Quick capsule replacing center mechanism for tire vulcanizer

A technology of tire vulcanization and central mechanism, which is applied in the direction of tires, other household appliances, household appliances, etc., and can solve the problems of long time for replacing capsules and sealing rings, unreliable sealing, and high welding requirements, so as to achieve accurate and reliable positioning and prolong service life The effect of life and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

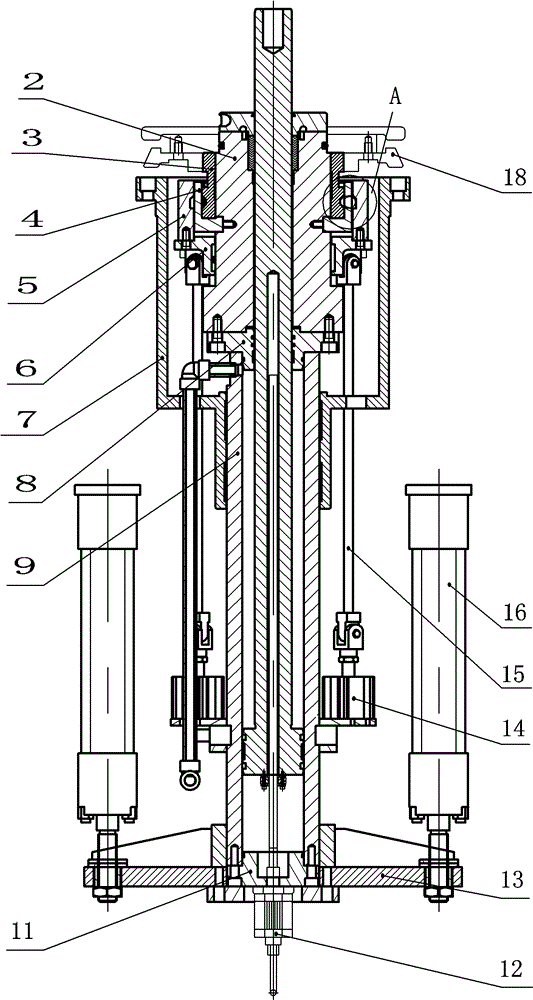

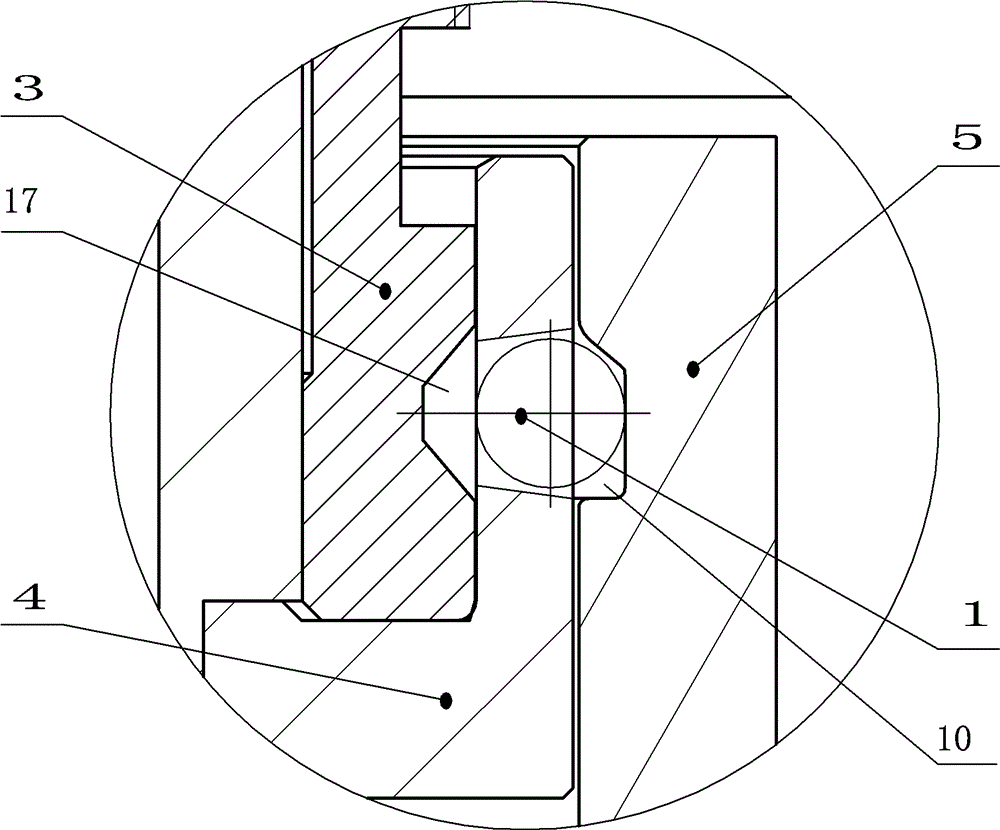

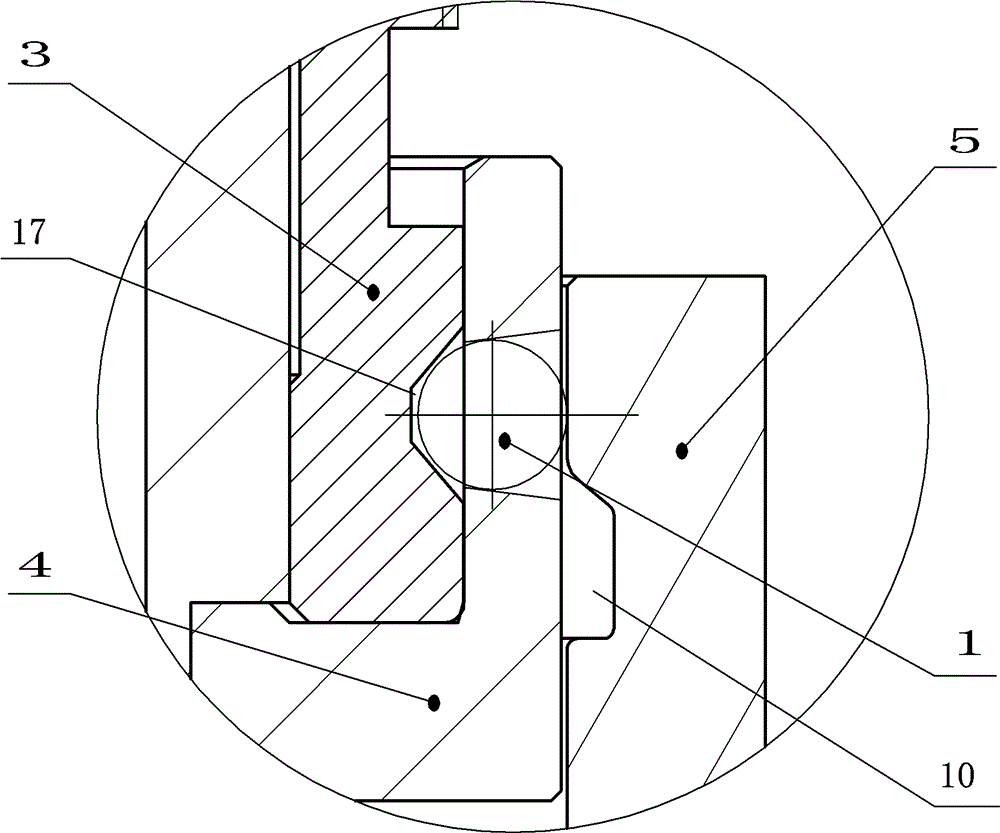

[0019] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

[0020] The tire vulcanizer quick replacement capsule central mechanism of the present invention includes a ring seat 2, a clamping ring 3, an upper ring lifting water cylinder 9 and a ring seat lifting cylinder 16, and the clamping ring 3 is fixed to the lower chuck 18 through a T-shaped thread Together, the upper ring lifting water cylinder 9 is a single-piston cylinder, and its cylinder barrel is placed in the piston guide sleeve 7. The top of the cylinder barrel is connected to the bottom of the ring seat 2 through the upper flange cylinder head 8 with screws, and the bottom of the cylinder barrel is passed through The lower flange cylinder head 11 is connected and installed with the base 13, and the ring seat lifting cylinder 16 is arranged symmetrically around the cylinder above the edge of the base 13, and the piston rod of the ring seat lifting cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com