Ink fountain reset device for gravure printing machine and control method thereof

A technology of reset device and printing machine, which is applied to printing machines, general parts of printing machinery, printing, etc. It can solve the problems of rapid adjustment of the position of the ink tank, which is laborious and inconvenient, time-consuming and labor-intensive, and achieves accurate and reliable positions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

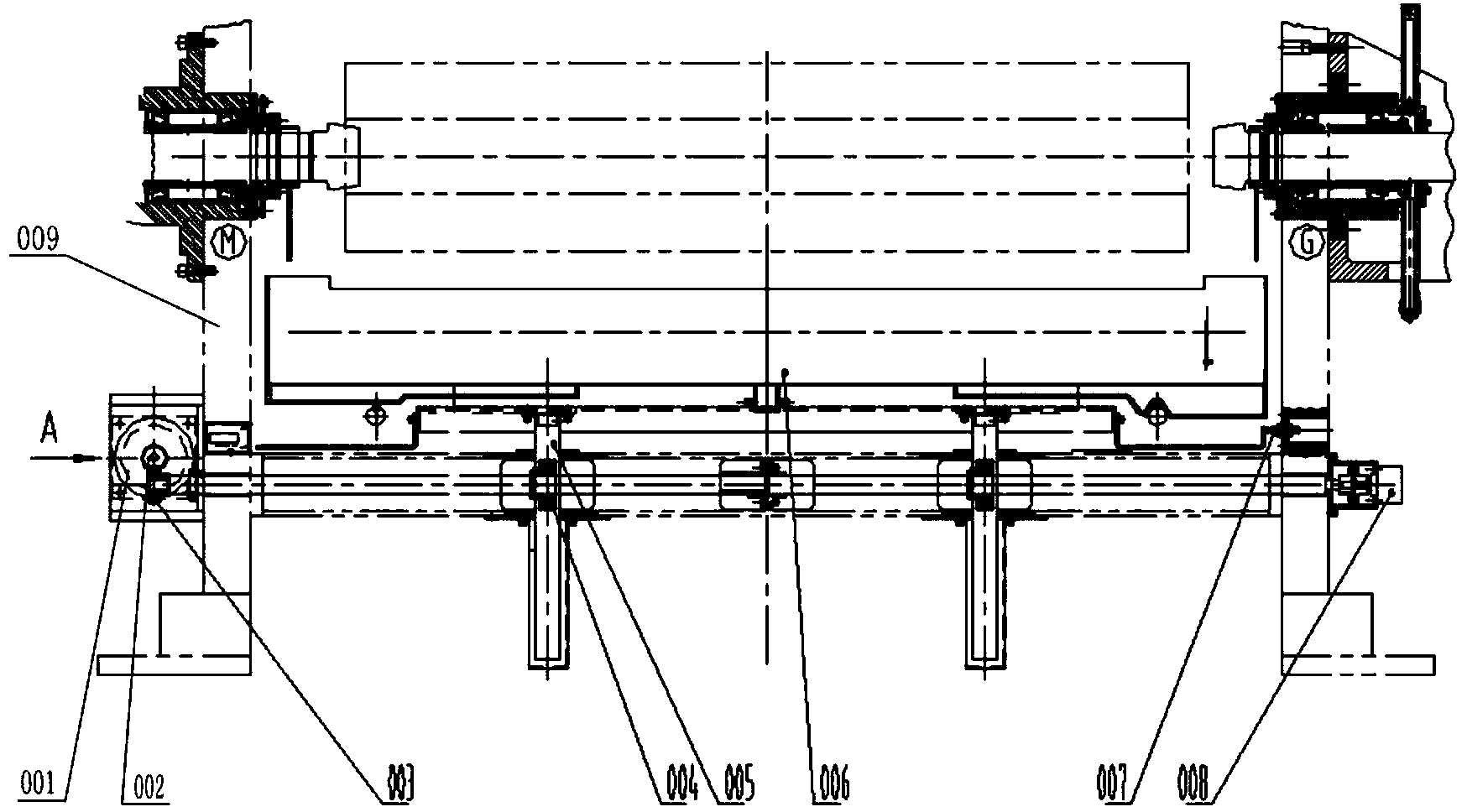

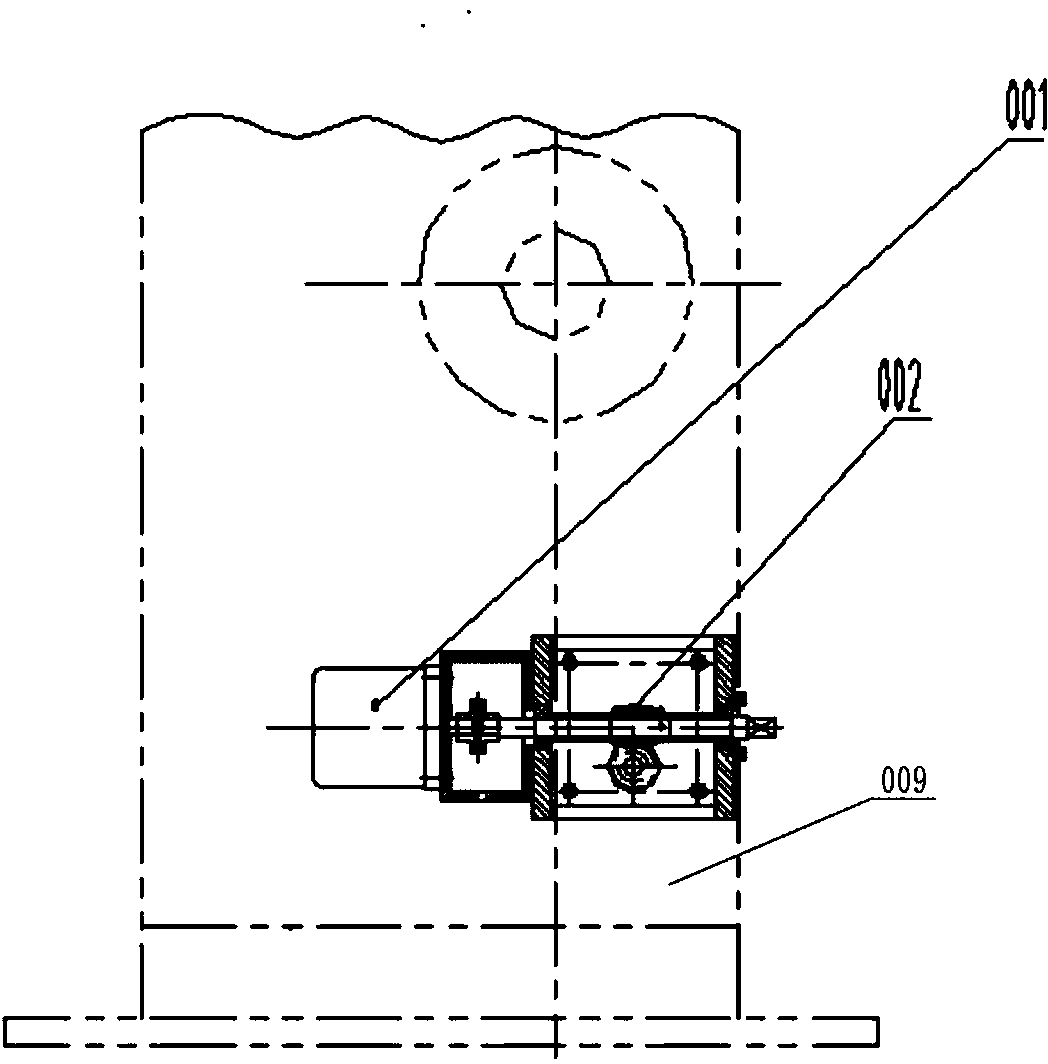

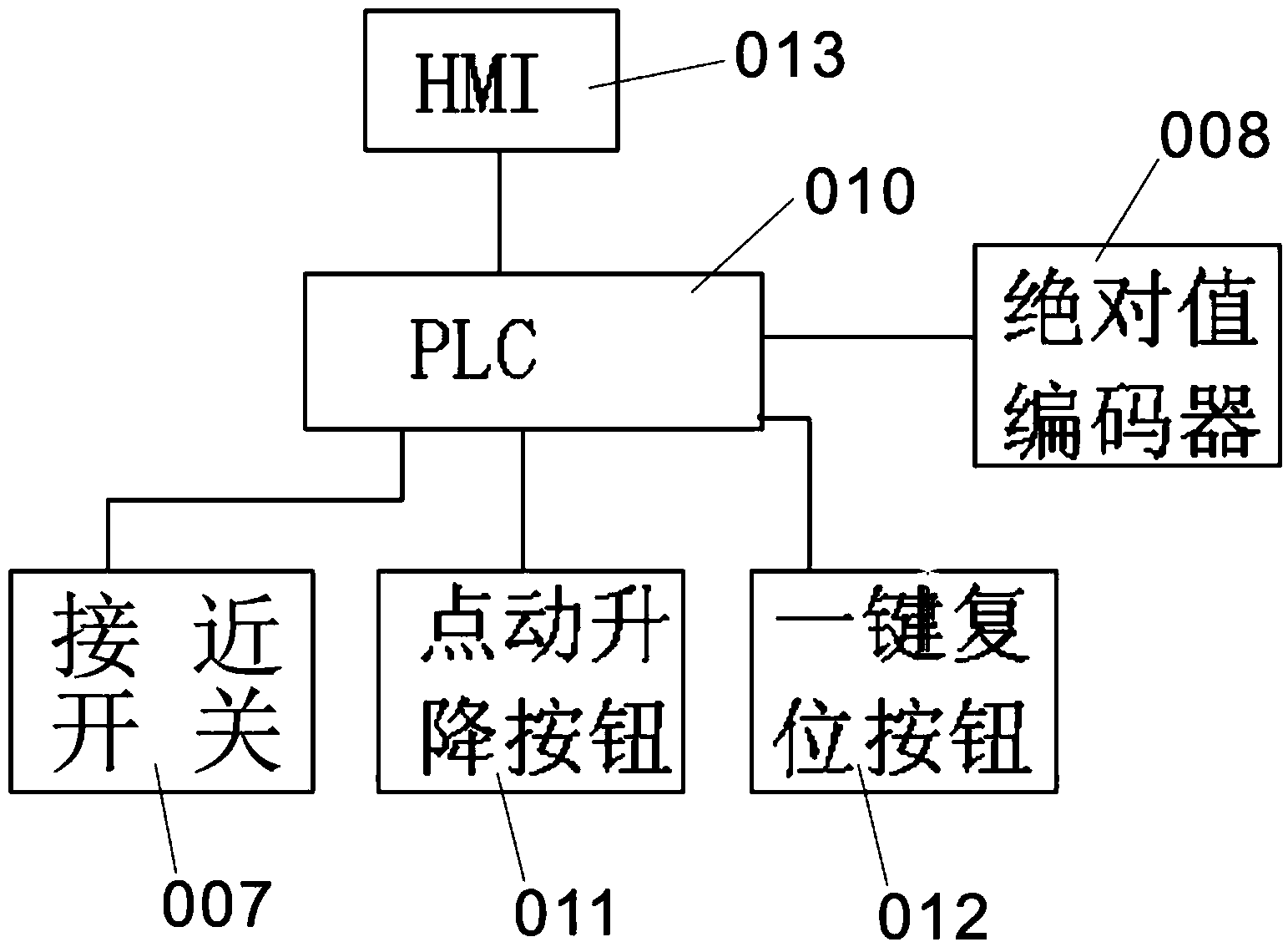

[0032] The invention provides a gravure printing machine ink tank reset device, such as figure 1 and figure 2 As shown, including 2 gears 004 installed on the frame 009, the 2 gears 004 are respectively equipped with racks 005 meshing with them, the 2 racks 005 are all vertically arranged, and the frame 009 is also equipped with The rack 005 is vertical to the worm gear 003, the worm gear 003 meshes with the gear 004, the synchronous motor 001 is fixedly connected to one side of the frame 009, the rotor end of the synchronous motor 001 is connected to the worm 002, the worm 002 meshes with the worm wheel 003, and the frame 009 Proximity switch 007 and absolute value encoder 008 are installed on the other side, proximity switch 007 is installed on the inner side of frame 009, and absolute value encoder 008 is installed on the outside of frame 009.

[0033] The working principle of this mechanism is that the synchronous motor 001 drives the worm 002 to move, the worm 002 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com