High-fire-retardant PPO/ECTFE (polyphenylene oxide/ethylene-chlorotrifluoroethylene) copolymer alloy prepared through in-situ method and preparation method thereof

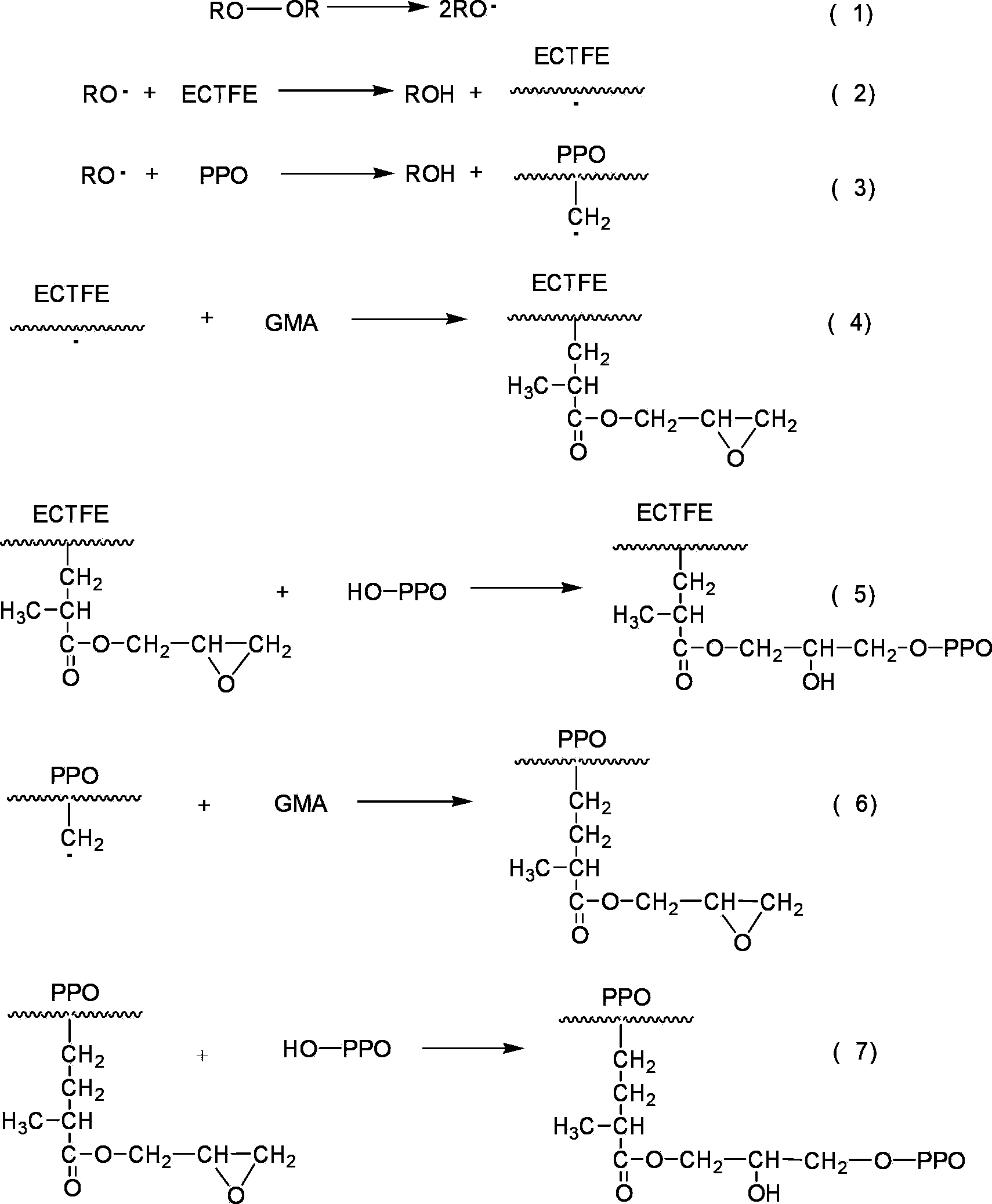

A technology of chlorotrifluoroethylene and polyphenylene ether, applied in the field of high flame-retardant polyphenylene ether/ethylene-chlorotrifluoroethylene copolymer alloy and its preparation, achieving good comprehensive performance, wide application fields, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

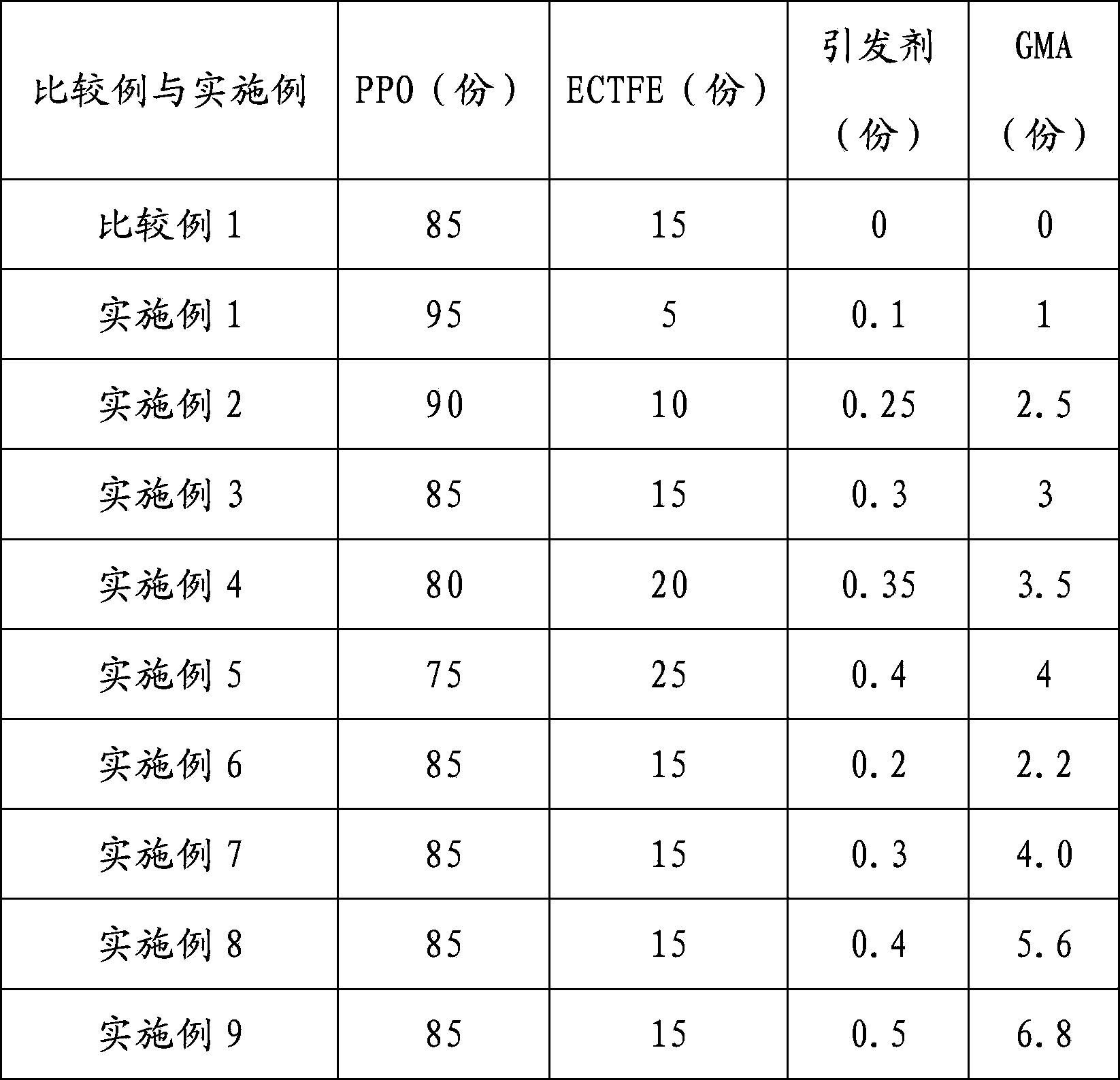

[0059] A kind of highly flame-retardant PPO / ECTFE alloy, its raw material composition and weight parts are:

[0060] PPOs

95 copies

ECTFE

5 copies

L-101

0.1 part

GMA

1 copy

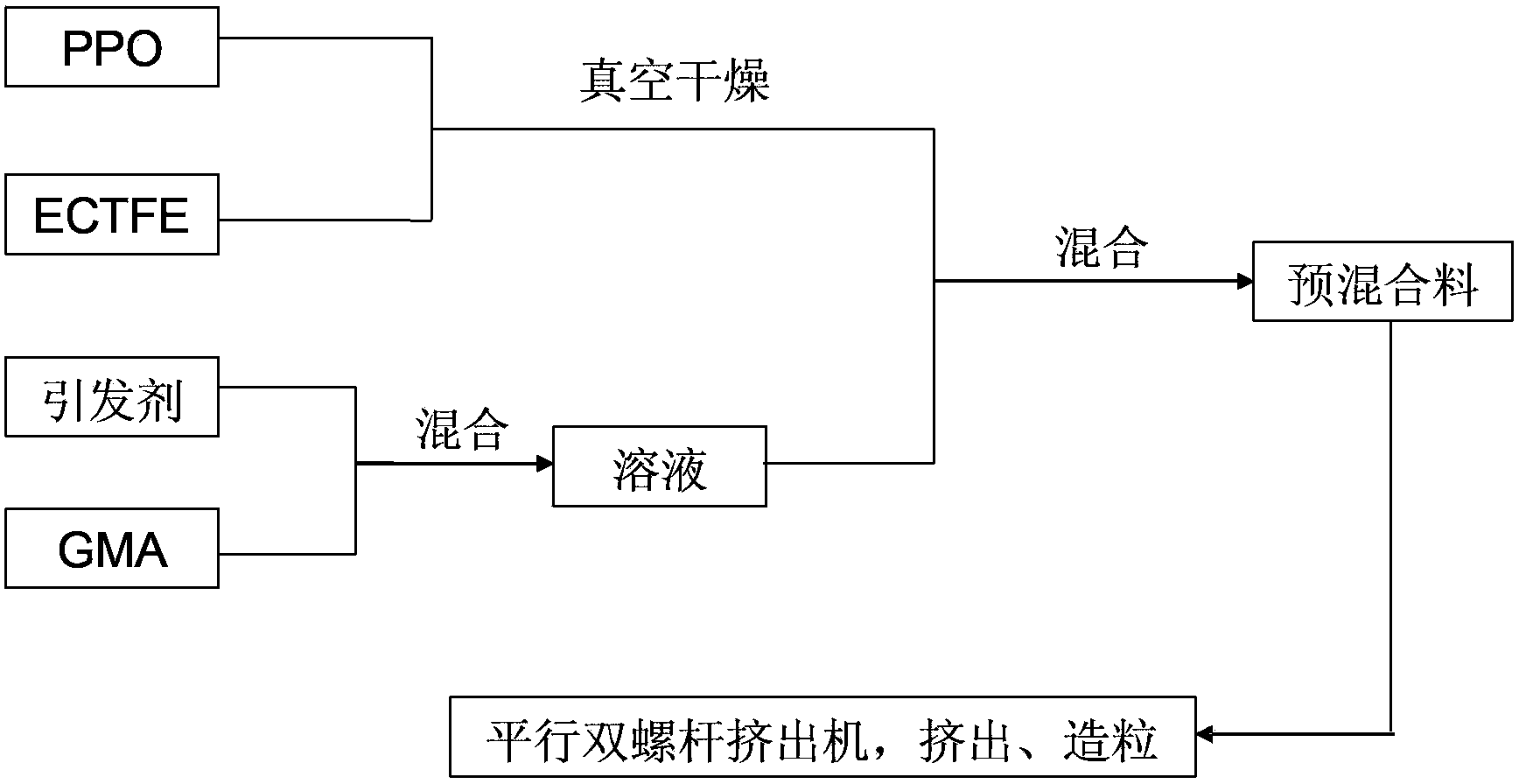

[0061] The preparation method of above-mentioned high flame-retardant PPO / ECTFE alloy comprises the following steps:

[0062] (1) Put PPO and ECTFE in a vacuum oven, dry PPO at 90°C for 8 hours, and dry ECTFE at 80°C for 5 hours;

[0063] (2) Mix L-101 with glycidyl methacrylate to obtain a solution for later use;

[0064] (3) Mix PPO and ECTFE evenly, and then add the solution obtained in step (2) to obtain a premix;

[0065] (4) Put the premixed material obtained in step (3) into a parallel twin-screw extruder to melt and extrude, and granulate. The process parameters are as follows: The screw speed of the parallel twin-screw extruder is 120r / min. The temperature is 170°C, the temperature in the second zone is 240°C, the temperature in the third zo...

Embodiment 2

[0068] A kind of highly flame-retardant PPO / ECTFE alloy, its raw material composition and weight parts are:

[0069] PPOs

90 copies

ECTFE

10 copies

L-101

0.25 parts

GMA

2.5 servings

[0070] The preparation method of above-mentioned high flame-retardant PPO / ECTFE alloy comprises the following steps:

[0071] (1) Put PPO and ECTFE in a vacuum oven, dry PPO at 90°C for 8 hours, and dry ECTFE at 80°C for 5 hours;

[0072] (2) Mix L-101 with glycidyl methacrylate to obtain a solution for later use;

[0073] (3) Mix PPO and ECTFE evenly, and then add the solution obtained in step (2) to obtain a premix;

[0074] (4) Put the premixed material obtained in step (3) into a parallel twin-screw extruder to melt and extrude, and granulate. The process parameters are as follows: The screw speed of the parallel twin-screw extruder is 120r / min. The temperature is 170°C, the temperature in the second zone is 240°C, the temperature in the...

Embodiment 3

[0077] A kind of highly flame-retardant PPO / ECTFE alloy, its raw material composition and weight parts are:

[0078] PPOs

85 copies

ECTFE

15 copies

DCP

0.3 parts

GMA

3 copies

[0079] The preparation method of above-mentioned high flame-retardant PPO / ECTFE alloy comprises the following steps:

[0080] (1) Put PPO and ECTFE in a vacuum oven, dry PPO at 90°C for 8 hours, and dry ECTFE at 80°C for 5 hours;

[0081] (2) Mix DCP and glycidyl methacrylate to obtain a solution for later use;

[0082] (3) Mix PPO and ECTFE evenly, and then add the solution obtained in step (2) to obtain a premix;

[0083] (4) Put the premixed material obtained in step (3) into a parallel twin-screw extruder to melt and extrude, and granulate. The process parameters are as follows: The screw speed of the parallel twin-screw extruder is 120r / min. The temperature is 170°C, the temperature in the second zone is 240°C, the temperature in the third zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com