A kind of hollow fiber polymer membrane, preparation method and its application in brine refining

A fiber polymer, brine refining technology, applied in chemical instruments and methods, membranes, membrane technology and other directions, can solve the problems of difficult control of PTFE membrane pore size, high packing density, and low strength of hollow fiber membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

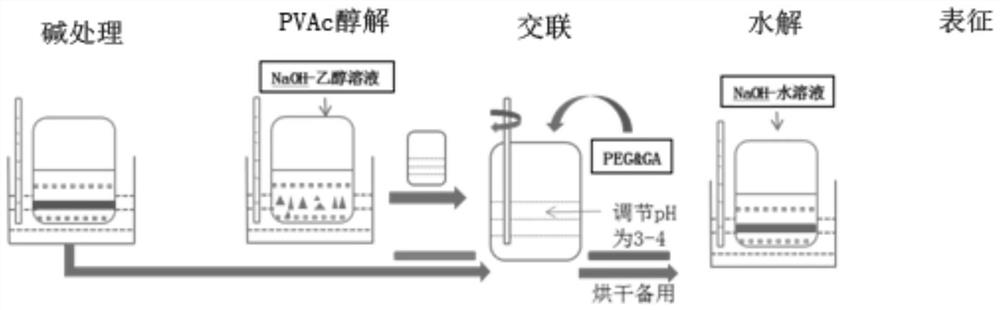

Method used

Image

Examples

Embodiment 1

[0103] Accurately weigh 20g of diluent (acetyl tributyl citrate: dioctyl terephthalate = 1:1), 35g of ECTFE (Halar® 902), 45g of calcium carbonate, stir well and pour into a 500 mL high-temperature container , the temperature of the oil bath used was 250°C, nitrogen was used as a protective gas, and then the solution was stirred with an electric stirrer for 4 h, and then left in the oil bath for defoaming for 4 h; the casting solution was extruded into a hollow Fibrous, then put the membrane silk into a water quenching bath (20-25°C) to solidify to form a film; put the obtained hollow fiber membrane in an ethanol solution for a certain period of time to extract the diluent, after drying, and then After washing with hydrochloric acid whose pH is between 1 and 2 for 12 hours, and washing with deionized water, the ECTFE porous membrane is prepared.

Embodiment 2

[0105] Accurately weigh 20g of diluent (acetyl tributyl citrate: dioctyl terephthalate = 3:1), 35g of ECTFE (Halar® 902), 45g of calcium carbonate, stir well and pour into a 500 mL high-temperature container , stirred evenly and poured into a 500 mL high-temperature container, the temperature of the oil bath used was 250°C, nitrogen was used as the protective gas, and then the solution was stirred with an electric stirrer for 4 hours, and then stood in the oil bath for 4 hours to defoam; The spinning method extrudes the casting solution into a hollow fiber shape, and then puts the membrane filament into a water quenching bath (20-25°C) to solidify to form a membrane; the obtained hollow fiber membrane is extracted in an ethanol solution for a certain period of time. The diluent is extracted, dried, washed with hydrochloric acid with a pH between 1 and 2 for 12 hours, and washed with deionized water to prepare an ECTFE porous membrane.

Embodiment 3

[0107]Accurately weigh 20g of diluent (acetyl tributyl citrate: dioctyl terephthalate = 1:3), 35g of ECTFE (Halar® 902), 45g of silicon dioxide, stir well and pour into a 500 mL high-temperature container , stirred evenly and poured into a 500 mL high-temperature container, the temperature of the oil bath used was 250 °C, nitrogen was used as the protective gas, and then the solution was stirred with an electric stirrer for 4 h, and then left in the oil bath for 4 h to defoam ; Extrude the casting solution into a hollow fiber shape by spinning, and then put the membrane filament into a water quenching bath (20-25°C) to solidify into a membrane; put the obtained hollow fiber membrane in an ethanol solution to extract a certain time, extract the diluent, after drying, wash with sulfuric acid whose pH is between 1 and 2 for 12 hours, and wash with deionized water to prepare the ECTFE porous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com