Polyether ketone ketone composite material that can replace metal and preparation method thereof

A polyetherketone ketone and composite material technology, which is applied in the field of special engineering plastics, polyetherketone ketone composite materials and their preparation, can solve the problem of reducing the quality stability of products and material practicability, reducing the mechanical properties of composite materials, and being easy to disperse. Uniformity and other issues, to achieve significant economic and social benefits, cost and weight reduction, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

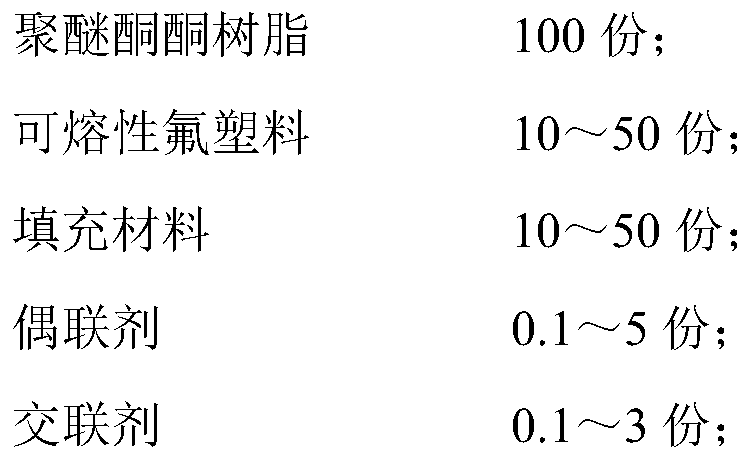

Method used

Image

Examples

Embodiment 1~3

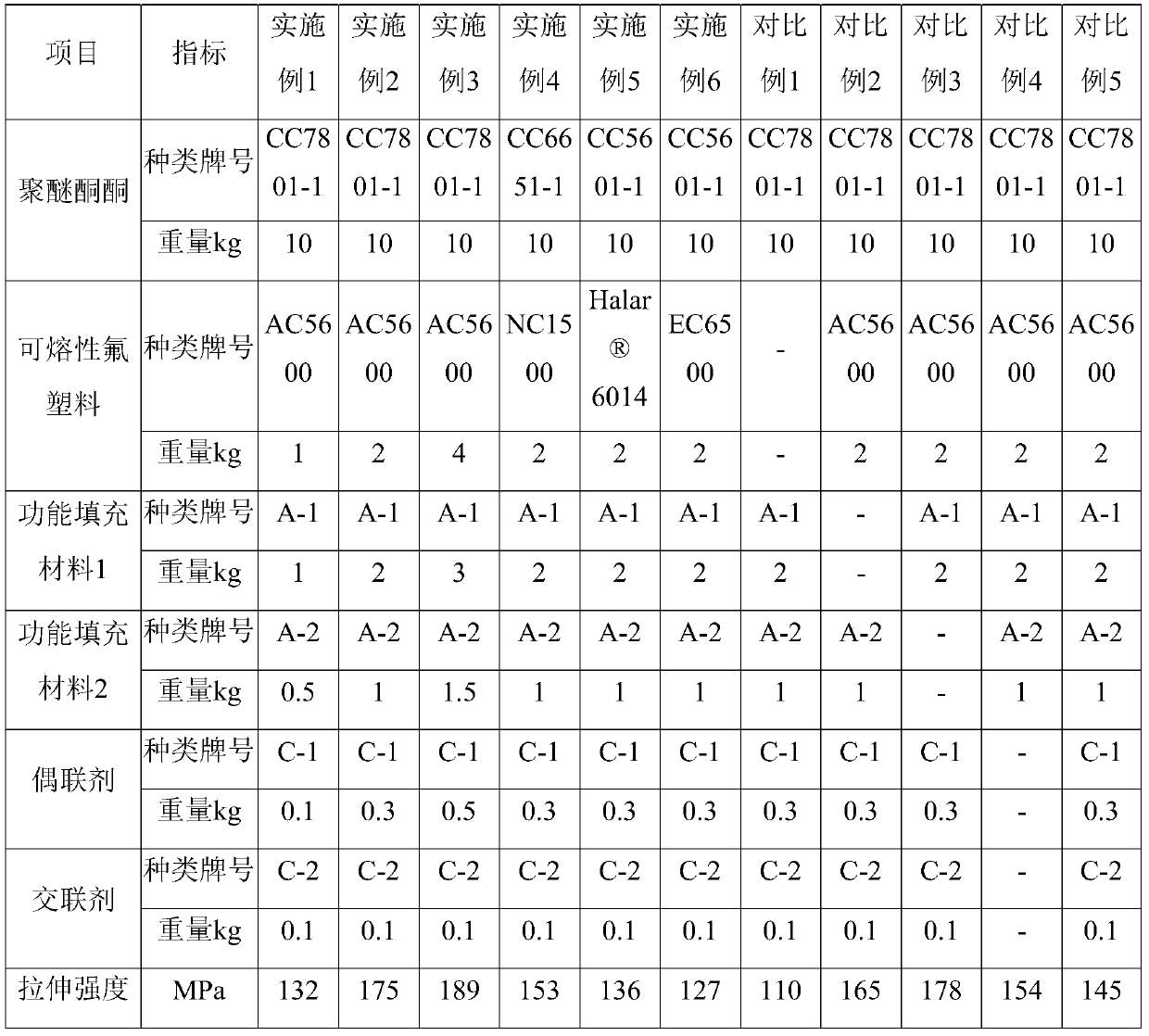

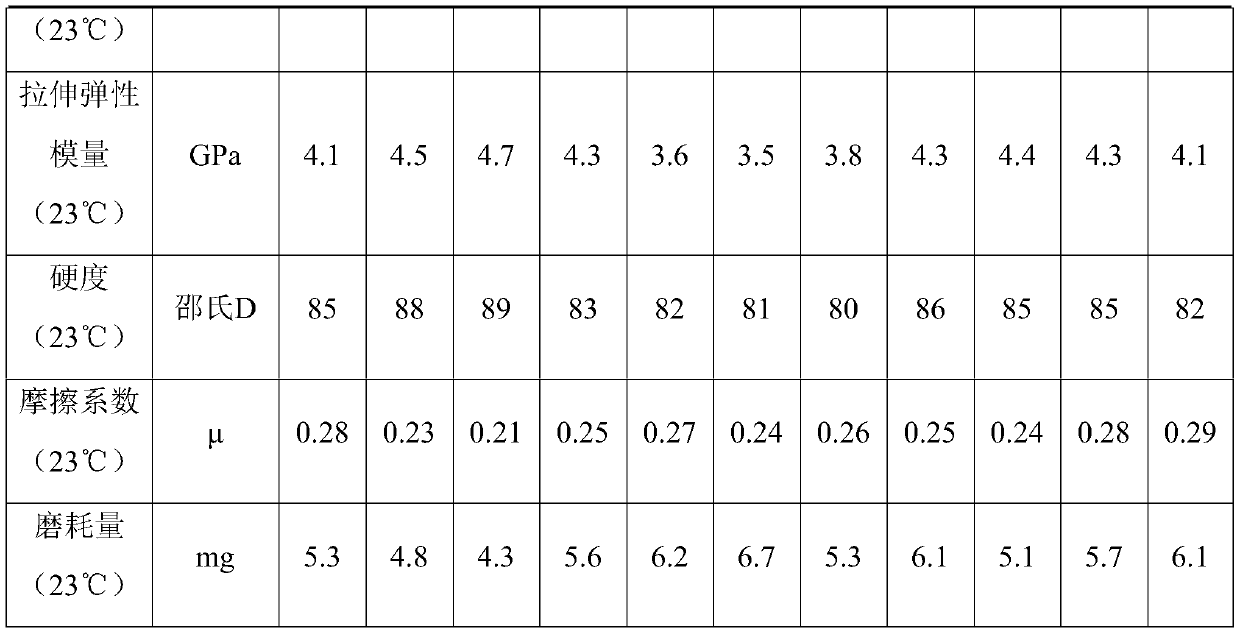

[0044] After adding the components shown in Table 1 to the high-speed mixer and mixing for 5 minutes according to the ratio shown in Table 1, the mixed mixture A was bagged for use; the above-mentioned mixture A was integrated with a fluidized bed jet mill at high speed. For modified crushing and mixing treatment, the frequencies of the feeder and the induced draft fan are set to 40 Hz and 50 Hz respectively, the frequency of the classifier is set to 10 Hz, the air supply pressure is 0.7 MPa, and the fine powder with a particle size of 150 μm or less is selected for use in bags; The fine powder is suitable for dry heat treatment at 240°C for 4 hours in a hot air circulating oven; the above dry heat-treated mixture B is added in batches to the mold cavity of the hot press for pre-pressing and pre-forming, and the charging temperature of the hot press is set to 285±5℃, the feeding pressure is 4MPa, and the difference between the supplementary pressure and the feeding pressure is ...

Embodiment 4~6

[0046] Since the grades of the selected polyetherketone ketone resin binders are CC6651-1 and CC5601-1, the relevant processing temperatures are 25°C and 40°C lower than those in Example 1, respectively. method, after the integrated pulverization and mixing treatment, the hot pressing is carried out. The strength, wear resistance and hardness of each sample were measured, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com