Processing device and processing method of polyethylene glass fiber reinforced plastic composite molding spiral corrugated pipe

A spiral corrugated pipe and composite molding technology, which is applied to corrugated products, tubular objects, and other household appliances, can solve the problems of small ring stiffness, collapse, and fast corrosion speed, and achieve high strength, light weight, and corrosion resistance powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] see Figure 5 , polyethylene glass fiber reinforced plastic composite molding spiral bellows, two layers of polyethylene layer 24 coated on the inside and outside of the glass fiber reinforced plastic layer 21, the structure is consistent with the traditional steel belt reinforced polyethylene spiral bellows, the difference is that the steel belt is replaced by glass fiber reinforced plastics.

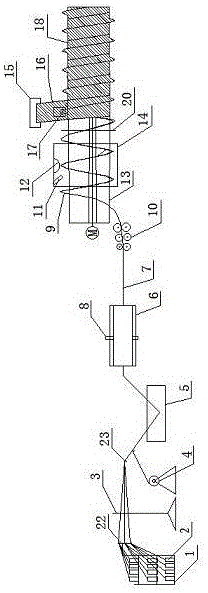

[0035] As a preferred embodiment of the present invention, the attached Figure 1~4 Shown is a processing device for compositely forming a spiral corrugated pipe made of polyethylene fiberglass, and the specific structure is as follows:

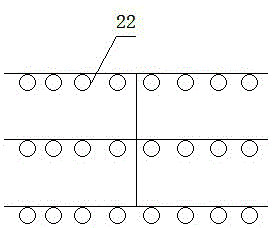

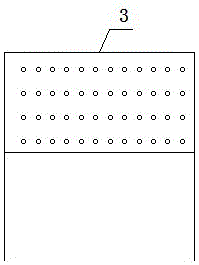

[0036] The alkali-free glass fiber is the glass fiber pultrusion yarn 2 placed on the glass fiber pultrusion creel 1, which is drawn out through the glass fiber wire ring frame 22, the glass fiber wire mesh plate 3 and the glass fiber row rod 23 in sequence, and the glass fiber knitted mat Leading out from the knitted felt support 4, the non-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com