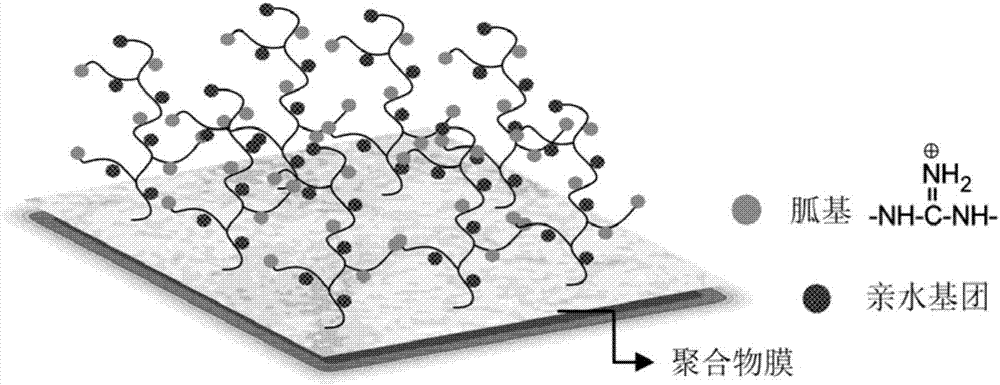

Method for preparing antibacterial and antifouling separation membrane through surface grafting modification

A surface graft modification and separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve problems such as increasing production and operating costs, reducing membrane flux and life, and achieving high efficiency and stability. Antibacterial properties, prevention of adsorption and deposition, effect of good selection properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

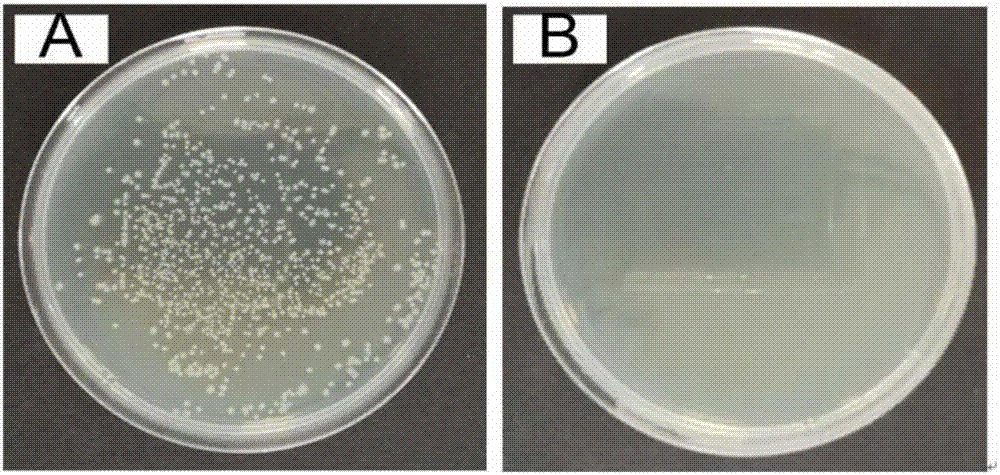

[0028] Take 10 g of guanidine hydrochloride, 5 g of 1,6-hexanediamine, and 1 g of polyethyleneimine (molecular weight 600), add them to the reactor, mix them evenly, under nitrogen protection, heat up to 120 ° C, and reflux with stirring for 10 hours. , to obtain polyethyleneimine-based guanidine-containing polymers.

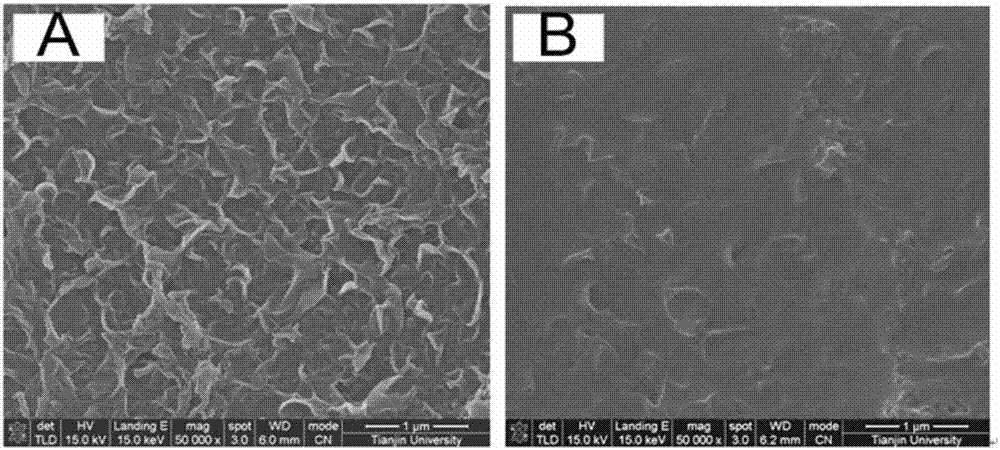

[0029] Dissolve 0.1 g of tris(hydroxymethyl)aminomethane in 100 mL of water, add 0.05 g of dopamine hydrochloride, and mix well. The reaction solution configured above is poured into the frame of the fixed polyamide reverse osmosis membrane, the membrane surface is contacted with the reaction solution, the reaction solution is poured out after 2 hours of reaction in the shaker, and the membrane surface is washed with water; then, the configuration concentration is 5g / L of polyethyleneimine-based guanidine-containing polymer aqueous solution, mixed evenly, poured into the frame, shaken and reacted for 2 hours, poured off the reaction solution, and washed the memb...

Embodiment 2

[0032] Take aminoguanidine hydrochloride 10g, trimethylhexanediamine 10g, polyoxyethylene diamine (molecular weight 1000) 5g, add to the reactor, mix well, under nitrogen protection, heat up to 160 ℃, and reflux under stirring for reaction 6 After one hour, a polyoxyethylene diamine-based guanidine-containing polymer was obtained.

[0033] Dissolve 0.1 g of tris(hydroxymethyl)aminomethane in 100 mL of water, add 0.2 g of dopamine hydrochloride, and mix well. The reaction solution of the above configuration is poured into the frame of the fixed polysulfone ultrafiltration membrane, the membrane surface is contacted with the reaction solution, the reaction solution is poured out after 1 hour of reaction in the shaker, and the membrane surface is washed with water; then, the configuration concentration is 2 g / L aqueous solution of polyoxyethylene diamine guanidine-containing polymer, mixed evenly, poured into the frame, shaken and reacted for 1 hour, poured out the reaction solut...

Embodiment 3

[0036] Take 10 g of triaminoguanidine hydrochloride, 20 g of triethylene tetramine, and 10 g of polyetheramine (molecular weight: 230), put them into the reactor, mix them evenly, under nitrogen protection, heat up to 200 ° C, and reflux with stirring for 4 hours. A polyetheramine-based guanidine-containing polymer was obtained.

[0037]Dissolve 0.1 g of tris(hydroxymethyl)aminomethane in 100 mL of water, add 0.3 g of dopamine hydrochloride, and mix well. Pour the above-configured reaction solution into the frame of the fixed polyvinylidene fluoride ultrafiltration membrane, make the membrane surface contact the reaction solution, pour out the reaction solution after reacting in the shaker for 0.5 hours, and wash the membrane surface with water; then, configure The aqueous solution of polyetheramine guanidine-containing polymer with a concentration of 1 g / L was mixed evenly and poured into the frame. After shaking reaction for 4 hours, the reaction solution was poured out, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com