Spacers, Ribbed Floors Using Spacers and Construction Formwork Systems

A technology of dense-ribbed floor and positioning parts, applied in the field of construction, can solve the problems of low reliability, poor safety, low efficiency, etc., and achieve the effect of widening the application scope, low cost, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

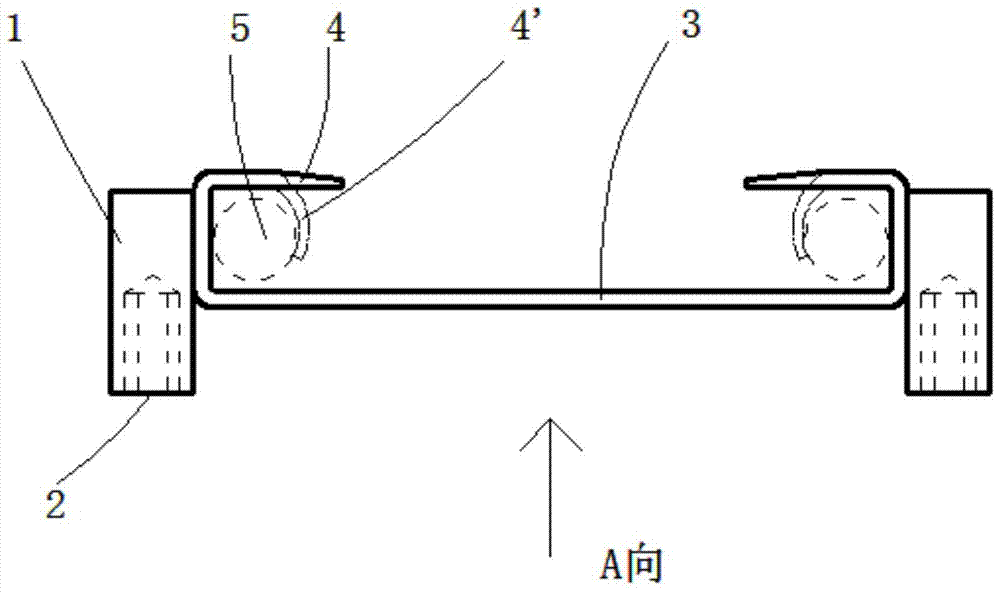

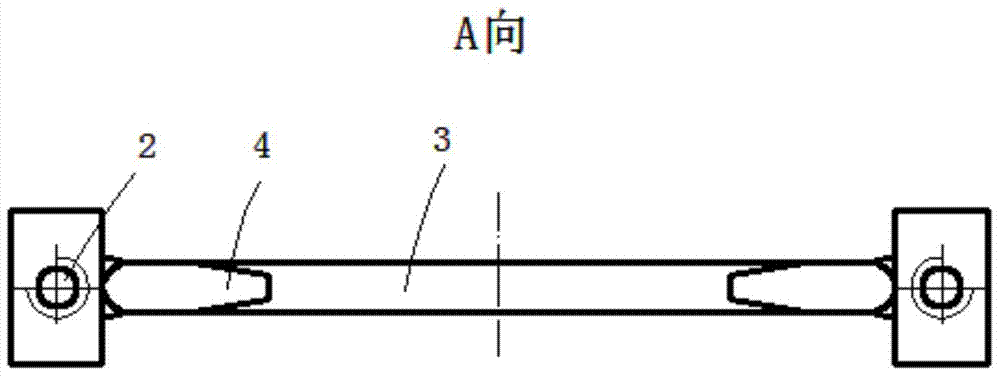

[0054] Such as figure 1 , figure 2As shown, the two ends of the cross support 3 are respectively provided with retaining legs 1, and the retaining legs 1 are used as a limiting part, and the outer surface resists the side wall of the permanent template or the filling block to limit the position. The bottom of the retaining leg 1 is provided with a screw hole a2 for For its own fixing, the buckle 4 is a fixed steel bar component, the longitudinal bar 5 at the bottom of the rib beam is bent from the buckle 4 to the position where the buckle bends 4' for fixing, and the positioning part is a steel part.

Embodiment 2

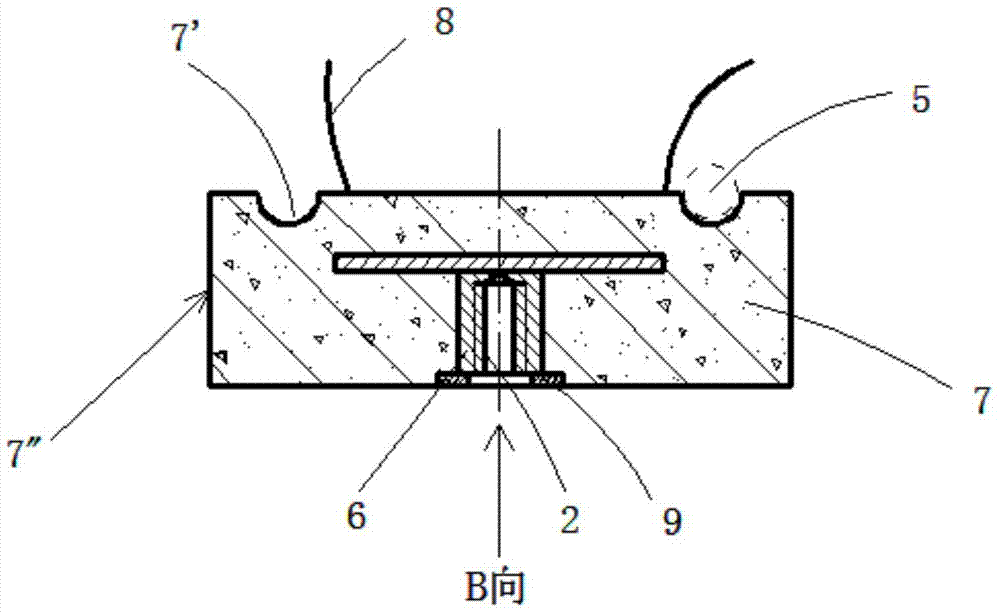

[0056] Such as image 3 and Figure 4 As shown, the base 6 is embedded in the concrete pad 7, the bottom surface of the base 6 is provided with a screw hole a2 through the bottom, a gasket 9 is also provided under the screw hole a2, and a groove 7' and a binding wire 8 are provided on the concrete pad 7. , used to fix the longitudinal reinforcement 5 at the bottom of the rib beam, and the two ends of the concrete pad 7, as a retaining edge 7", blocking the spacing or position of the permanent formwork or filling block.

Embodiment 3

[0058] Such as Figure 5 , Figure 6 As shown, the two ends of the cross support 3 are provided with retaining legs 1', the lower part is provided with a leg 11, the right leg 11 is provided with a screw hole b12, the left leg is provided with a light hole 12', and a matching nut b13 is placed on it. The leg structures on both sides can be substituted for each other. The horizontal support 3 is provided with a bolt hole 10 to fix the binding wire 8, and the binding wire 8 fixes the longitudinal rib 5 at the bottom of the rib beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com