Quick-dismantling building formwork and light-weight cast-in-place wall body construction method

A technology for building templates and cast-in-place walls, which is applied to the preparation of formwork/formwork/work frames, building components on site, construction, etc., which can solve the problem of poor quality assurance of pouring bodies and low overall cost of pouring effects Obvious problems such as large appearance defects of wall mechanism components, etc., to achieve the effect of improving function and reuse rate, reducing construction cost and construction period, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

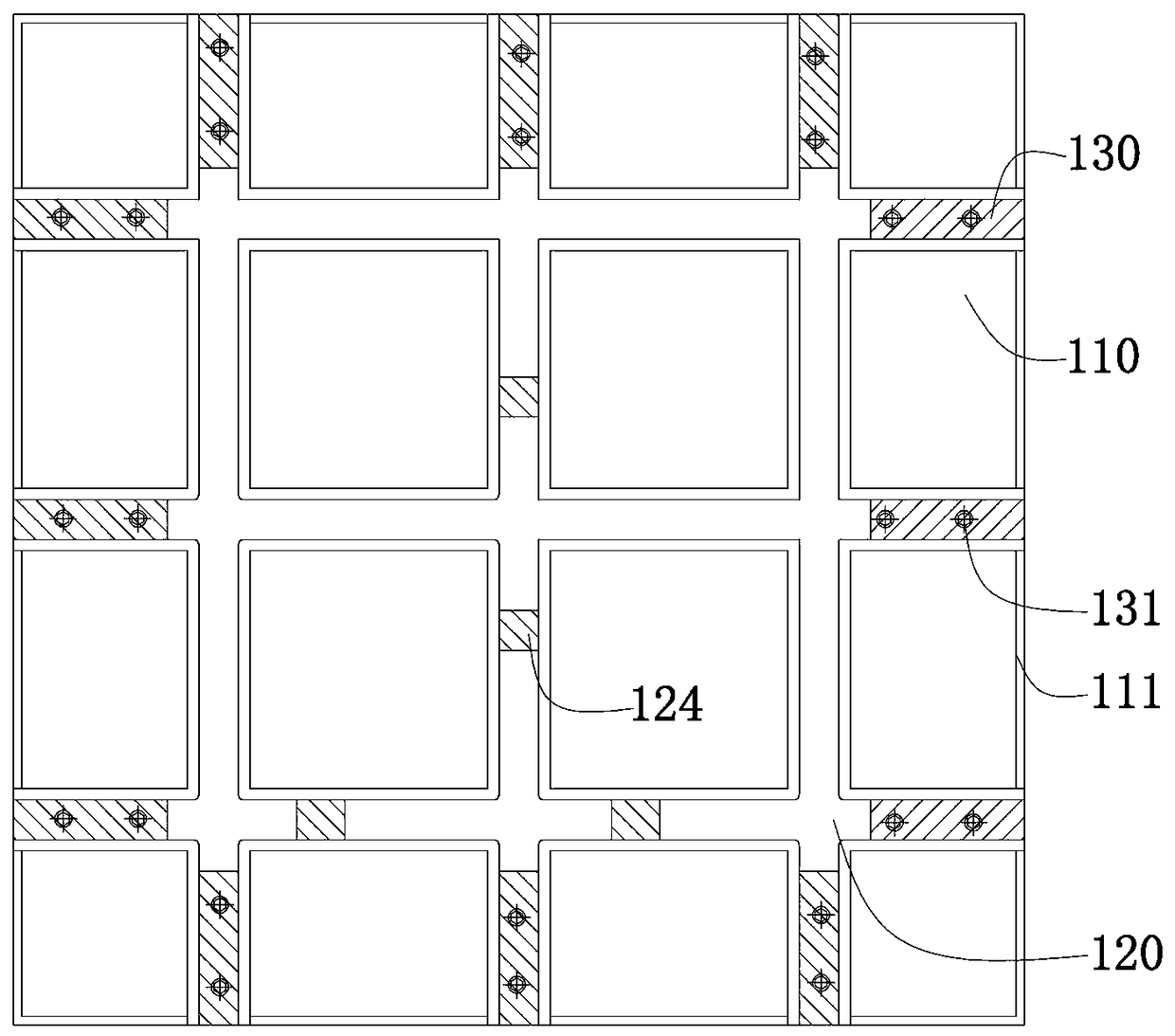

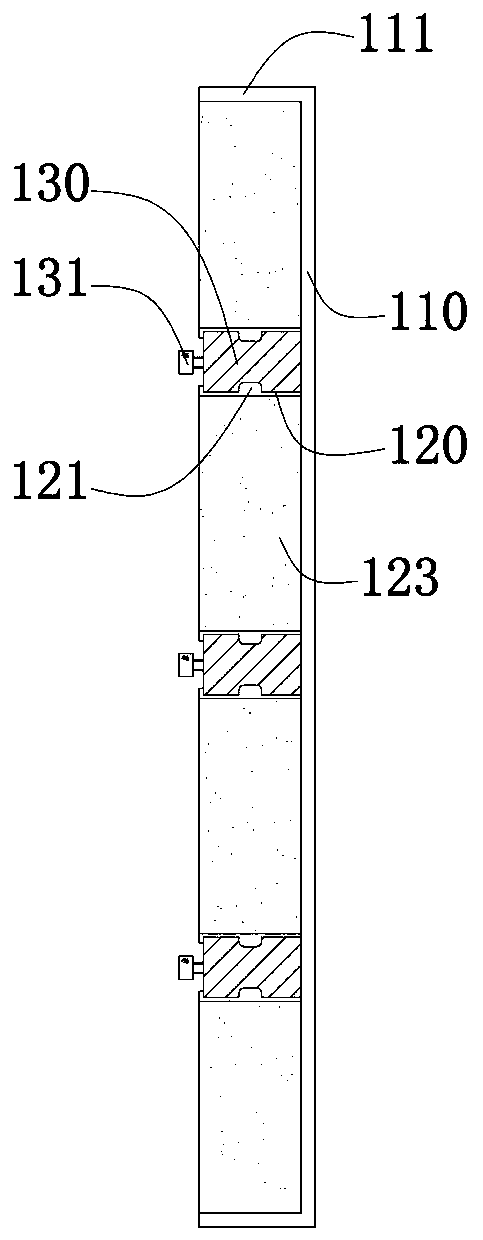

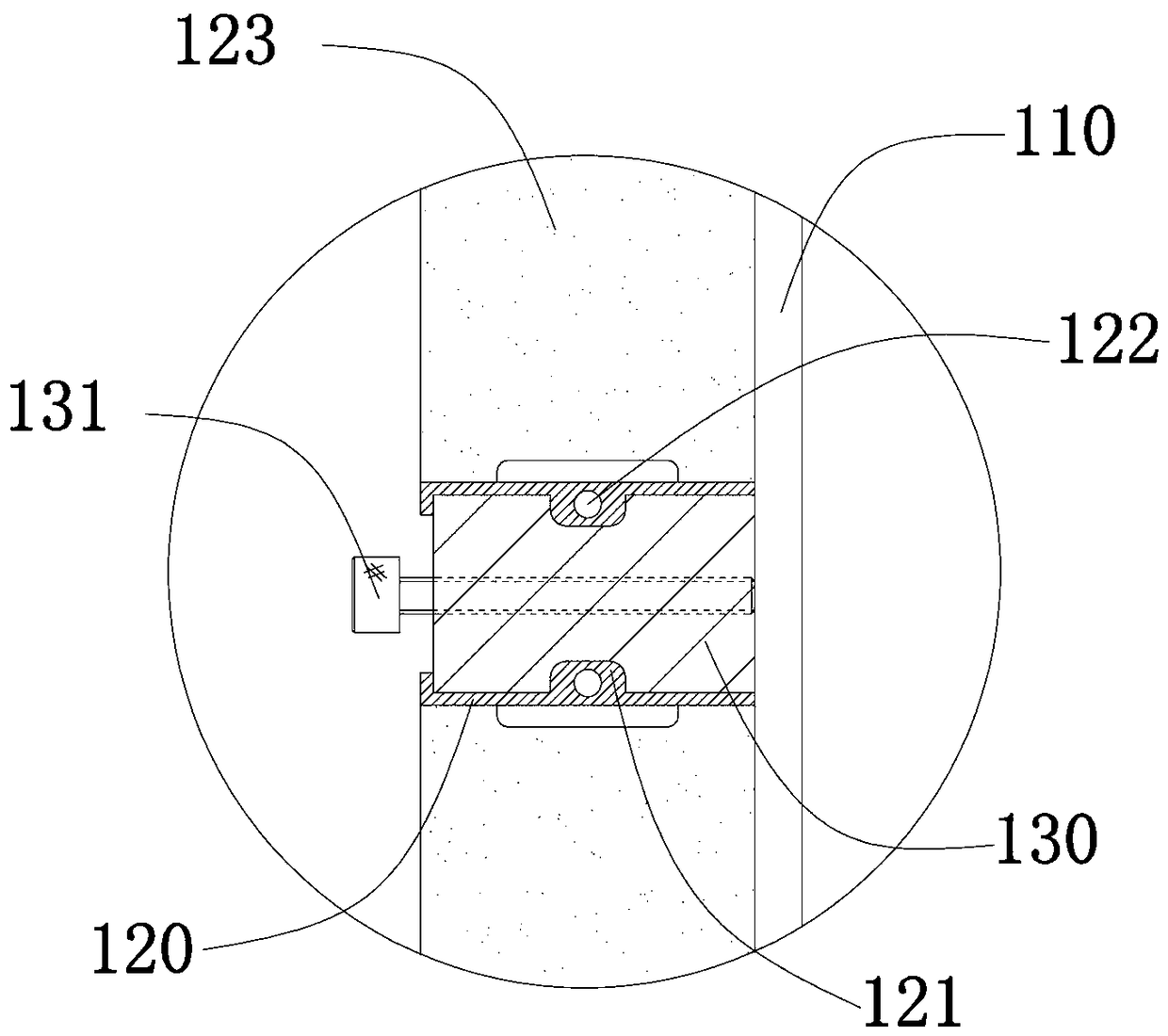

[0035] Embodiment one: see Figure 1-Figure 6 , a quick-dismantling building formwork of the present invention, comprising a panel 110, a ribbed channel beam 120 and butt purlins 130, the ribbed channel beam 120 includes multiple transverse ribbed channel beams and multiple longitudinal ribbed channel beams, and the transverse ribbed channel beams Beams and longitudinal ribbed channel beams are arranged in a cross on the rear side of the panel 110; butt purlins 130 are matched and slide-fitted in the ribbed channel beams 120, and locking pieces 131 are arranged between the butt joint purlins 130 and the ribbed channel beams 120 , when the butt purlin 130 is moved into place, the butt purlin is locked by the locking member 131 , and the locking member 131 in this embodiment is a locking bolt arranged on the butt purlin 130 .

[0036] In the actual building construction process, there are combined assembly of flat molds, female corner molds and male corner molds, so the butt pur...

Embodiment 2

[0042] Embodiment two: see Figure 1-Figure 8 , a light-weight cast-in-place wall construction method of the present invention uses the quick-release building formwork of the above-mentioned embodiment to carry out the construction of a light-weight cast-in-place wall, comprising the following steps: aligning and assembling the formwork, adjusting butt purlins for connection and fixing, and The butt purlins are locked and fixed by the locking parts; the air bag mesh is flattened in the middle of the two rows of formwork, and the air bag mesh includes uniformly arranged air bags and ribs connecting adjacent air bags; wall pouring is performed in the middle of the formwork.

[0043] In order to improve the waterproof performance of the bottom of the wall, a waterproof pouring wall 500 is poured at the bottom, such as waterproof gypsum or waterproof foamed concrete, when pouring a non-load-bearing wall, when pouring to the top, add expansion agent mixed pouring material , so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com