Machining device and method of high-precision intaglio roller

A gravure plate roll and processing device technology, applied in the field of gravure plate roll processing, can solve the problems of increased production cost of plate roll, uneven wall thickness of plate roll, long processing time, etc. The effect of precise round results and reduced production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

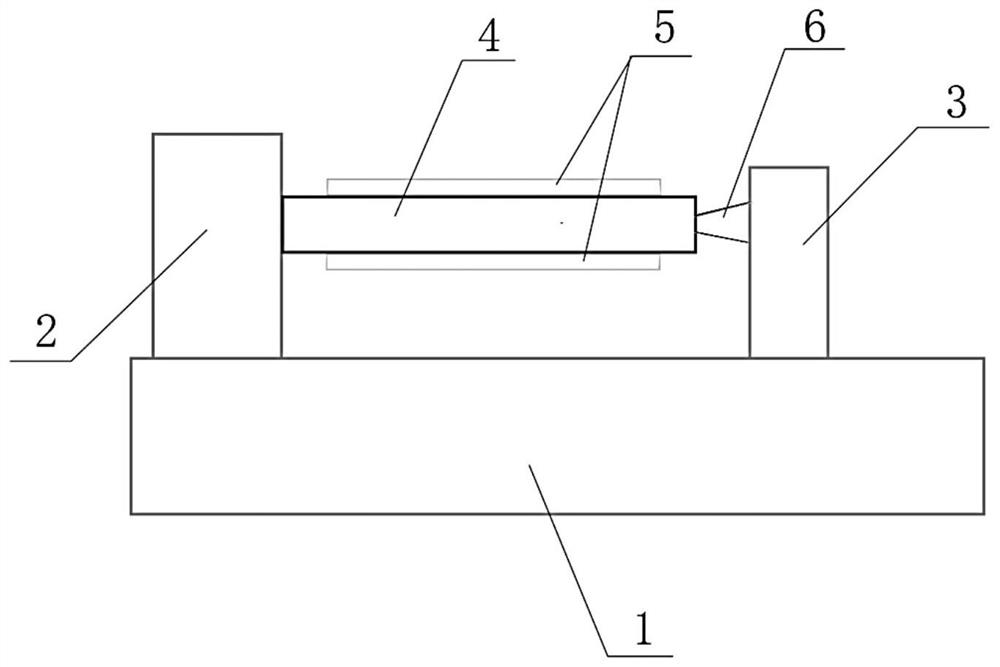

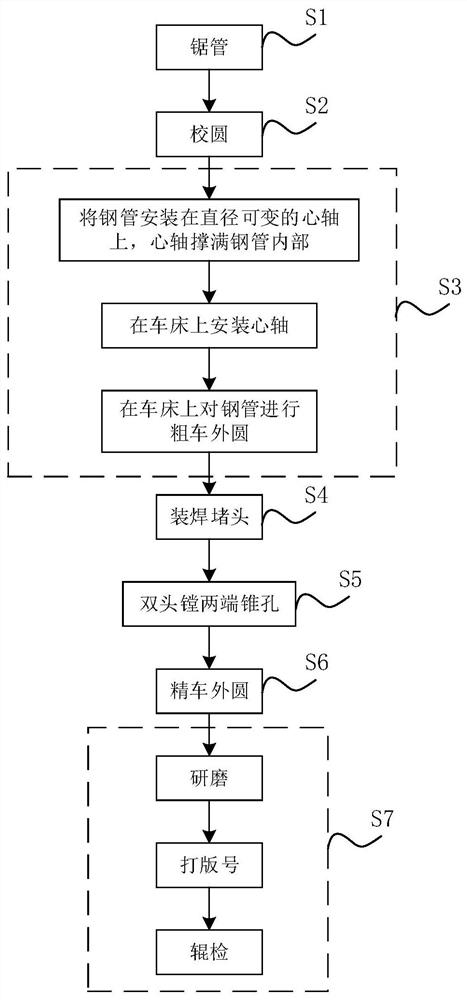

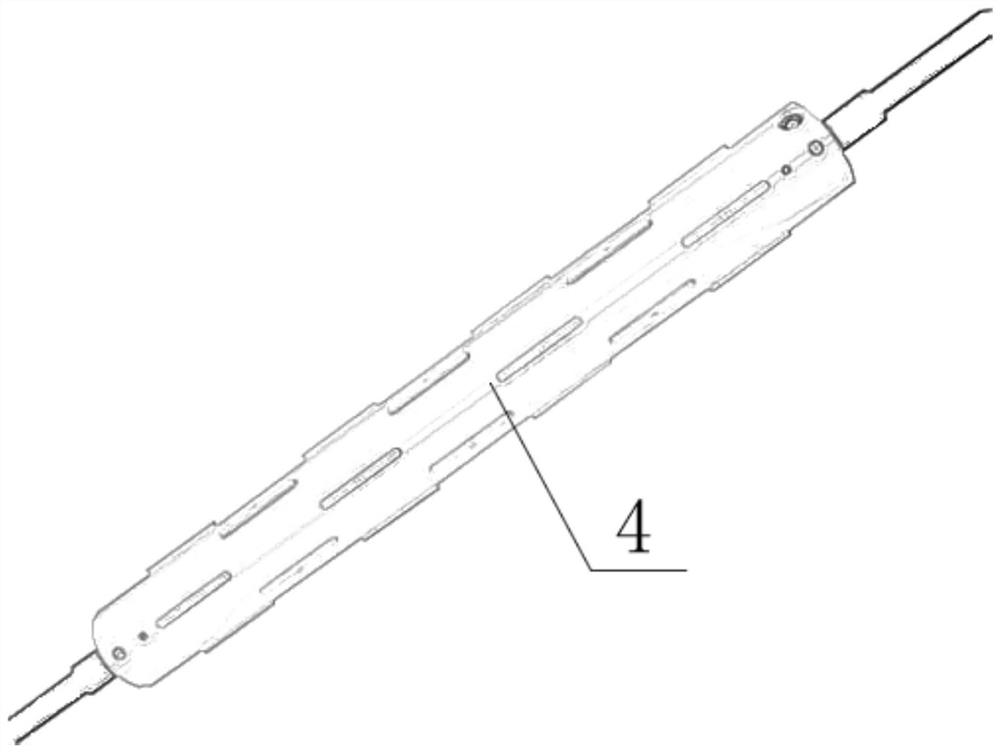

[0052] Such as figure 1 As shown, this embodiment provides a high-precision gravure roll processing device, which is used for rough turning the outer circle of the steel pipe 5 to be processed, and the processed steel pipe is used to manufacture the gravure roll, and the high-precision gravure roll processing device It includes a lathe and a mandrel 4, the mandrel 4 is detachably connected to the lathe, the lathe is used to support the mandrel 4, and drives the mandrel 4 to rotate, the diameter of the mandrel 4 is variable, and is matched with the steel pipe 5 to be processed to support The inside of the steel pipe 5 is to be processed; the runout of the outer circle of the mandrel 4 is less than 0.02 mm.

[0053] When carrying out the process of rough turning the outer circle, install the steel pipe 5 to be processed on the mandrel 4, and the mandrel 4 tightens the inside of the steel pipe 5 to be processed, start the lathe, drive the mandrel 4 to rotate, and carry out rough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com