Spring-type locking mechanism provided with stopping power adjustment function

A locking mechanism and spring-type technology, applied in the field of locking mechanism to prevent rockets from falling off, can solve the problems of unstable stopping force, non-reusable, inaccurate position, etc., and achieve the effect of convenient operation, accurate and reliable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings and examples.

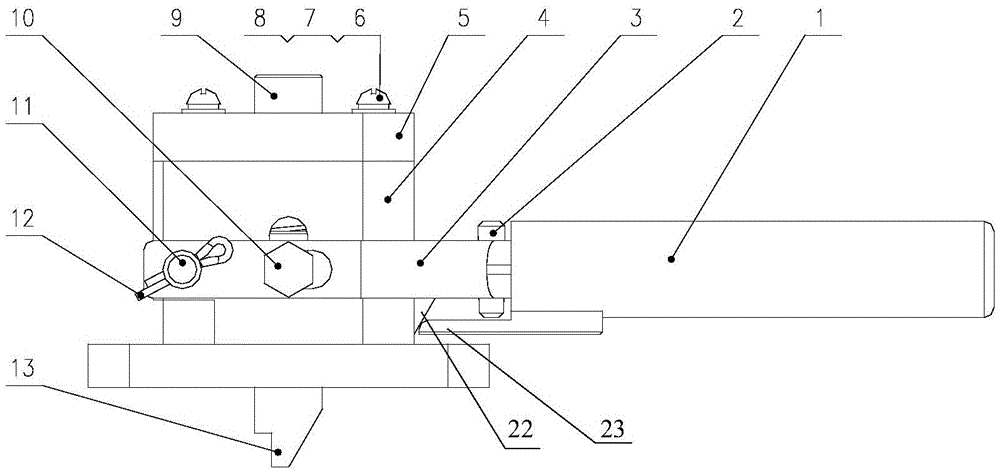

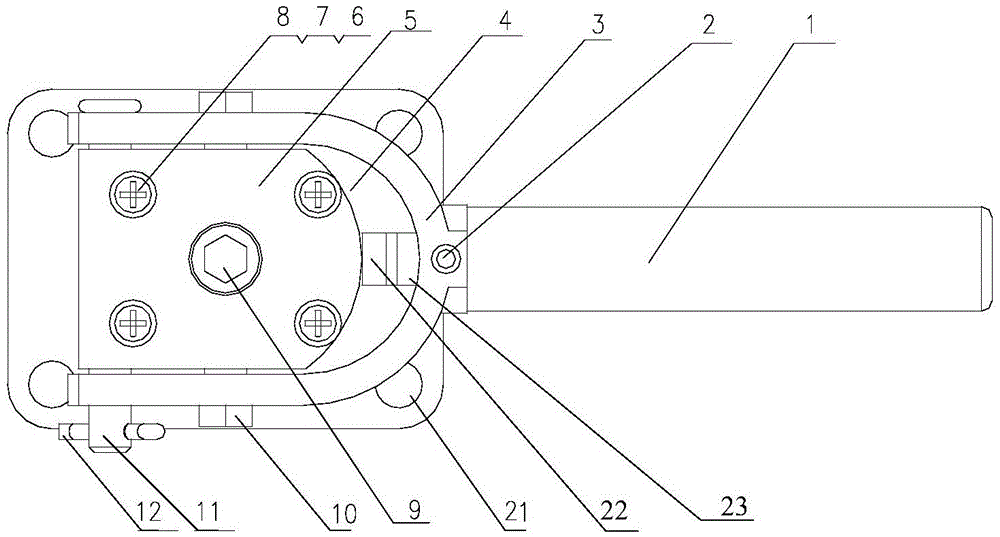

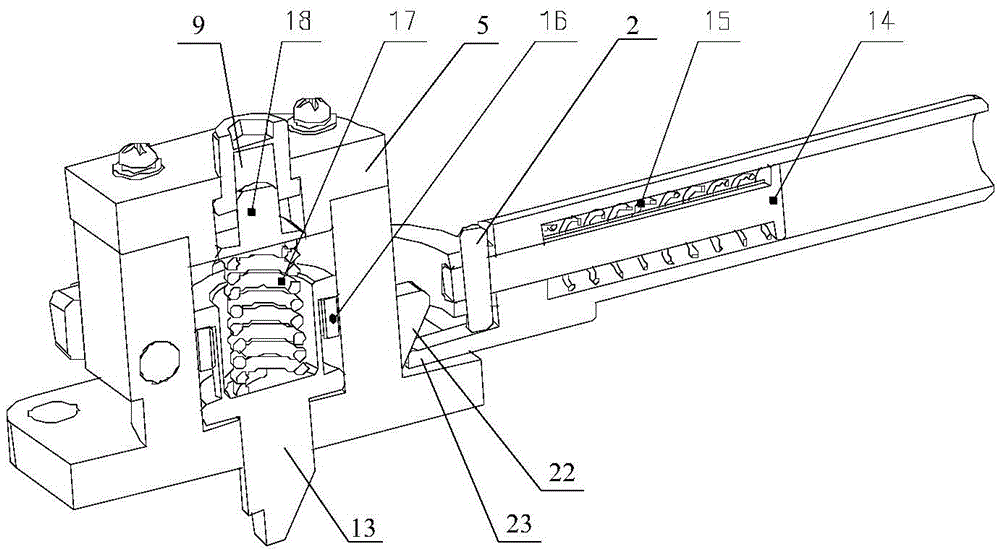

[0014] See attached figure 1 , 2 3. A spring-type locking mechanism with the function of adjusting the stopping force, which includes: handle 1, conical pin 2, lever fork 3, seat body 4, cover 5, screw 6, spring washer 7, flat washer 8, adjustment rod 9, Guide pin 10, pin shaft 11, cotter pin 12, stop body 13, guide shaft 14, spring I15, support half ring 16, spring II17, screw rod 18;

[0015] The seat body 4 is a supporting structure of the spring-type locking mechanism. There are four through holes 21 for mounting on the orienter 20 on the flange side of the seat body 4 . The seat body 4 is provided with a triangular The protrusion 22 is in contact with the protruding end 23 of the handle 1; the upper part of the stop body 13 is inserted into the guide groove at the lower part of the seat body 4, the spring II 17 is loaded into the upper inner hole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com