High voltage wire support for utility poles

A technology for utility poles and high-voltage lines, applied in the field of high-voltage line supports, can solve the problems of general support strength of iron cross-arms, potential safety hazards, fragile ceramic insulators, etc., and achieve good insulation performance, light weight, and increased support strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

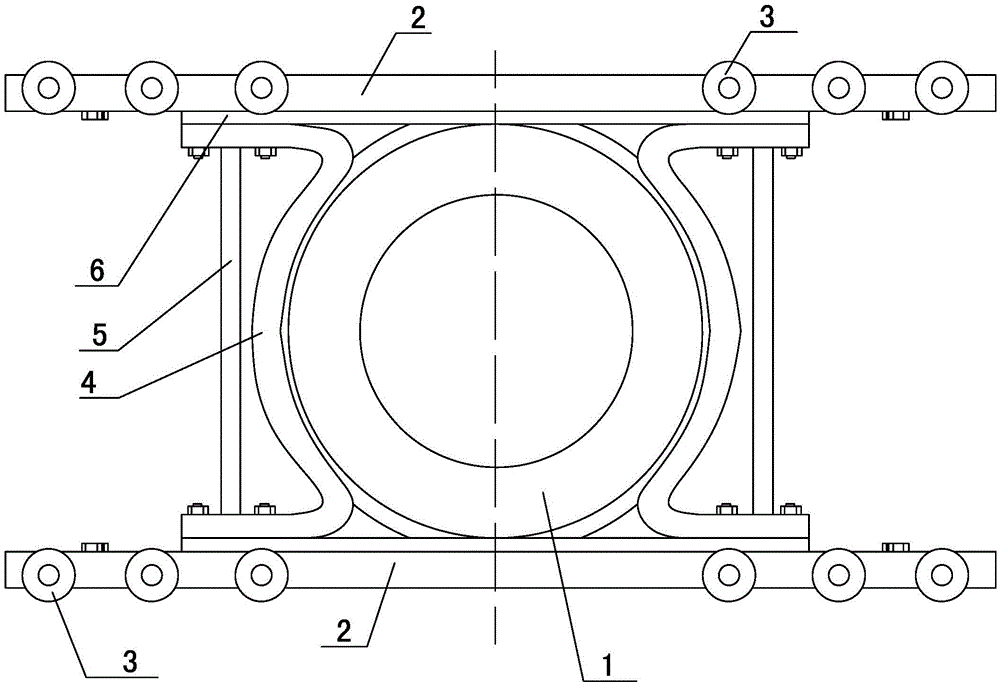

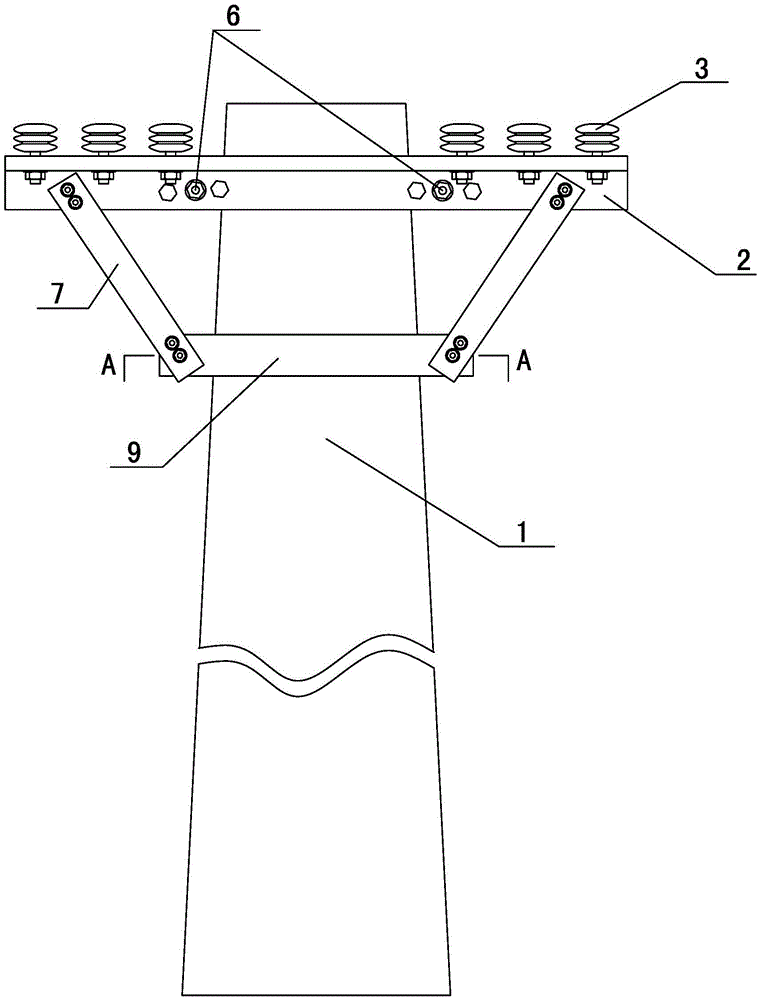

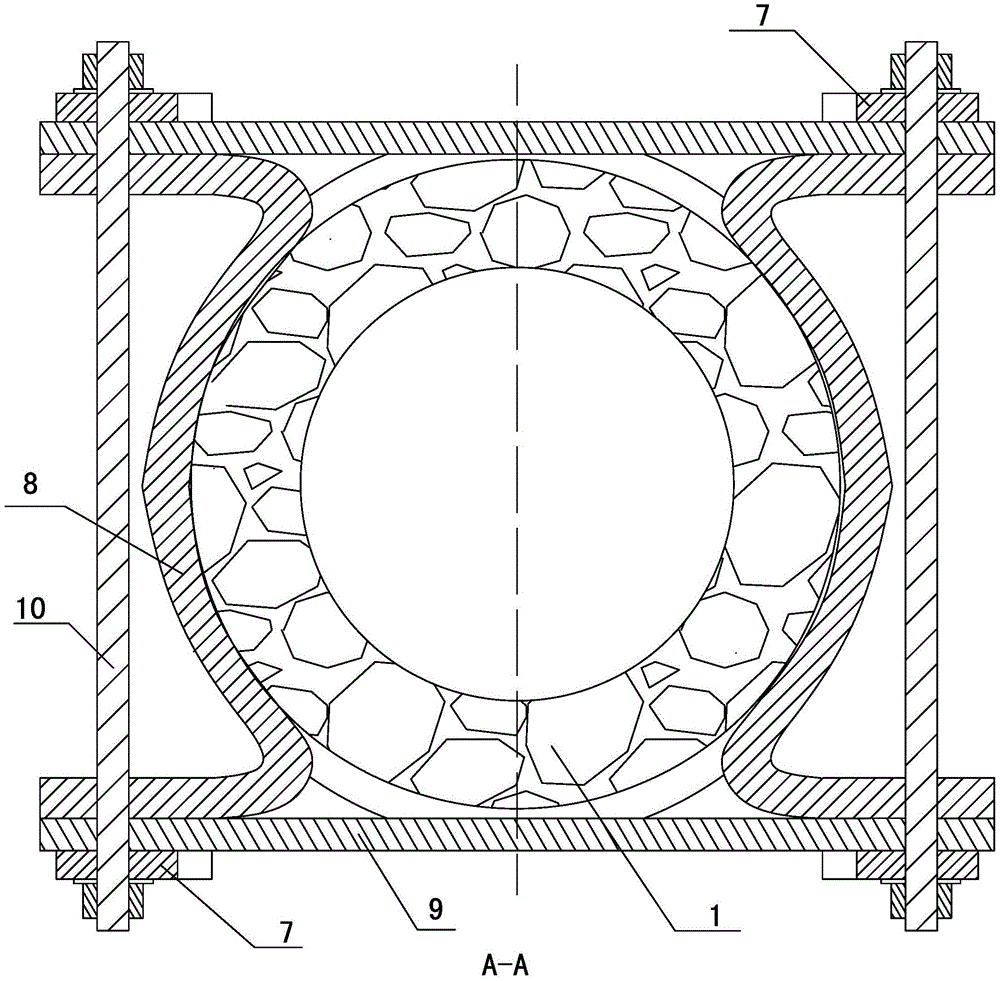

[0014] This preferred embodiment is Figure 1 to Figure 3 Shown is a support for high-voltage wires used on utility poles, including two parallel arms 2 and 6-wire insulators 3 fixed on the horizontal plates of the arms 2, and the vertical plates of the arms 2 are connected to the wires through the first hoop The rod 1 is fixed; it also includes four oblique support rods 7 and a second hoop fixed to the utility pole, the second hoop is arranged below the first hoop, between the end of the vertical plate of the cross arm 2 and the second hoop All are connected by a diagonal support rod 7. Among them, the crossarm 2 is made of FRP, which has corrosion resistance, good insulation performance, light weight and high strength; the insulator 3 is made of glass fiber impregnated with vinyl ester resin through the existing FRP winding process, and has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com