Patents

Literature

43 results about "ECTFE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ECTFE (ethylene chlorotrifluoroethylene) was designed to provide chemical resistance in heavy duty corrosion applications. It is a partially fluorinated polymer (a fluoropolymer), semi-crystalline and can be processed in the melt. Chemically it is a copolymer of ethylene and chlorotrifluoroethylene. It is marketed under the brand name Halar ECTFE by Solvay Specialty Polymers, a subsidiary of Solvay.

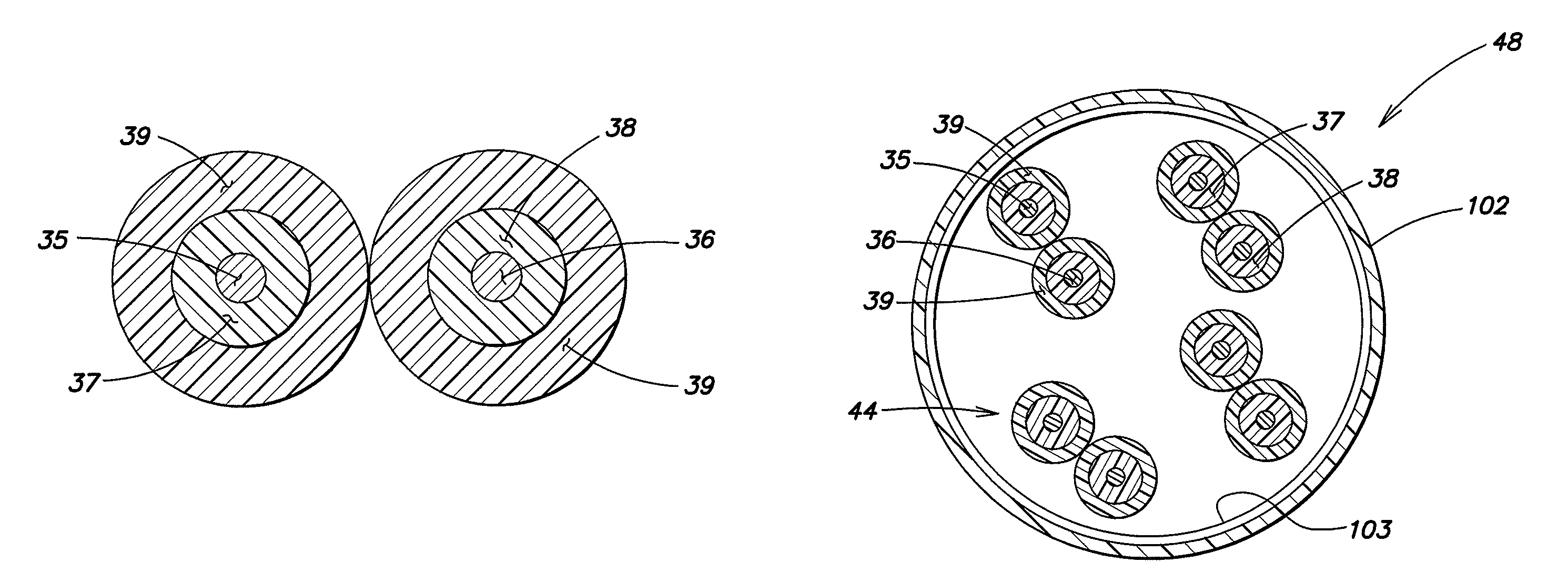

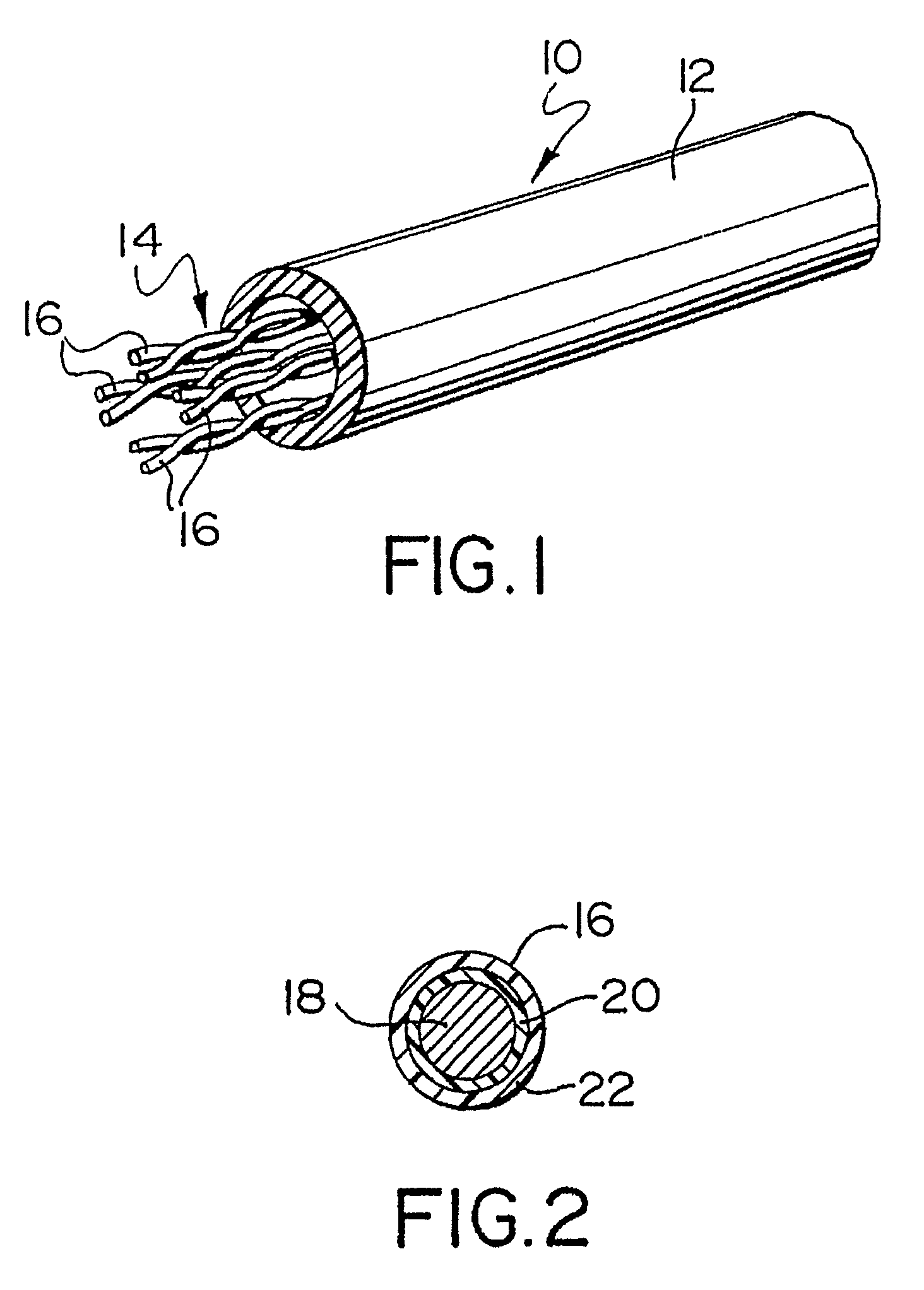

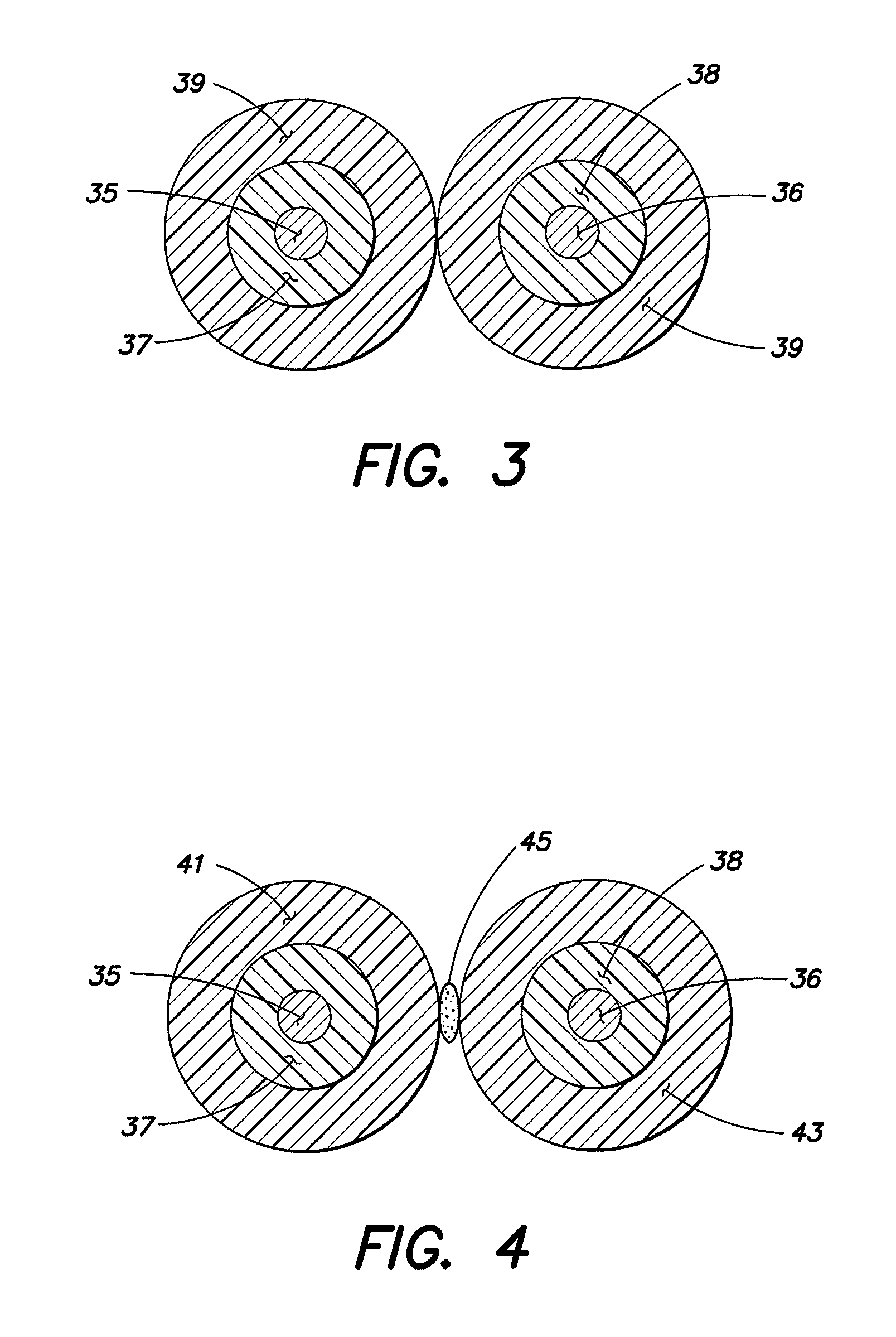

Telecommunications cable

ActiveUS7696437B2Suppress generationDampens spreadPlastic/resin/waxes insulatorsEmergency protective circuit arrangementsElectrical conductorPolyolefin

A telecommunications cable having a cable core in which each conductor is surrounded by an individual dual layer insulation of an inner layer of flame retardant polyolefin and an outer layer of another material, for example, fluorinated ethylene propylene, MFA, PVDF, ECTFE, PTFE, or foamed PFA.

Owner:BELDEN TECHNOLOGY INC

ECTFE surfaces modified by fluoro-oxidation and a process therefor

A process for fluoro-oxidation of the surface(s) of an ECTFE substrate, film or three-dimensional object, and the surface-modified substrate, film or object produced thereby. The process includes exposing the surface(s) to concentrations of fluorine and oxygen for a time sufficient to increase the surface energy and thereby lower the surface contact angle sufficiently to permit bonding. The surface modification allows bonding to an adhesive with the adhesive being bondable to a plastic or metal substrate.

Owner:BAUMAN BERNARD D +1

Highly filled unsaturated fluoropolymer compositions for cables

A non-dripping, flame retardant, fluoropolymeric composition comprising: (a) a fluoropolymeric base polymer; (b) at least one char forming agent; and (c) a compatibilizer agent. The fluoropolymeric base polymer is preferably selected from the group consisting of PVDF (polyvinylidene fluoride), ECTFE, poly-ethylene chlorotrifluoroethylene, and ETFE poly-ethylene tetrafluoroethylene. Such compositions are especially useful for appliance wire, aerospace / military wire, cable raceways, blown fiber tubes, fire alarm cables, circuit integrity cables, fiber optic distribution cables & breakout components, heat tracing cable jacket, stage lighting cable, industrial cable, shipboard cable (military & passenger), shielded cable jackets.

Owner:MEXICHEM AMANCO HLDG DE C V

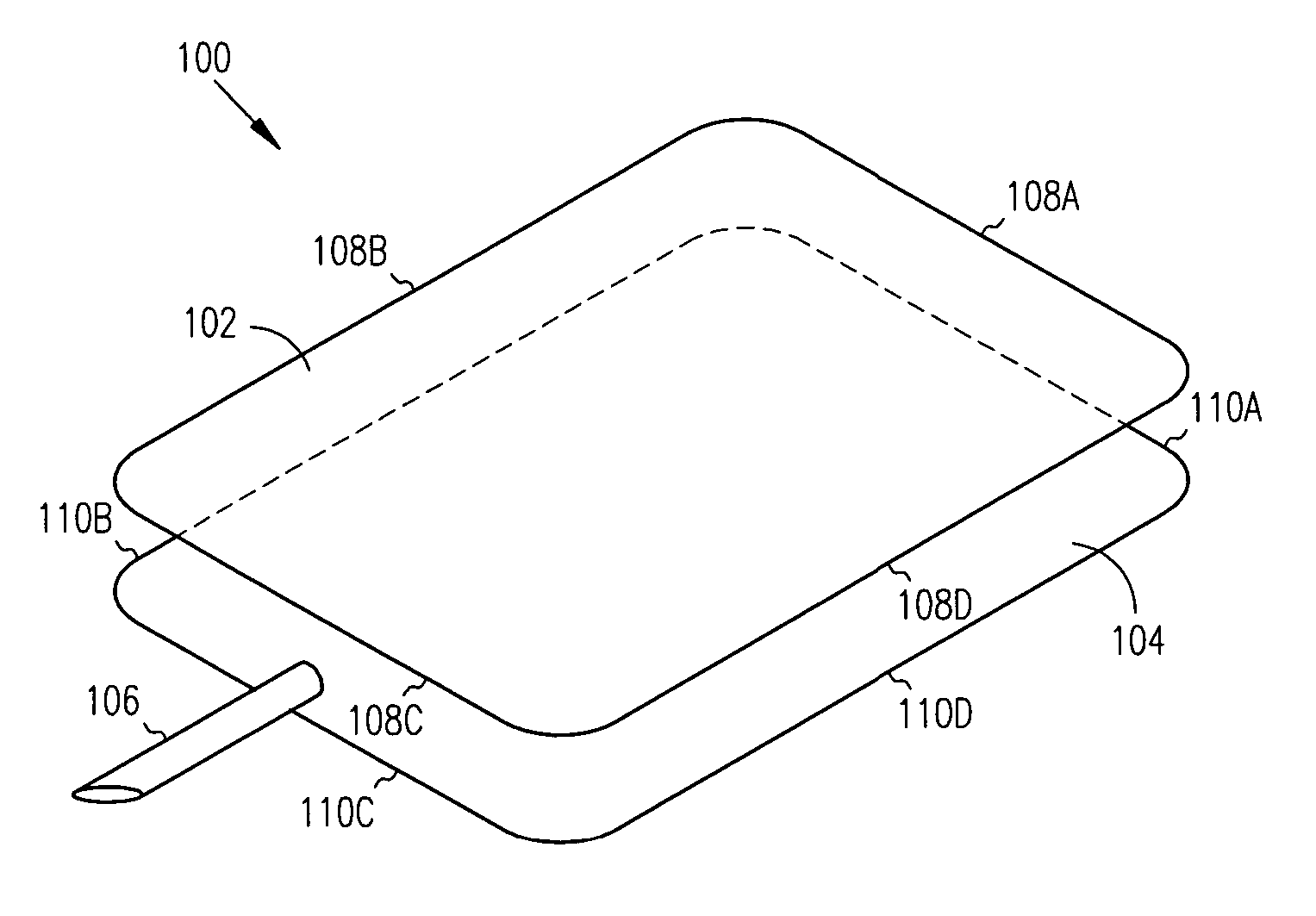

Sterile, pyrogen-free, polymeric film-based heating bag

In one embodiment, there is a method for storing fluids in a bag that has an inner lining that is essentially sterilized and essentially free of pyrogen. The method comprises heating the bag that is comprised of a polymeric film to at least approximately 253° Celsius. The polymeric film includes a polymer selected from the group of poly(oxy-1,4-phenylene-oxy-1,4-phenylene-carbonyl-1,4-phenylene) (PEEK); polytetrafluoroethylene (PTFE); a perfluoroalkoxy (PFA) polymer; poly(tetrafluoroethylene-co-perfluoromethyl vinyl ether) (MFA); polyperfluoro(ethylene-co-propylene) (FEP); poly(ethylene-alt-chlorotrifluoroethylene) (ECTFE); poly(ethylene-co-tetrafluoroethylene) (ETFE); poly(vinylidene fluoride) (PDVF); tetrafluoroethylene-co-hexafluoropropylene-co-vinylidene fluoride terpolymer (THV); ultra-high molecular weight polyethylene (UHMW PE); (poly(bisphenol A-co-4-nitrophthalic anhydride-co-1,3-phenylenediamine) (PEI); poly(4-methyl-1-pentene) (PMP); and suitable mixtures thereof.

Owner:ADVANCED TECH MATERIALS INC +1

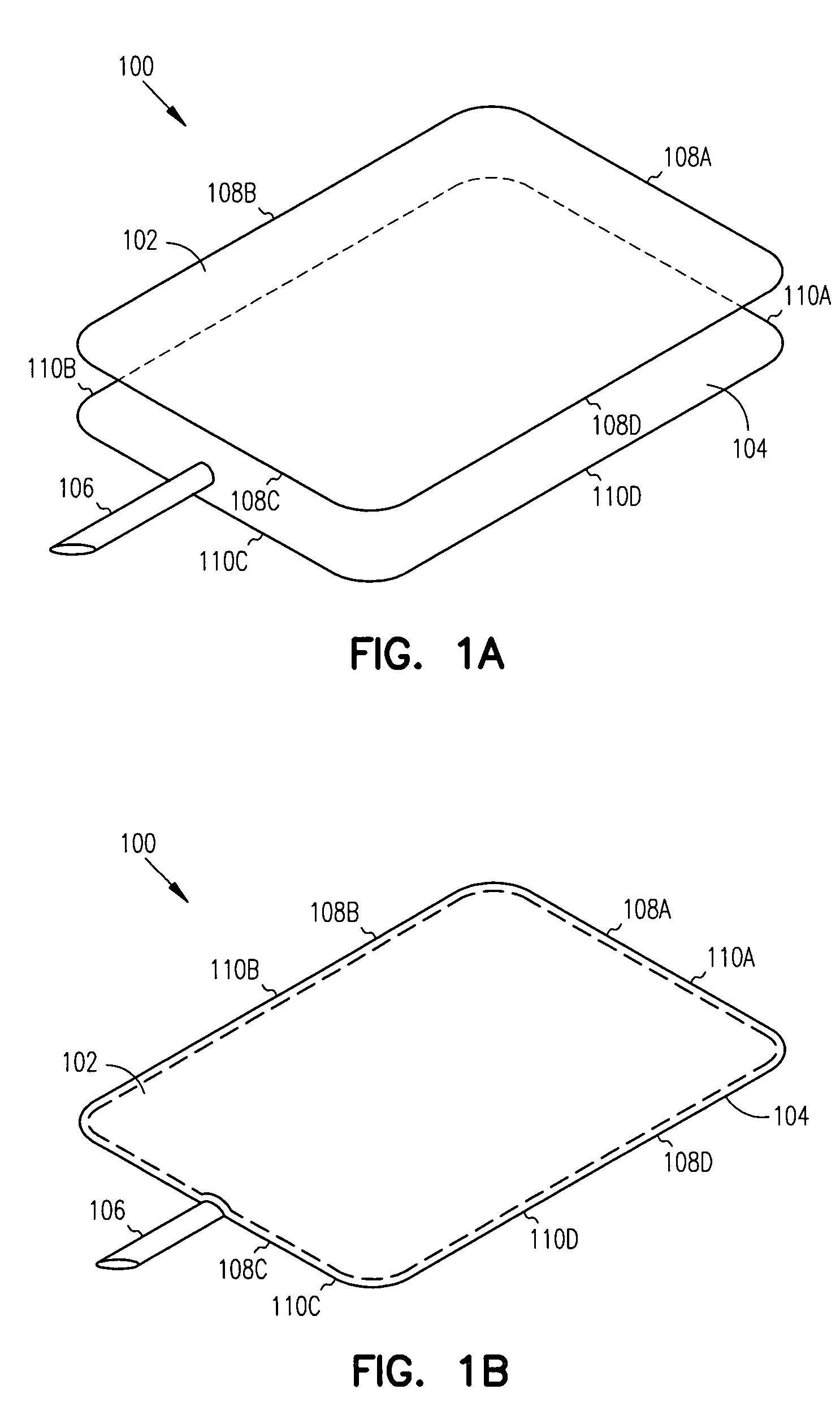

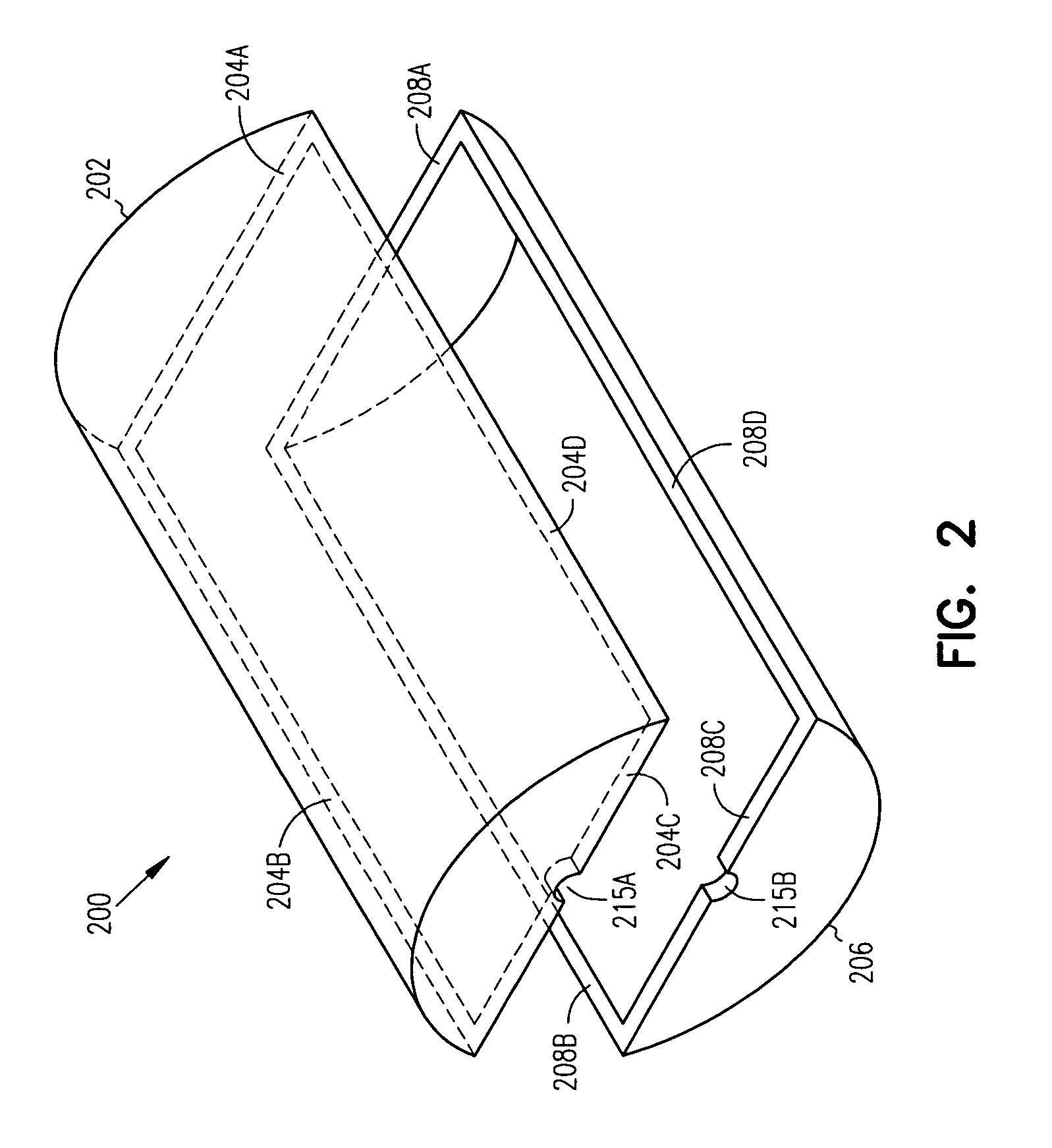

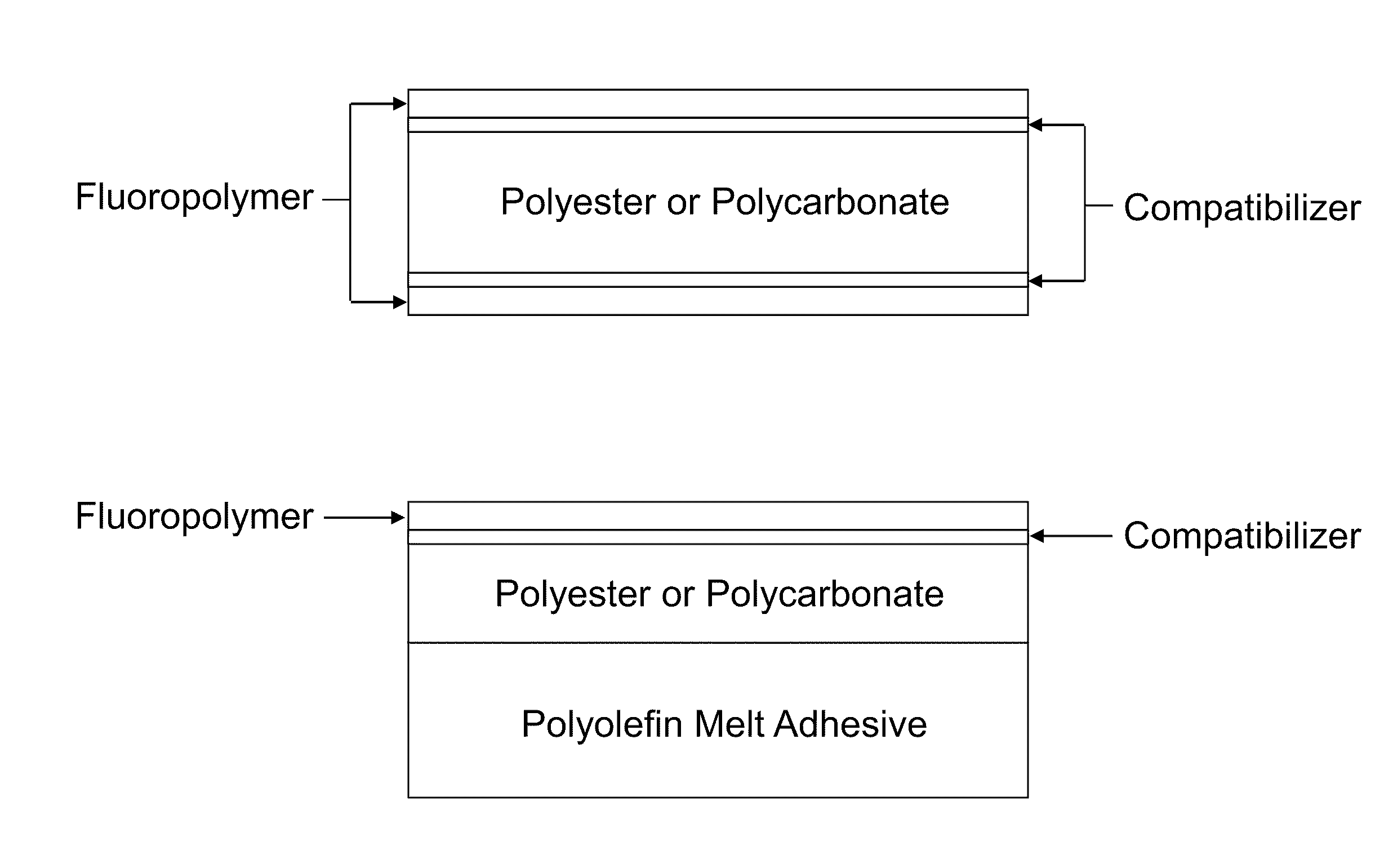

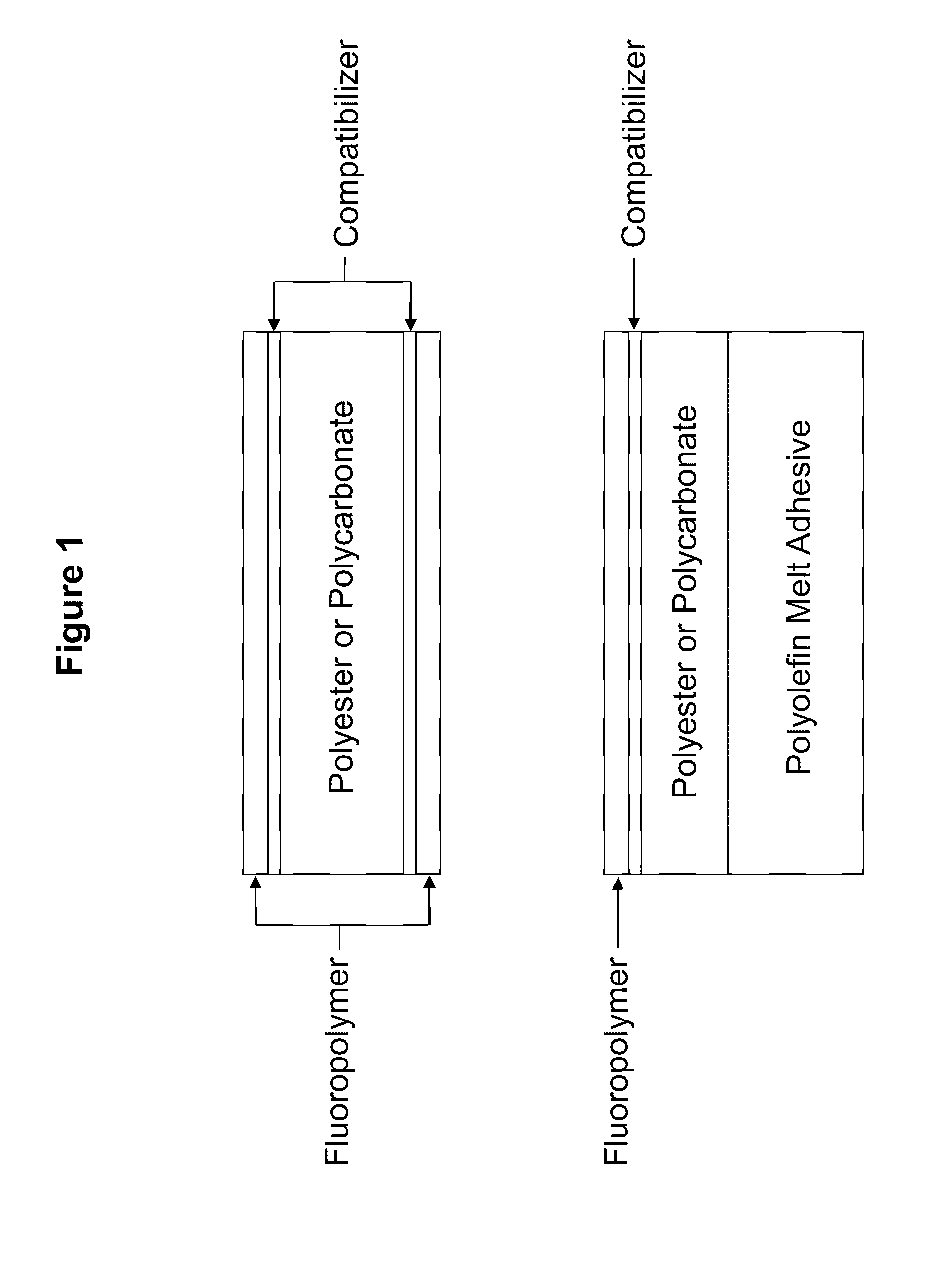

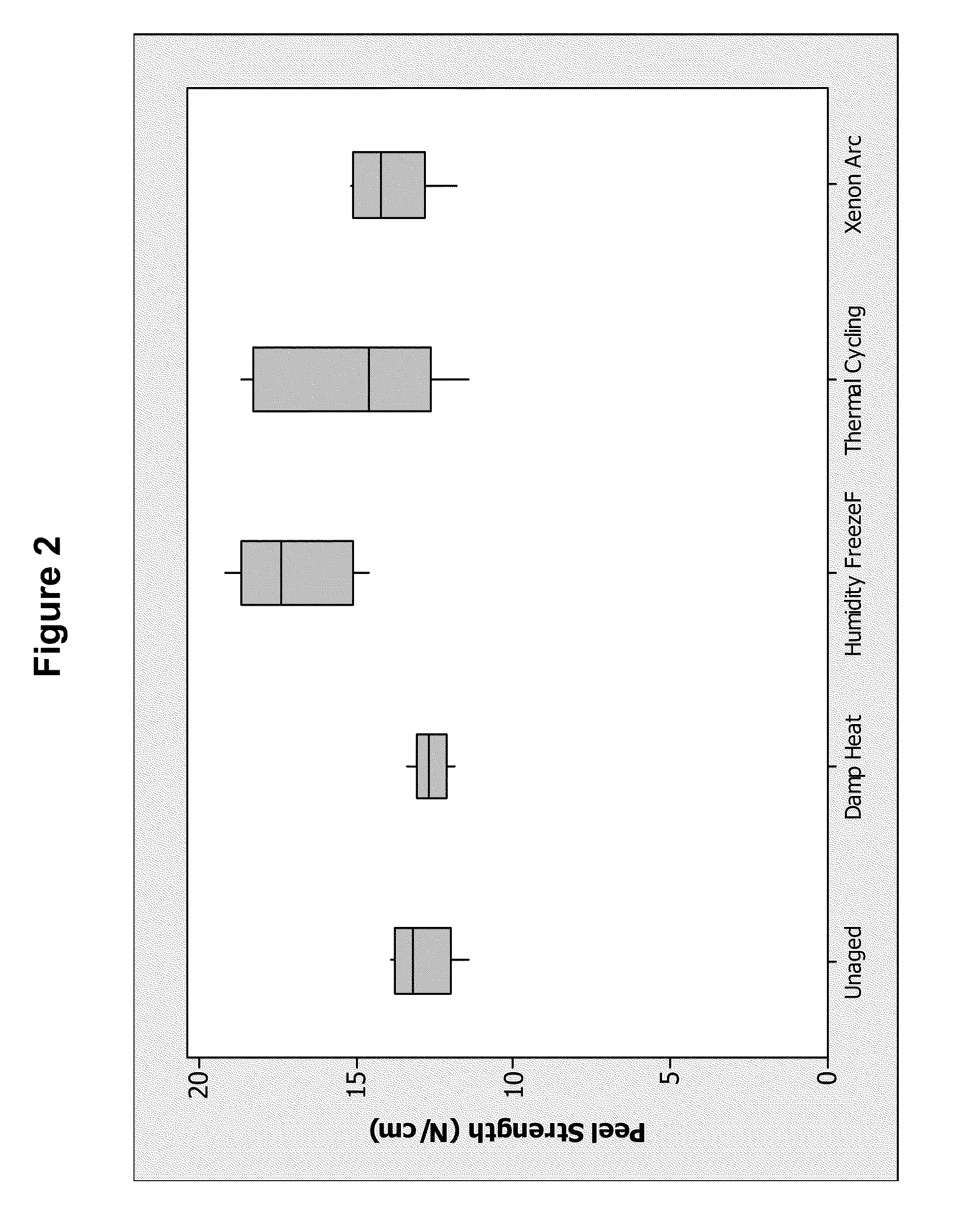

Adhesion in ectfe/polyester co-extruded structures using tie layers

InactiveUS20110244241A1Overcome disadvantagesLow costSynthetic resin layered productsLaminationPolyesterFluoropolymer

The invention describes coextruded multi-layer films comprising a first fluoropolymer layer; a second layer comprising a glycidyl acrylate or glycidyl methacrylate or mixtures thereof adhered to the first layer; and a third layer comprising a polyester or polycarbonate adhered to the second layer.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

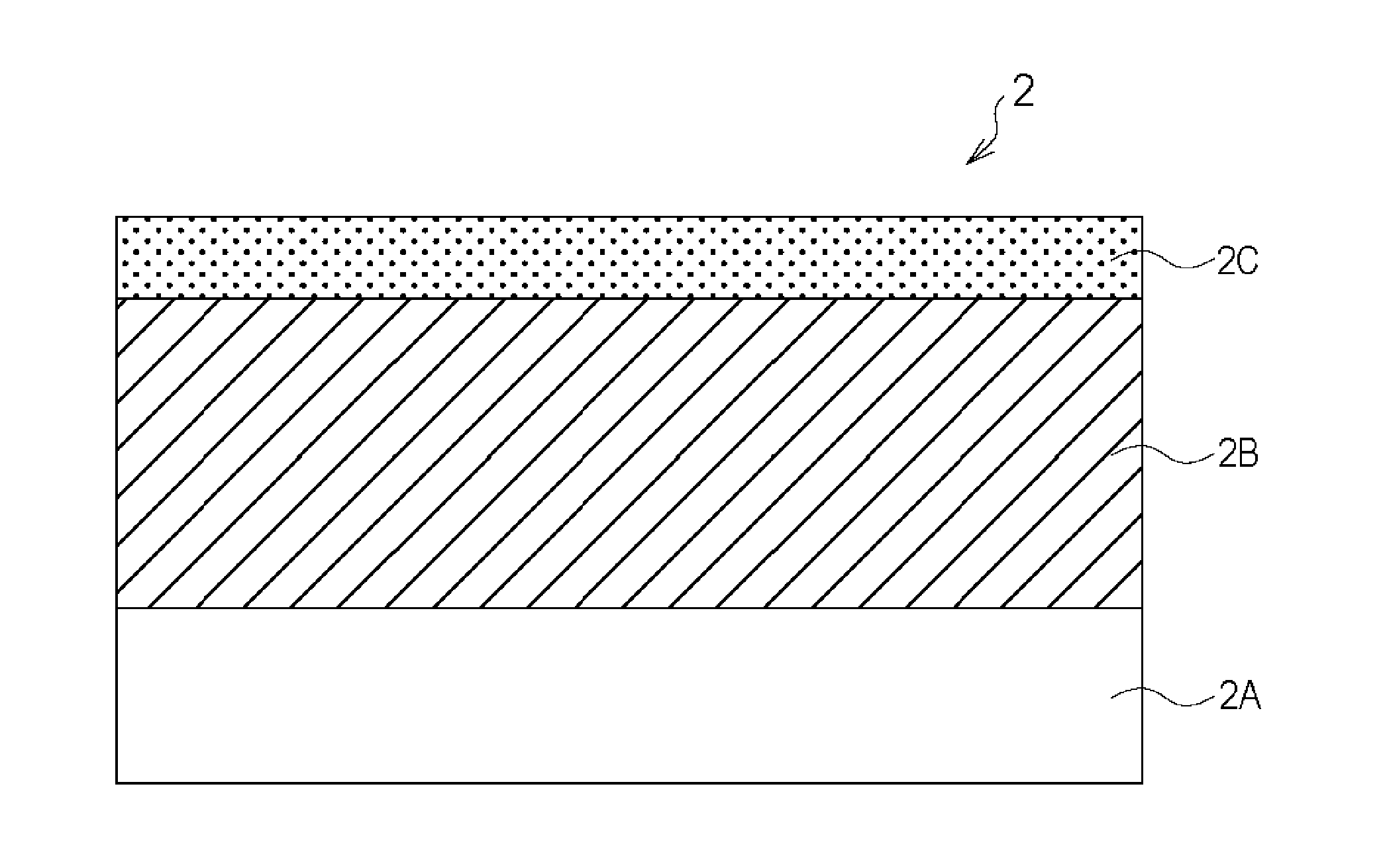

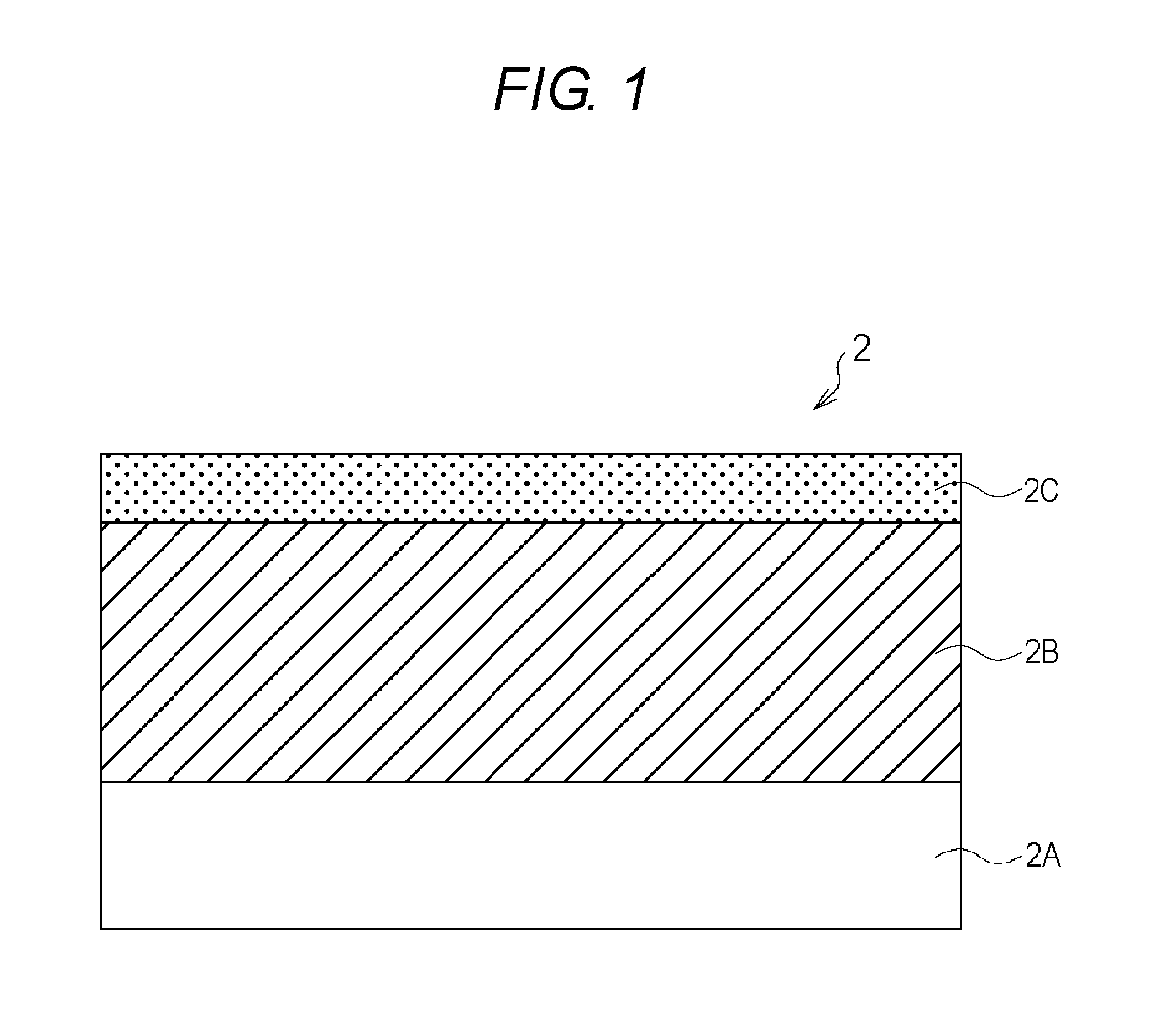

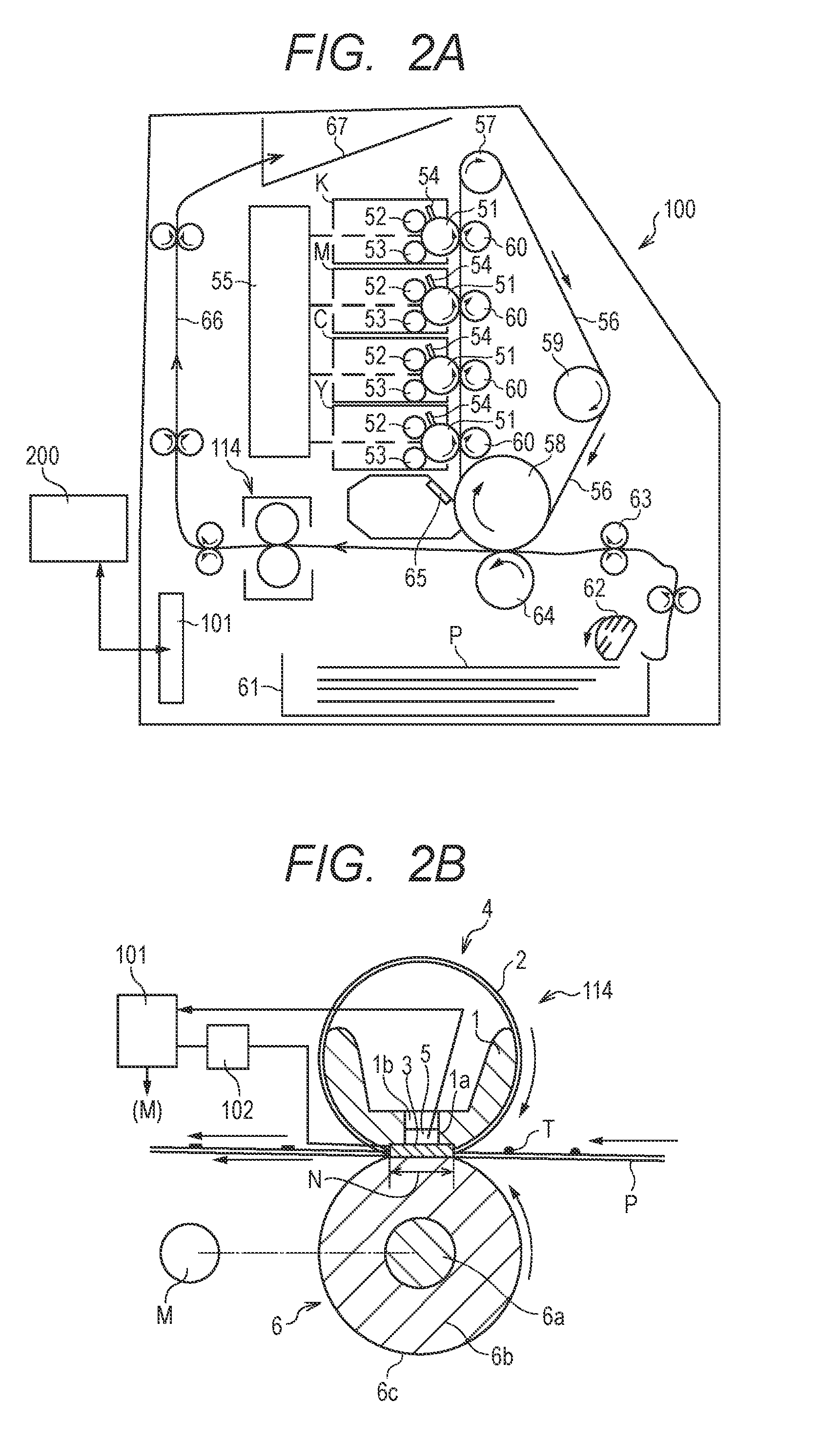

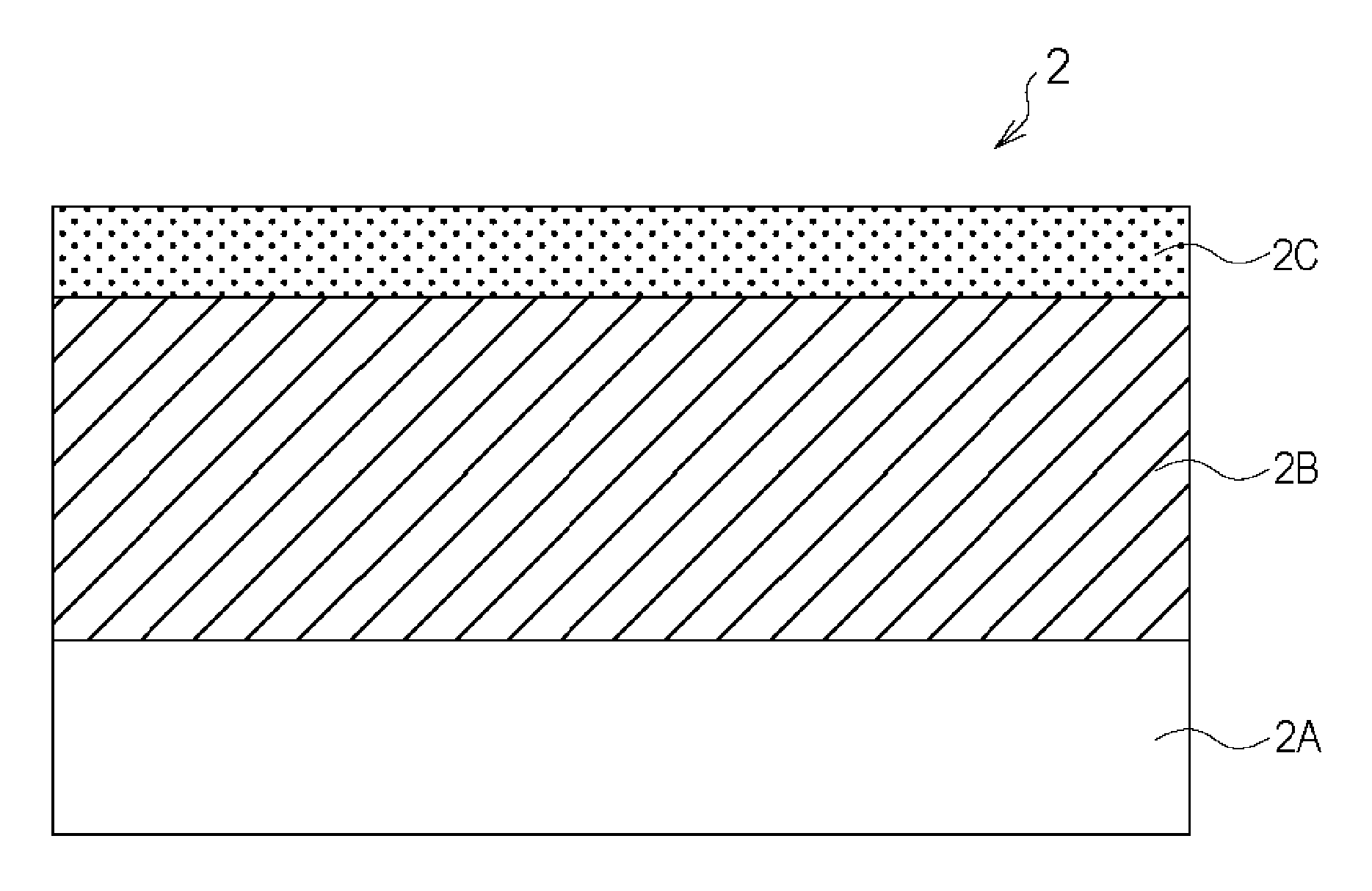

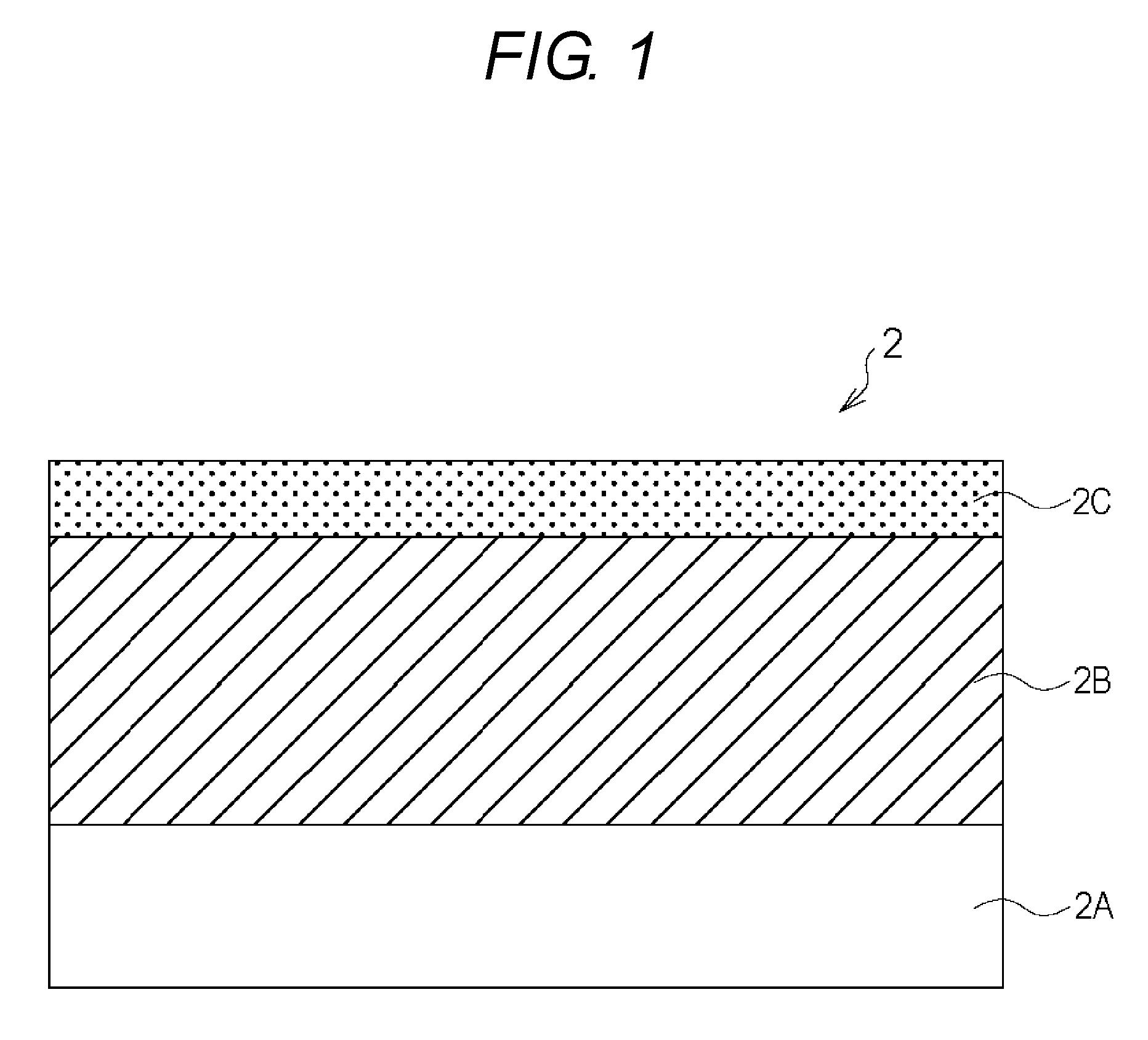

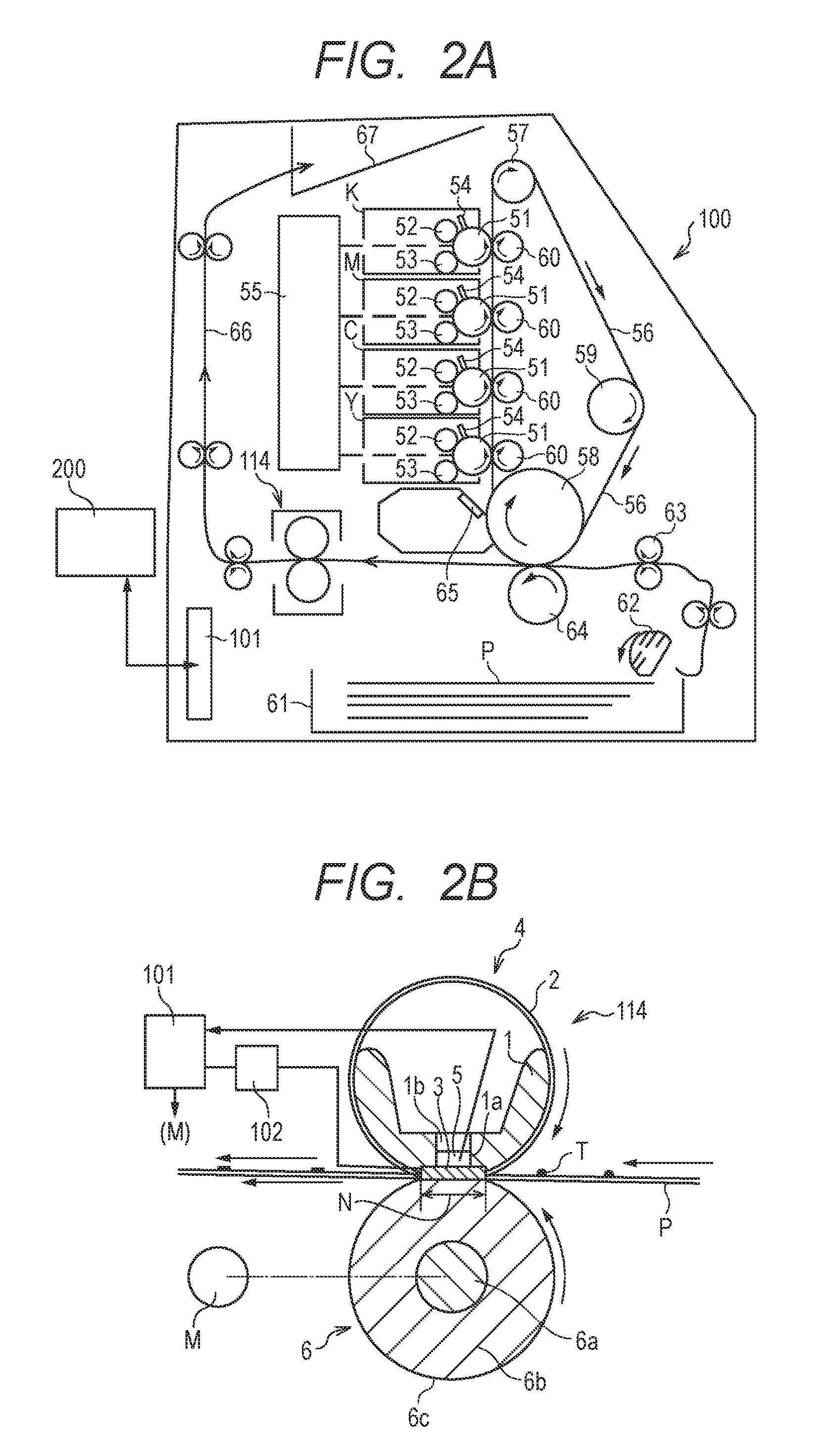

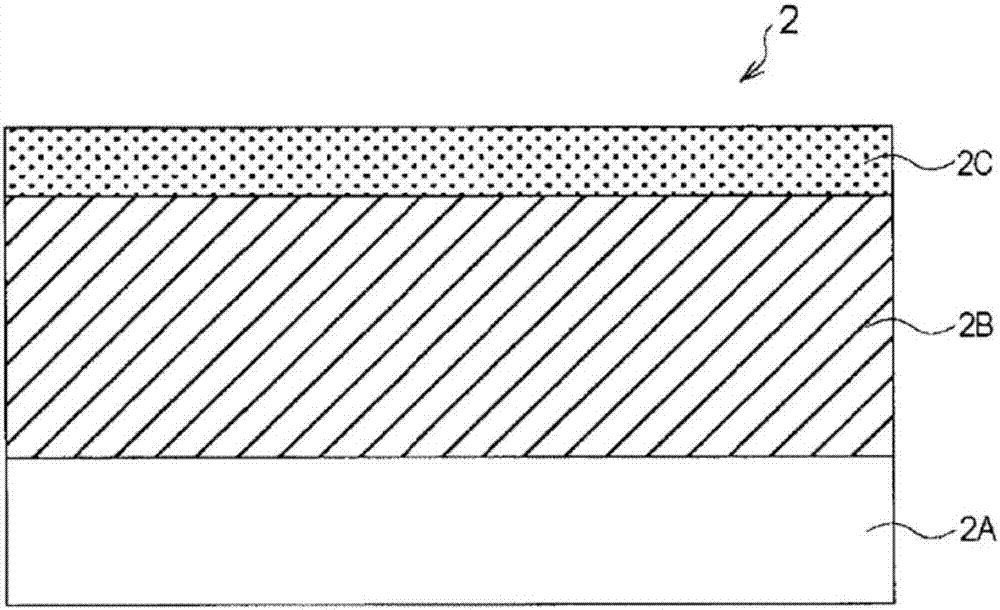

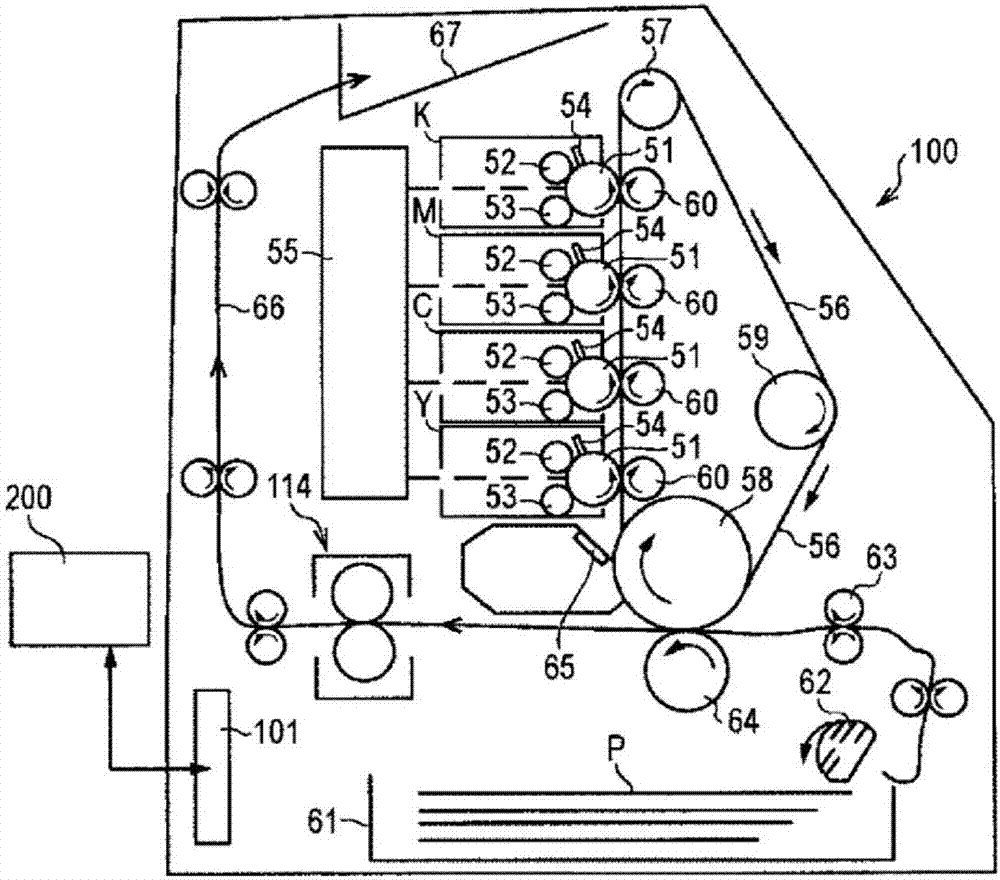

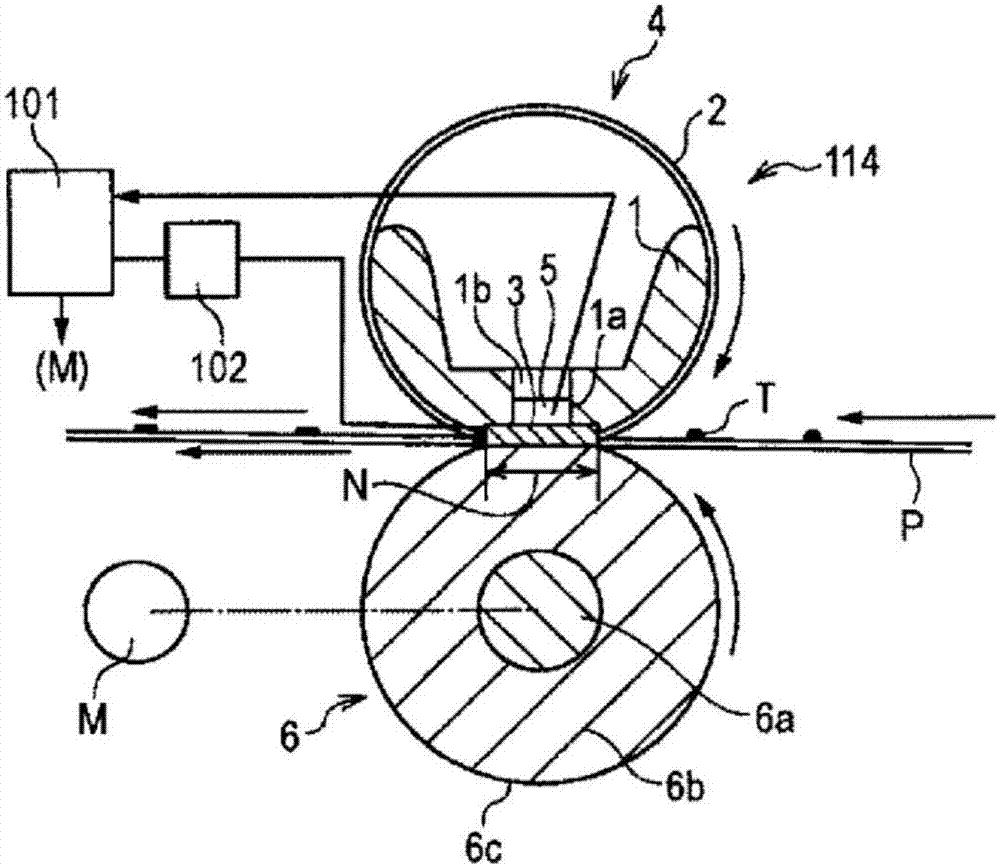

Member for electrophotography, image heating apparatus, image forming apparatus, and method for manufacturing member for electrophotography

ActiveUS20160091841A1Improve thermal conductivityIncrease printing speedLamination ancillary operationsLayered product treatmentEngineeringUltimate tensile strength

Provided is a member for electrophotography, where an elastic layer including a silicone rubber and a release layer including a fluorine resin are bonded sufficiently without any adhesive layer interposed therebetween.The member for electrophotography includes a substrate; an elastic layer including a silicone rubber, on the substrate; and a release layer provided in direct contact with the surface of the elastic layer, where the release layer includes a fluorine resin selected from the group consisting of PFA, FEP, PTFE, ETFE, PCTFE, ECTFE, and PVDF, and the elastic layer undergoes a cohesive failure when the release layer is peeled from the elastic layer in accordance with “Determination of peel strength of bonded assemblies. Part 1: 90 degree peel” specified by the Japanese Industrial Standards (JIS) K 6854-1:1999.

Owner:CANON KK

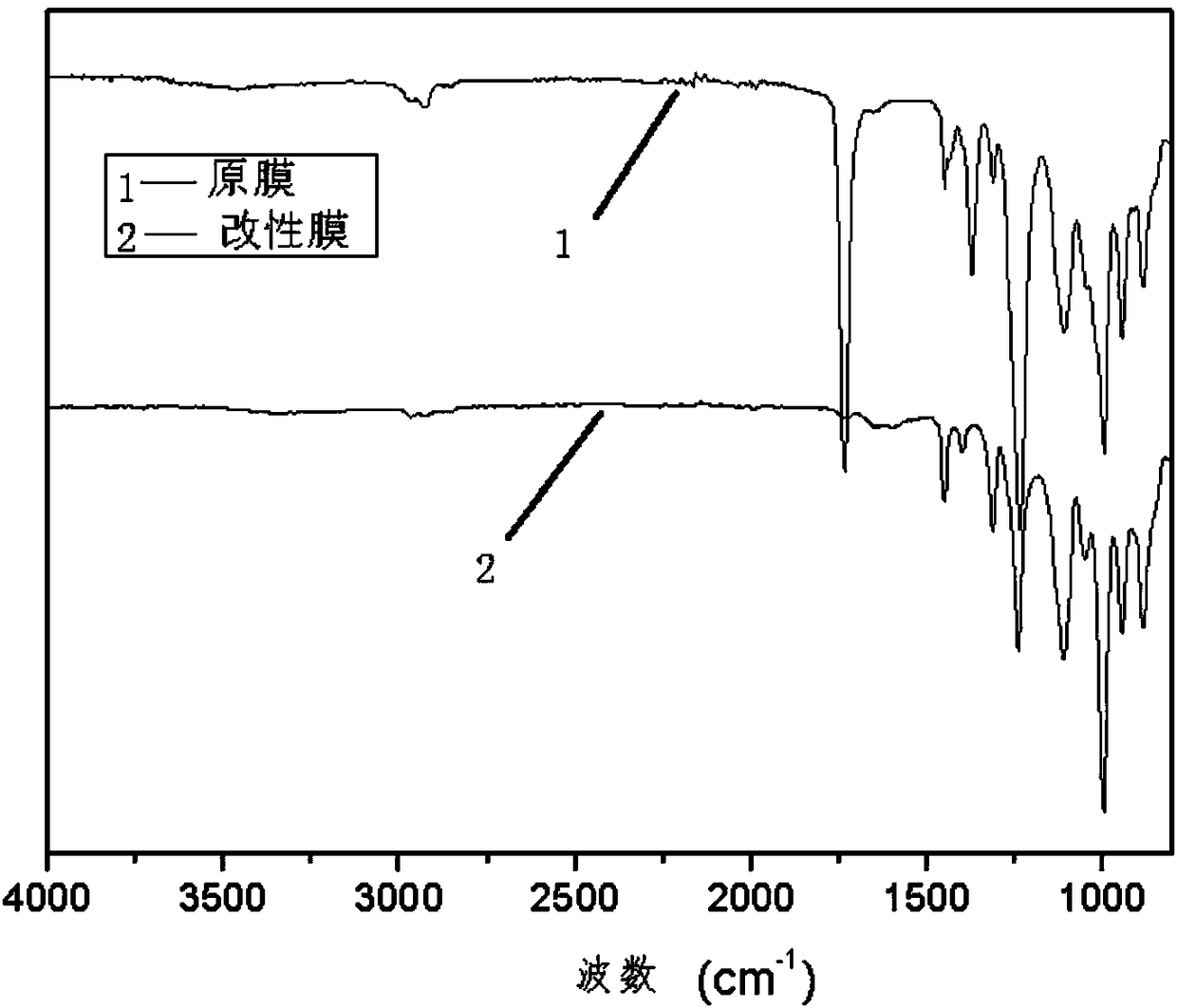

Hollow fiber polymer membrane, preparation method of hollow fiber polymer membrane and application of hollow fiber polymer membrane to brine refining

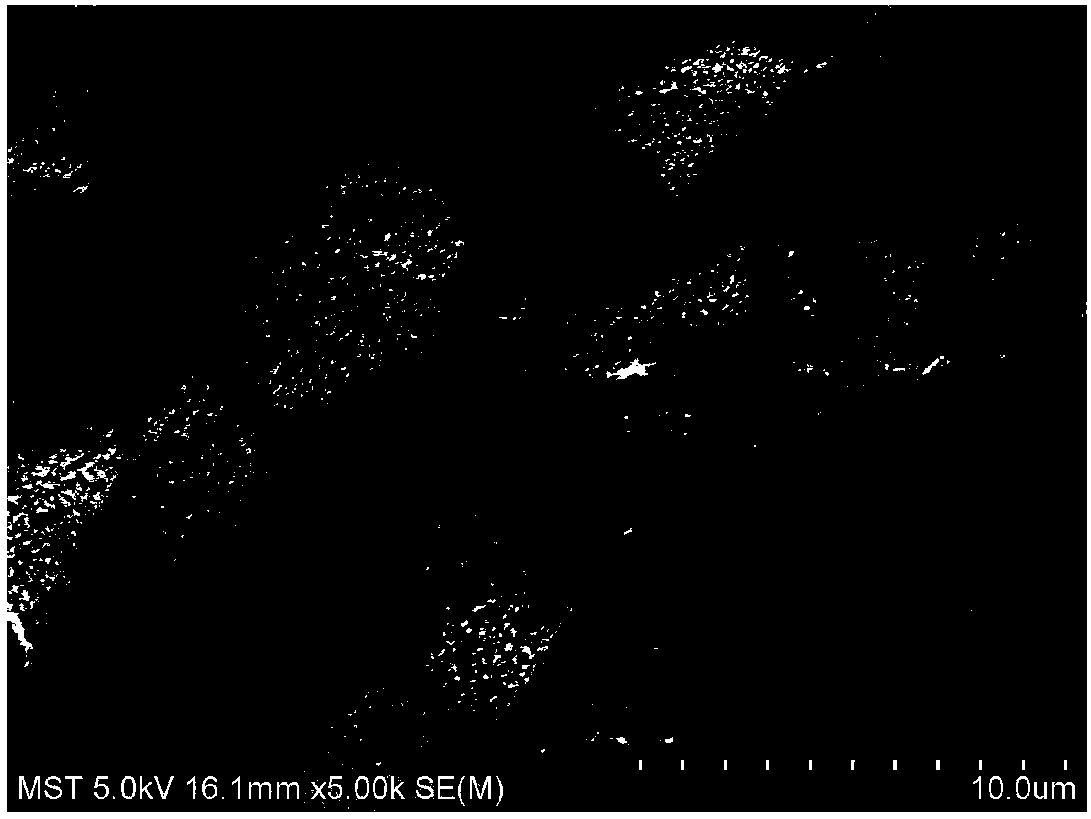

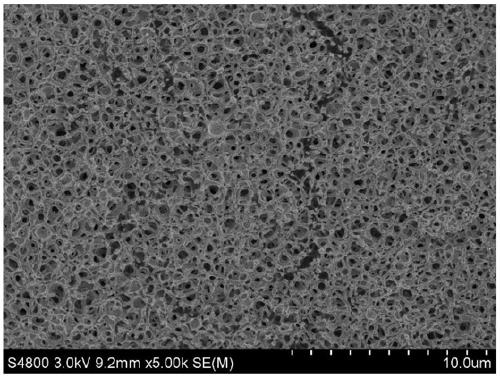

ActiveCN108479414AGood anti-pollutionIncreased osmotic fluxMembranesSemi-permeable membranesPolymer scienceSolvent

The invention provides a preparation method of a hollow fiber polymer membrane, particularly relates to a membrane filter using the membrane in the process field of brine refining, and belongs to thefield of polymer separation membrane preparation. ECTFE (ethylene-chlorotrifluoroethylene copolymer) is used as a membrane material for preparing the hollow fiber membrane; the hollow fiber membrane is applied to a brine refining process. The average pore diameter of the prepared hollow fiber membrane is 150 to 220nm; the tensile strength is 2.5 to 4.7MPa; the pure water flux at 25 DEG C is 320 to710L / (m2.h.bar). The ECTFE, a diluent and an inorganic additive are proportionally mixed; heating dissolving is performed; a prepared casting membrane solution is spun into a hollow fiber shape by aspinning machine; then, quenching is performed; the prepared membrane silk is firstly subjected to acid pickling; then, the diluent is extracted by a proper solvent; drying is performed to obtain an ECTFE hollow fiber membrane. The hydrophilicity of the membrane prepared by the method is improved; the tensile strength is high; the pure water flux of the membrane is great; the pore diameter is concentrated; the pollution resistant performance is good; a good application effect is realized in the brine refining process.

Owner:NANJING UNIV OF TECH

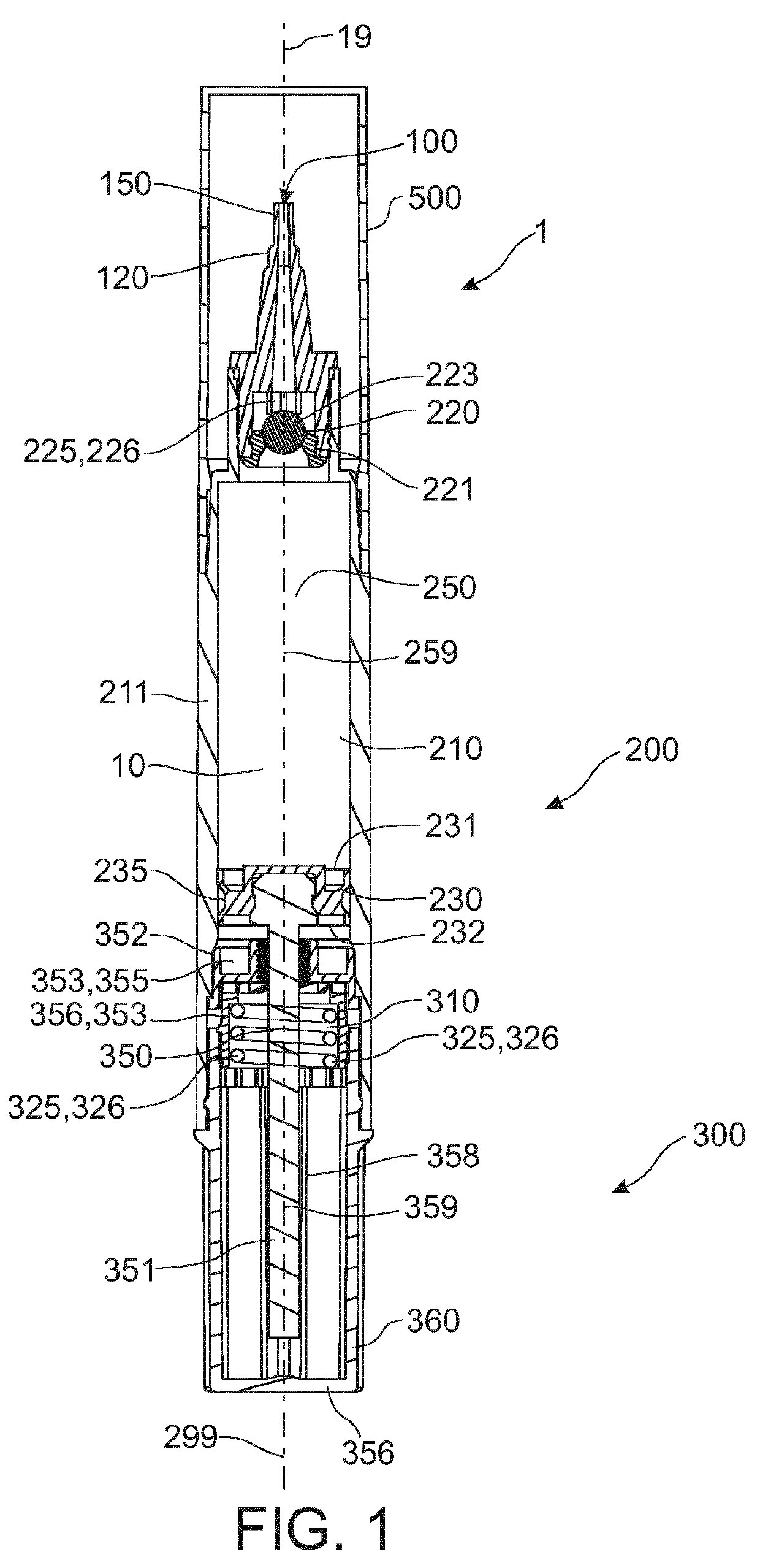

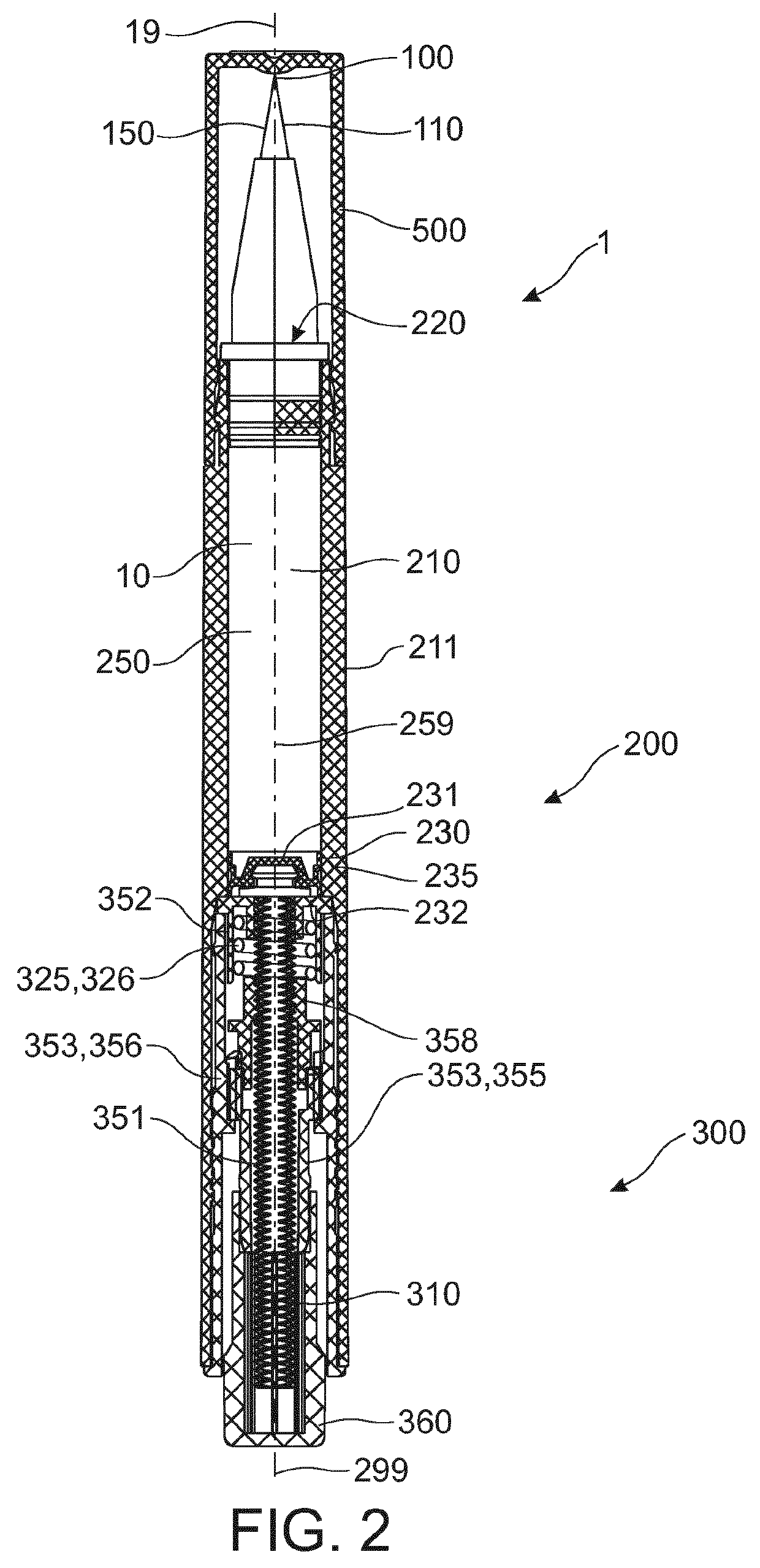

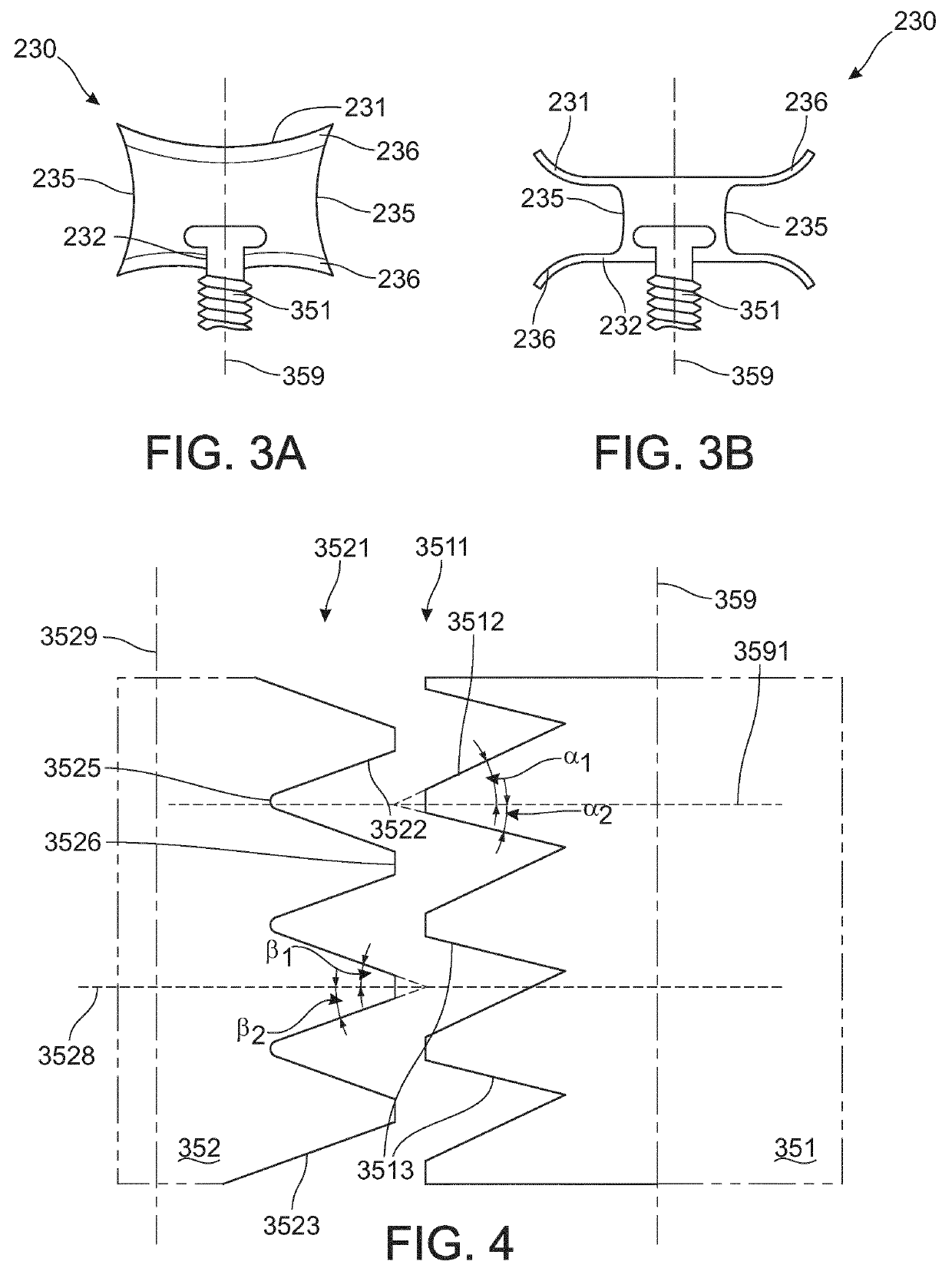

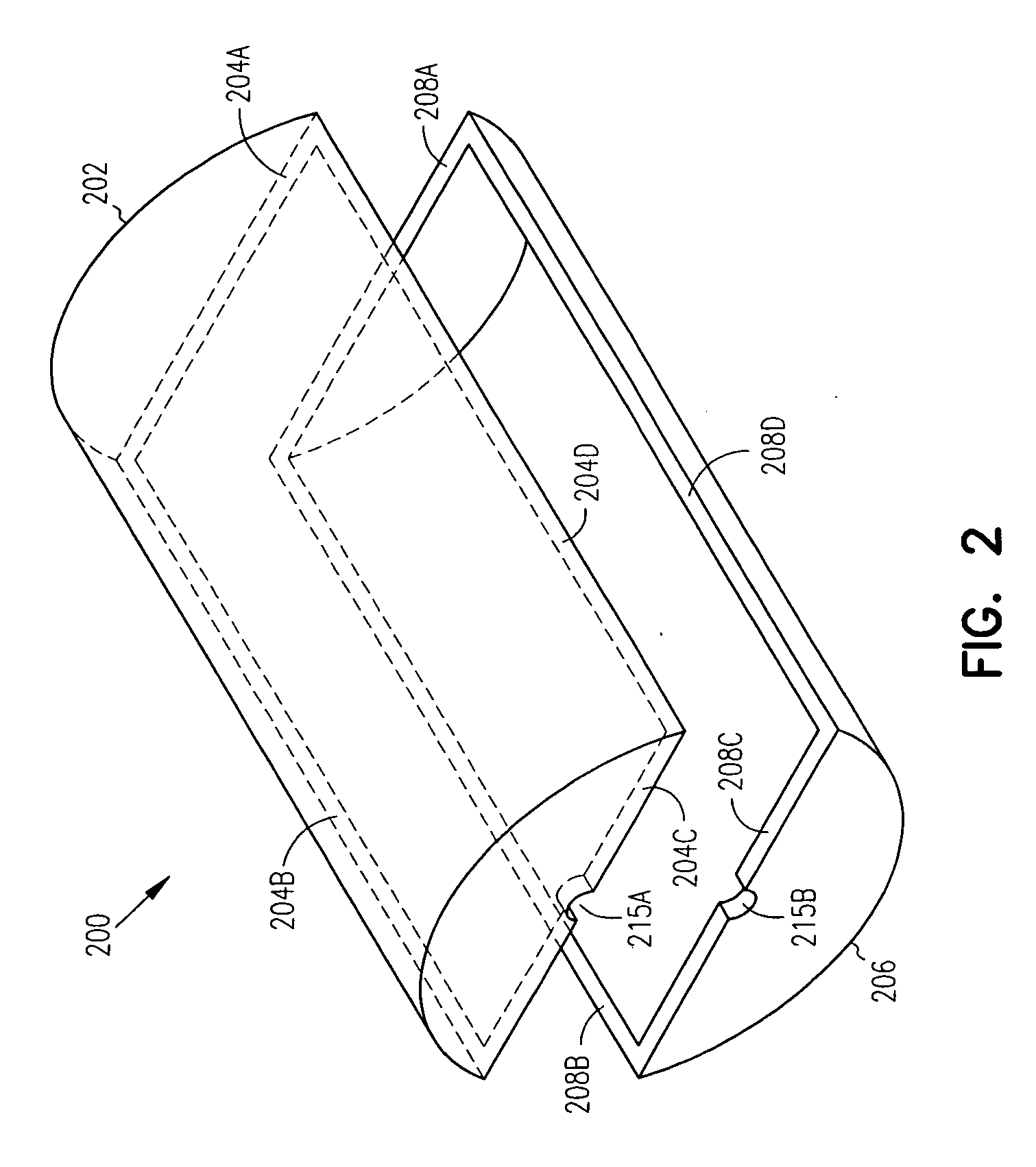

Applicator device

ActiveUS20190255305A1Prevent relapseAvoid it happening againCosmetic preparationsDispensing apparatusPolyoxymethyleneSS - Stainless steel

The invention relates to an applicator device comprising an applicator tip and a container part, wherein the container part comprises: (i) a container comprising a container wall, a valve, and a plunger, wherein the container wall, the valve, and the plunger together define a storage volume for containing a liquid, wherein the plunger comprises a circumferential wall, sealingly contacting the container wall; and (ii) a plunger advance system functionally coupled to the plunger and configured to advance the plunger for reducing the storage volume for expelling at least part of the liquid via said valve to said tip, wherein the plunger advance system is arranged outside the storage volume; wherein (a) the valve comprises a first spring system comprising a first spring material comprising a stainless steel material comprising a molybdenum content selected in the range of 0.5-7 wt. %, and (b) the plunger advance system comprises a second spring system comprising a second spring material comprising a stainless steel material comprising a molybdenum content selected in the range of 0.5-7 wt. %, applies; and the plunger advance system comprises a polymer selected from the group consisting of polypropylene (PP), ethylene chlorotrifluoroethylene (ECTFE), and polyoxymethylene (POM); and wherein the plunger advance system comprises a spindle system comprising a ratchet system comprising a first element and a second element, wherein the second spring system is configured to provide the first element and the second element to engage on each other.

Owner:MEDICAL BRANDS RES

High-throughput polymer separation membrane, preparation method, diluent composition and application

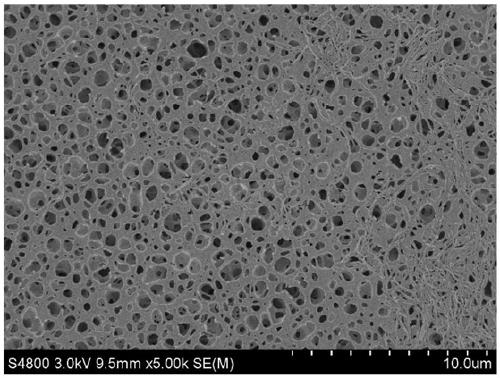

ActiveCN108057346ANo pollution in the processIncreased pure water fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiberSolvent

The invention provides a high-throughput polymer separation membrane, a preparation method, a diluent composition and an application, and belongs to the technical field of preparation of polymer separation membranes. The invention relates to a method for preparing an ECTFE porous membrane by adopting a two-element diluent through a thermally-induced phase separation method. The method comprises the following steps: with 15 to 70 wt% of an ECTFE polymer and two solvents with a total mass percentage of 30 to 85 wt% as the two-element diluent for preparation of a membrane casting solution, subjecting the ECTFE polymer and two solvents to heating under stirring and carrying out standing and defoaming, or mixing the ECTFE polymer and two solvents through a double screw extruder so as to preparea polymer homogeneous membrane casting solution; scraping the casting solution into a plate shape or into a hollow fiber shape through spinning of a spinning nozzle, then carrying out soaking in a cooling liquid, carrying out quenching, and carrying out curing so as to form a membrane; and soaking the formed film into an extractant, allowing the diluent to be extracted out of the formed membrane,and carrying out drying in the air so as to prepare the ECTFE porous membrane. The invention is characterized by adopting two environment-friendly solvents as the two-element diluent for preparationof the ECTFE porous membrane; the preparation process is simple and has green and environment-friendly process; and the ECTFE porous membrane prepared by using the preparation process provided by theinvention has large throughput which is improved by 1.5 times or above compared with the throughput of the ECTFE porous membrane prepared by using a single diluent.

Owner:NANJING UNIV OF TECH

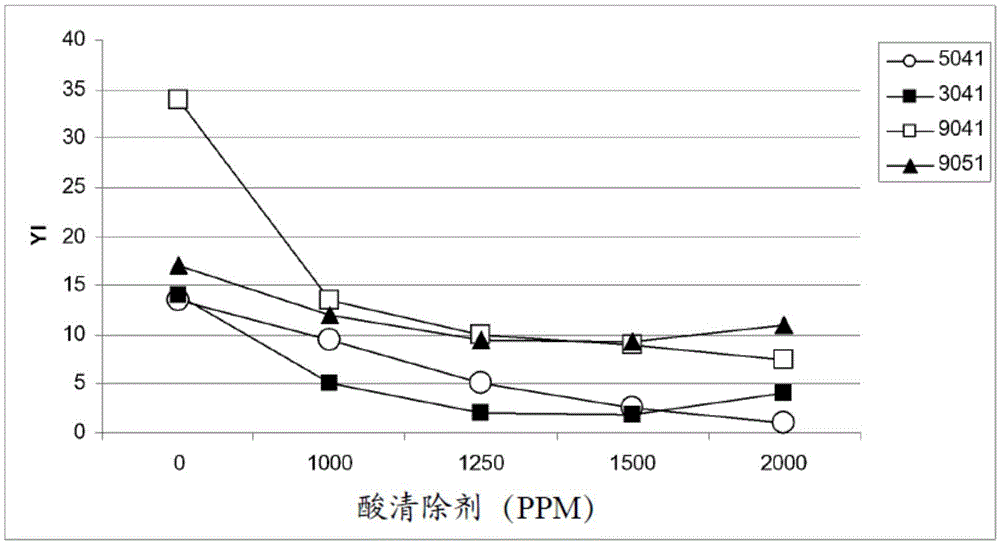

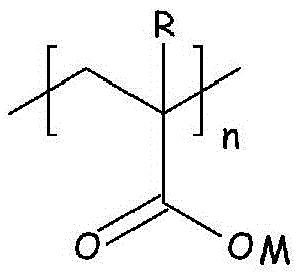

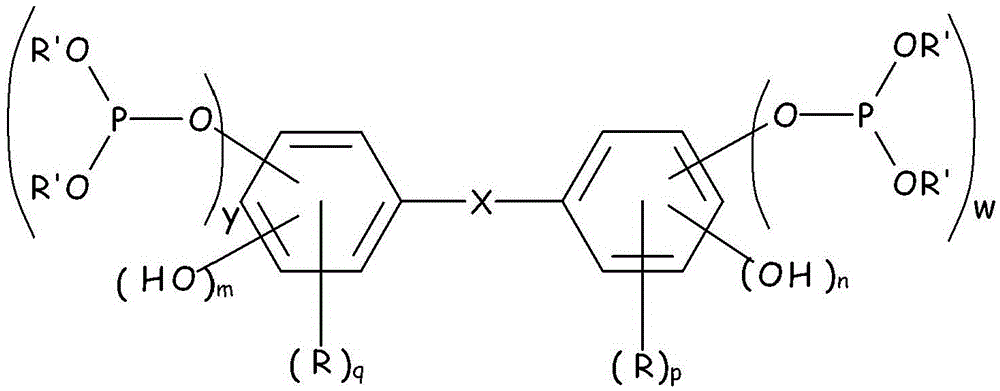

Fluoropolymer composition

The invention pertains to a fluoropolymer composition comprising: at least one polymer comprising recurring units derived from ethylene (E) and from chlorotrifluoroethylene (CTFE) [ECTFE polymer]; at least one water-soluble polyelectrolyte [polyelectrolyte (E)]; and at least one antioxidant compound [compound (P)], said composition having improved thermal resistance.

Owner:SOLVAY SOLEXIS

Highly filled unsaturated fluoropolymer compositions for cables

Owner:MEXICHEM AMANCO HLDG DE C V

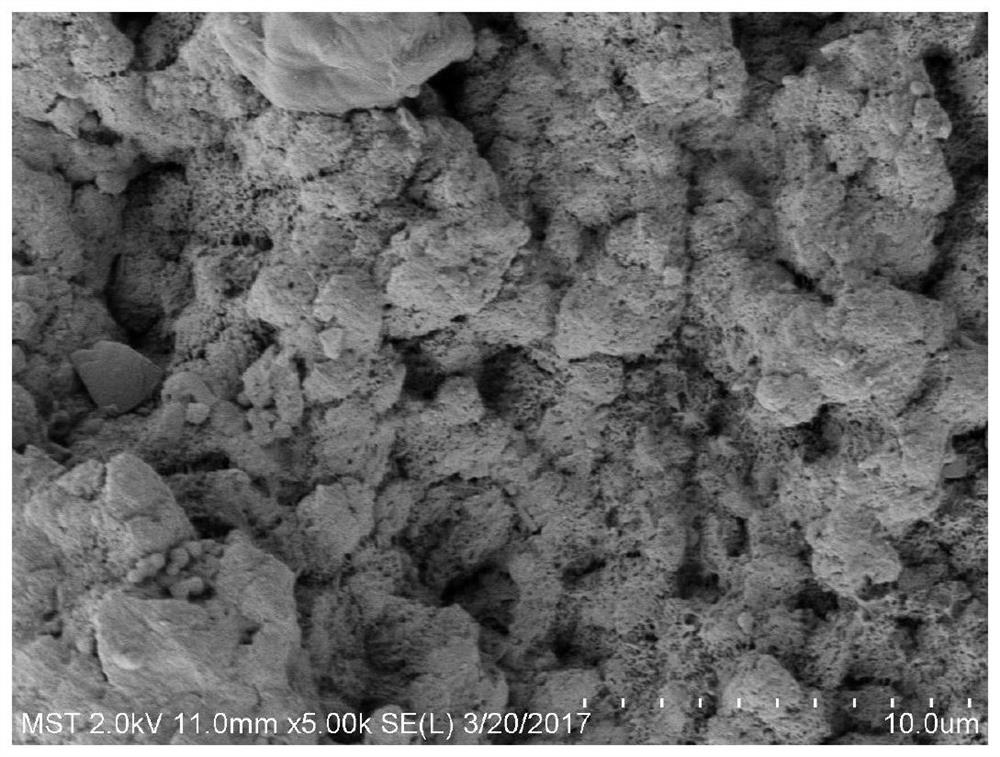

Ethylene-chlorotrifluor ethylene copolymer microporous separation membrane, preparation method and application thereof

InactiveCN109277004ANo damageEasy to separateSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisHigh concentrationFiltration

The present invention provides an ethylene-chlorotrifluor ethylene copolymer microporous separation membrane. A multiphase blend system composed of polymer ethylene-chlorotrifluor ethylene, a heat stabilizer and diluent is used as the membrane forming system, and the ECTFE microporous separation membrane is prepared by thermally induced phase separation (TIPS). The membrane possessed both high strength and high throughput characteristics. In the process of preparation, the waste liquor pollution is less, the preparation cost is low and the environmental protection performance is good. The invention also provides a preparation method of the ethylene-chlorotrifluor ethylene copolymer microporous separation membrane. The prepared ethylene-chlorotrifluor ethylene copolymer microporous separation membrane is suitable for zero discharge of high concentration wastewater from textile and dyeing industries, recovery of organic solvents and alkali liquor, filtration of etchant in microelectronics industry, separation and purification of antibiotics, decolorization of syrup, membrane distillation and water vapor separation.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

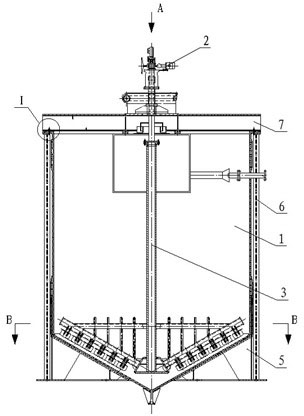

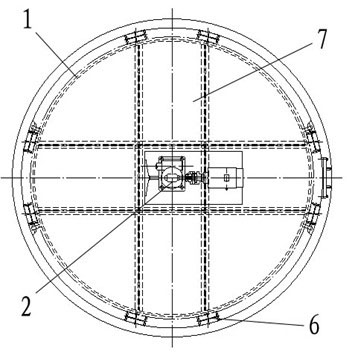

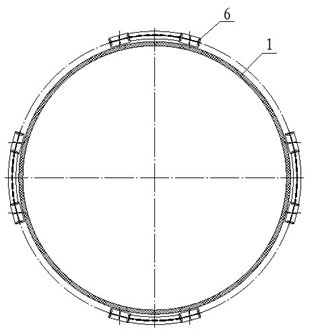

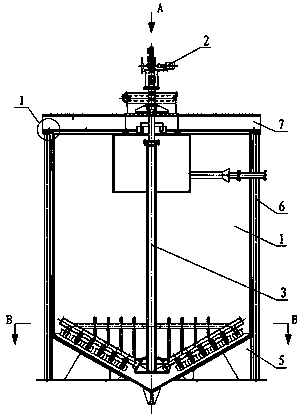

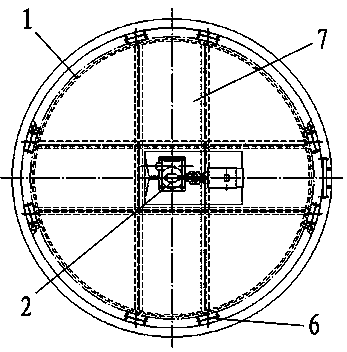

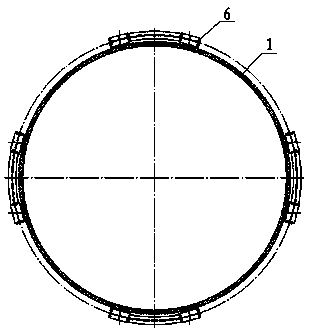

Anti-corrosion sedimentation tank and building method thereof

InactiveCN102462981ALight weight high strengthHigh strengthSedimentation settling tanksElectrolysisStructural engineering

The invention discloses an anti-corrosion sedimentation tank and a building method thereof. A tank body is made of glass fiber reinforced plastics, so the anti-corrosion problem is solved; and a support frame, a support tank body, a raking machine arranged in the tank body and a driving device driving the raking machine to operate are made of carbon steel, so the problem that the tank body has poor rigidity and can not support the raking machine to normally work is solved. The raking machine is a carbon steel welding element, in addition, ethylene-chlorotrifluoroethylene copolymer (ECTFE) anti-corrosion coatings with the thickness not less than 1.5mm are integrally sprayed and coated on the surface of the raking machine, the intensity requirement of the raking machine is met, and the anti-corrosion problem of the raking machine is also solved. A scraping plate is covered by more than 8.5mm of glass fiber wires or cloth, and the coatings on the scraping plate are prevented from being damaged when the scraping plate is used for scraping materials settled at the bottom of the tank body. The anti-corrosion problem of the sedimentation tank is perfectly solved, simultaneously, the work stability of the sedimentation tank is also ensured, and the production requirement of the electrolysis industry is met. The anti-corrosion sedimentation tank has the advantages that the structure is compact, the operation is stable, the sedimentation effect is good, economy and practicability are realized, and the like.

Owner:GUIYANG AL-MG DESIGN & RES INST

High-temperature-resistant colored fluororesin film, preparation method and application thereof

The invention discloses a high-temperature-resistant colored fluororesin film, a preparation method and application thereof. The film is prepared through blending and melt extrusion of fluororesin and fluororesin color master batch, the film is formed through curtain coating, the fluororesin is a mixture selected from any one or more than any two of FEP, ETFE or ECTFE and PFA, the fluororesin color master batch is obtained by blending 30% to 50% of an organic pigment, 45% to 65% of fluororesin and 5% to 10% of a dispersing agent according to the percentages accounting for total weight of the color master batch for 20 to 50 minutes and pelleting, and the processing temperature is 350 to 400 DEG C. According to the method provided by the invention, the fluororesin and the fluororesin color master batch are easily and sufficiently mixed, the film can be formed through curtain coating and extrusion as long as a small amount of a lubricating agent is needed, and the prepared colored film can be resistant to high temperature and can be used for release films in the manufacturing process of aircraft wings in the field of aerospace.

Owner:日氟荣高分子材料(上海)有限公司

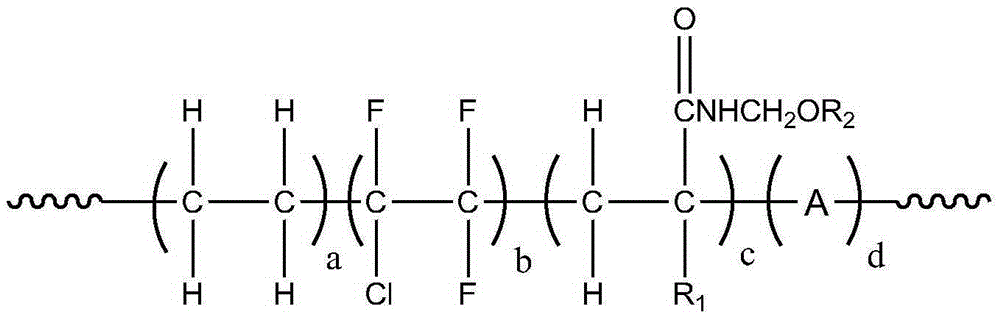

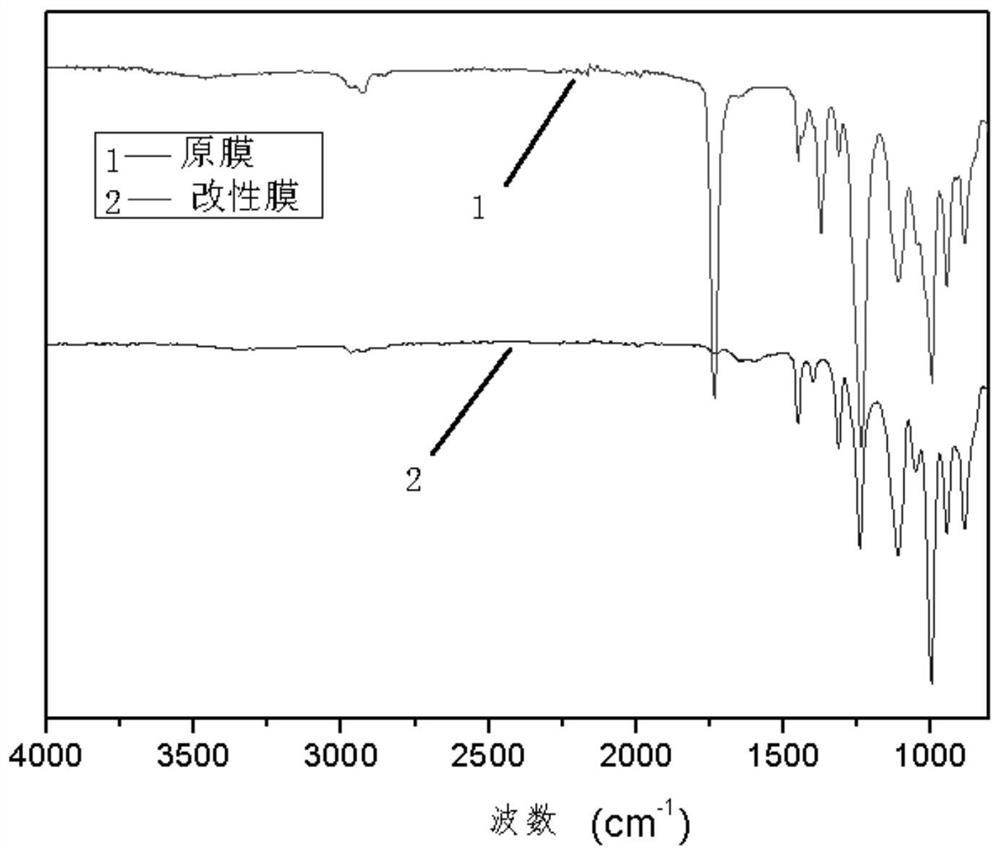

ECTFE (ethylene-chlorotrifluoroethylene copolymer) fluororesin with self-crosslinking structure, and preparation method thereof

InactiveCN106832077AImprove performanceEasy to use and constructThermal treatmentCorrosion resistant

The invention discloses ECTFE (ethylene-chlorotrifluoroethylene copolymer) resin with a self-crosslinking structure. A preparation monomer comprises ethylene, chlorotrifluoroethylene, alkoxy methyl (alkyl) acrylamide and a modified monomer A; the molar ratio of the ethylene to the chlorotrifluoroethylene to the alkoxy methyl (alkyl) acrylamide to the modified monomer A is (40-60):(60-40):(0.1-10):(0-5). The ECTFE resin provided by the invention can serve as a corrosion-resistant coating after being subjected to self-crosslinking solidification through heat treatment, and is particularly applicable to the field of chemical anticorrosion.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

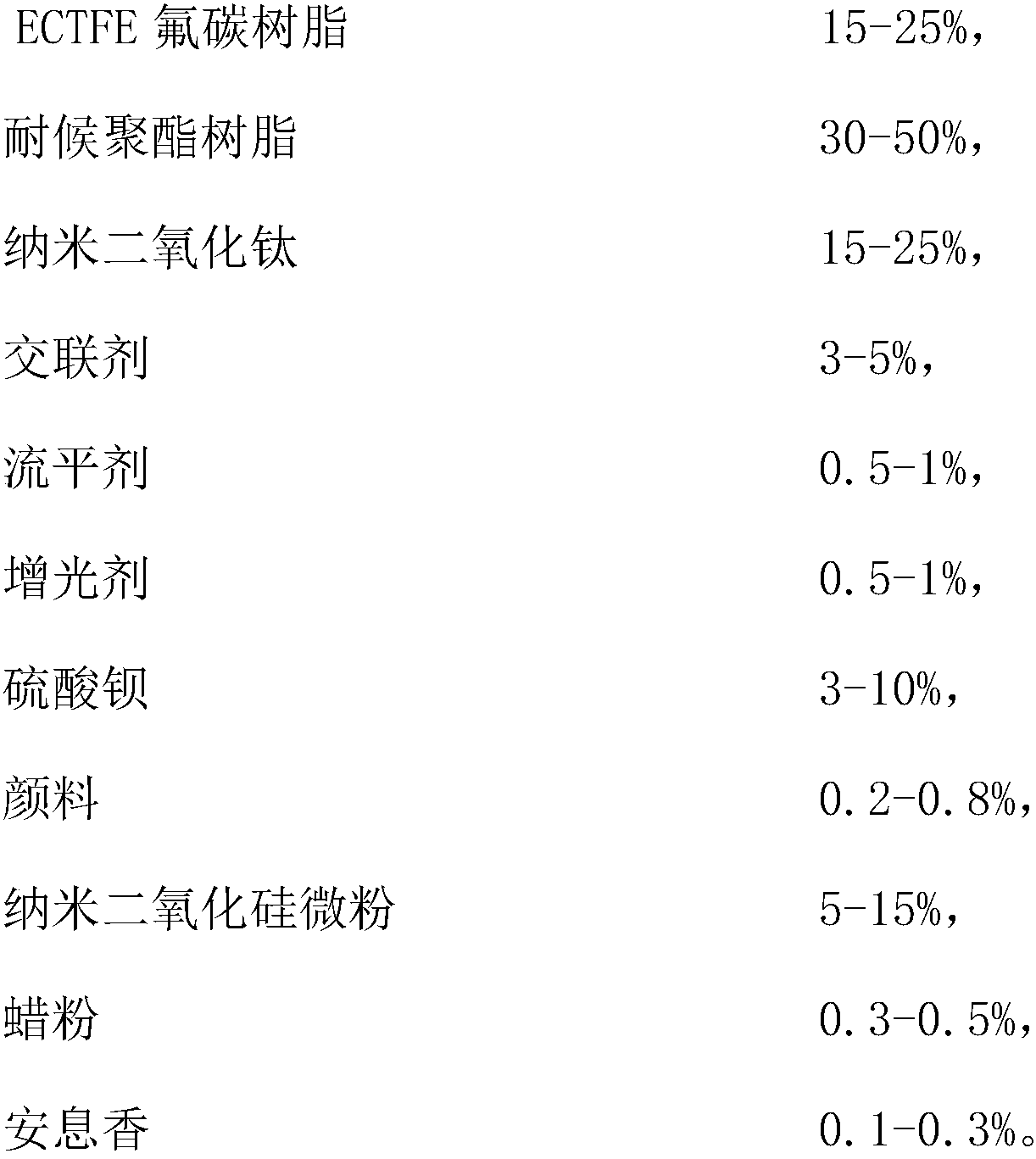

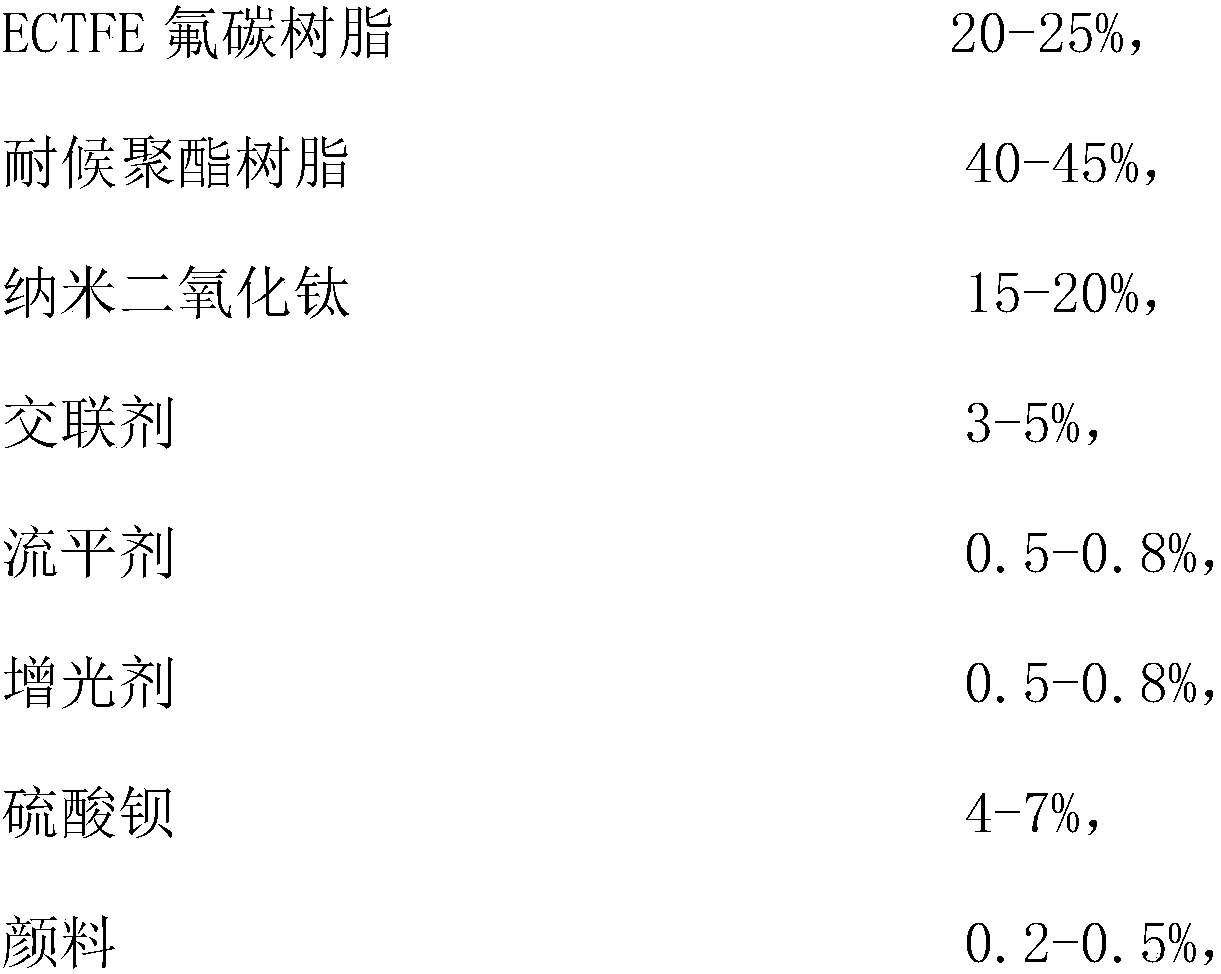

Fluorocarbon powder coating for automobile chassis and preparation method thereof

InactiveCN108384409AReduce surface tensionEasy to prepareAnti-corrosive paintsPowdery paintsSilicon dioxideMaterials science

The invention relates to a fluorocarbon powder coating for automobile chassis. The fluorocarbon powder coating comprises the following components in percentage by mass: 15-25% of ECTFE fluorocarbon resin, 30-50% of weather resistant polyester resin, 15-25% of nanometer titanium dioxide, 3-5% of cross-linking agent, 0.5-1% of leveling agent, 0.5-1% of light enhancing agent, 3-10% of barium sulfate,0.2-0.8% of pigment, 5-15% of nanometer silica micro powder, 0.3-0.5% of wax powder, and 0.1-0.3% of benzoin. The invention also provides a preparation method of the fluorocarbon powder coating for automobile chassis. The fluorocarbon powder coating for automobile chassis can effectively improve a painting appearance effect, and has higher chemical corrosion resistance and long service life, andthe preparation method of the powder coating is simple and easy to operate, therefore, the fluorocarbon powder coating is suitable for wide application and promotion.

Owner:中山市凯德美氟碳新材料有限公司

Member for electrophotography, image heating apparatus, image forming apparatus, and method for manufacturing member for electrophotography

ActiveUS9588471B2Smooth transferDecreases heat storage property and flexibilityLayered product treatmentSynthetic resin layered productsEngineeringUltimate tensile strength

Provided is a member for electrophotography, where an elastic layer including a silicone rubber and a release layer including a fluorine resin are bonded sufficiently without any adhesive layer interposed therebetween. The member for electrophotography includes a substrate; an elastic layer including a silicone rubber, on the substrate; and a release layer provided in direct contact with the surface of the elastic layer, where the release layer includes a fluorine resin selected from the group consisting of PFA, FEP, PTFE, ETFE, PCTFE, ECTFE, and PVDF, and the elastic layer undergoes a cohesive failure when the release layer is peeled from the elastic layer in accordance with “Determination of peel strength of bonded assemblies. Part 1: 90 degree peel” specified by the Japanese Industrial Standards (JIS) K 6854-1:1999.

Owner:CANON KK

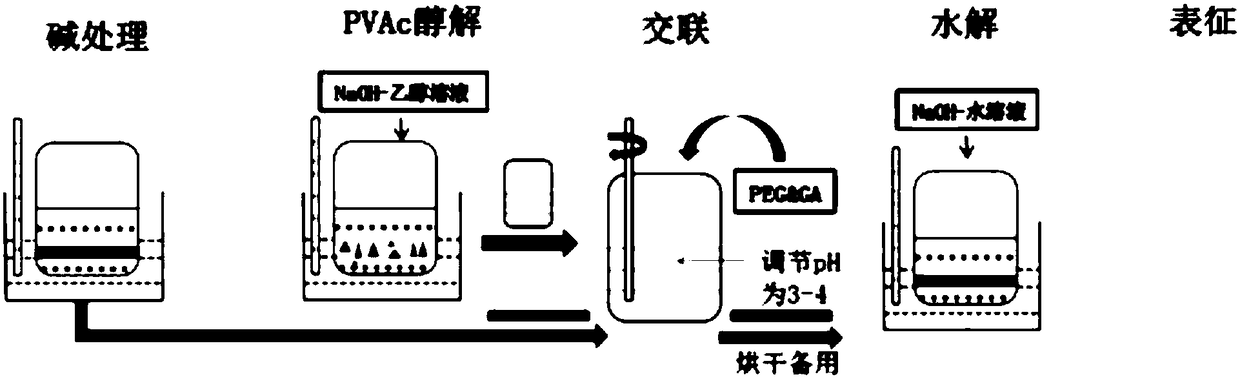

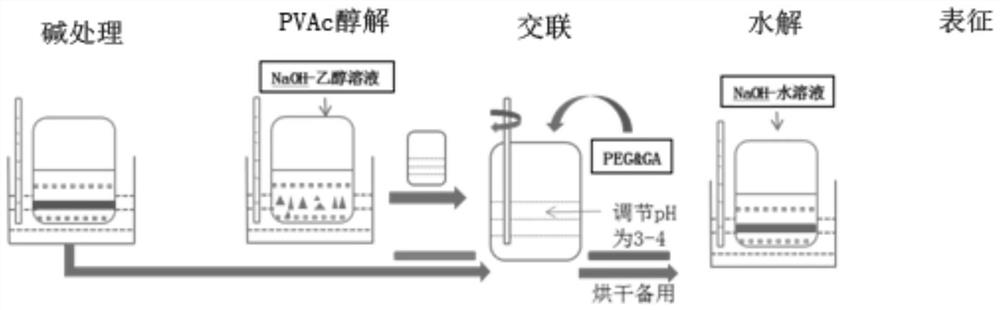

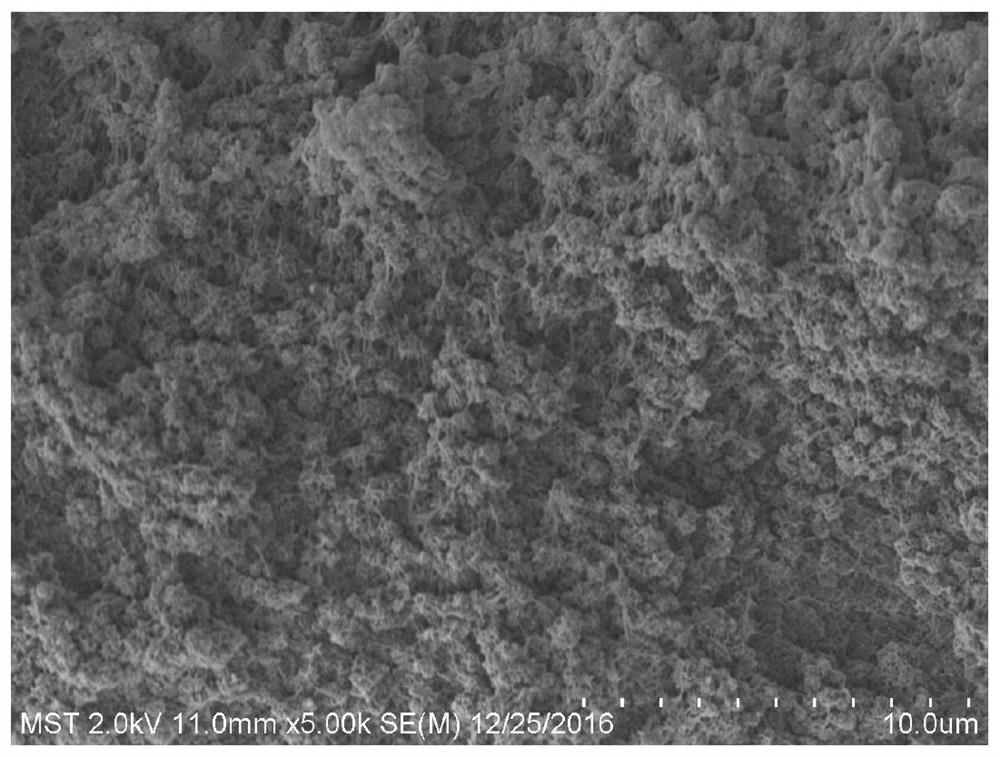

Preparation method of ECTFE hollow fiber porous membrane for a membrane chemical reactor process

Embodiments of the invention provide a preparation method of vinyl-trifluorochlor oethylene copolymer hollow fiber porous membrane for the membrane chemical reactor process. The preparation method comprises the following steps: (1) adding vinyl-trifluorochlor oethylene copolymer powder and a compound diluting agent into a melting device, melting, plasticizing, and obtaining a casting membrane solution; (2) extruding the casting membrane solution by virtue of a spinning nozzle, quenching in a gel bath at 0 to 50 DEG C, and obtaining a primary hollow fiber porous membrane; and (3) extracting a diluting agent in the primary hollow fiber porous membrane by using an extraction agent, and obtaining a hollow fiber porous membrane. The preparation method of the vinyl-trifluorochlor oethylene copolymer hollow fiber porous membrane provided by embodiments of the invention is simple in process; and by adjusting the type and proportion of the compound diluting agent as well as the technological parameters of the preparation process, the vinyl-trifluorochlor oethylene copolymer hollow fiber porous membrane with small aperture, high porosity and / or high strength can be obtained.

Owner:POTEN ENVIRONMENT GRP +1

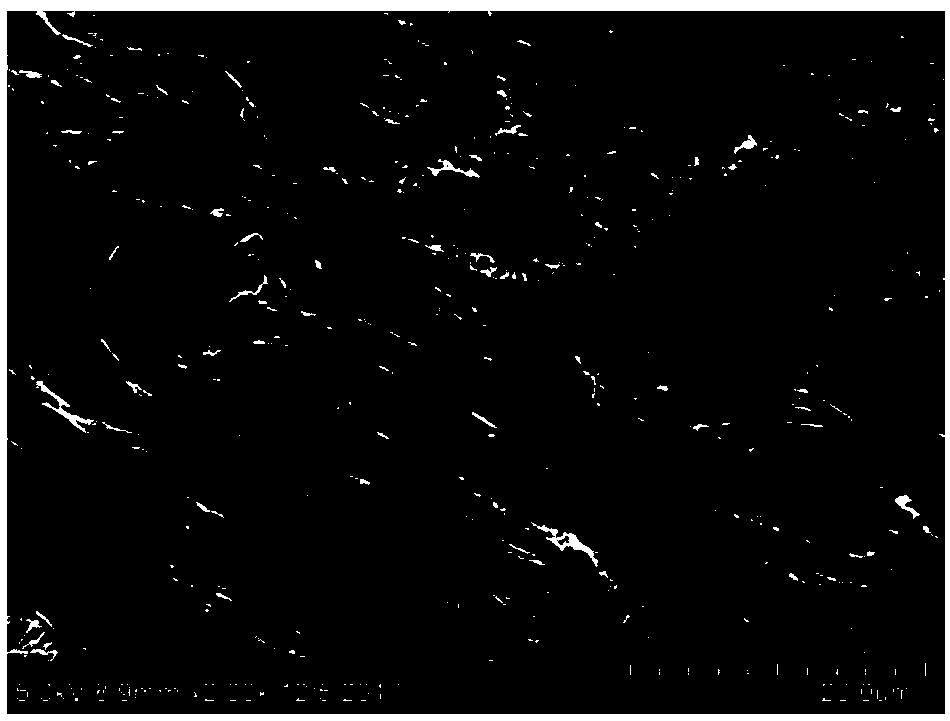

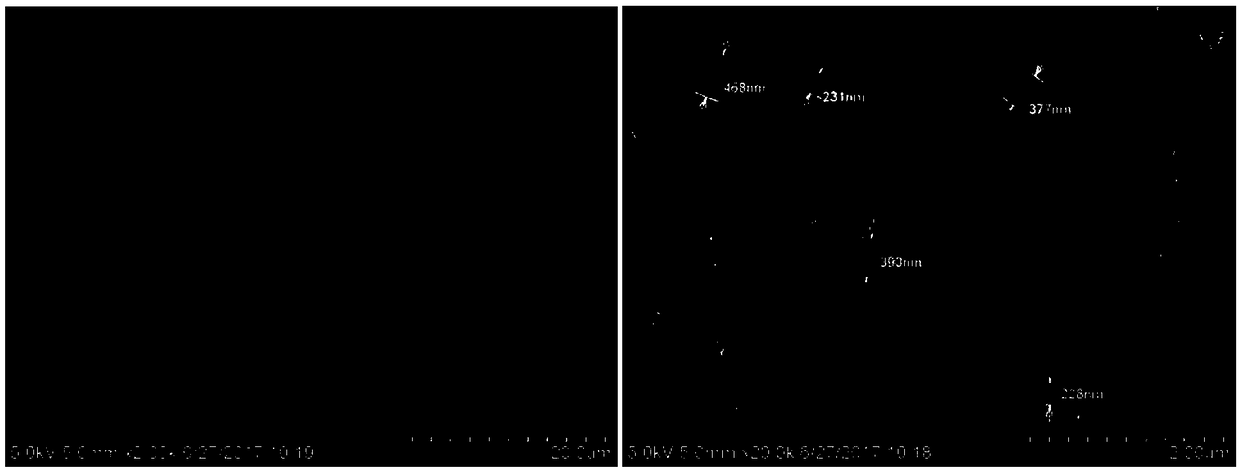

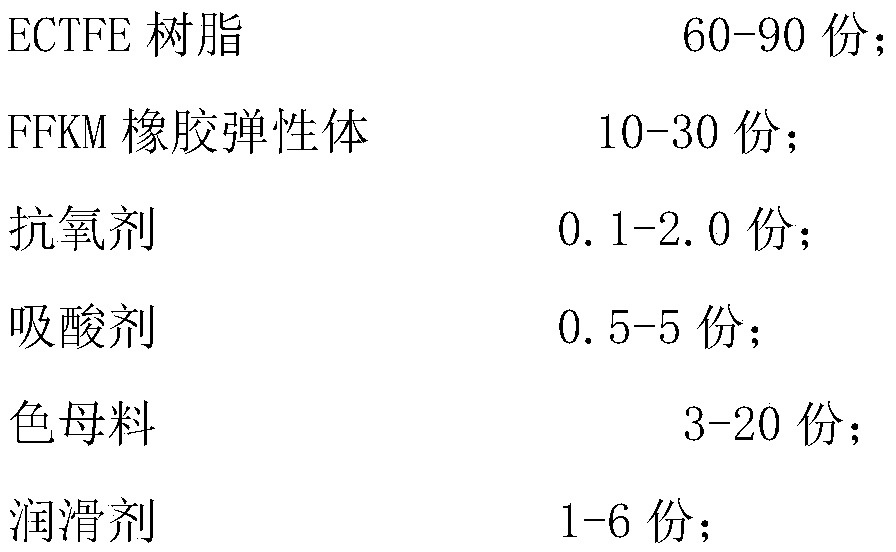

Irradiation crosslinking modified ECTFE (ethylene chlorotrifluoroethylene) heat shrinkable sleeve and preparation method thereof

InactiveCN110256762AImprove performanceOvercome product performanceTubular articlesHeat-shrinkable sleeveElastomer

An irradiation crosslinking modified ECTFE (ethylene chlorotrifluoroethylene) heat shrinkable sleeve comprises, by weight, 60-90 parts of ECTFE resin, 10-30 parts of FFKM rubber elastomers, 0.1-2.0 parts of antioxidants, 0.5-5 parts of acid absorbers, 3-20 parts of color masterbatches and 1-6 parts of lubricants. The irradiation crosslinking modified ECTFE heat shrinkable sleeve has outstanding properties of resistance to high temperature, oil, chemical solvents, ageing, mechanical damage and corrosion, can meet requirements for long-term use at the temperature of minus 55 DEG C to 200 DEG C, and can be applicable to the fields such as military projects, automobiles, ships, high-speed trains and aerospace.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

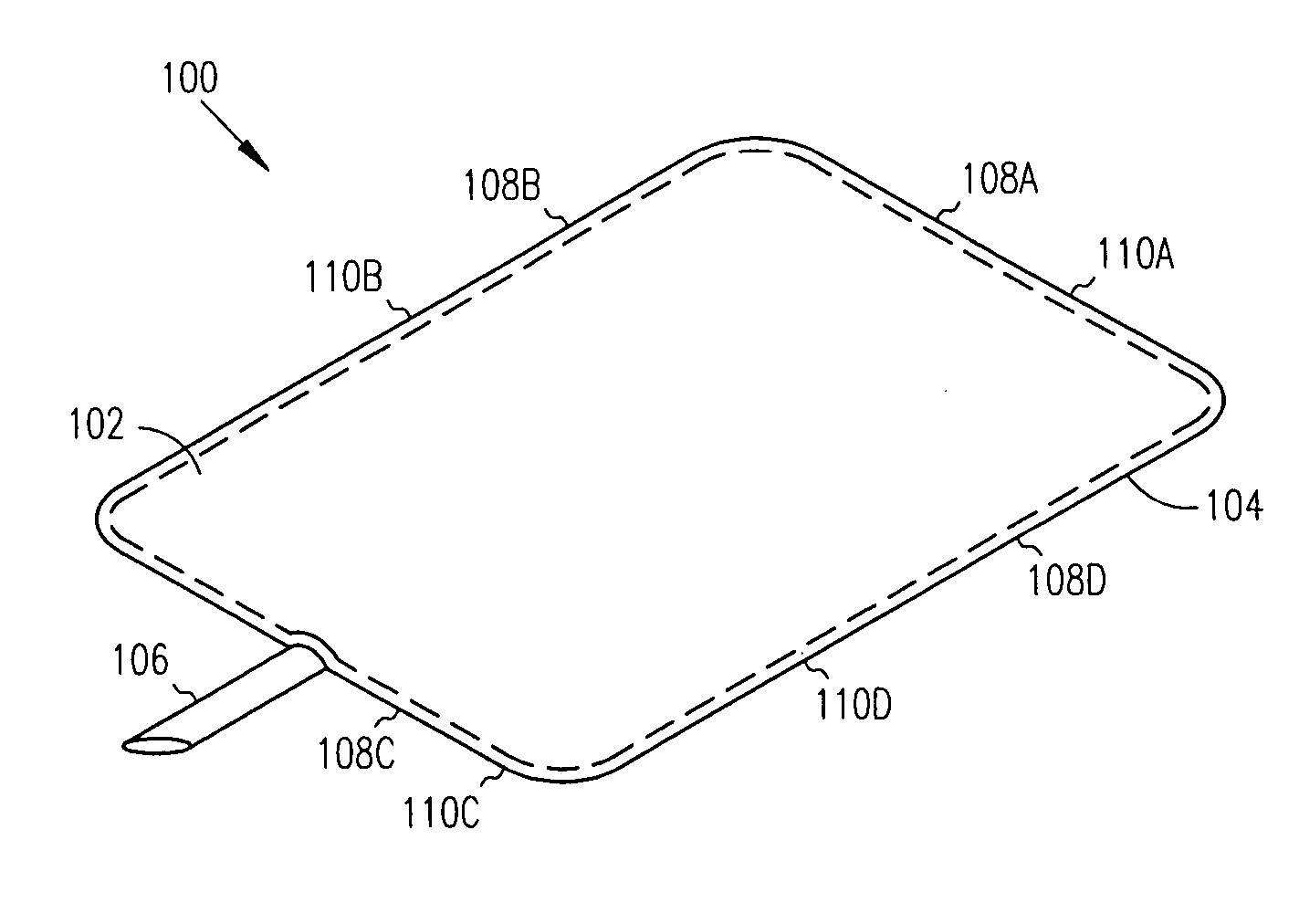

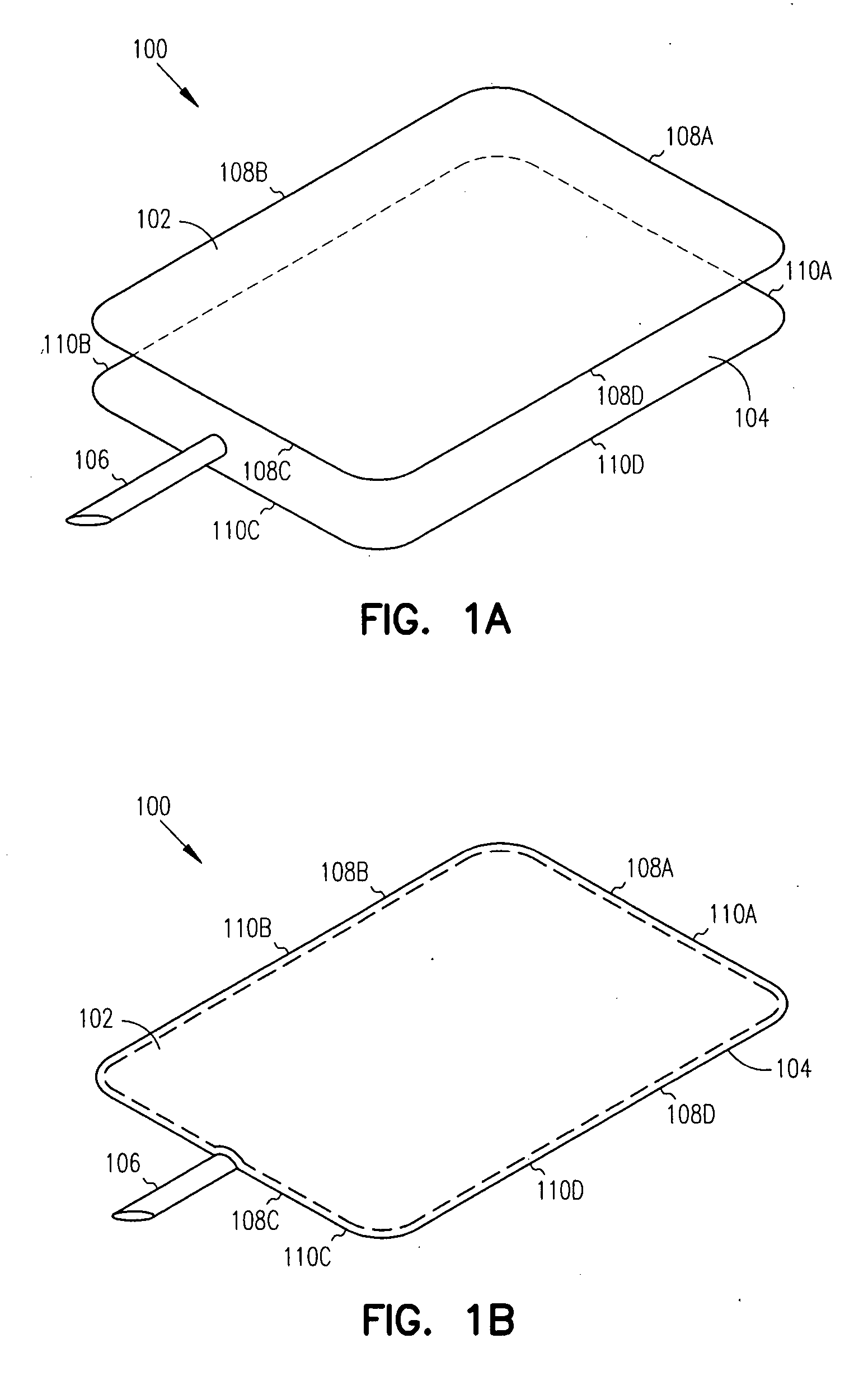

Sterile, pyrogen-free, polymeric film-based heating bag

In one embodiment, there is provided a method for producing a sterilized and pyrogen-free bag for storing fluids. The method includes providing a bag comprised of polymeric film and heating the bag to at least approximately 253 degrees Celsius for at least approximately 30 minutes for sterilization and pyrogen removal. The polymeric film is a polymer selected from the group of poly(oxy-1,4-phenylene-oxy-1,4-phenylene-carbonyl-1,4-phenylene) (PEEK); polytetrafluoroethylene (PTFE); a perfluoroalkoxy (PFA) polymer; poly(tetrafluoroethylene-co-perfluoromethyl vinyl ether) (MFA); polyperfluoro(ethylene-co-propylene)(FEP); poly(ethylene-alt-chlorotrifluoroethylene) (ECTFE); poly(ethylene-co-tetrafluoroethylene) (ETFE); poly(vinylidene fluoride) (PDVF); tetrafluoroethylene-co-hexafluoropropylene-co-vinylidene fluoride terpolymer (THV); poly(bisphenol A-co-4-nitrophthalic anhydride-co-1,3-phenylenediamine) (PEI); poly(4-methyl-1-pentene) (PMP); and suitable mixtures thereof.

Owner:PALL LIFE SCI BELGIUM

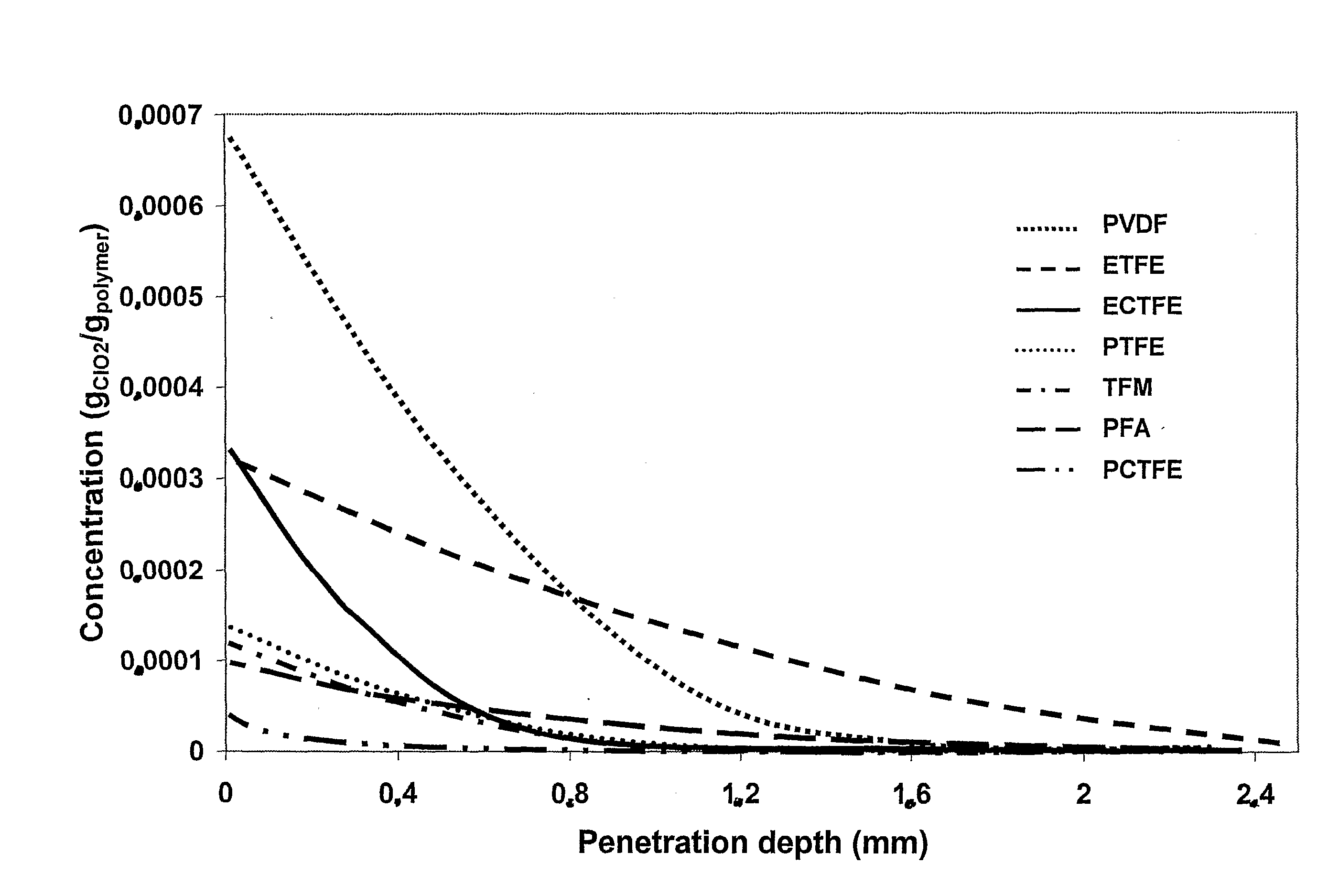

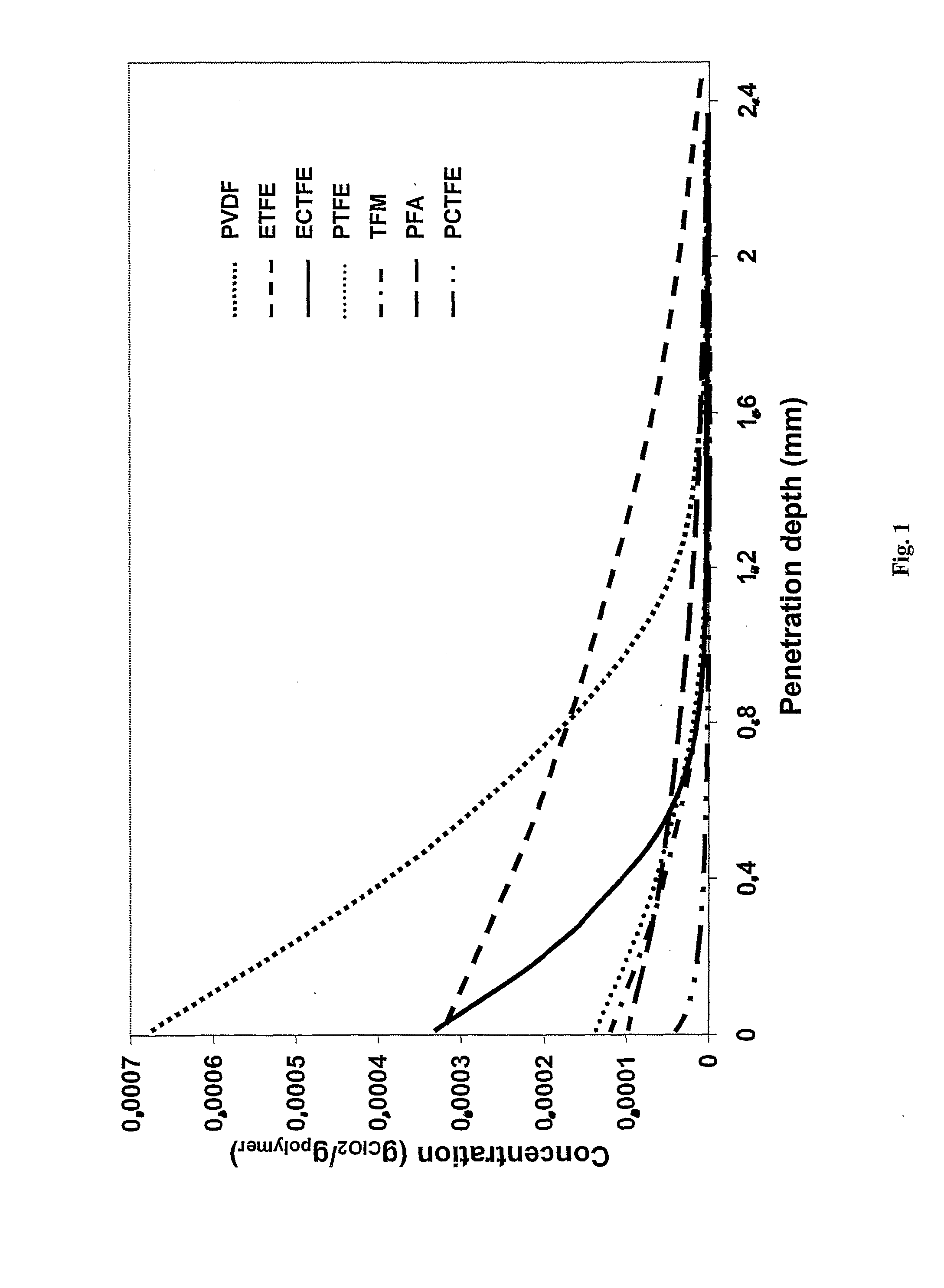

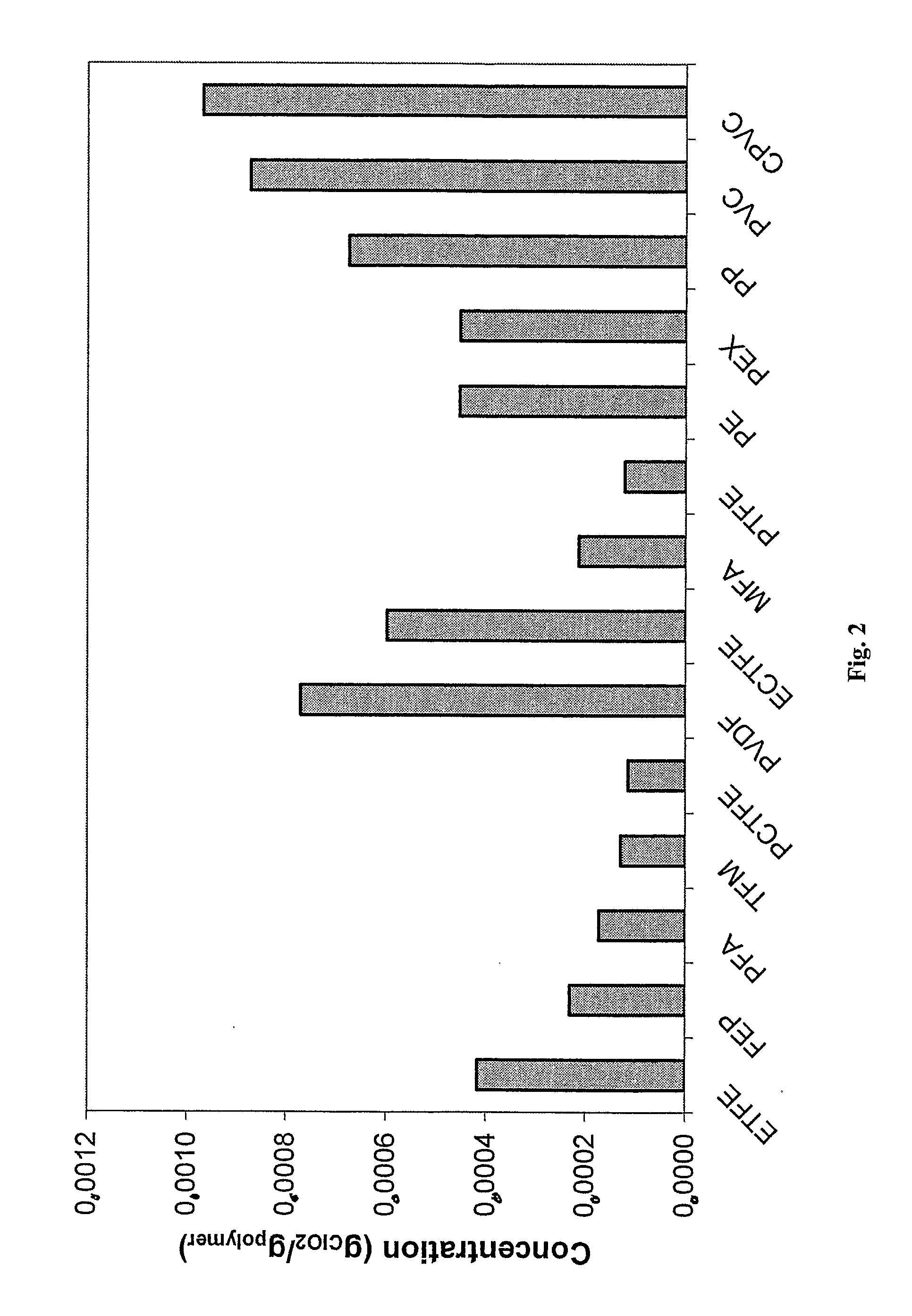

Diffusion retardation in fluoroplastics

InactiveUS20100093945A1Diffusion slowRemarkable effectOrganic chemistryFlexible pipesECTFECombined use

A process of slowing down diffusion of an element or a compound through a fluoroplastic comprising the addition of a reactive additive having reactive groups that react with the element or compound. A process of preventing degradation of the fluoroplastics PVDF and ECTFE used in, or in connection with a reactor where chlorine dioxide is produced comprising mixing the fluoroplastic with a reactive additive having reactive groups. A diffusion resistant fluoroplastic which comprises a reactive additive having reactive groups that react with an element and / or compound to which the fluoroplastic is diffusion resistant. The use of a reactive additive having reactive groups as an additive in a fluoroplastic to prevent or slow down the diffusion of an element or a compound through the fluoroplastic. The use of a reactive additive having reactive groups as an additive in the fluoroplastics PVDF and ECTFE used in, or in connection with a reactor for producing chlorine dioxide to prevent or slow down degradation of the fluoroplastic.

Owner:SWEREA KIMAB

Electrophotographic member, image heating device, image forming device and method for manufacturing electrophotographic member

ActiveCN107077089AImprove thermal conductivityHigh thermal conductivitySynthetic resin layered productsElectrographic process apparatusUltimate tensile strengthBond strength

Provided is an electrophtographic member wherein an elastic layer containing a silicone rubber is sufficiently adhered to a mold-release layer containing a fluororesin without via any adhesive layer. The electrophtographic member comprises a base material, an elastic layer containing a silicone rubber that is disposed on the base material, and a mold-release layer that is provided on the surface of the elastic layer directly in contact therewith, wherein: the mold-release layer contains a fluororesin selected from the group consisting of PFA, FEP, PTFE, ETFE, PCTFE, ECTFE and PVDF; and the elastic layer undergoes cohesive failure in a 90degree peel bond strength test in accordance with Japanese Industrial Standards (JIS) K 6854-1:1999.

Owner:CANON KK

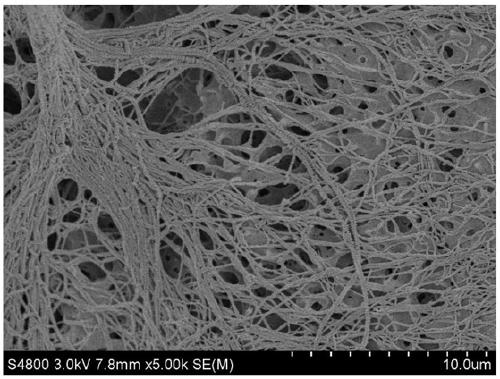

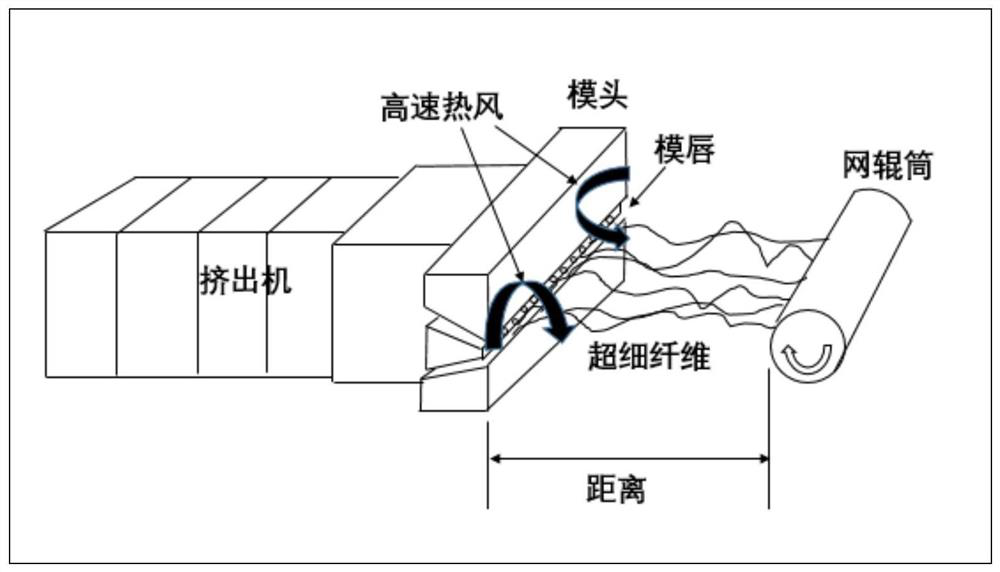

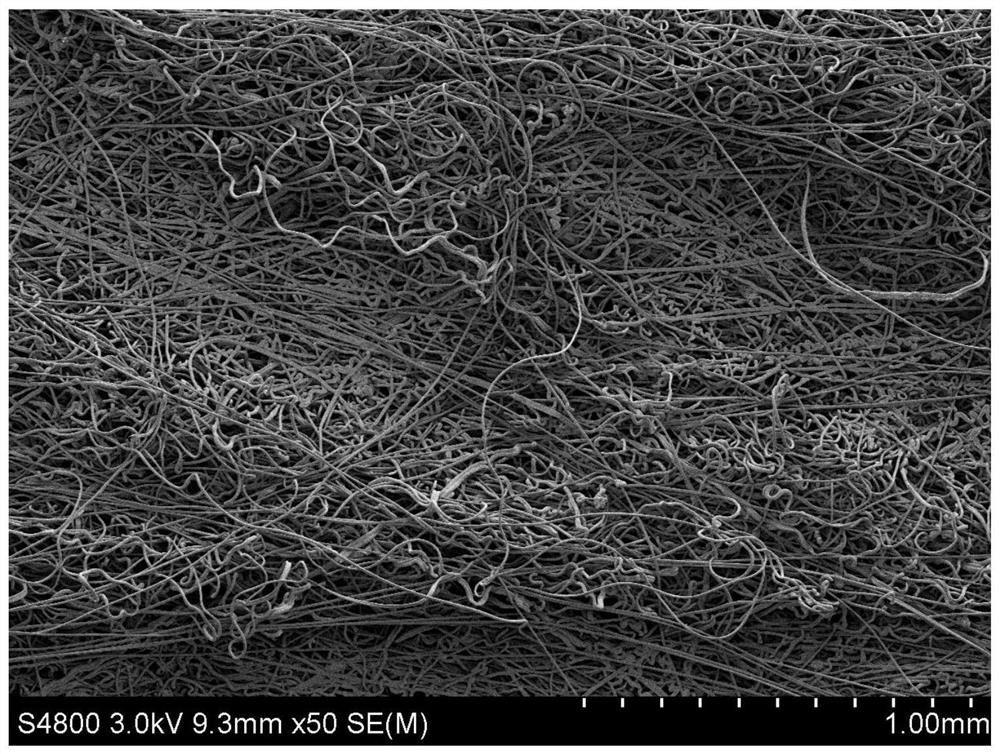

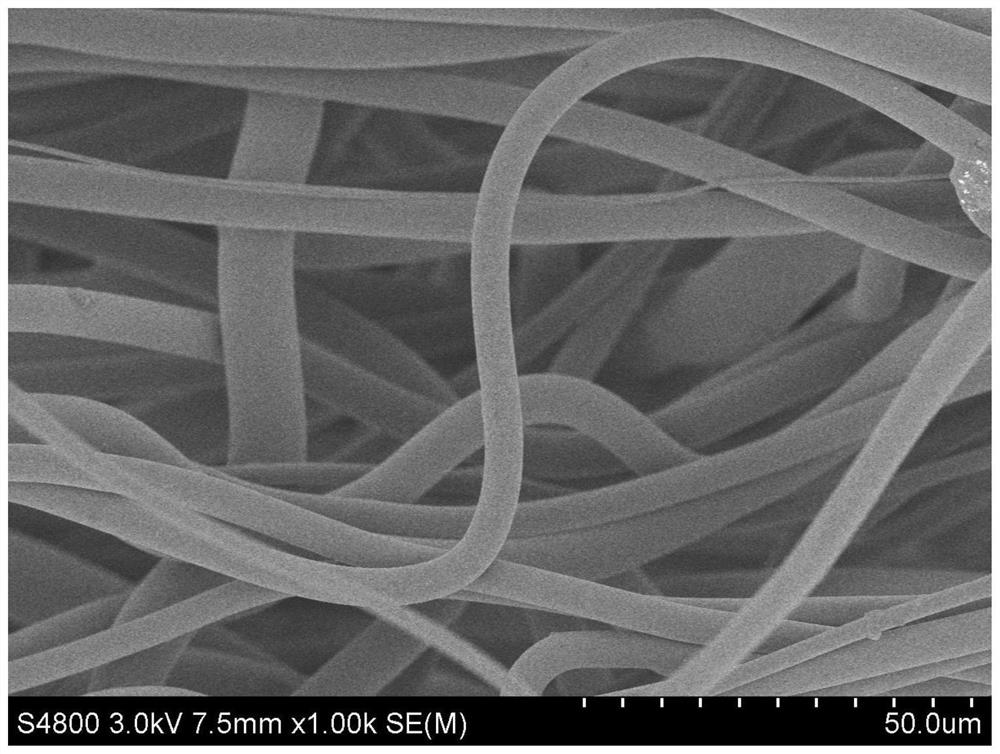

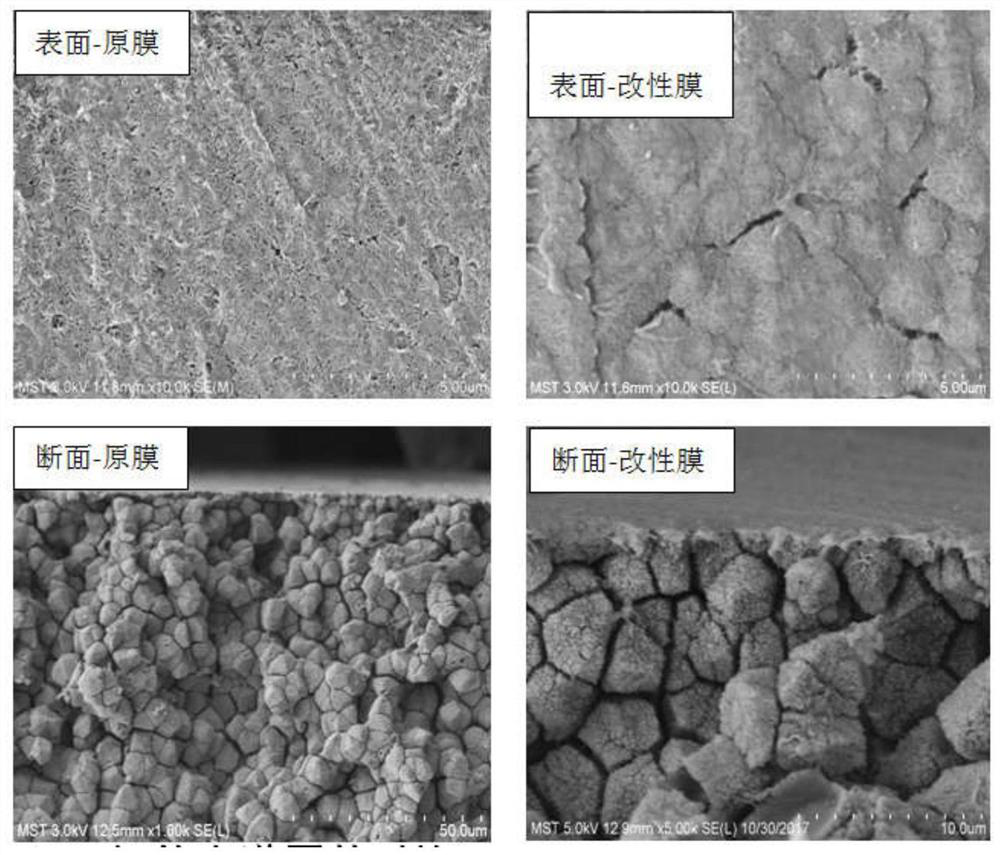

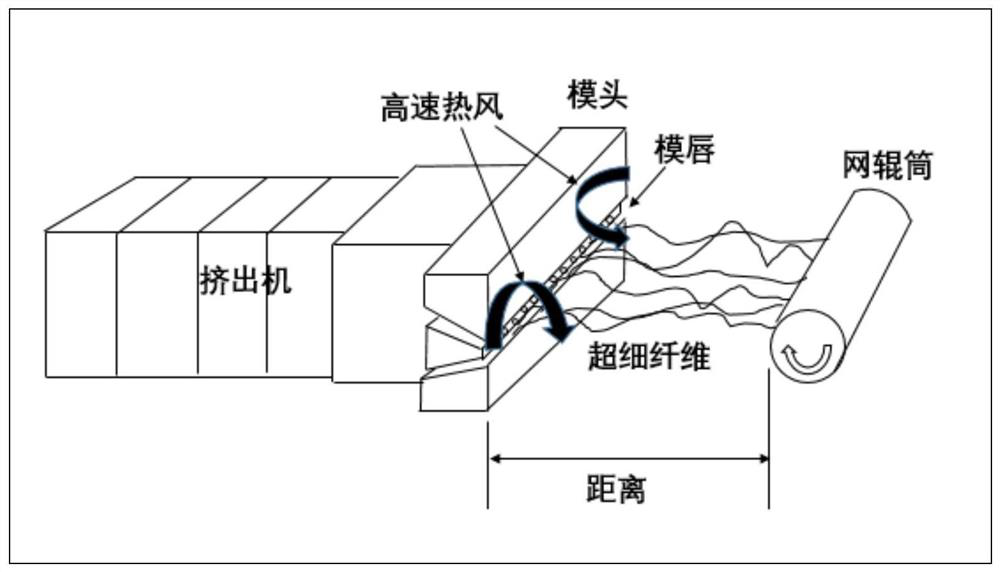

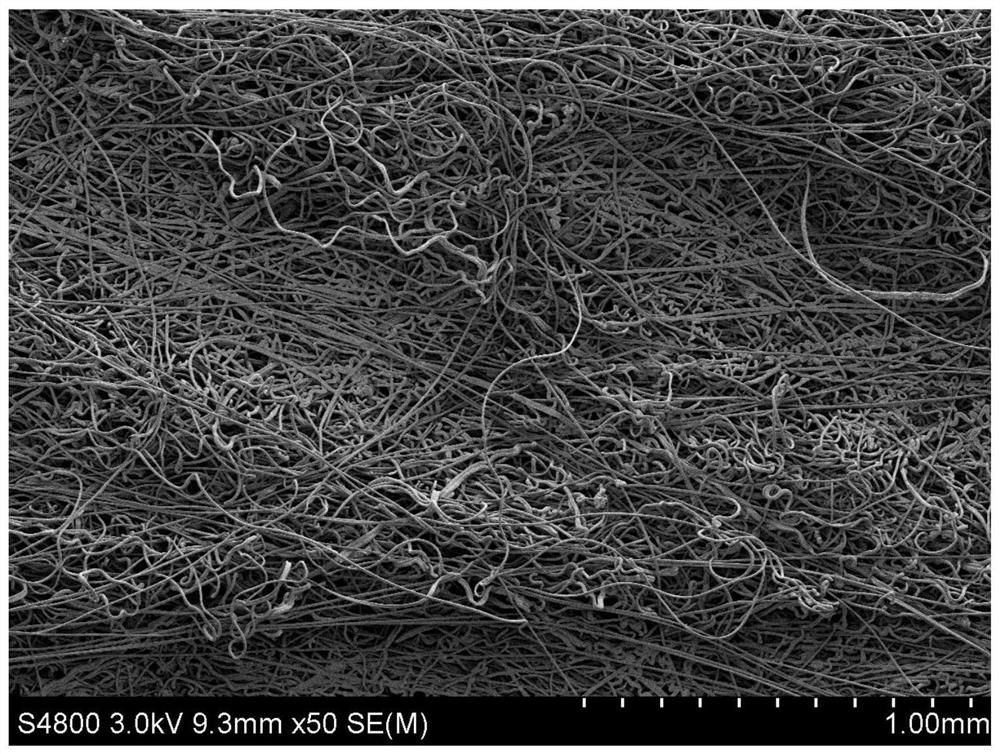

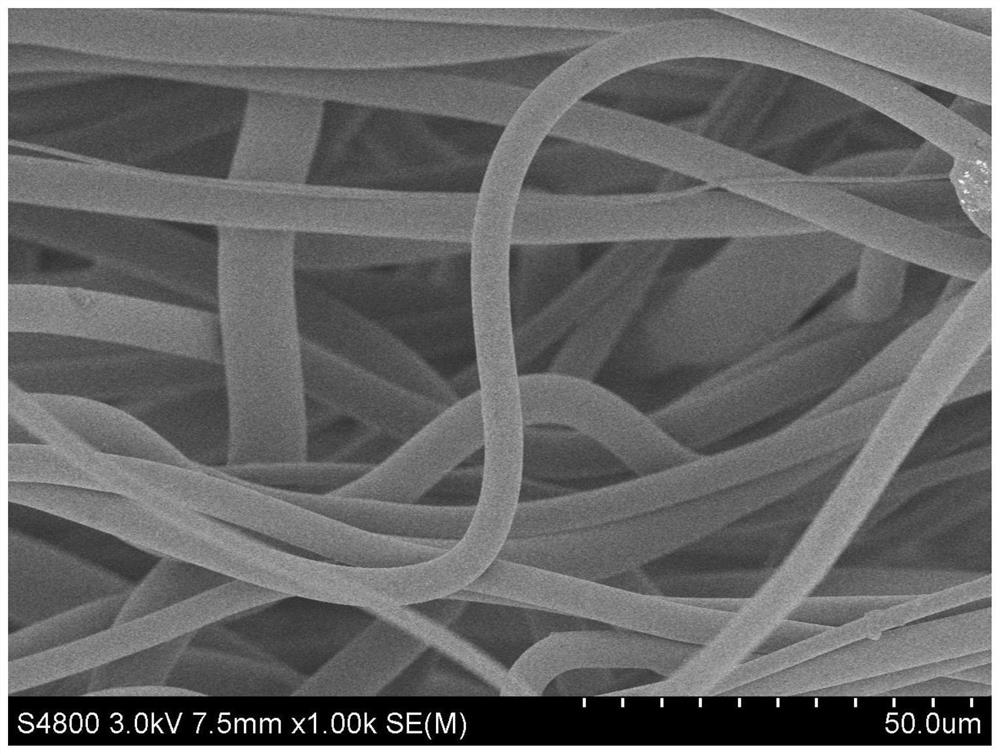

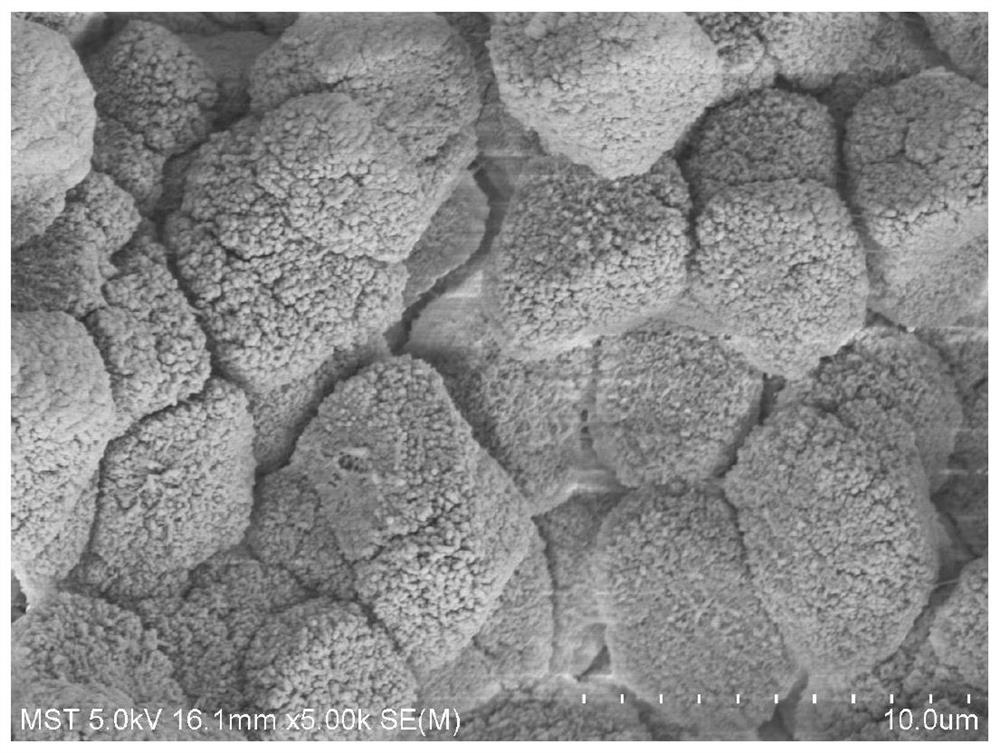

ECTFE melt-blown film and preparation method thereof

ActiveCN112853626AUniform pore size distributionHigh tensile strengthMonocomponent synthetic polymer artificial filamentNon-woven fabricsPolymer scienceUltimate tensile strength

The invention discloses an ECTFE melt-blown film and a preparation method thereof. The melt-blown film is composed of superfine fibers with the diameter of 0.1 [mu] m-5 [mu] m; and the aperture of at least 60% of the melt-blown film is 0.3 [mu] m-0. 7 [mu] m, the aperture of less than 20% of the melt-blown film is 0.1 [mu] m-0. 3 [mu] m, and the aperture of less than 20% of the melt-blown film is 0.7 [mu] m-1. 0 [mu] m. The melt-blown film disclosed by the invention has the advantages of high tensile strength, high elongation at break, small average pore size, high filtering precision, suitability for high-temperature-resistant, acid-base-resistant and corrosion-resistant environments and the like.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

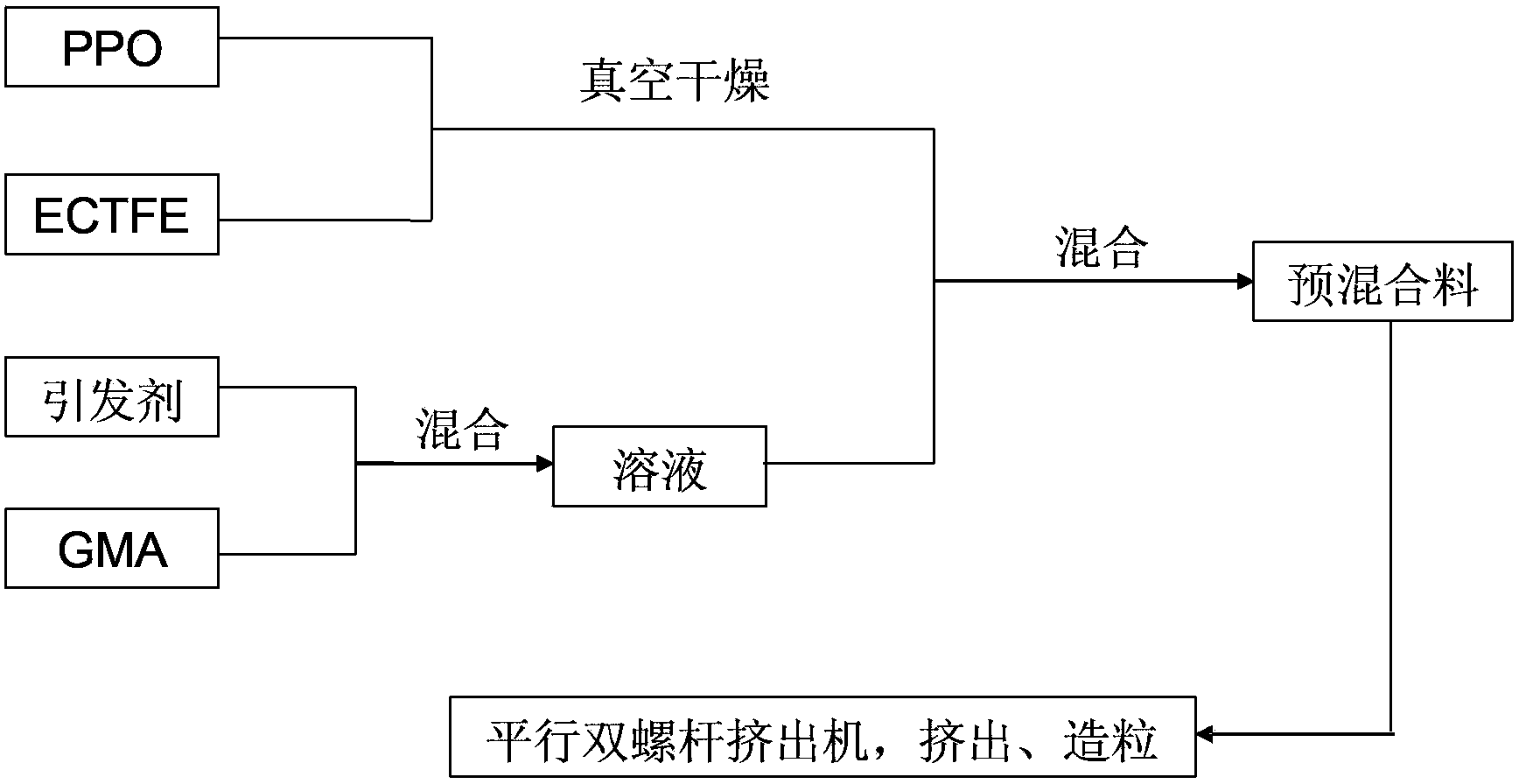

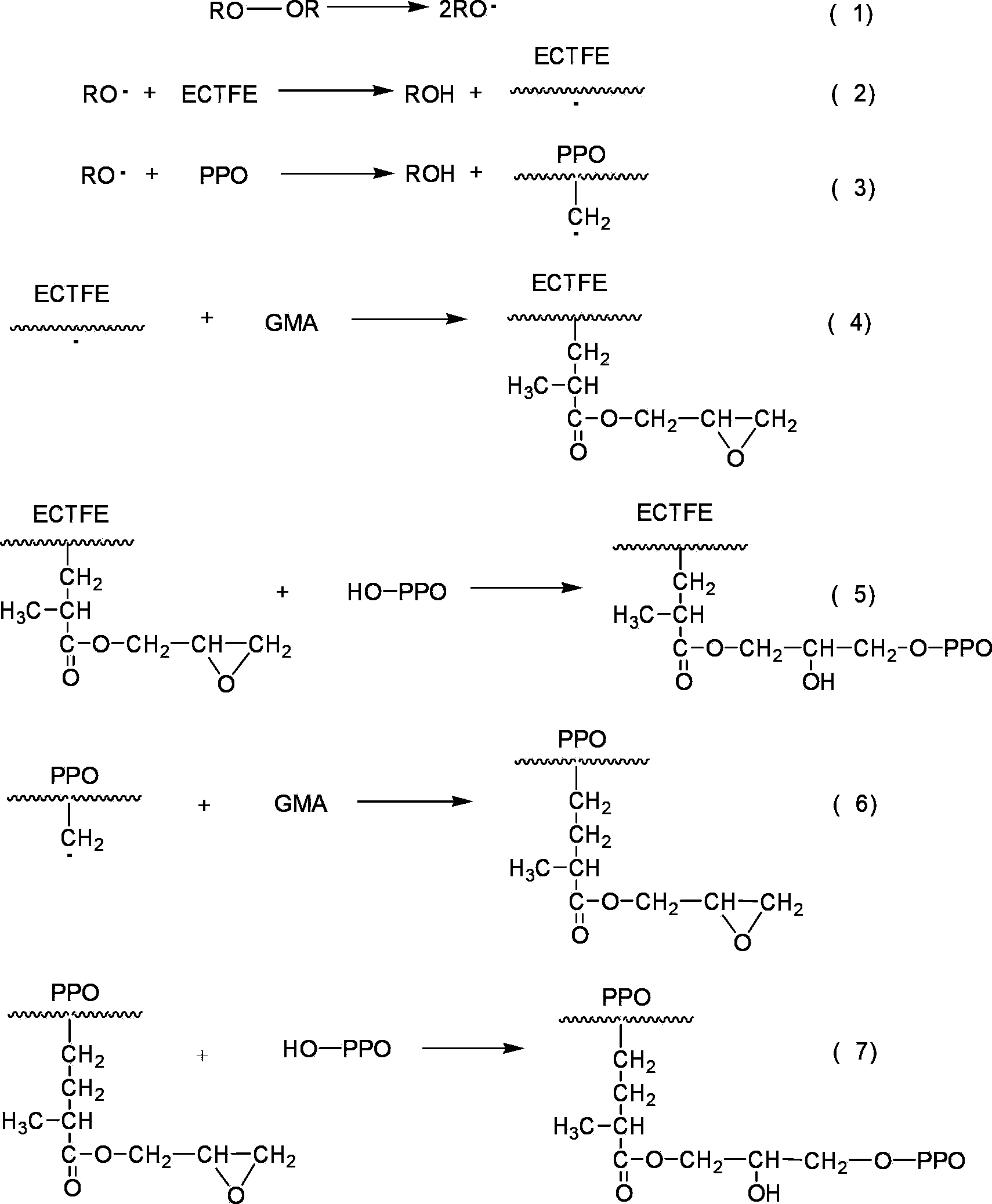

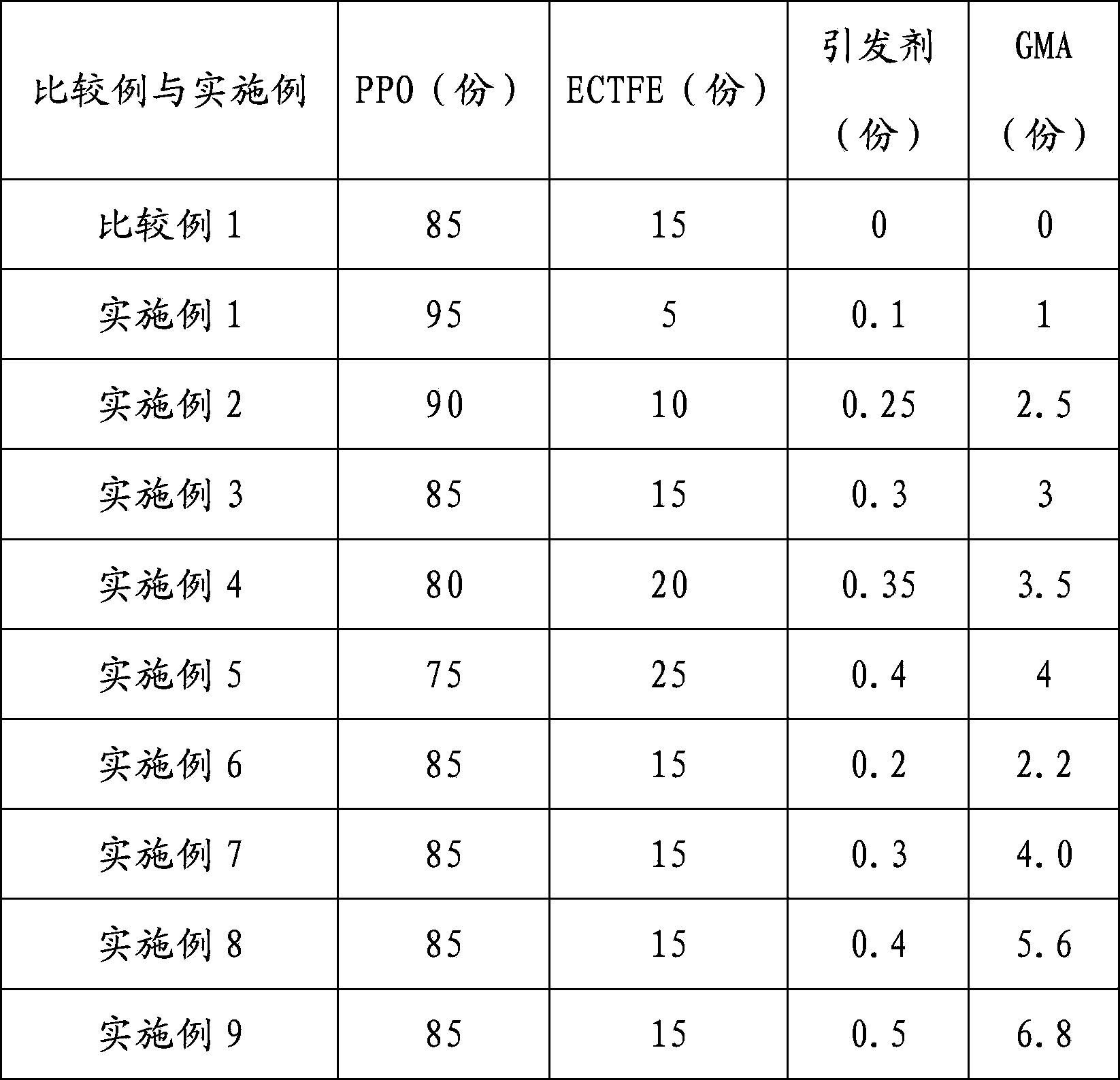

High-fire-retardant PPO/ECTFE (polyphenylene oxide/ethylene-chlorotrifluoroethylene) copolymer alloy prepared through in-situ method and preparation method thereof

ActiveCN102924665BImprove performanceImprove flame retardant performanceGlycidyl methacrylateCompound (substance)

The invention discloses a high-fire-retardant PPO / ECTFE (polyphenylene oxide / ethylene-chlorotrifluoroethylene) copolymer alloy prepared through an in-situ method and a preparation method thereof. The alloy comprises the following raw materials in parts by weight: 65-95 parts of PPO, 5-35 parts of ECTFE copolymer, 0.01-1 part of initiator and 0.1-10 parts of glycidyl methacrylate, wherein the sum of the parts by weight of the PPO and the parts by weight of the ECTFE copolymer is 100 parts. The PPO / ECTFE alloy has excellent fire retardance and simultaneously has high tensile strength and impact strength, thereby having wide application values in the fields such as chemical engineering, electronics, electric appliances and the like.

Owner:SINOPLAST NEW MATERIAL

Anti-corrosion sedimentation tank and building method thereof

InactiveCN102462981BLight weight high strengthHigh strengthSedimentation settling tanksElectrolysisStructural engineering

The invention discloses an anti-corrosion sedimentation tank and a building method thereof. A tank body is made of glass fiber reinforced plastics, so the anti-corrosion problem is solved; and a support frame, a support tank body, a raking machine arranged in the tank body and a driving device driving the raking machine to operate are made of carbon steel, so the problem that the tank body has poor rigidity and can not support the raking machine to normally work is solved. The raking machine is a carbon steel welding element, in addition, ethylene-chlorotrifluoroethylene copolymer (ECTFE) anti-corrosion coatings with the thickness not less than 1.5mm are integrally sprayed and coated on the surface of the raking machine, the intensity requirement of the raking machine is met, and the anti-corrosion problem of the raking machine is also solved. A scraping plate is covered by more than 8.5mm of glass fiber wires or cloth, and the coatings on the scraping plate are prevented from being damaged when the scraping plate is used for scraping materials settled at the bottom of the tank body. The anti-corrosion problem of the sedimentation tank is perfectly solved, simultaneously, the work stability of the sedimentation tank is also ensured, and the production requirement of the electrolysis industry is met. The anti-corrosion sedimentation tank has the advantages that the structure is compact, the operation is stable, the sedimentation effect is good, economy and practicability are realized, and the like.

Owner:GUIYANG AL-MG DESIGN & RES INST

A kind of hollow fiber polymer membrane, preparation method and its application in brine refining

ActiveCN108479414BGood anti-pollutionIncreased osmotic fluxSemi-permeable membranesMembranesHollow fibrePolymer science

The invention provides a preparation method of a hollow fiber polymer membrane, particularly relates to a membrane filter using the membrane in the process field of brine refining, and belongs to thefield of polymer separation membrane preparation. ECTFE (ethylene-chlorotrifluoroethylene copolymer) is used as a membrane material for preparing the hollow fiber membrane; the hollow fiber membrane is applied to a brine refining process. The average pore diameter of the prepared hollow fiber membrane is 150 to 220nm; the tensile strength is 2.5 to 4.7MPa; the pure water flux at 25 DEG C is 320 to710L / (m2.h.bar). The ECTFE, a diluent and an inorganic additive are proportionally mixed; heating dissolving is performed; a prepared casting membrane solution is spun into a hollow fiber shape by aspinning machine; then, quenching is performed; the prepared membrane silk is firstly subjected to acid pickling; then, the diluent is extracted by a proper solvent; drying is performed to obtain an ECTFE hollow fiber membrane. The hydrophilicity of the membrane prepared by the method is improved; the tensile strength is high; the pure water flux of the membrane is great; the pore diameter is concentrated; the pollution resistant performance is good; a good application effect is realized in the brine refining process.

Owner:NANJING TECH UNIV

A kind of ectfe meltblown film and preparation method thereof

ActiveCN112853626BUniform pore size distributionHigh tensile strengthMonocomponent synthetic polymer artificial filamentNon-woven fabricsPolymer scienceUltimate tensile strength

The invention discloses an ECTFE melt-blown film and a preparation method thereof. The melt-blown film is composed of ultrafine fibers with a diameter of 0.1 μm to 5 μm, and at least 60% of the melt-blown film has a pore size of 0.3 μm to 0.7 μm. In between, the pore size of less than 20% of the meltblown film is between 0.1 μm and 0.3 μm, and the pore size of less than 20% of the meltblown film is between 0.7 μm and 1.0 μm. The melt-blown film of the present invention has the advantages of high tensile strength, high elongation at break, small average pore size, high filtration precision, and is suitable for high temperature resistance, acid and alkali resistance and corrosion resistance environment.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

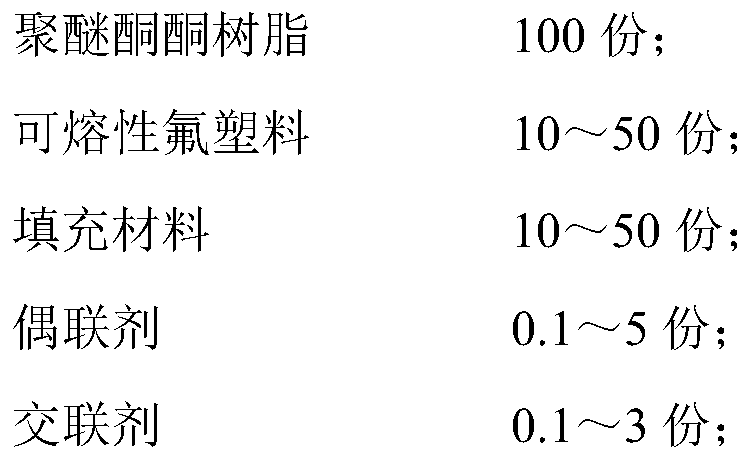

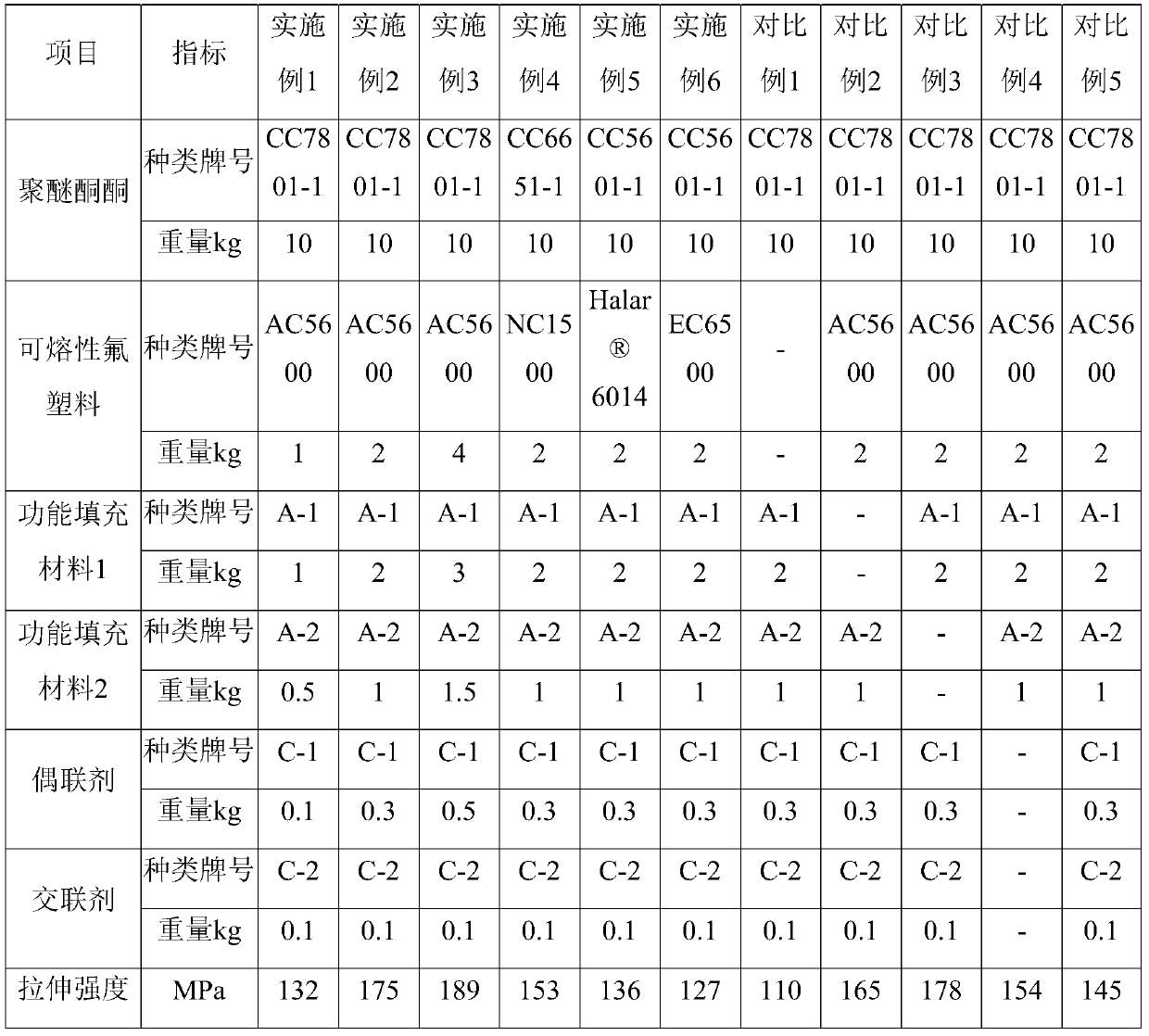

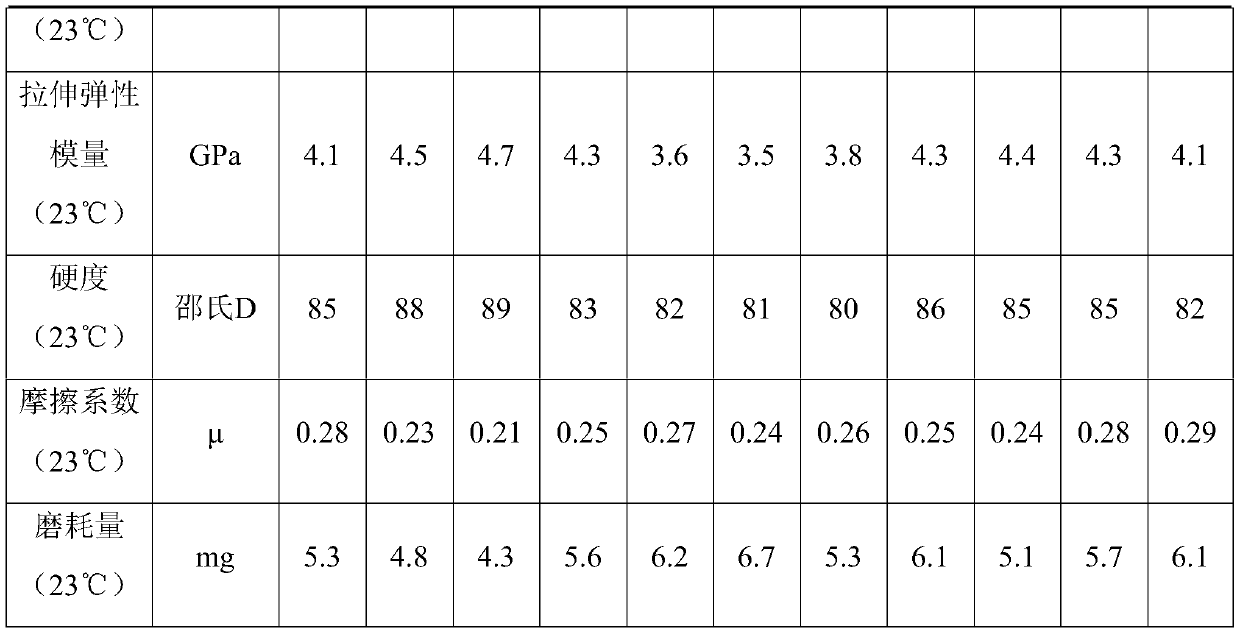

Polyether ketone ketone composite material that can replace metal and preparation method thereof

ActiveCN108129826BImprove high temperature resistanceImprove flame retardant performanceEngineering plasticCross linker

The invention relates to a polyether ketone ketone composite material capable of replacing metal and a preparation method thereof, belonging to the field of special engineering plastic industries. Thepolyether ketone ketone composite material capable of replacing metal comprises the following raw materials: 100 parts of polyether ketone ketone resin, 10 to 50 parts of fusible fluoroplastic, 10 to50 parts of a filling material, 0.1 to 5 parts of a coupling agent and 0.1 to 3 parts of a cross-linking agent, wherein the fusible fluoroplastic is at least one selected from the group consisting ofFEP, PFA, ECTFE or ETFE. The polyether ketone ketone composite material provided by the invention remains inherent properties like excellent high-temperature resistance, flame retardancy, chemical resistance and heat and humidity resistance and good strength and stiffness of the PEKK resin, and has performances like excellent wear resistance and chemical corrosion resistance, high hardness and light weight; and the preparation method for the polyether ketone ketone composite material is scientific, reasonable, simple and practicable.

Owner:SHANDONG KAISHENG NEW MATERIALS

A high-flux polymer separation membrane, preparation method, diluent composition and application

ActiveCN108057346BNo pollution in the processIncreased pure water fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisHollow fibreFiber

The invention provides a high-throughput polymer separation membrane, a preparation method, a diluent composition and an application, and belongs to the technical field of preparation of polymer separation membranes. The invention relates to a method for preparing an ECTFE porous membrane by adopting a two-element diluent through a thermally-induced phase separation method. The method comprises the following steps: with 15 to 70 wt% of an ECTFE polymer and two solvents with a total mass percentage of 30 to 85 wt% as the two-element diluent for preparation of a membrane casting solution, subjecting the ECTFE polymer and two solvents to heating under stirring and carrying out standing and defoaming, or mixing the ECTFE polymer and two solvents through a double screw extruder so as to preparea polymer homogeneous membrane casting solution; scraping the casting solution into a plate shape or into a hollow fiber shape through spinning of a spinning nozzle, then carrying out soaking in a cooling liquid, carrying out quenching, and carrying out curing so as to form a membrane; and soaking the formed film into an extractant, allowing the diluent to be extracted out of the formed membrane,and carrying out drying in the air so as to prepare the ECTFE porous membrane. The invention is characterized by adopting two environment-friendly solvents as the two-element diluent for preparationof the ECTFE porous membrane; the preparation process is simple and has green and environment-friendly process; and the ECTFE porous membrane prepared by using the preparation process provided by theinvention has large throughput which is improved by 1.5 times or above compared with the throughput of the ECTFE porous membrane prepared by using a single diluent.

Owner:NANJING TECH UNIV

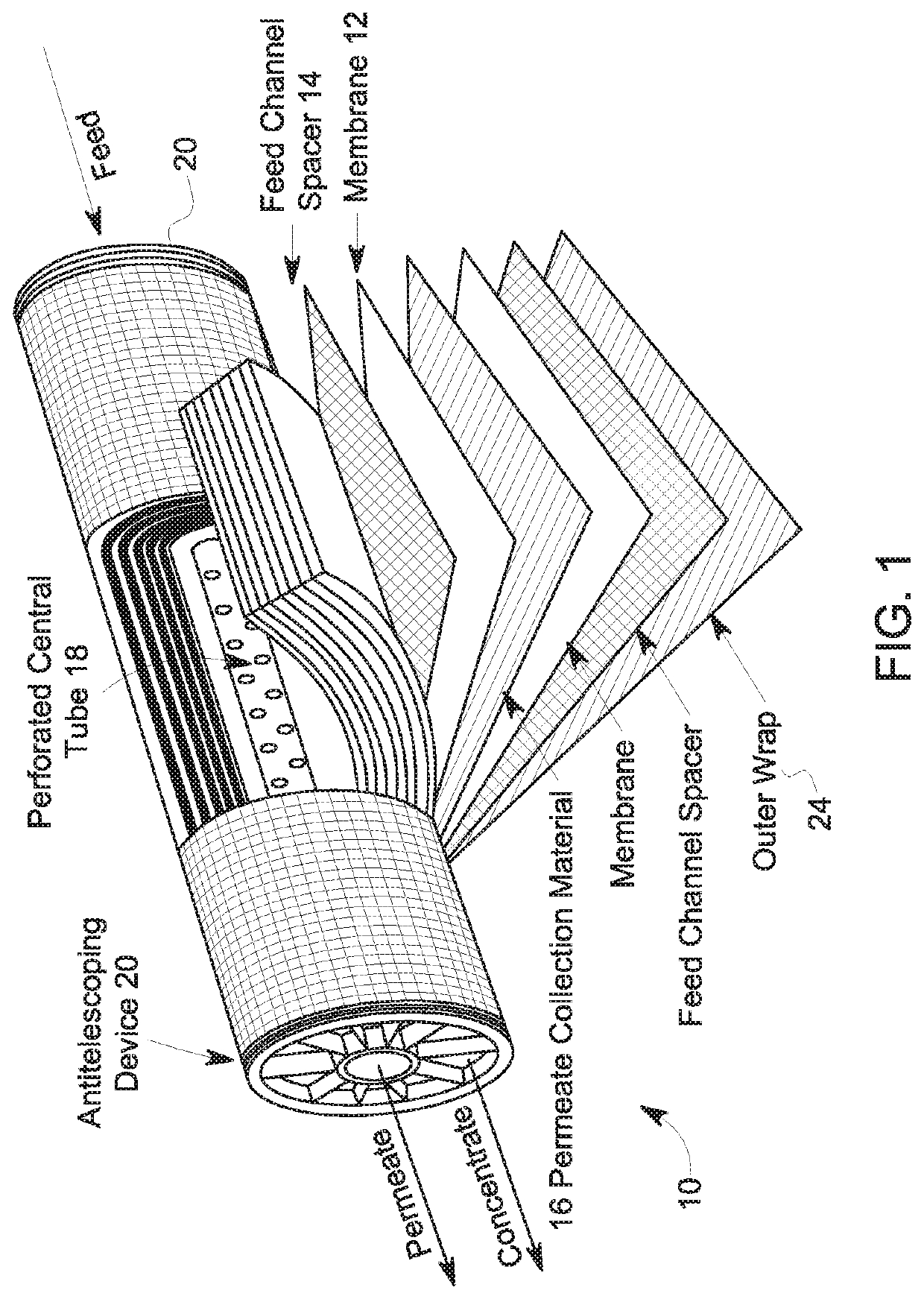

Spiral wound membrane element for high temperature filtration

A spiral wound membrane module is suitable for use with high temperature water that may also have a high pH, for example steam injection produced water. The module uses a membrane with a polyphenylene sulfide (PPS) backing material. The feed spacer of the module may be made from polyphenylene sulfide (PPS) or ethylene chlorotrifluoroethylene (ECTFE). The permeate carrier may be made of a woven nylon (i.e. nylon 6, 6) fabric coated with high temperature epoxy. The core tube and anti-telescoping device may be made of polysulfone. In some examples, the module may be used at a temperature of up to 130 ° C. Optionally, the module may be used at a pH of 9.5 or more. In a filtration method, the module may be operated at a pressure in the range of 150 to 450 psi. The module may be operated at a generally constant pressure.

Owner:BL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com