Porous composite filter tube and preparation method thereof

A technology for filter tubes and porous materials, which is applied in the field of porous composite filter tubes. The preparation field of the porous composite filter tubes can solve the problem of reducing the anti-corrosion and anti-oxidation capabilities of porous thin layers, affecting the development and promotion of composite filter tubes, and the lack of air permeability. Clear expression and other issues to achieve the effect of convenient operation and maintenance, low resistance and high permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of porous composite filter tube of the present invention, specifically carries out according to the following steps:

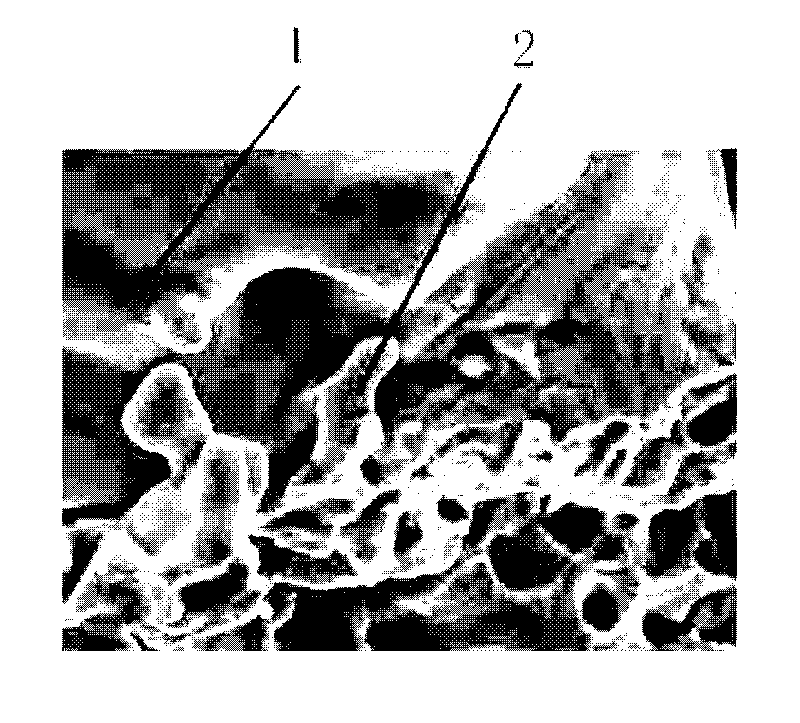

[0020] Step 1: According to the powder metallurgy method, prepare a porous material matrix with a pore size of 20-150 μm, a thickness of 2-10 mm, and unlimited length and diameter;

[0021] Powder metallurgy is the process of using metal powder or alloy powder as raw material, forming and sintering to manufacture metal materials, composite materials and various types of products well known to those skilled in the art;

[0022] Step 2: According to mass percentage, weigh 30%-60% of the multilayer powder, 70%-40% of the carrier, and the total amount of the above components is 100%, wherein the multilayer powder is one of metal, alloy or ceramic One or more combinations, the average particle size of the multilayer powder is 3 μm-10 μm; the carrier is an organic solvent, such as ethanol, carbon tetrachloride, etc., and the weighed mul...

Embodiment 1

[0036] Prepare a stainless steel filter tube with a pore diameter of 20 μm and a thickness of 10 mm, mix 60 parts by weight of iron-aluminum powder with an average particle size of 3 μm and 40 parts by weight of ethanol, put it into an air distribution mixing tank, and prepare a suspension liquid. The suspension was deposited layer by layer on the outer surface of the stainless steel filter tube under the atomization pressure by the gas atomization equipment, with a thickness of 200 μm. Then under a hydrogen atmosphere, the sintering temperature is 600°C, and the temperature is kept for 1 hour, which is obtained.

[0037] After testing, the thickness of the functional layer of the composite filter tube is 200 μm, the porosity of the composite filter tube is 40%, the filtration accuracy is 0.1 μm, and the relative air permeability coefficient is 100m3 / h.m2.kPa. It can be widely used in pipeline high-temperature gas purification, coal-fired boilers, nuclear waste gas treatment,...

Embodiment 2

[0039]Prepare a stainless steel filter tube with a pore diameter of 150 μm and a thickness of 2 mm, mix 50 parts by weight of stainless steel powder with an average particle size of 5 μm and 50 parts by weight of ethanol, put it into an air distribution mixing tank, and prepare a suspension . The suspension was deposited layer by layer on the outer surface of the stainless steel filter tube by centrifugal spraying, with a thickness of 100 μm. In a hydrogen atmosphere, the composite filter tube is sintered at a temperature of 1400° C. and kept for 3 hours to obtain the composite filter tube.

[0040] After testing, the thickness of the functional layer of the composite filter tube is 100 μm, the porosity of the composite filter tube is 42%, the filtration accuracy is 1 μm, and the relative air permeability coefficient is 120m3 / h.m2.kPa. It can be used for microfiltration of liquid and gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com