Steel shotcrete support internal force self-compensation, displacement control system and control method

A technology of displacement control and automatic compensation, which is applied in excavation, construction, infrastructure engineering, etc., can solve the timely control of unfavorable support structures and deformation requirements of the surrounding environment, and cannot meet the stringent requirements of subway deformation and settlement. No research has been found Methods, research results or products, etc., to achieve the effects of reducing human resource costs, facilitating construction, and achieving significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

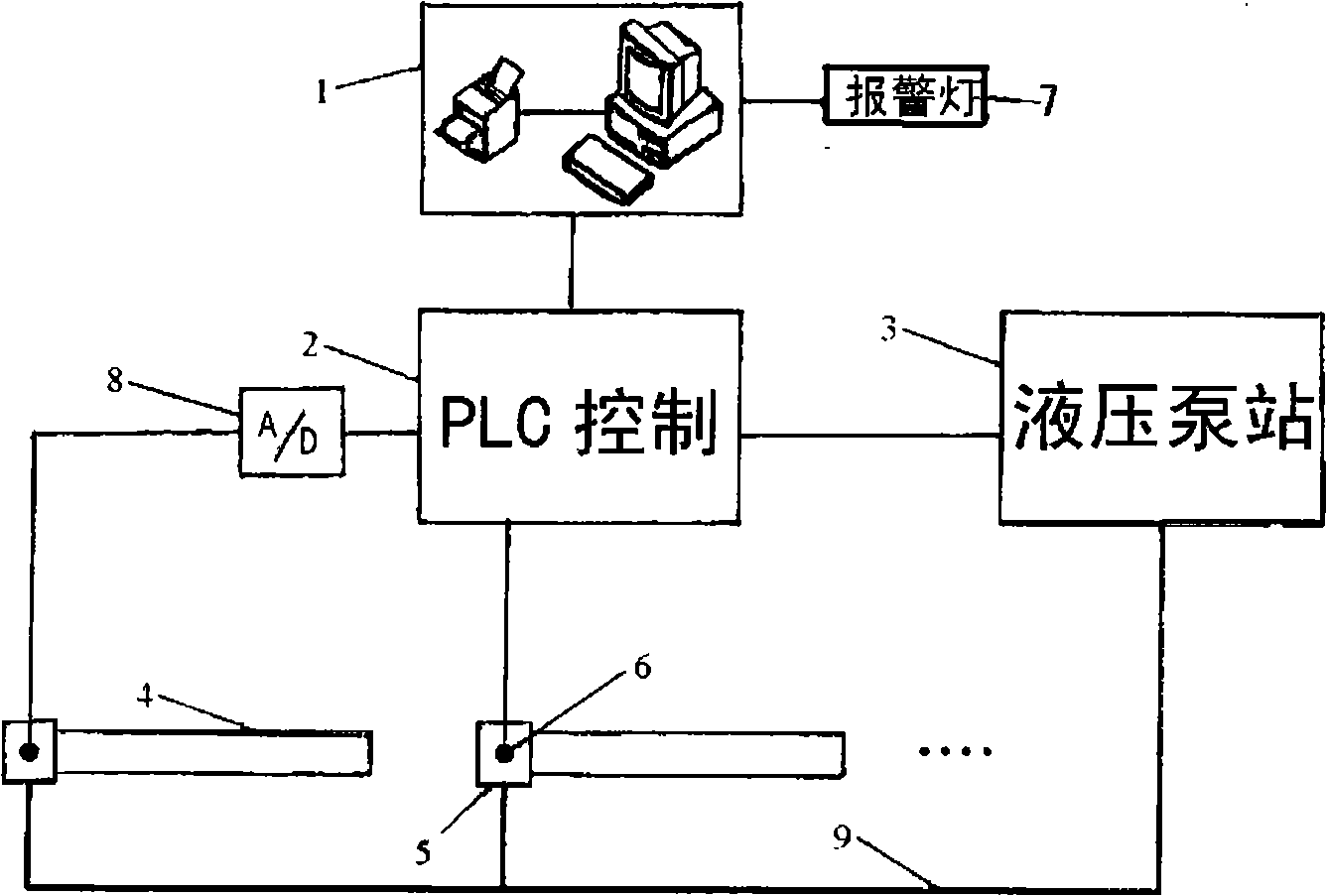

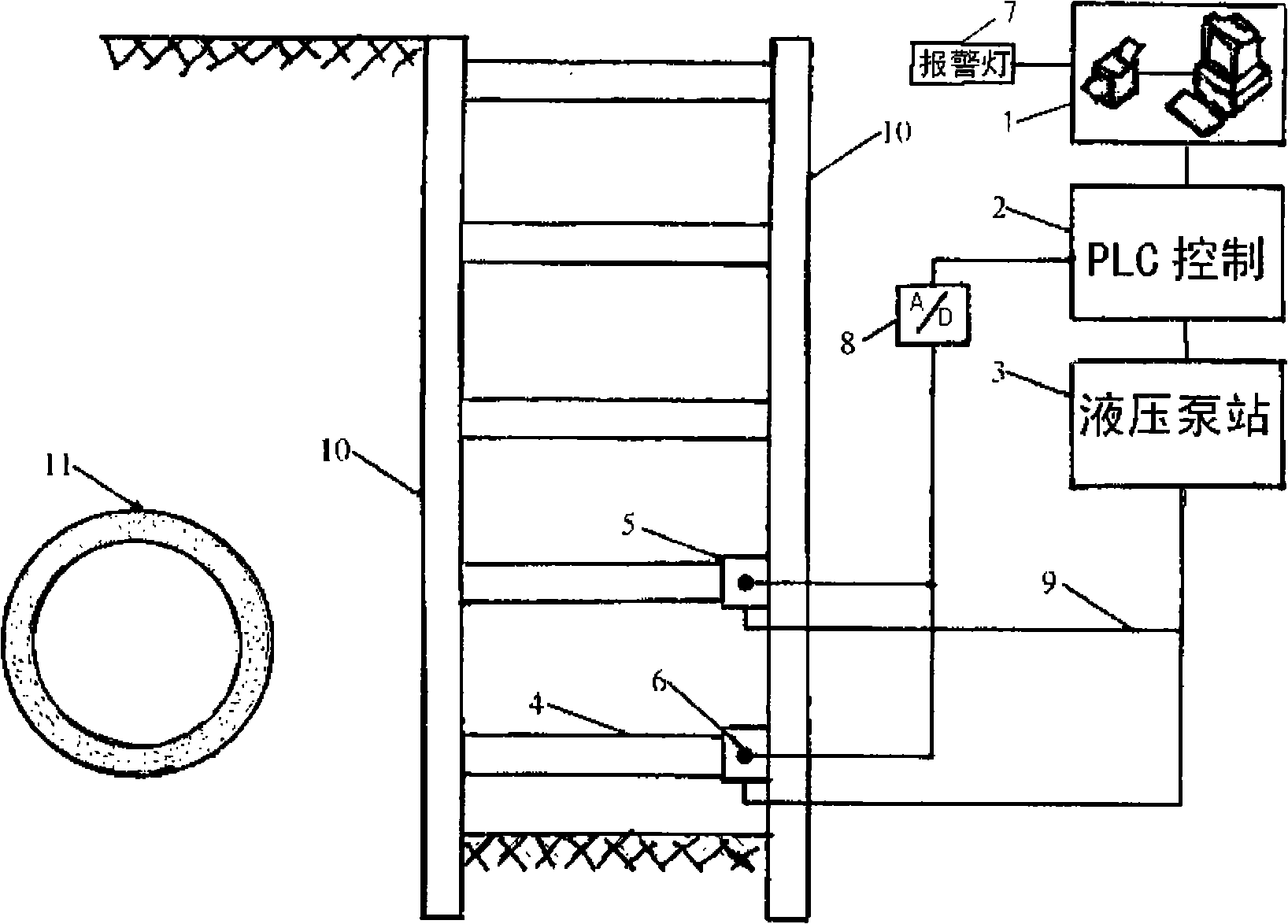

[0018] Construction process of the present invention is as follows:

[0019] 1. The hydraulic pump station is in place, the PLC control system is in place, and the upper system is in place;

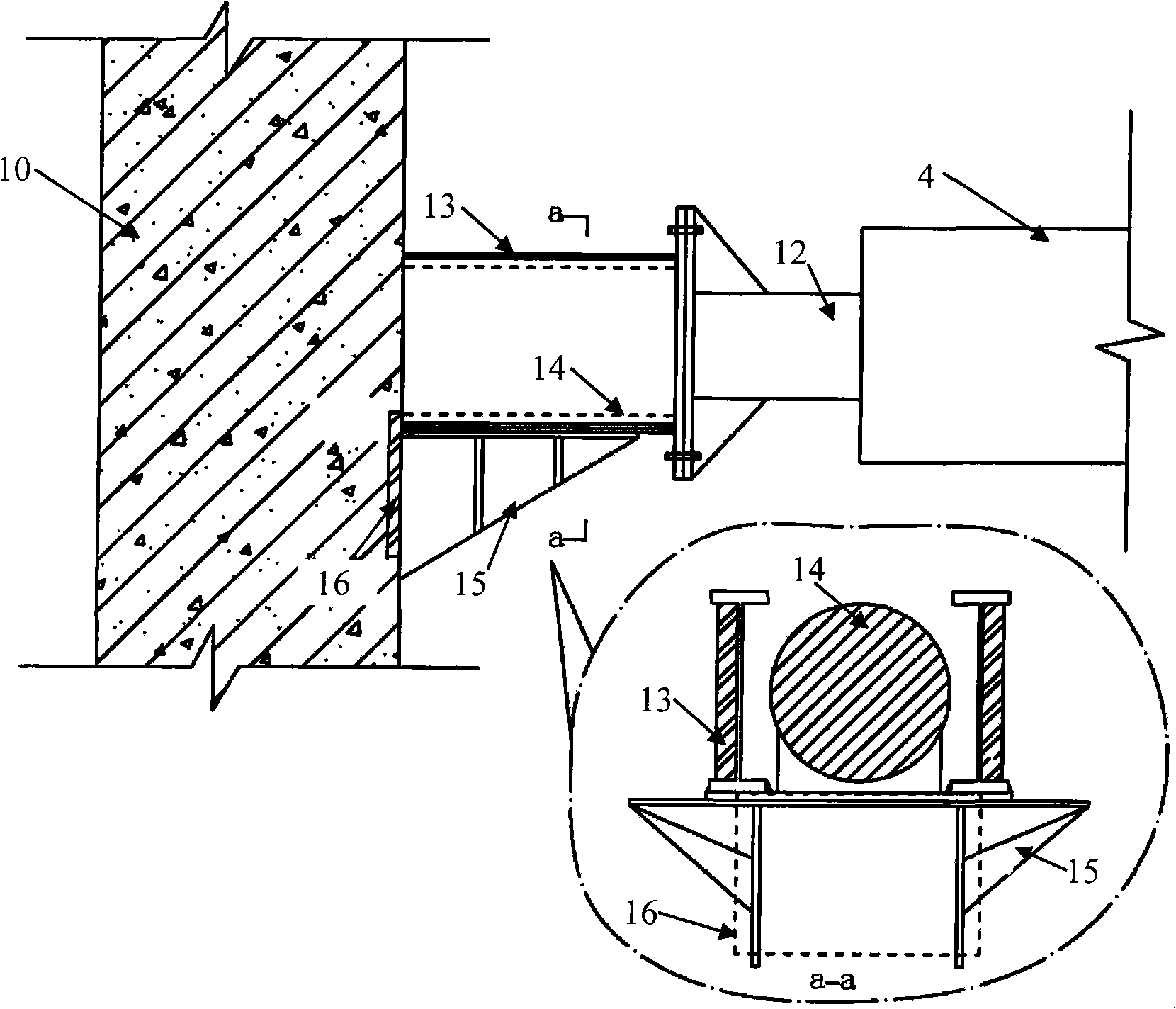

[0020] 2. Following the excavation progress of the building foundation pit, install steel supports, hydraulic jacks, and pressure sensors.

[0021] 3. On-site wiring to realize circuit signal communication connection and hydraulic oil circuit connection.

[0022] 4. The automatic control system starts to work.

[0023] 5. Through parameter adjustment in the automatic control software interface of the upper system, the pressure adjustment of the steel support axial force is realized.

[0024] 6. After the adjustment of the axial pressure of the steel support meets the design requirements, it enters the automatic control state (pressure maintaining state).

[0025] In the process of automatic control of steel support axial force, under normal circumstances, unattended monitoring and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com