Preparation method of composite forward osmosis membrane added with acid-activated black talc nano material

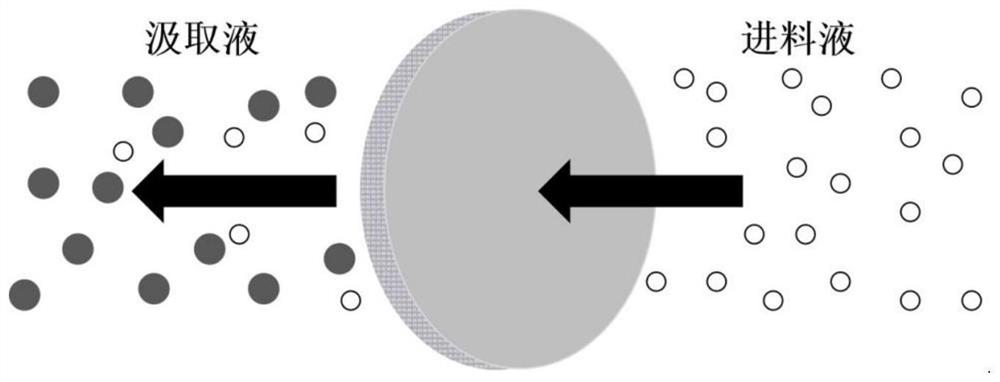

A nanomaterial and forward osmosis membrane technology is applied in the field of preparation of acid-activated black talc nanomaterial composite forward osmosis membranes, which can solve the problems of low flux and concentration polarization of polyamide composite forward osmosis membranes, and achieve a reduction in Small concentration polarization problem, high rejection rate, the effect of improving permeation flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

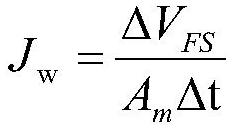

Method used

Image

Examples

Embodiment 1

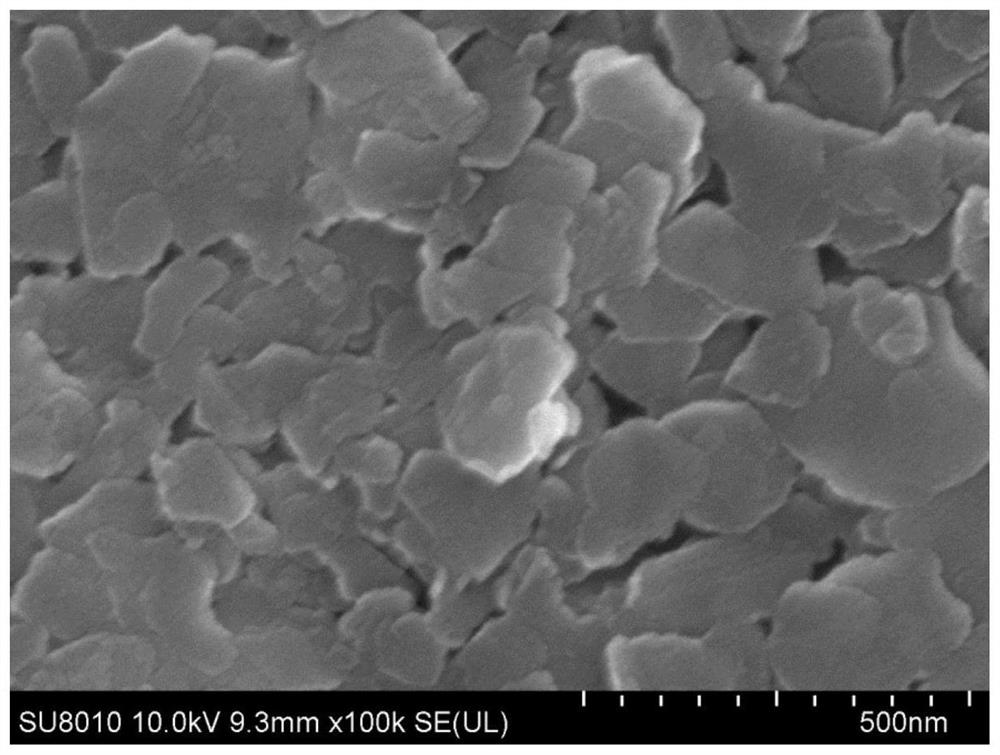

[0036] (1) Preparation of acid-activated black talc nanomaterials

[0037] 10 g of black talc (the black talc originates from Guangfeng District, Shangrao City, Jiangxi Province) was ball milled, wet-milled with a ball mill at 600 r / min for 5 h, washed with water, centrifuged and dried to obtain 8.8 g of black talc nanoparticles. Vigorously stirring the black talc nanoparticles in deionized water at room temperature for one week, fully exfoliated, to obtain the black talc nanomaterials (average particle diameter is 220nm). Add 0.5 g of the above-prepared black talc nanomaterials to 20 mL of 65% nitric acid solution, reflux at 90 °C for 5 h, wash the acidified powder after reflux, centrifuge at 5000 r / min for 10 min, and dry in a vacuum oven at 120 °C.

[0038] (2) Preparation of polymer porous support layer

[0039] Dissolve 4.96g polysulfone in 30mL N,N-dimethylacetamide solution, let stand to defoam, form a stable and uniform casting solution, scrape the casting solution on...

Embodiment 2

[0044] (1) Preparation of acid-activated black talc nanomaterials

[0045] 10 g of black talc (the black talc originates from Guangfeng District, Shangrao City, Jiangxi Province) was ball milled, wet-milled with a ball mill at 600 r / min for 5 h, washed with water, centrifuged and dried to obtain 8.8 g of black talc nanoparticles. Vigorously stirring the black talc nanoparticles in deionized water at room temperature for one week, fully exfoliated, to obtain the black talc nanomaterials (average particle diameter is 220nm). Add 0.4g of the above-prepared black talc nanomaterials to 20mL of 65% nitric acid solution, reflux at 90°C for 6h, wash the acidified powder after reflux, centrifuge at 5000r / min for 10min, and dry in a vacuum oven at 120°C.

[0046] (2) Preparation of polymer porous support layer

[0047] Dissolve 3.675g of polyethersulfone in 20mL of N-methylpyrrolidone solution, let it stand for degassing, and form a stable and uniform casting solution, scrape the casti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com