Universal full-automatic box covering mechanism

A fully automatic and general-purpose technology, which is applied in the direction of closing containers tightly with lids, applications, household appliances, etc. It can solve the problems of inaccurate lid box position, complex structure of lid box machine, and low labor intensity, etc., to achieve the lid box position Accurate and reliable, the process of capping the box is intuitive, and the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

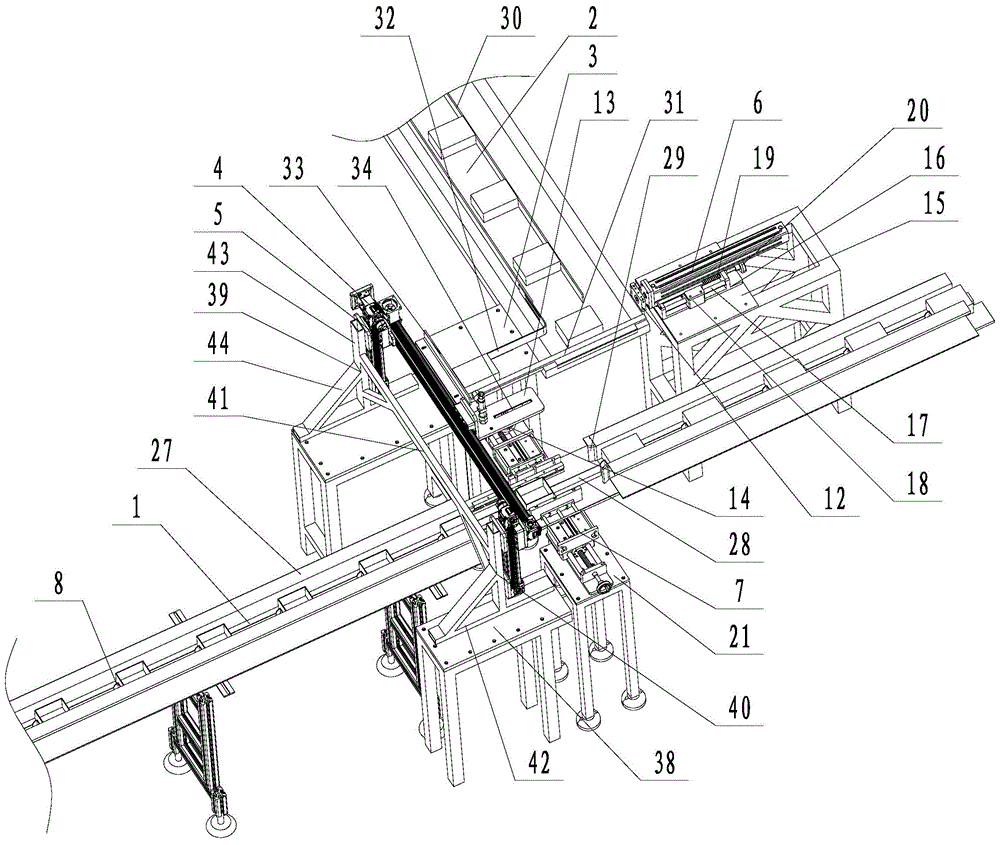

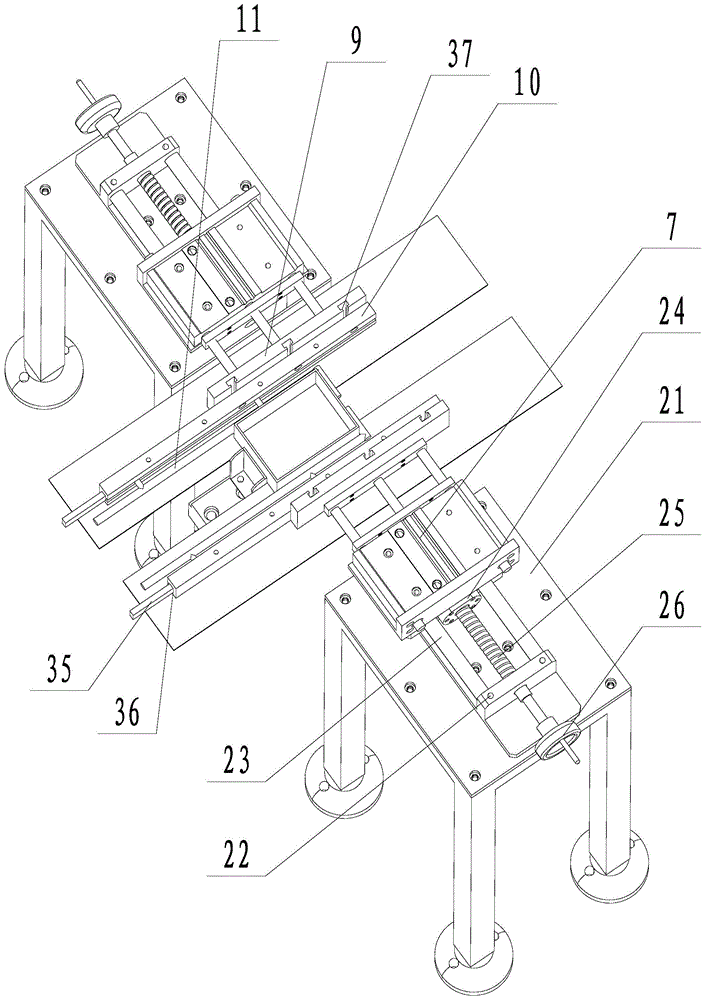

[0019] Embodiment: a kind of general-purpose full-automatic cover box mechanism (see attached figure 1 , attached figure 2), including box conveyor line 1, box cover conveyor line 2, box cover buffer table 3, horizontal linear module 4, vertical linear module 5, push piston cylinder 6, pre-tightening piston cylinder 7, box cover conveyor line, etc. The distance is provided with several driving rods 8, and the pre-tightening piston cylinder is relatively provided with two connecting plates 9 are connected to the telescopic rods of the pre-tightening piston cylinders. A pre-tension rod 11 is connected, and the rear ends of the pre-tension rods are in an L-shaped structure. Pushing away the piston cylinder expansion rod is connected with the push plate 12 that the lid is pushed to the lid buffer table from the lid conveying line, and the delivery direction of the lid and the pushing direction of the push plate to the lid are perpendicular to each other. A push table 15 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com