Anti-corrosion sedimentation tank and building method thereof

A construction method and technology of settling tank, applied in the direction of settling tank, etc., to achieve the effect of good designability, light weight, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

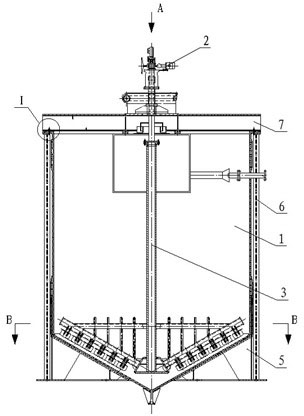

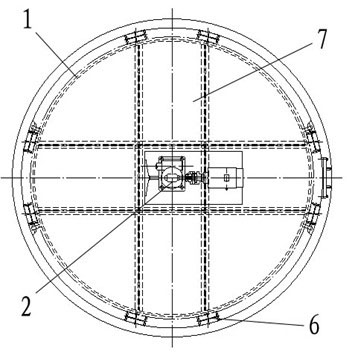

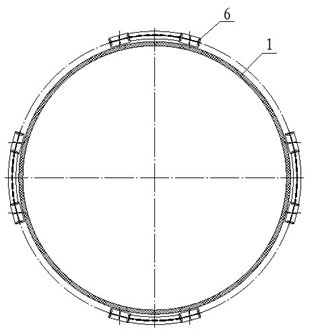

[0029] Embodiments of the invention. The structure diagram of the present invention is as Figure 1 to Figure 6 As shown, when implementing a construction method of a corrosion-resistant settling tank of the present invention, the method uses glass fiber reinforced plastics to make the tank body 1 to solve the anti-corrosion problem; make a support with carbon steel to support the tank body and the rake machine installed in the tank body 3 and the driving device 2 that drives the rake machine to run, to solve the problem that the poor rigidity of the tank cannot support the normal operation of the rake machine. The rake is a carbon steel weldment to meet the strength requirements of the rake; the surface of the rake is sprayed with an ECTFE anti-corrosion coating not less than 1.5mm thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com