Preparation method of high-strength XPS (extruded polystyrene) thermal insulation board

An insulation board and high-strength technology, which is applied in the field of preparation of high-strength XPS extruded insulation board, can solve the problems of increased bulk weight and decreased foaming ratio of XPS extruded insulation board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

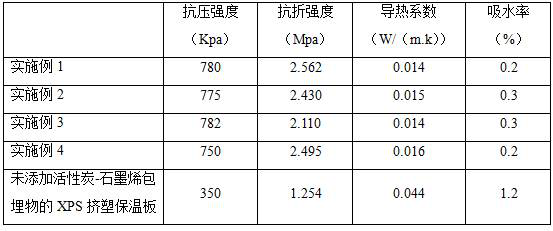

Examples

Embodiment 1

[0022] A preparation method of high-strength XPS extruded plastic insulation board, specifically the following steps:

[0023] Step 1: Prepare polystyrene raw materials: crush polystyrene to below 100 mesh, extrude and granulate with thermal crosslinking agent through a twin-screw extruder to obtain polystyrene masterbatch; each part of the twin-screw extruder The segment extrusion temperatures were 165°C, 175°C, and 185°C, respectively.

[0024] Step 2: Prepare activated carbon-graphene embeddings: weigh 5% tungsten carbide, 10% graphene powder, and the rest are activated carbon powder, and dry tungsten carbide and graphene powder together for 2 hours, Then add activated carbon and continue ball milling for 20 minutes to obtain a ball milling mixture; the speed of ball milling is 240-300r / min.

[0025] Add the ball mill mixture to water 5 times its mass, adjust the pH to 8 with sodium bicarbonate, perform ultrasonic treatment under stirring, and centrifugally filter the solu...

Embodiment 2

[0030] A preparation method of a high-strength XPS extruded insulation board. The main steps are the same as those in Example 1, except that a flame retardant with a mass percentage of 1% is added to the raw materials in Step 3.

Embodiment 3

[0032] A preparation method of high-strength XPS extruded insulation board, the main steps are the same as in Example 1, the difference is that 25% hydroxymethyl silicone oil is added in the activated carbon-graphene embedding prepared in step 2 , and then mixed with polystyrene masterbatch to prepare XPS extruded insulation board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com