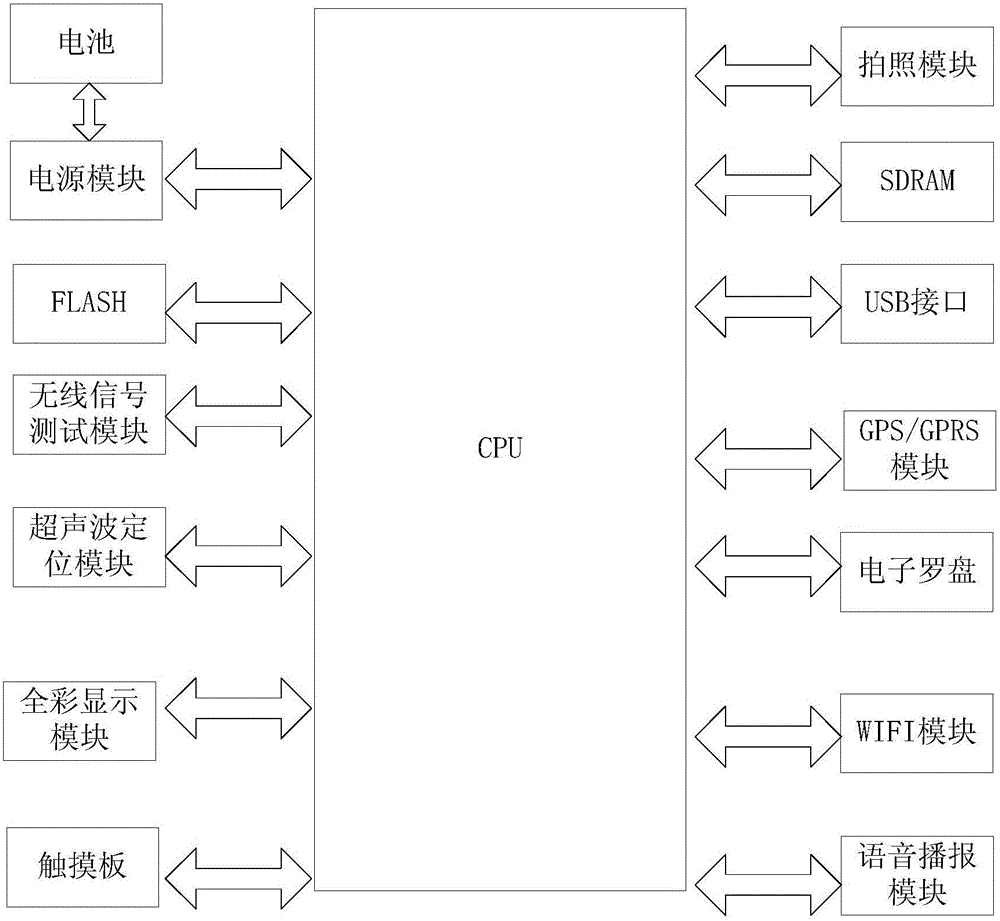

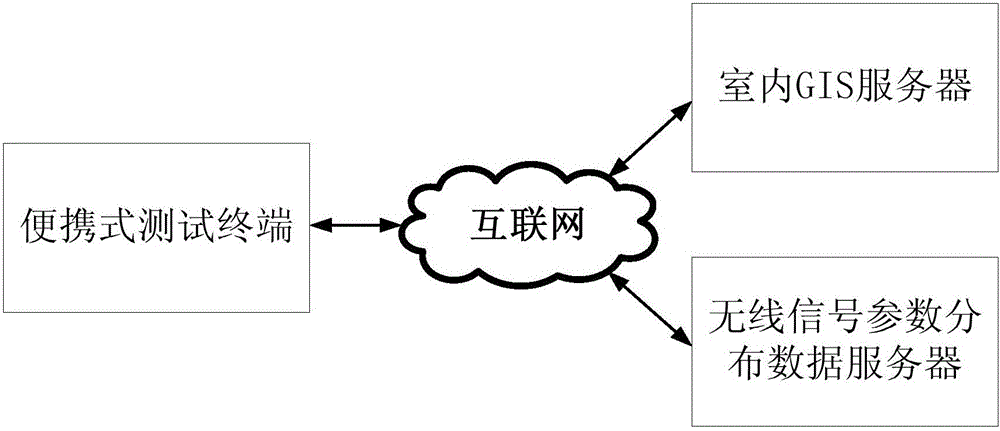

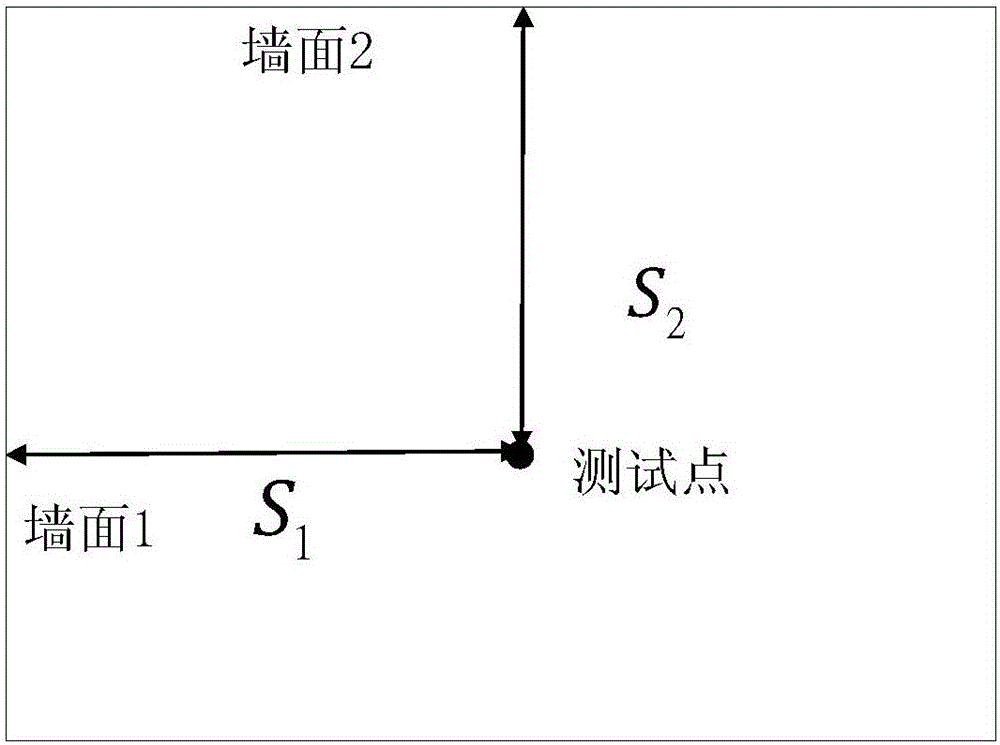

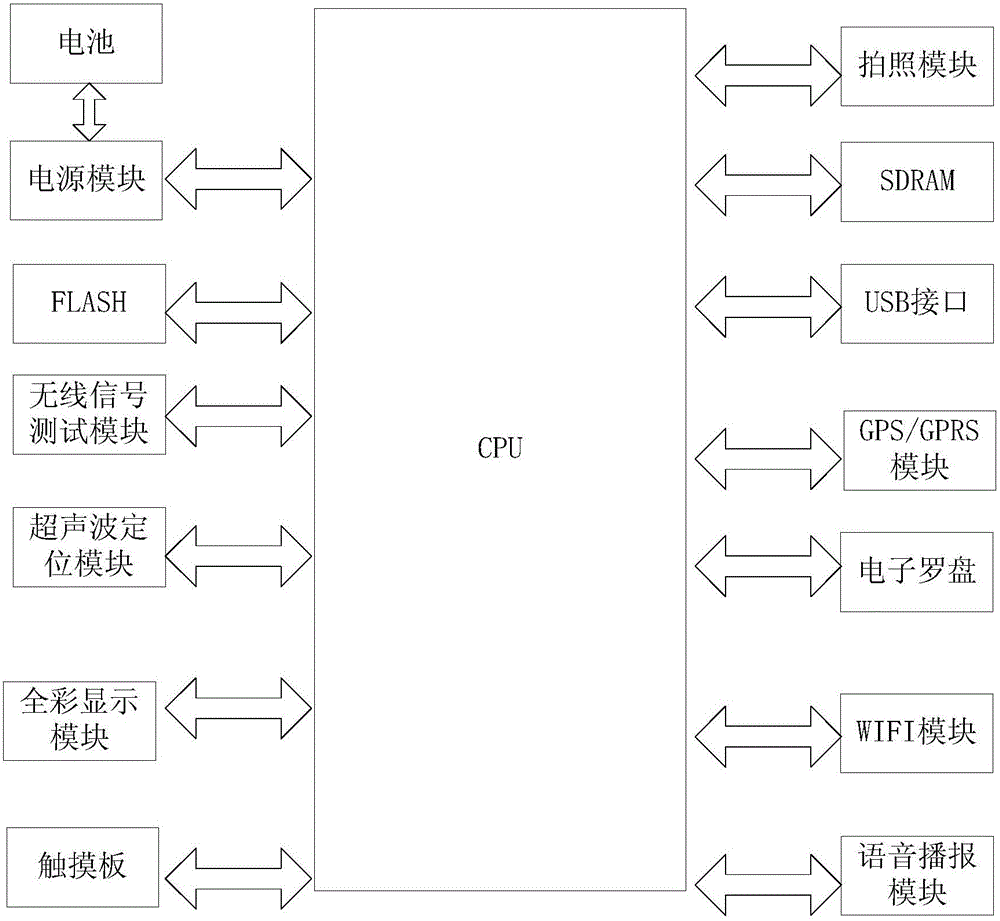

Method for testing LTE (Long Term Evolution) indoor wireless signal parameter distribution data

InactiveCN105072627AImprove portabilityStrong real-time dataWireless communicationVisibilityTest efficiency

The invention discloses a method for testing LTE (Long Term Evolution) indoor wireless signal parameter distribution data. The testing method comprises a testing system. The testing system comprises a portable testing terminal, an indoor GIS (Geographic Information System) server and a wireless signal parameter distribution data server, wherein the portable testing terminal is in wireless connection with the indoor GIS server and the wireless signal parameter distribution data server respectively via the Internet. Before start of testing, the portable testing terminal downloads the map information of the GIS server into a local memory. During testing, the portable testing terminal synchronously transmits measured indoor distribution parameters to the wireless signal parameter distribution data server in real time. The method is suitable for investigation testing of an indoor distributed system, and has the advantages of high portability, accurate and reliable testing data and position information, high data instantaneity, high parameter display visibility, high testing efficiency and the like.

Owner:GUANGDONG SOUTHERN PLANNING & DESIGNING INST OF TELECOM CONSULTATION CO LTD

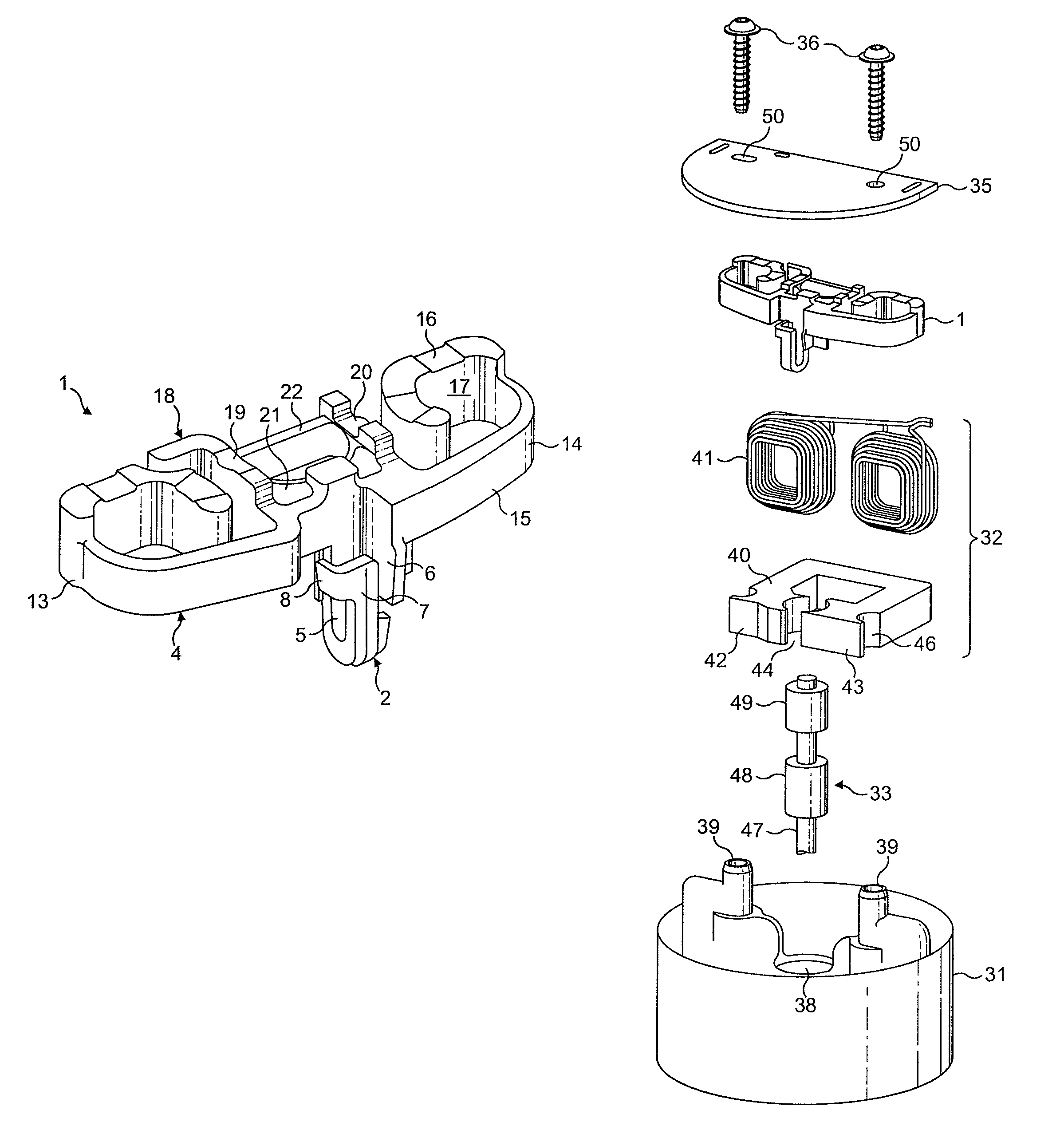

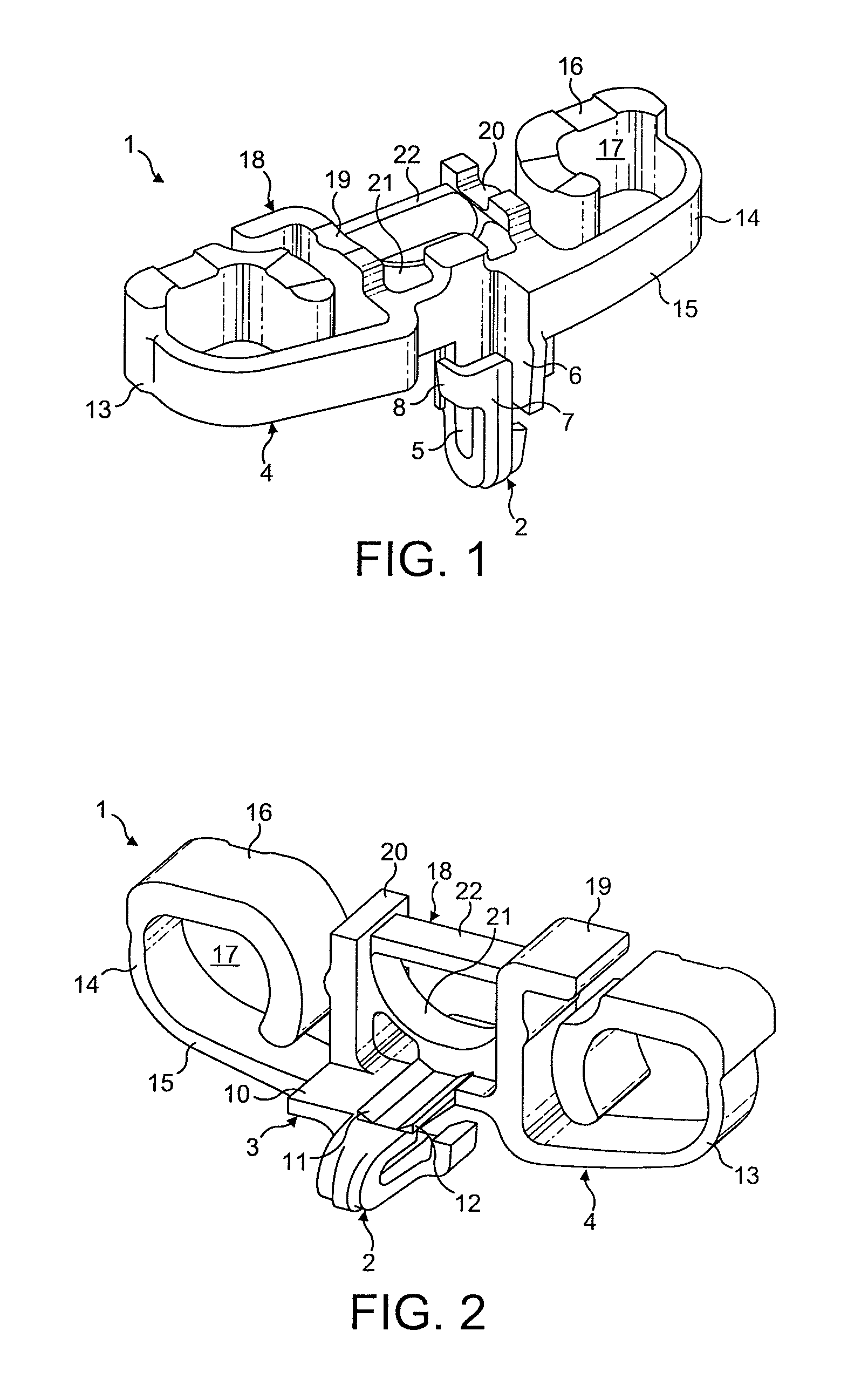

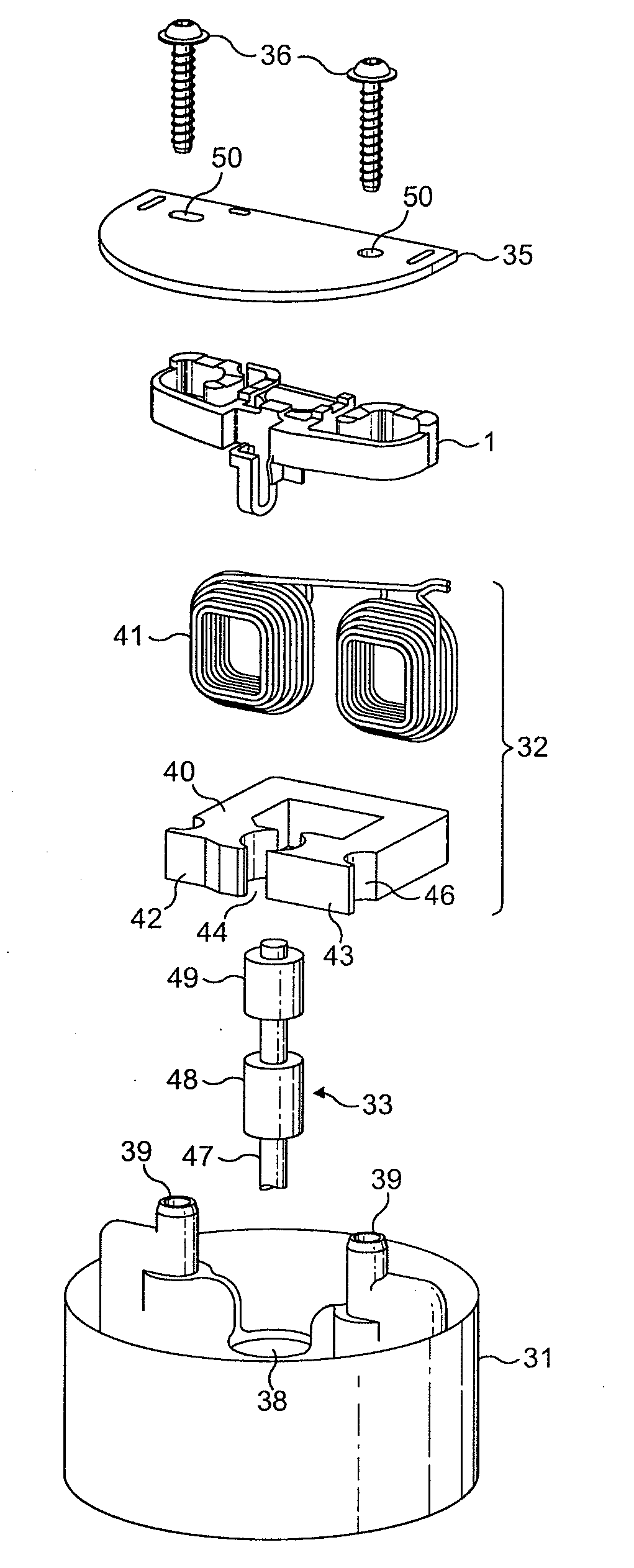

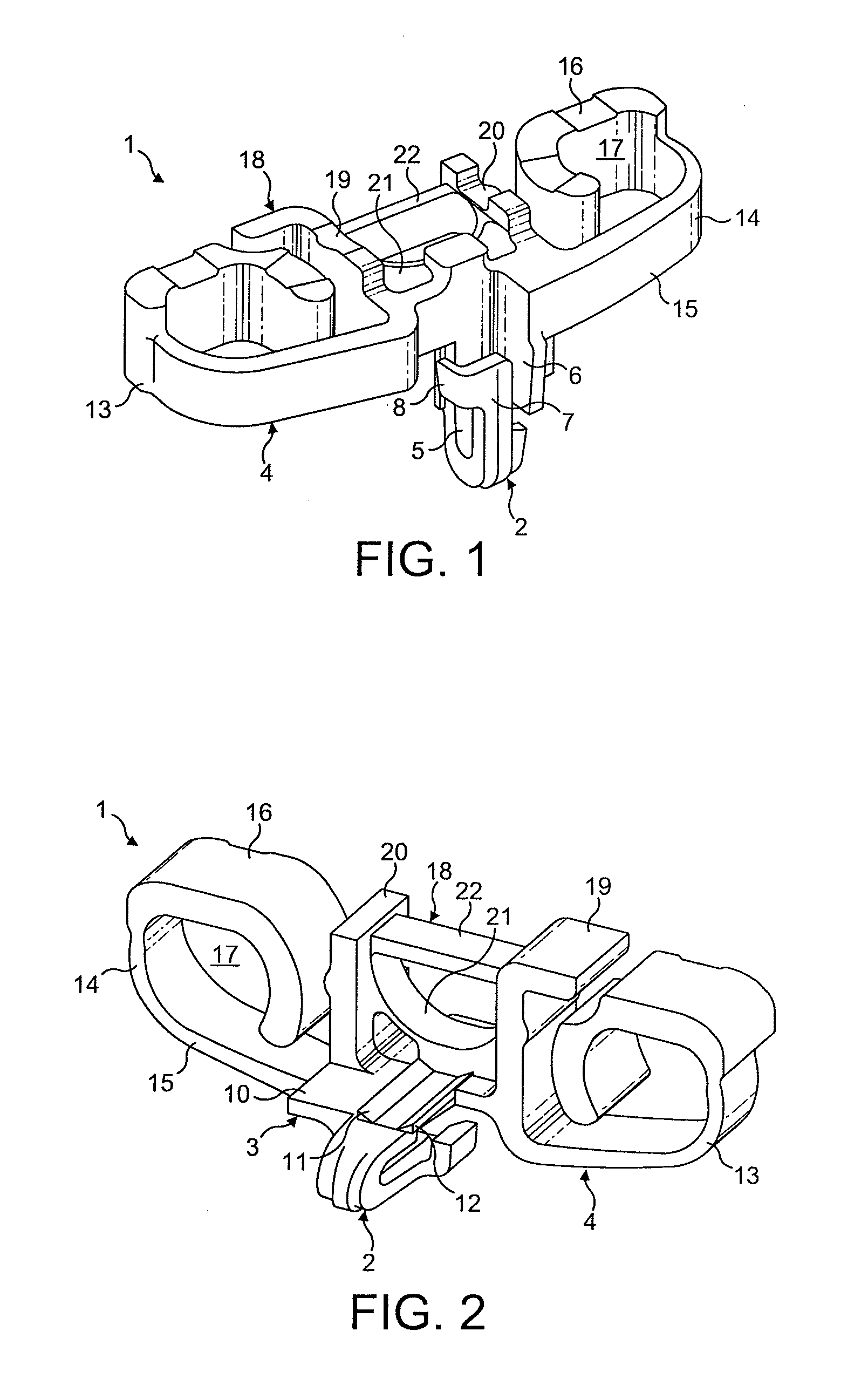

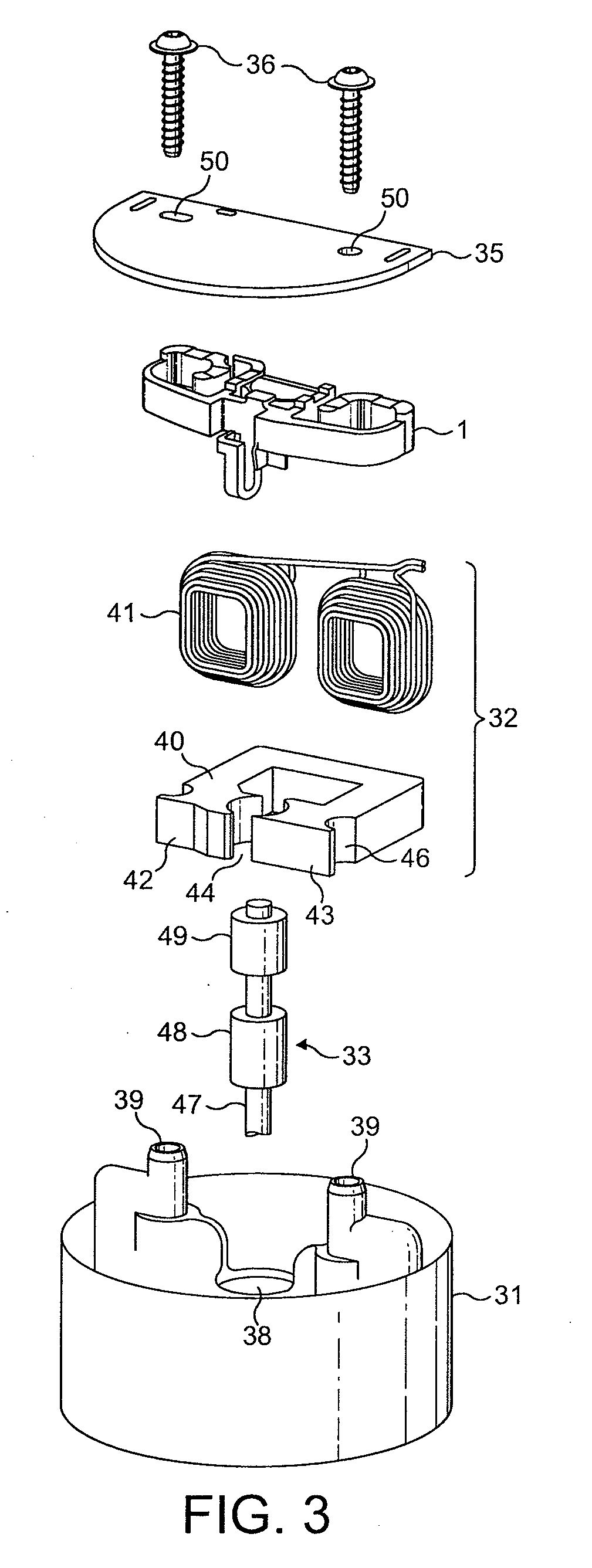

Holder for a position sensor

InactiveUS8350425B2Accurate and reliable positioningImprove positionSynchronous machinesDC commutatorElectric machineAbutment

Owner:DYSON TECH LTD

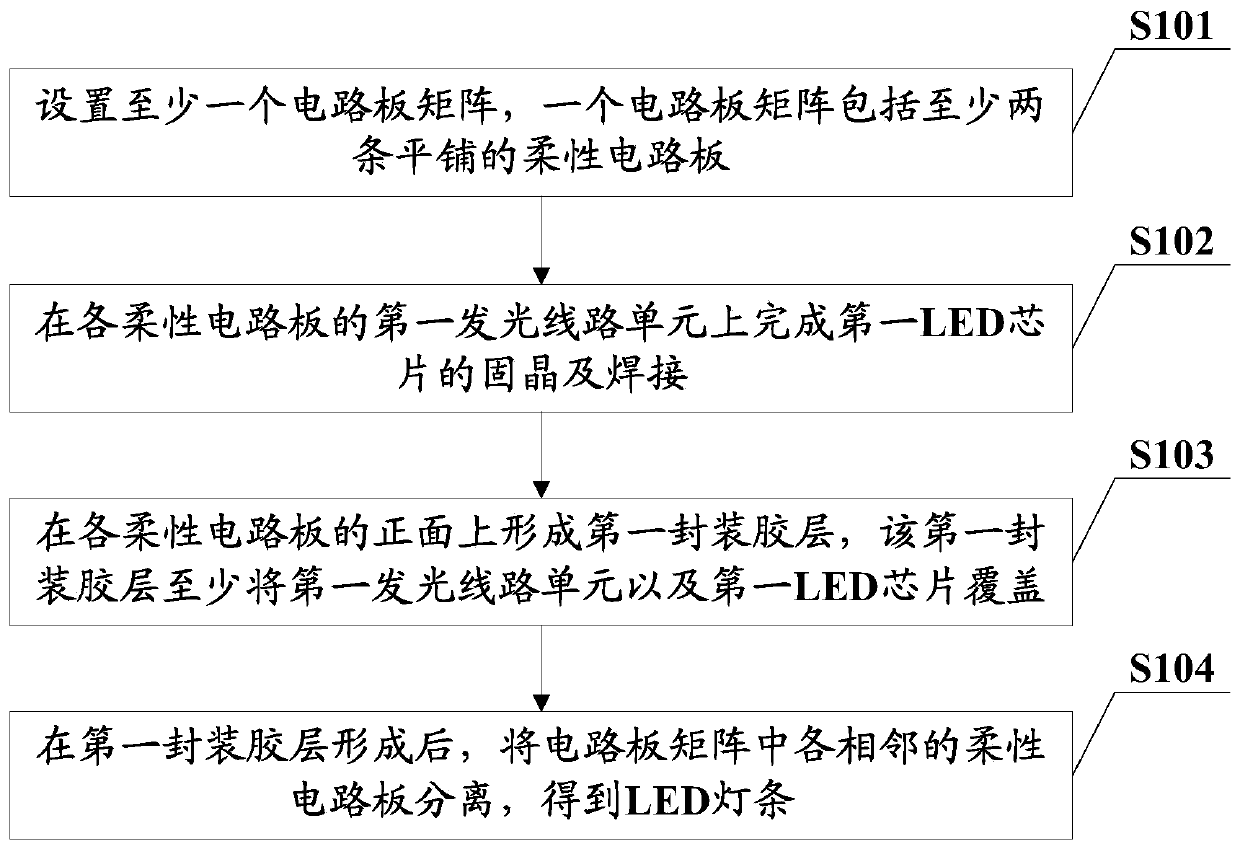

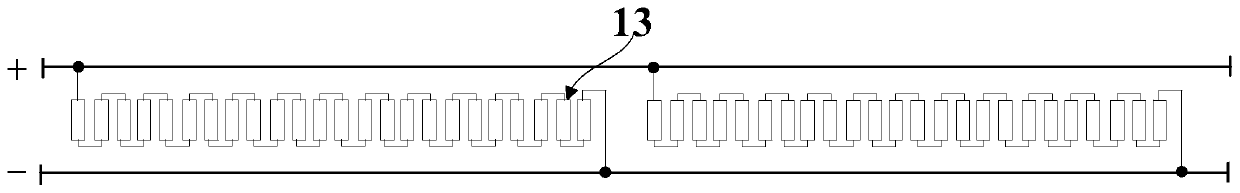

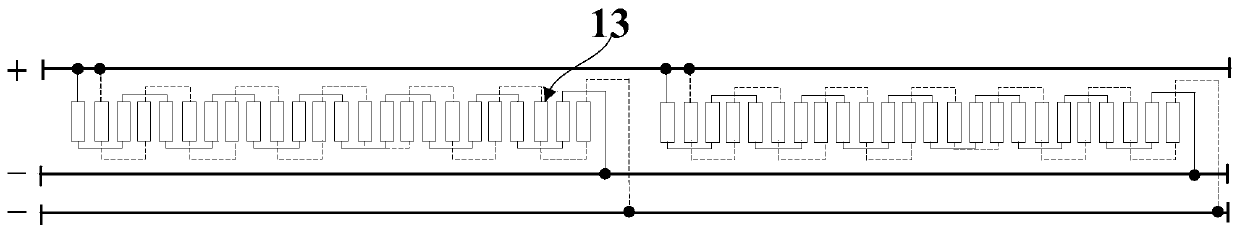

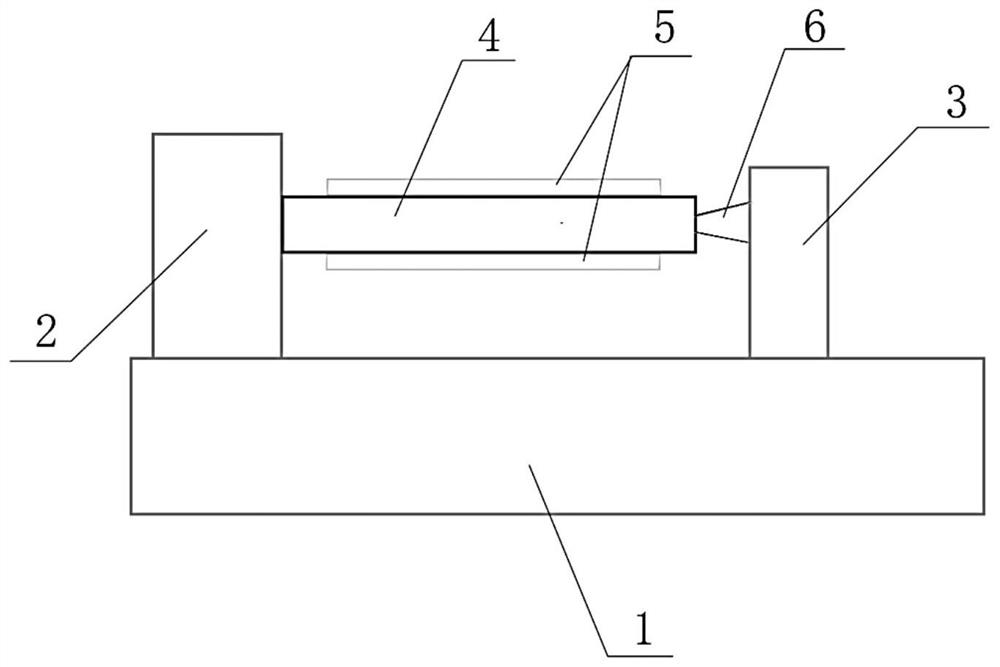

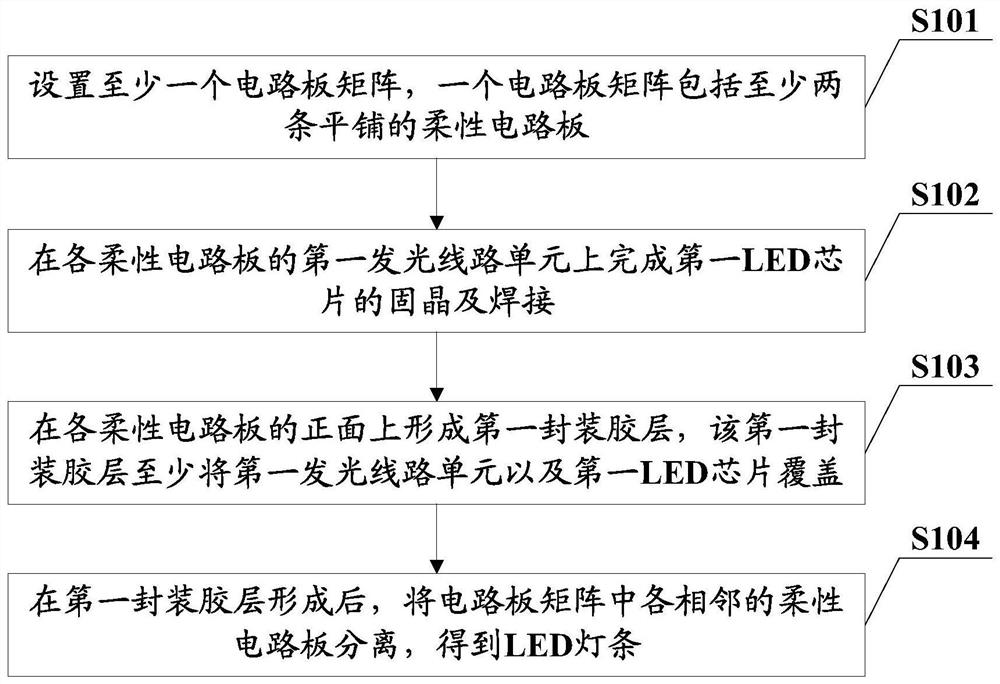

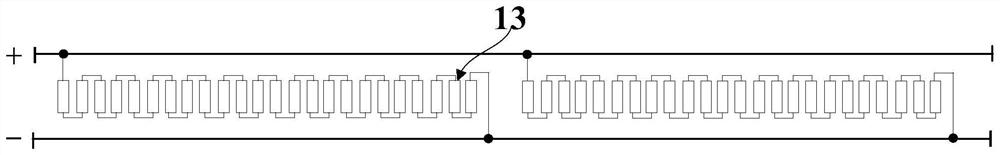

LED light bar and manufacturing method thereof

ActiveCN111288312AImprove production efficiencyLow costElectric circuit arrangementsLight fasteningsManufacturing efficiencyEngineering

The invention discloses an LED light bar and a manufacturing method thereof. The objective of the invention is to solve problems that an existing LED light bar is thick, cost is high, and the shear marks are prone to position deviation and falling off; according to the LED light bar manufactured through the LED light bar manufacturing method, mark holes or mark notches are directly formed in the flexible circuit board to mark the shearing position, and compared with the mode that shearing marks are printed on the surface of a light bar packaging adhesive layer, the situation of falling cannotoccur, and reliability is higher; the marking holes are directly formed between the adjacent line shearing units on the flexible circuit board, so that the arrangement position is more accurate and reliable, and the situation that the sheared LED light bar cannot work normally is avoided; meanwhile, according to the LED light bar, the first LED chip can be directly arranged on the flexible circuitboard to be packaged; compared with an existing LED light bar, the manufacturing process of an LED support and LED light beads can be omitted, the manufacturing efficiency is higher, the cost is lower, the obtained LED light bar is a COB light bar, the thickness is smaller, and the requirements of various application scenes can be better met.

Owner:重庆慧库科技有限公司

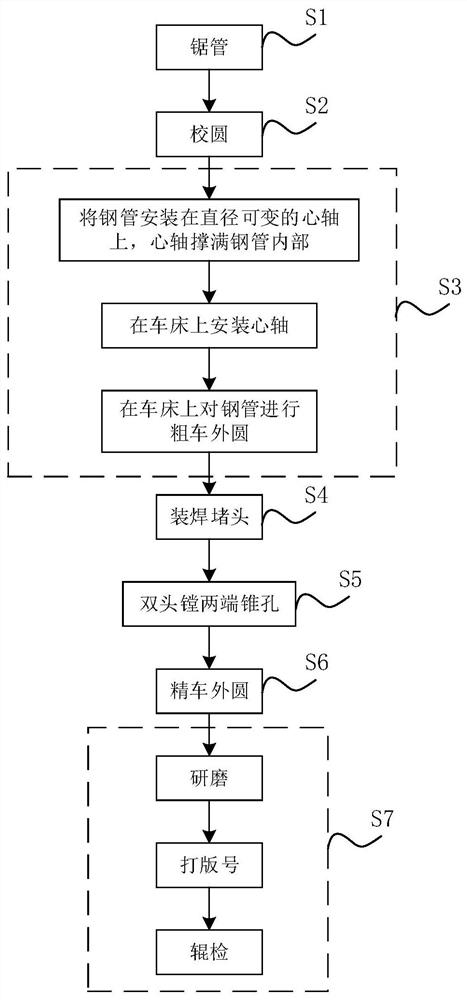

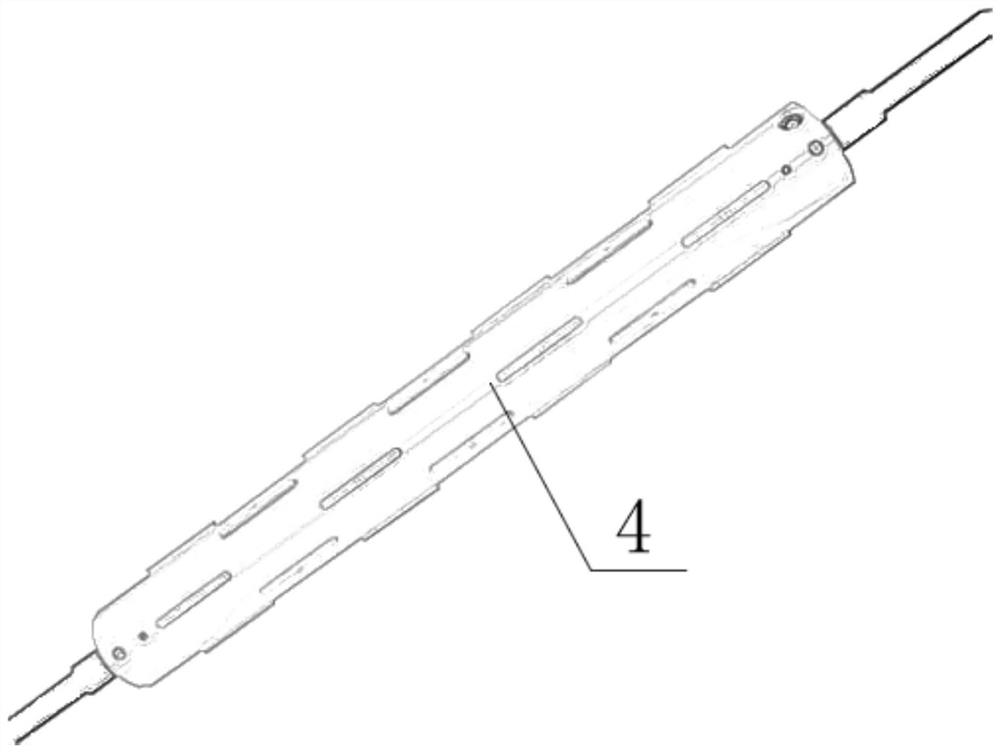

Machining device and method of high-precision intaglio roller

PendingCN111644821AAccurate result of rough turning outer circleThe outer circle of the pipe wall is flatSteel tubeEngineering

The invention relates to a machining device of a high-precision intaglio roller. The machining device is used for roughly turning the external circle of a steel pipe to be machined, the steel pipe tobe machined is used for manufacturing the intaglio roller, the machining device of the high-precision intaglio roller comprises a lathe and mandrel, the mandrel is detachably connected with the lathe,the lathe is used for supporting the mandrel and driving the mandrel to rotate, and the mandrel is matched with the steel pipe to be machined and used for supporting the inside of the steel pipe to be machined. When the external circle rough turning process is carried out, the steel pipe to be machined is mounted on the mandrel, the mandrel tightly supports the inside of the steel pipe to be machined, the lathe is started, the mandrel is driven to rotate, and external circle rough turning is carried out. Compared with the prior art, the result of roughly turning the external circle is more accurate, the steel pipe with the smooth external circle of the pipe wall and more uniform thickness of the pipe wall can be obtained, complicated dynamic balance detection, counterweight and re-detection procedures in the machining process of the high-precision intaglio roller can be omitted, the production cost is reduced, and the production time is shortened.

Owner:上海运申制版模具有限公司

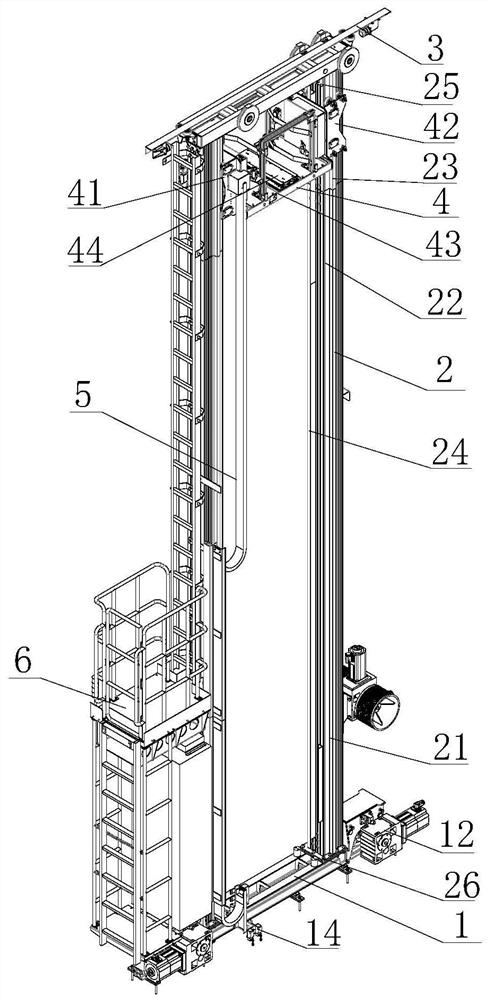

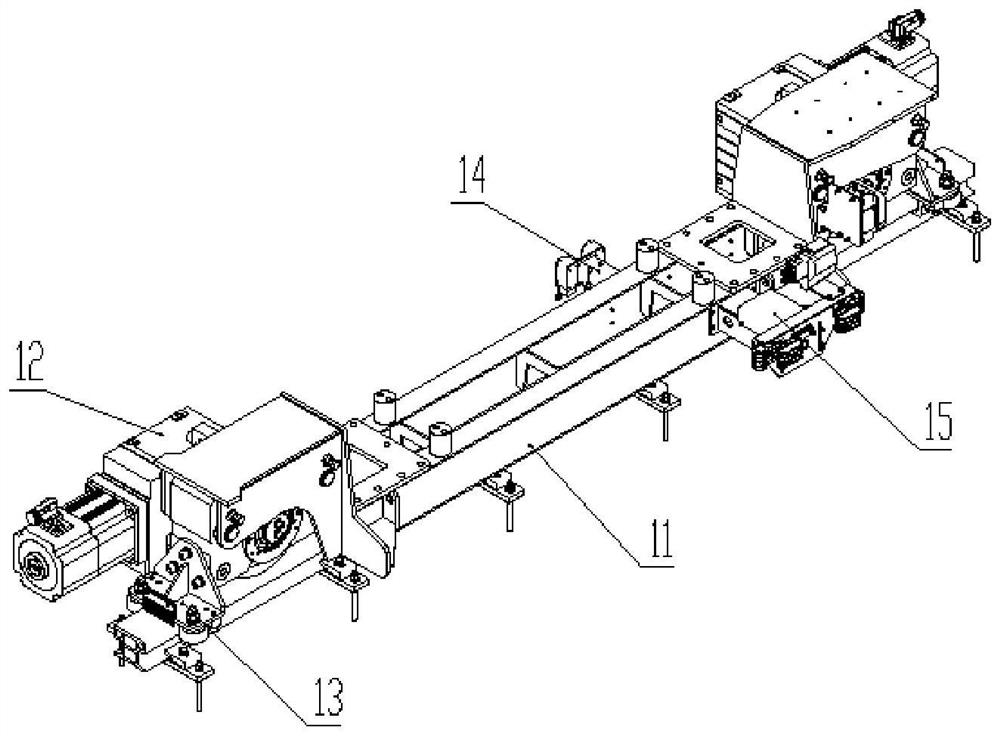

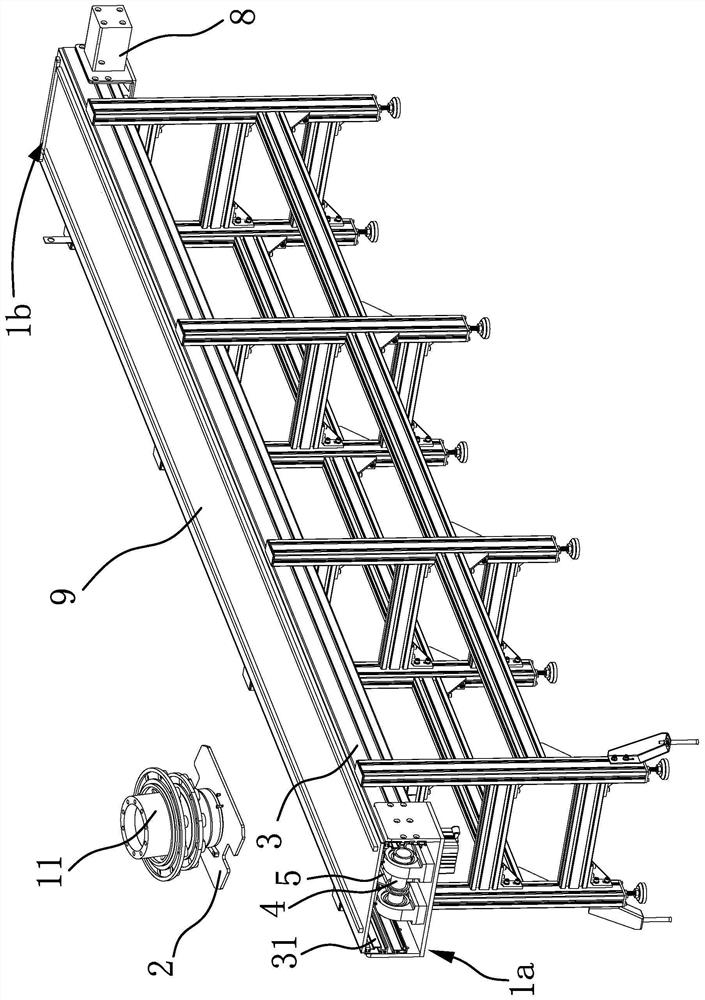

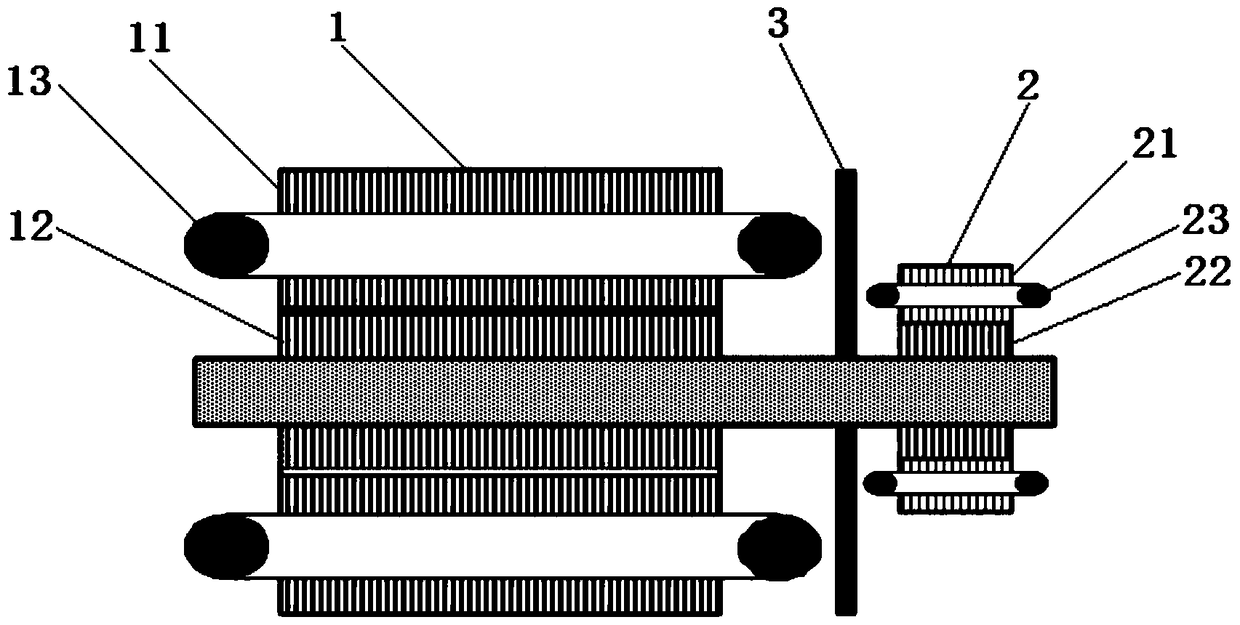

High-speed dual-drive stacking machine

PendingCN114852925AGuaranteed uptimeIncrease heightSafety devices for lifting equipmentsElectric machineryMachine

The invention belongs to the technical field of automatic three-dimensional storage, and particularly relates to a high-speed dual-drive stacking machine. Comprising a main body frame, a cargo carrying table and a dual-drive walking mechanism, and the cargo carrying table is arranged on the main body frame and can ascend and descend; the dual-drive walking mechanism is arranged at the bottom of the main body frame and can drive the main body frame to walk on the ground rail. The main body frame comprises a lower cross beam, stand columns and an upper cross beam, the lower cross beam and the upper cross beam are connected through the two stand columns, and the cargo carrying table is arranged between the two stand columns; and the dual-drive walking mechanism is arranged on the lower cross beam. The dual-drive walking mechanism comprises two motor driving devices; the two motor driving devices are arranged at the two ends of the lower cross beam respectively. The stacking machine is driven by the double motors, and the stacking machine has the advantages of being stable in operation, capable of providing increased acceleration and capable of rapidly increasing the operation speed in a short time.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Holder for a position sensor

InactiveUS20100225208A1Precise alignmentPrecise positioningSynchronous machinesDC commutatorElectric machineAbutment

A holder for a position sensor of an electric machine. The holder includes a pocket for holding the position sensor, an abutment, and a biasing mechanism mountable to a fixture of the electric machine so as to bias the abutment relative to the fixture. Additionally, an electric machine that incorporates the holder, the electric machine including a stator against which the biasing mechanism biases the abutment.

Owner:DYSON TECH LTD

Crankcase plug riveting device

InactiveCN105598300BEnsure plug riveting assembly qualityEliminate damageMetal-working feeding devicesPositioning devicesCrankcaseEngineering

Owner:JIANGSU LINHAI YAMAHA MOTOR CO LTD

A method for identification of main transition planes between delta construction and destruction

The invention provides a method for identifying a main transform plane of delta construction and destruction. Identification is carried out from perspectives of lithology, sand body types, sedimentary tectonics, paleontology, and geophysics and a precise position of a key transform plane of delta construction and destruction is determined. The method is characterized in that a main transform plane of delta construction and destruction is put forward firstly; and the sedimentary period of the delta is divided into a delta construction period and a delta destruction period based on the delta sedimentary effect for the first time. On the basis of the core, welllogging, logging, and seismic data, precision improvement is realized step by step; the position of the main transform plane of delta construction and destruction is determined comprehensively; and the data reliability and precision are high.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Spacers, Ribbed Floors Using Spacers and Construction Formwork Systems

ActiveCN104989037BEasy to assemble and disassembleWith limit functionFloorsForms/shuttering/falseworksJoistRebar

The invention discloses a positioning piece, which includes a fixed steel bar part, a limit part and a self-positioning structure, the fixed steel bar part is a buckle, a collar, a tie hole or a wire, and the limit part is a leg or a side bar or a bar or a bar The self-fixing structure of the block is a down-through screw hole or a clamping hole provided on the bottom surface of the retaining leg or the foot or the base. The positioning piece makes the size of the rib beam and the position of the steel bar accurate and reliable; the invention discloses a densely ribbed floor, including a rib beam, an upper panel, and a permanent formwork or a filling block, and the side wall of the permanent formwork or filling block is a side formwork or a rib beam / and the superimposed surface, the lower part of the rib beam also contains a positioning piece. The dense rib floor is convenient for construction and low in cost. The invention discloses a construction formwork system, which includes a joist and a permanent formwork or a filling block, and also includes a positioning piece, a plurality of positioning pieces are arranged at intervals, fixed on the top surface of the joist by a fastener that can be detached from the bottom, and the permanent formwork or filling block The interval forms the rib beam cavity. The construction formwork system is simple and reliable, with less aerial work.

Owner:张玉华

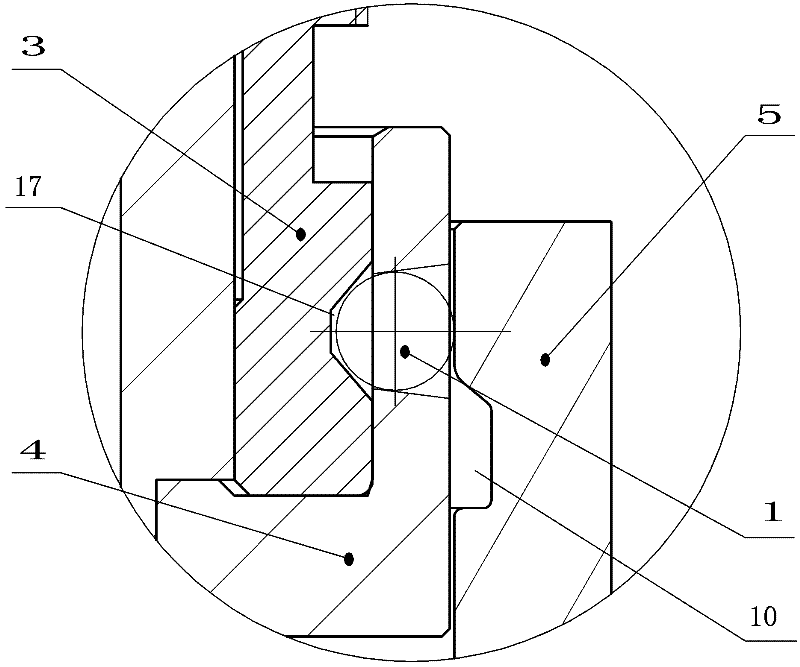

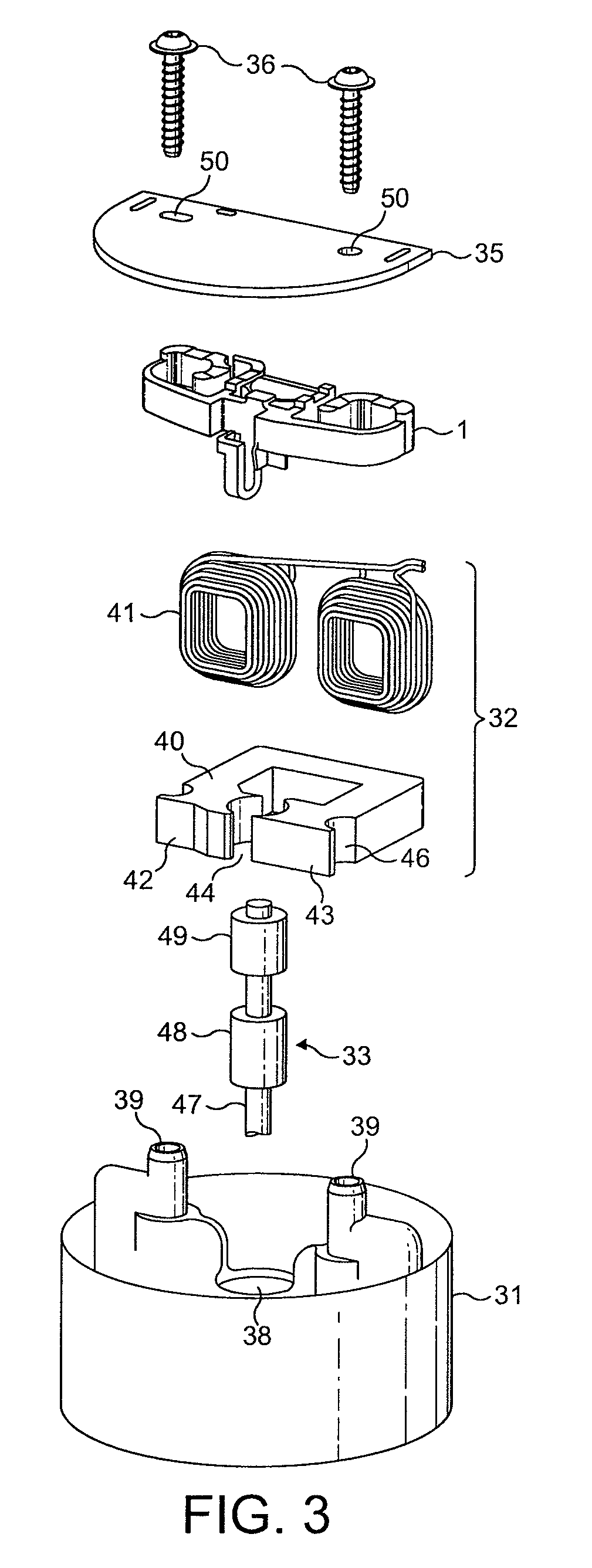

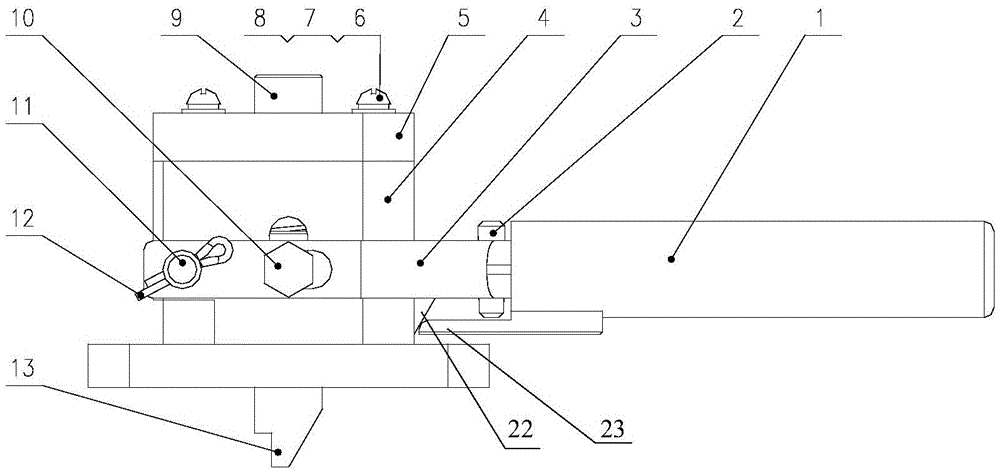

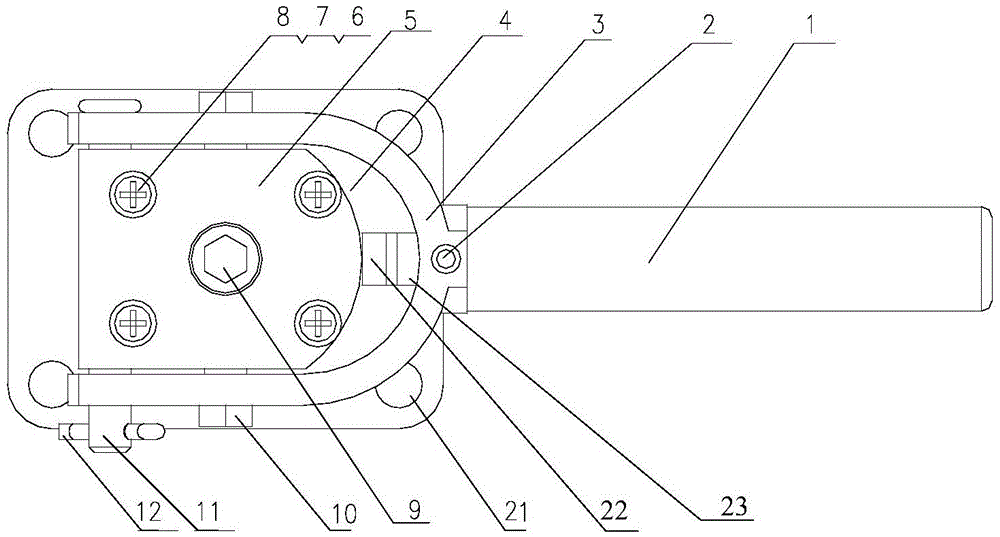

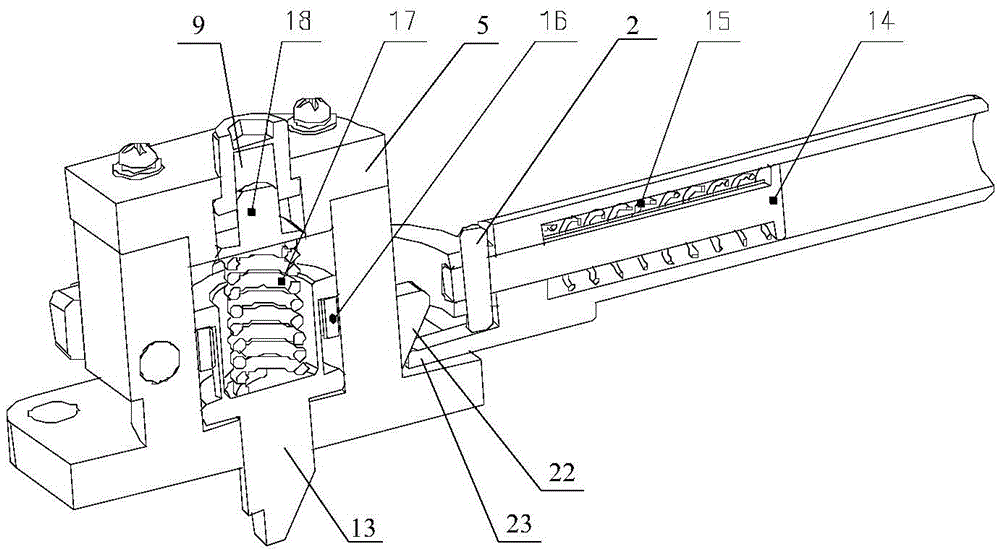

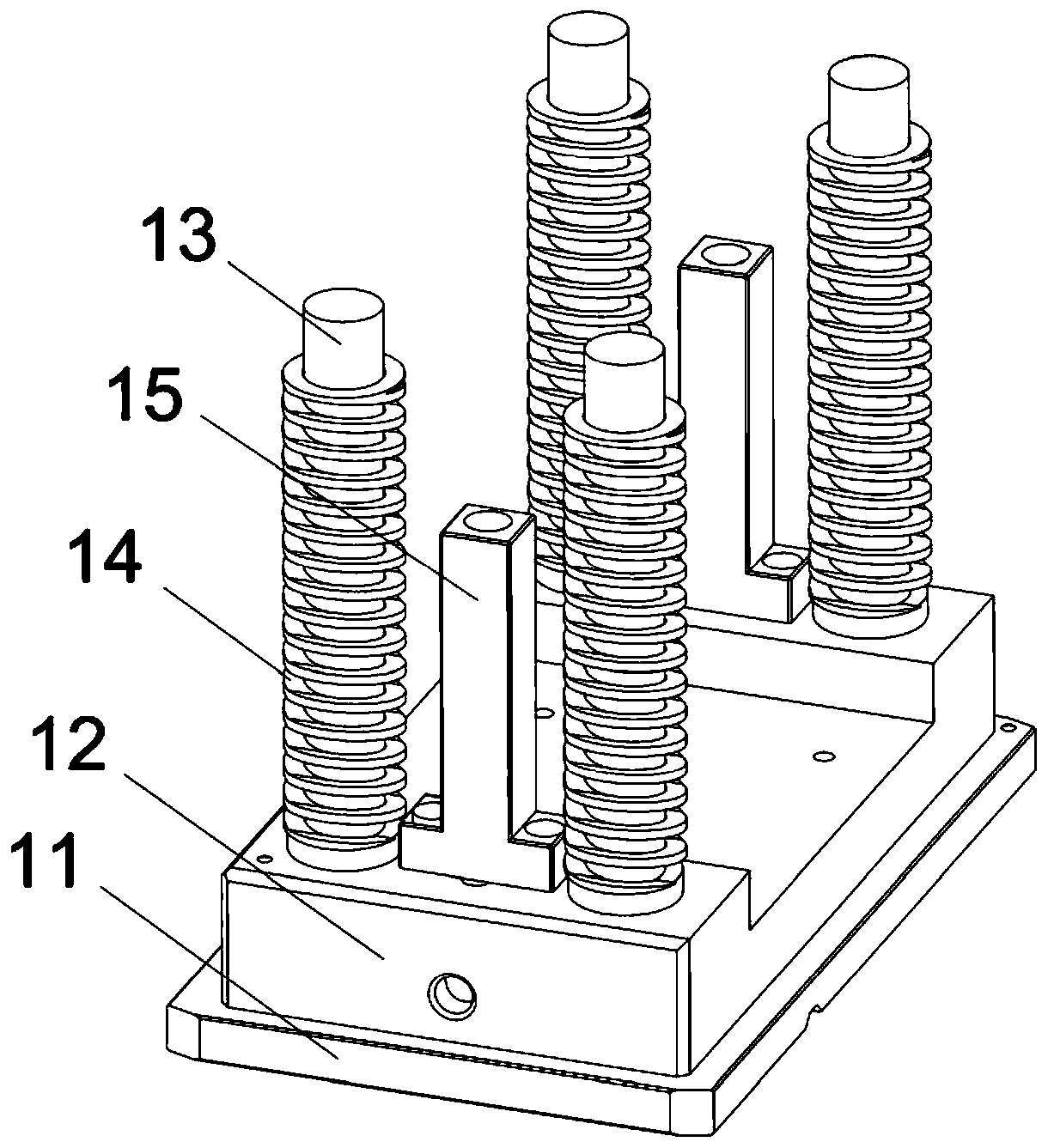

Spring-type locking mechanism provided with stopping power adjustment function

The invention belongs to a mechanical structure, and particularly relates to a locking mechanism which is used for preventing a rocket projectile from falling off. The technical scheme of the spring-type locking mechanism provided with the stopping power adjustment function is characterized in that the spring-type locking mechanism comprises a handle (1), a conical pin (2), a lever fork (3), a base body (4), a cover (5), screws (6), spring washers (7), flat washers (8), an adjustment rod (9), a guiding pin (10), a pin shaft (11), an opening pin (12), a stopping body (13), a guiding shaft (14), a spring I (15), a support semi-ring (16), a spring II (17) and a screw rod (18). According to the spring-type locking mechanism, the position of the rocket projectile is fixed accurately and reliably; the stopping power is adjustable; the stopping power function is provided when the rocket projectile is repeatedly assembled and disassembled, or when the rocket projectile is launched. The spring-type locking mechanism has the advantages that the use and operation are convenient, safe and reliable and the like.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

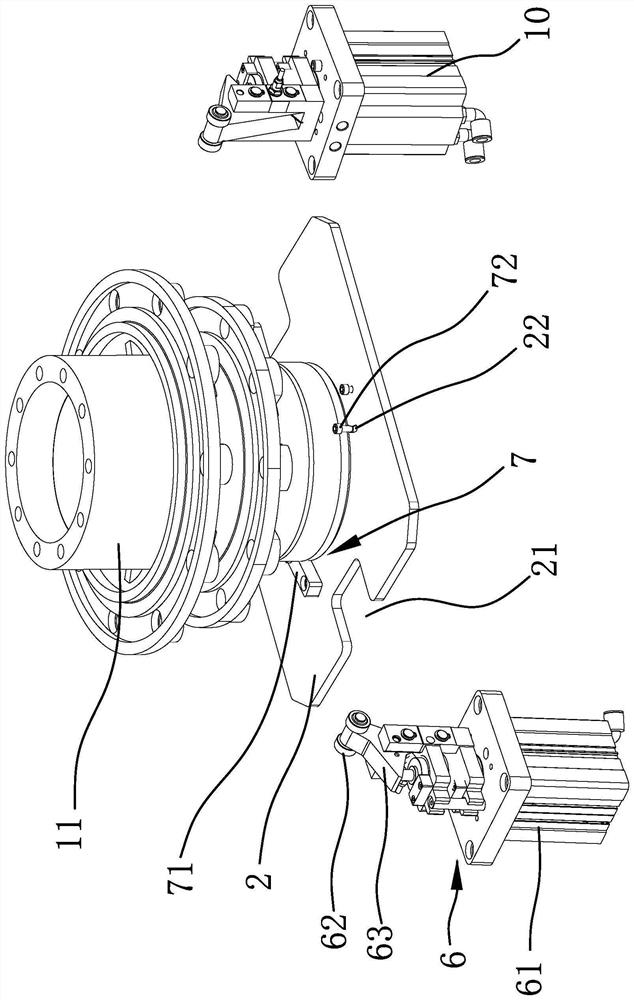

A conveying device for the production and manufacture of automobile wheel hubs

ActiveCN109205282BAvoid collisionAvoid frictional damageConveyorsConveyor partsDrive shaftEngineering

The invention provides a conveying device used in the manufacture of automobile wheel hubs, which belongs to the technical field of conveying devices. It solves the technical problems such as the insufficient stability of the automatic conveying of the existing automobile wheel hub. The conveying device includes a strip-shaped frame and a tray. Guide plates are provided on both sides of the top of the frame. The two guide plates are arranged in parallel and spaced apart, and the inner side of the guide plate has guide rails along the length direction of the frame. The two sides of the tray are slidingly embedded. In the guide rails of the two guide plates, one end of the frame is provided with a drive shaft, the other end of the frame is provided with a driven shaft, and a transmission part is set between the drive shaft and the driven shaft, and a drive tray is fixedly connected to the transmission part The pusher moves along the guide rail; the tray is provided with a placement plane for placing the hub and a positioning piece for fixing the hub. The conveying device designed in the present invention avoids collision or frictional damage on the surface of the hub; moreover, the hub does not shift or shake, and the position is accurate and reliable.

Owner:ZHEJIANG YUELING

LED light bar and method of making the same

ActiveCN111288312BAvoid malfunctioningNo sheddingElectric circuit arrangementsElectric lightingFlexible circuitsLED lamp

The invention discloses an LED light bar and a manufacturing method thereof. Aiming at the problems that the existing LED light bar has a thick thickness, high cost, positional deviation and easy falling off of shear marks, the manufacturing method of the LED light bar provided by the present invention makes The flexible circuit board of the obtained LED light strip is directly provided with marked holes or marked gaps to mark the cutting position. Compared with printing cutting marks on the surface of the light strip packaging adhesive layer, there will be no falling off, and the reliability is better; Mark holes are set between adjacent circuit cutting units on the flexible circuit board, and the setting position is more accurate and reliable, so as to avoid the cut LED light bar from not working normally; at the same time, the LED light bar can directly set the first LED chip Encapsulation on a flexible circuit board can omit the production process of LED brackets and LED lamp beads compared to the current LED light strips. The production efficiency is higher and the cost is lower. The obtained LED light strips are COB light strips, which are thinner and can be Better meet the needs of various application scenarios.

Owner:重庆慧库科技有限公司

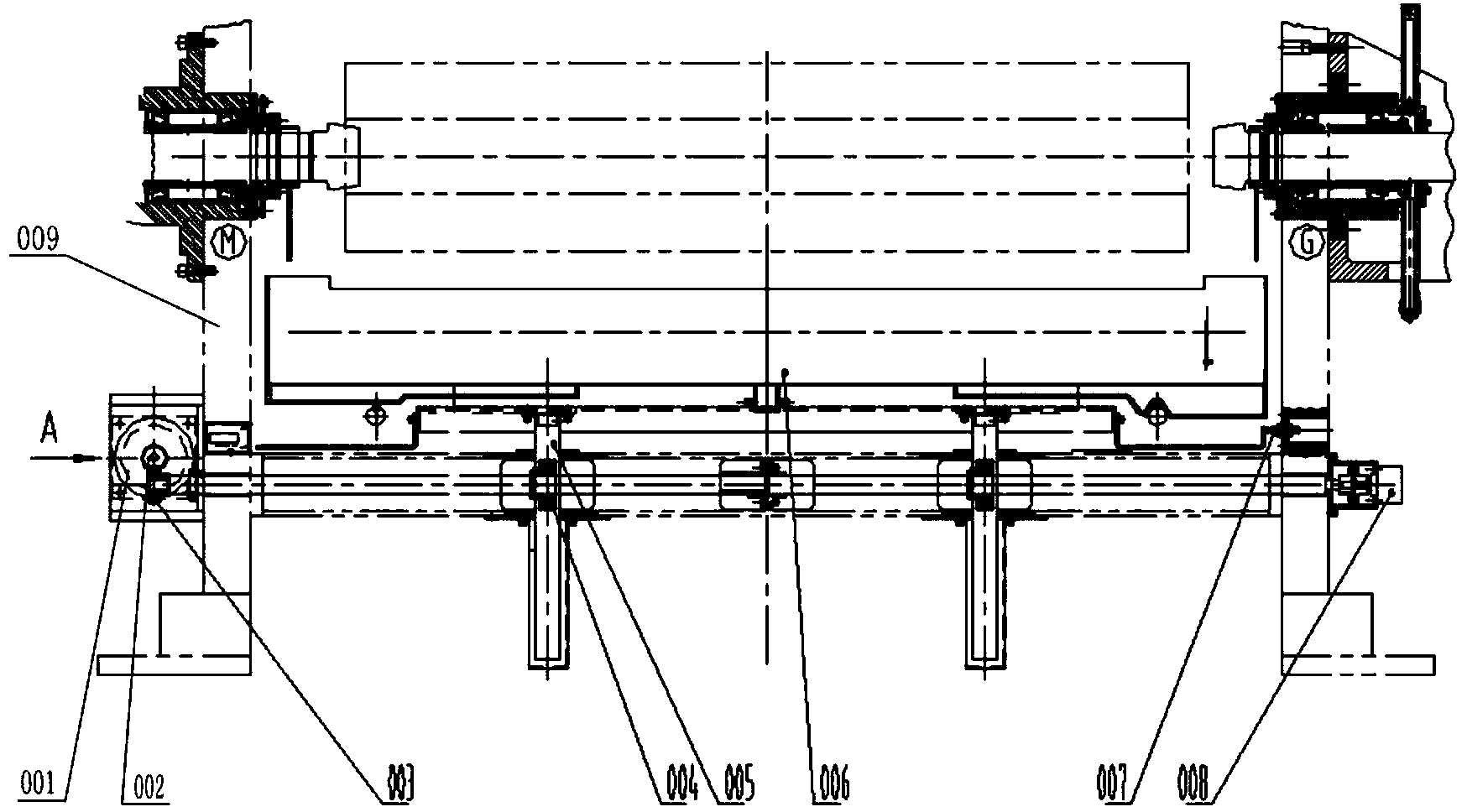

Position sensor of free piston engine

InactiveCN103217180ANo motion interferenceAccurate and reliable locationFree piston enginesConverting sensor output electrically/magneticallyFree-piston engineReciprocating motion

The invention discloses a position sensor of a free piston engine. The position sensor of the free piston engine comprises the free piston engine composed of a hydraulic pump body assembly, a first cylinder and a second cylinder, wherein the first cylinder is connected with one side of the hydraulic pump body assembly, the second cylinder is connected with the other side of the hydraulic pump body assembly, an inner piston assembly is arranged in the first cylinder, an outer piston assembly is arranged in the second cylinder, and an internal position sensor body and a second internal position sensor body are arranged on the hydraulic pump body assembly. The position sensor of the free piston engine has the advantages that accurate and reliable position and speed information of the piston assemblies are provided by the position sensor bodies, the information can be obtained in the whole travel distance of each piston, interference of the motion of the piston assemblies is avoided, and the position sensor body of the inner piston assembly can be used for preventing the piston assemblies from rotating when the piston assemblies make reciprocating motion in the cylinders.

Owner:ANHUI ZHONGDING POWER

LTE indoor wireless signal parameter distribution data test system

PendingCN105120488AImprove portabilityStrong real-time dataNetwork planningTest efficiencyDistribution system

The invention discloses a LTE indoor wireless signal parameter distribution data test system. The system comprises a portable test terminal, an indoor GIS server storing a target exploration building indoor GIS map and a wireless signal parameter distribution data server used for storing wireless signal parameter information of a target exploration building indoor test point. The portable test terminal is wirelessly connected to the indoor GIS server and the wireless signal parameter distribution data server through an Internet. The system is suitable for exploration and a test of an indoor distribution system and possesses advantages of high portability, accurate and reliable test data and position information, high real-time performance of data, good intuitive performance of parameter display, high test efficiency and the like.

Owner:GUANGDONG SOUTHERN PLANNING & DESIGNING INST OF TELECOM CONSULTATION CO LTD

Contents border detection apparatus, monitoring method, and contents location detection method and program and storage medium therefor

InactiveUS7606388B2Accurate and reliable locationAccurate specificationsPublic key for secure communicationMultimedia data retrievalLocation detectionTime element

A contents border detection apparatus and monitoring method. The apparatus comprises a digital watermark detector for detecting a digital watermark embedded in contents for which a time element is provided; and a border detector for detecting border locations for the contents corresponding to the state of the digital watermark detected by the digital watermark detector. The border detector includes a first border specification device for specifying the border locations for the contents based on information, written in the digital watermark, that is detected by the digital watermark detector and includes a second border specification device for specifying the border locations for the contents based on bit patterns embedded as the digital watermark. The border locations for the contents are detected by using the process result obtained both by the first and the second border specification devices.

Owner:INT BUSINESS MASCH CORP +1

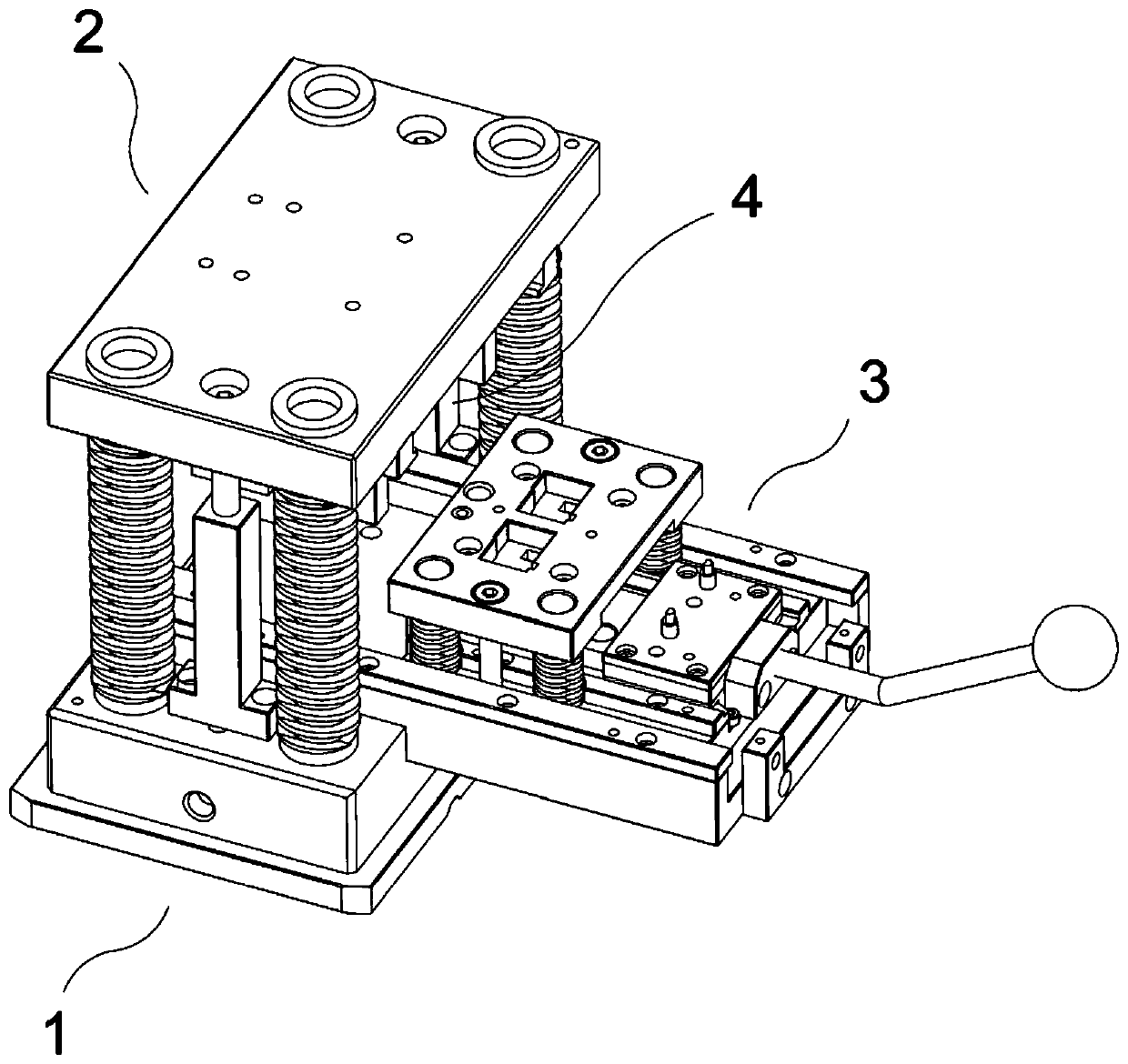

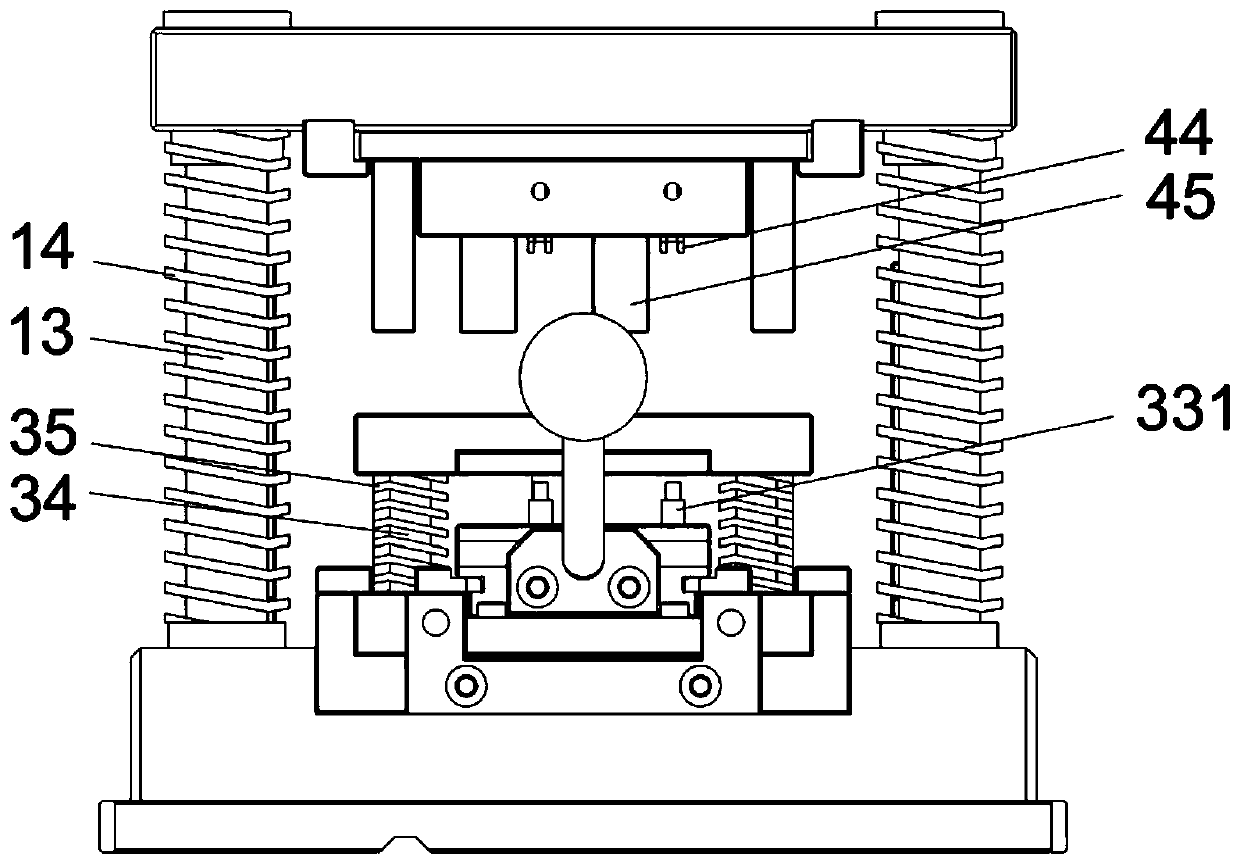

Multifunctional pressing jig

PendingCN110061404AReduce manufacturing costReduce labor costsContact member assembly/disassemblyEngineeringMechanical engineering

The present invention provides a multifunctional pressing jig, comprising a lower die base assembly, an upper die base assembly, a lower die assembly and an upper die assembly. The present invention provides a multifunctional pressing jig capable of pressing a conductive terminal or a grounding terminal into a connector housing separately or simultaneously pressing the conductive terminal and thegrounding terminal into the connector housing, thereby realizing the requirement of combining two stations into one station and simultaneously reducing the production cost and labor cost of the jig. Finally, the effect of improving the production efficiency and shortening the manufacturing cycle of the product are achieved. The jig is highly compatible and highly precise in pressing.

Owner:FCI CONNECTORS DONGGUAN

A surgical device for ophthalmic surgery

Owner:广州瑞其纳医疗科技有限公司

Quick capsule replacing center mechanism for tire vulcanizer

Owner:BRIDGESTONE CORP

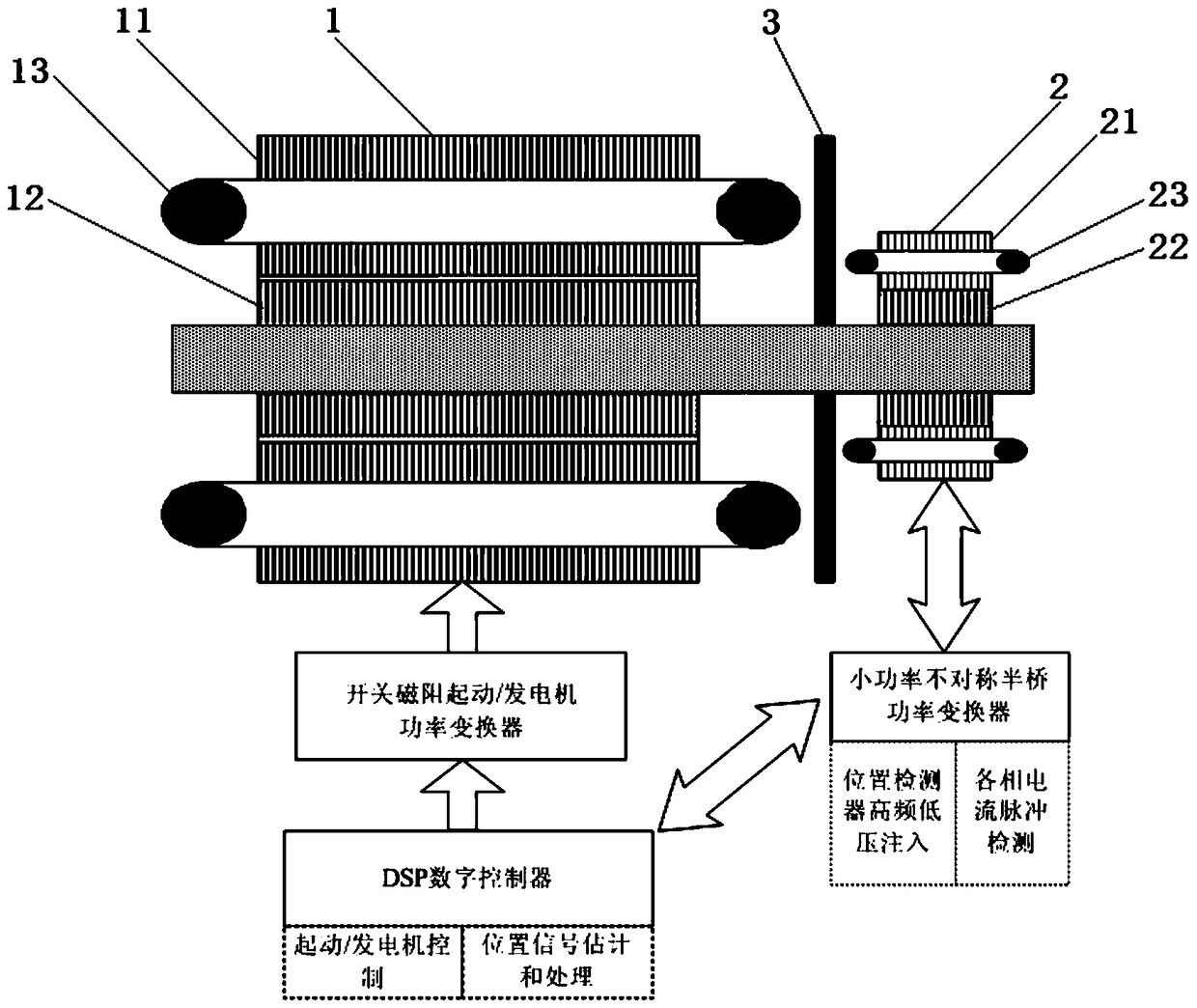

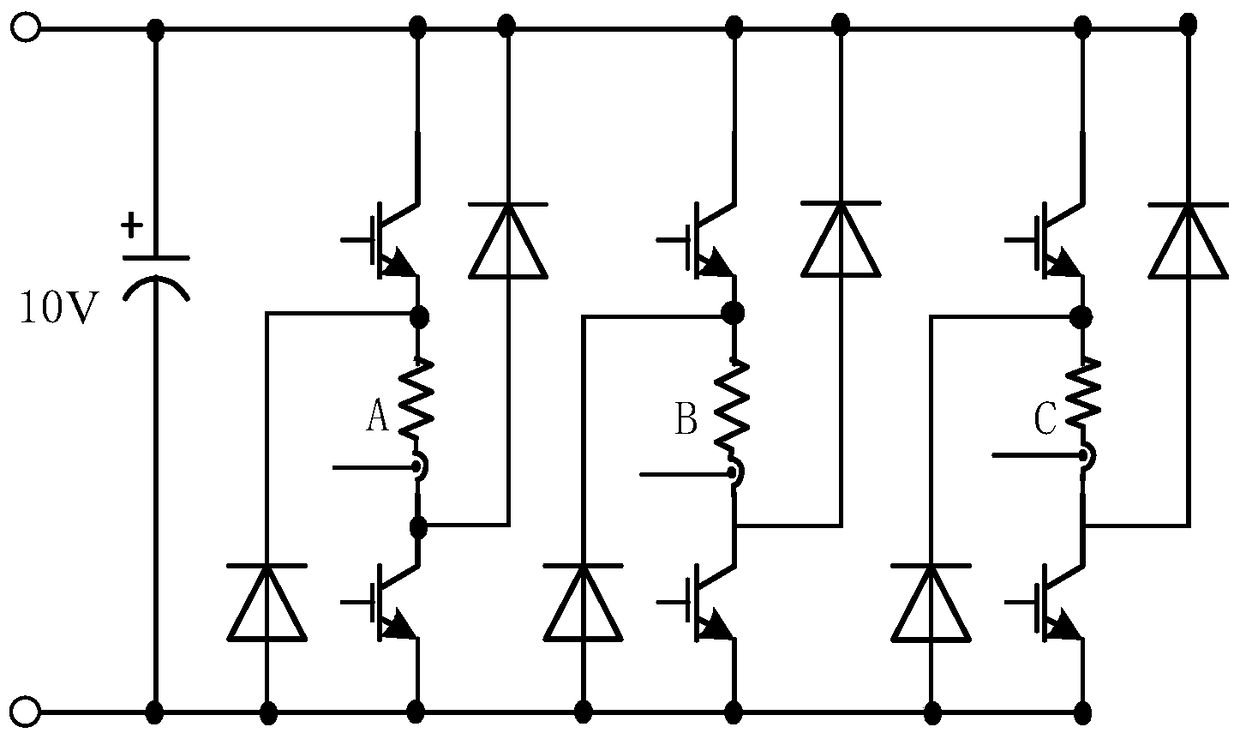

Rotor speed/position detection method for aviation switch reluctance starter/generator

ActiveCN105262383BSimple and strong structureAccurate and reliable locationElectronic commutatorsAviationLow voltage

The invention discloses a rotor speed / position detection method for an aeronautical switch reluctance starter / generator. A switched reluctance motor with the same number of poles as the stator and rotor teeth is coaxially installed on the aeronautical switch reluctance starter / generator. The position detector is a coaxially installed switched reluctance position detector. The position detector injects high-frequency and low-voltage pulses and performs digital low-pass filtering on the phase current to realize the estimation of the per-unit value of the inductance of each phase, so that the phase current can be estimated by using the The corresponding relationship between the inductance and the rotor position angle is used to obtain the rotor position signal, which provides accurate and reliable position and speed information for the aviation switched reluctance starter / generator. It can adapt to harsh operating environments such as high temperature, high speed and oil pollution, and has extremely high detection accuracy and reliability. The detection system is simple in structure, strong and safe, and low in cost. Position detection of generators at high temperature and high speed.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com