Production process of light load-bearing multifunctional plate

A production process and multi-functional technology, applied in the direction of building components, buildings, building structures, etc., can solve the problems of environmental pollution, waste formwork cannot be fully utilized, etc., and achieve good earthquake resistance, superior fire resistance, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

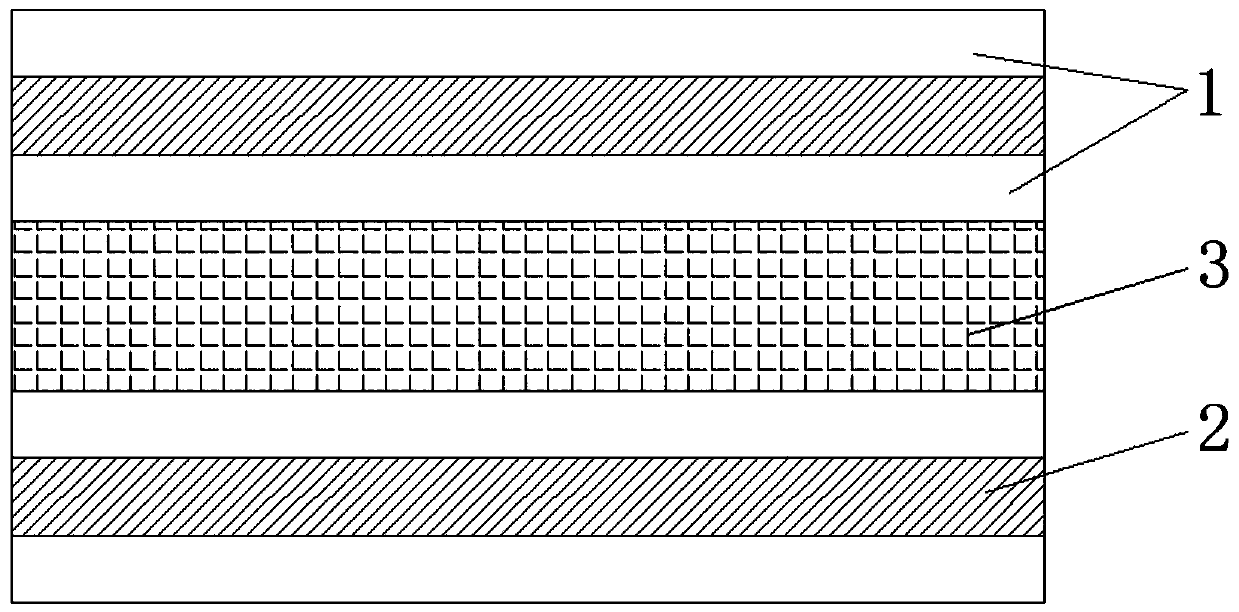

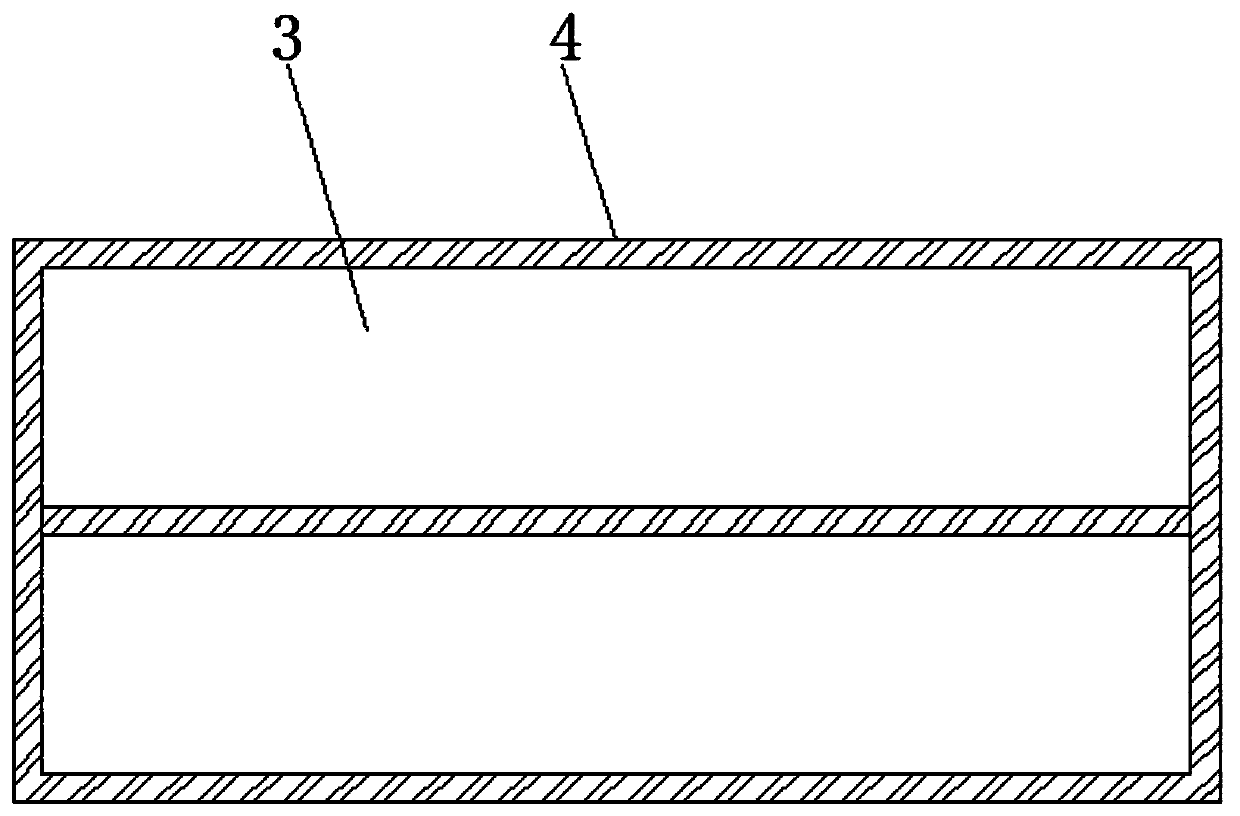

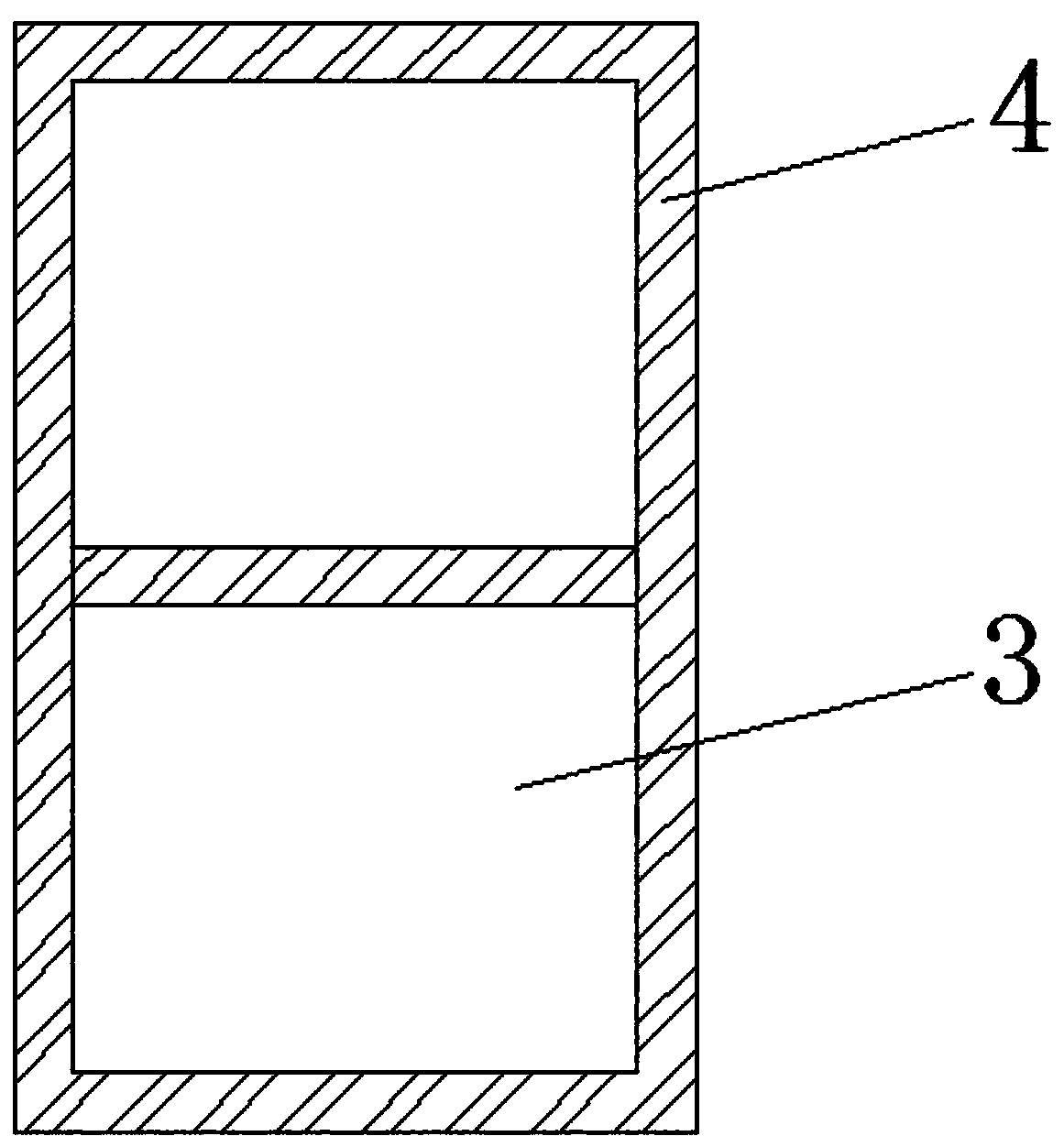

[0021] The present invention provides such Figure 1~4 The production process of a light-weight load-bearing multifunctional plate includes a multifunctional plate, and the multifunctional plate includes a group of composite veneers 4 and insulation layers 3, and the composite veneer 4 is arranged in a rectangular shape frame structure, and a partition layer of the same material is arranged in the middle of the rectangular frame structure. Plate 4 is fixedly connected.

[0022] Specifically, the composite sheet includes a wooden board 2 arranged in the middle and an adhesive 1 arranged at the upper and lower ends of the wooden board 2 , and the wooden board 2 is bonded and fixed to the upper and lower ends of the adhesive 1 .

[0023] Specifically, the wooden board 2 can also be a bamboo board, and the wooden board 2 is a cuboid plate-shaped structure, wherein the thickness of the wooden board 2 is 1 cm or 1.5 cm, the width is 4 cm, and the length dimensions include 1 meter, ...

Embodiment 2

[0030] The present invention provides such Figure 1~4 The production process of a light-weight load-bearing multifunctional plate includes a multifunctional plate, and the multifunctional plate includes a group of composite veneers 4 and insulation layers 3, and the composite veneer 4 is arranged in a rectangular shape frame structure, and a partition layer of the same material is arranged in the middle of the rectangular frame structure. Plate 4 is fixedly connected.

[0031] Specifically, the composite sheet includes a wooden board 2 arranged in the middle and an adhesive 1 arranged at the upper and lower ends of the wooden board 2 , and the wooden board 2 is bonded and fixed to the upper and lower ends of the adhesive 1 .

[0032] Specifically, the wooden board 2 can also be a bamboo board, and the wooden board 2 is a cuboid plate-shaped structure, wherein the thickness of the wooden board 2 is 1 cm or 1.5 cm, the width is 4 cm, and the length dimensions include 1 meter, ...

Embodiment 3

[0039] The present invention provides such Figure 1~4 The production process of a light-weight load-bearing multifunctional plate includes a multifunctional plate, and the multifunctional plate includes a group of composite veneers 4 and insulation layers 3, and the composite veneer 4 is arranged in a rectangular shape frame structure, and a partition layer of the same material is arranged in the middle of the rectangular frame structure. Plate 4 is fixedly connected.

[0040] Specifically, the composite sheet includes a wooden board 2 arranged in the middle and an adhesive 1 arranged at the upper and lower ends of the wooden board 2 , and the wooden board 2 is bonded and fixed to the upper and lower ends of the adhesive 1 .

[0041]Specifically, the wooden board 2 can also be a bamboo board, and the wooden board 2 is a cuboid plate-shaped structure, wherein the thickness of the wooden board 2 is 1 cm or 1.5 cm, the width is 4 cm, and the length dimensions include 1 meter, 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com