Patents

Literature

55results about How to "Does not affect corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pipeline repaired mouth anti-corrosive primer coating having high adhesive bonding ability with thermal contraction belt

ActiveCN101328380AFast curingShorten the construction periodCorrosion preventionAnti-corrosive paintsWaxSolvent

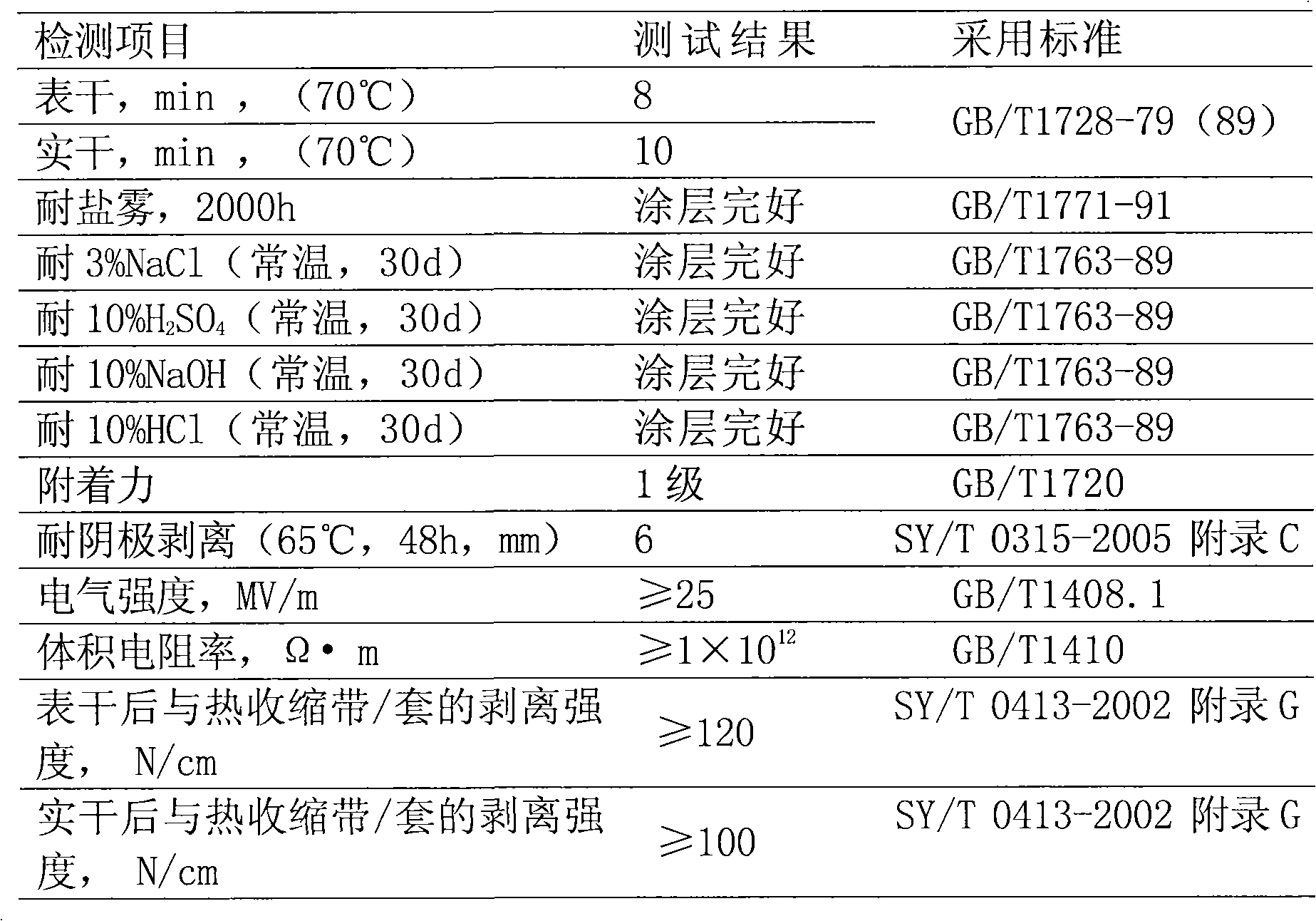

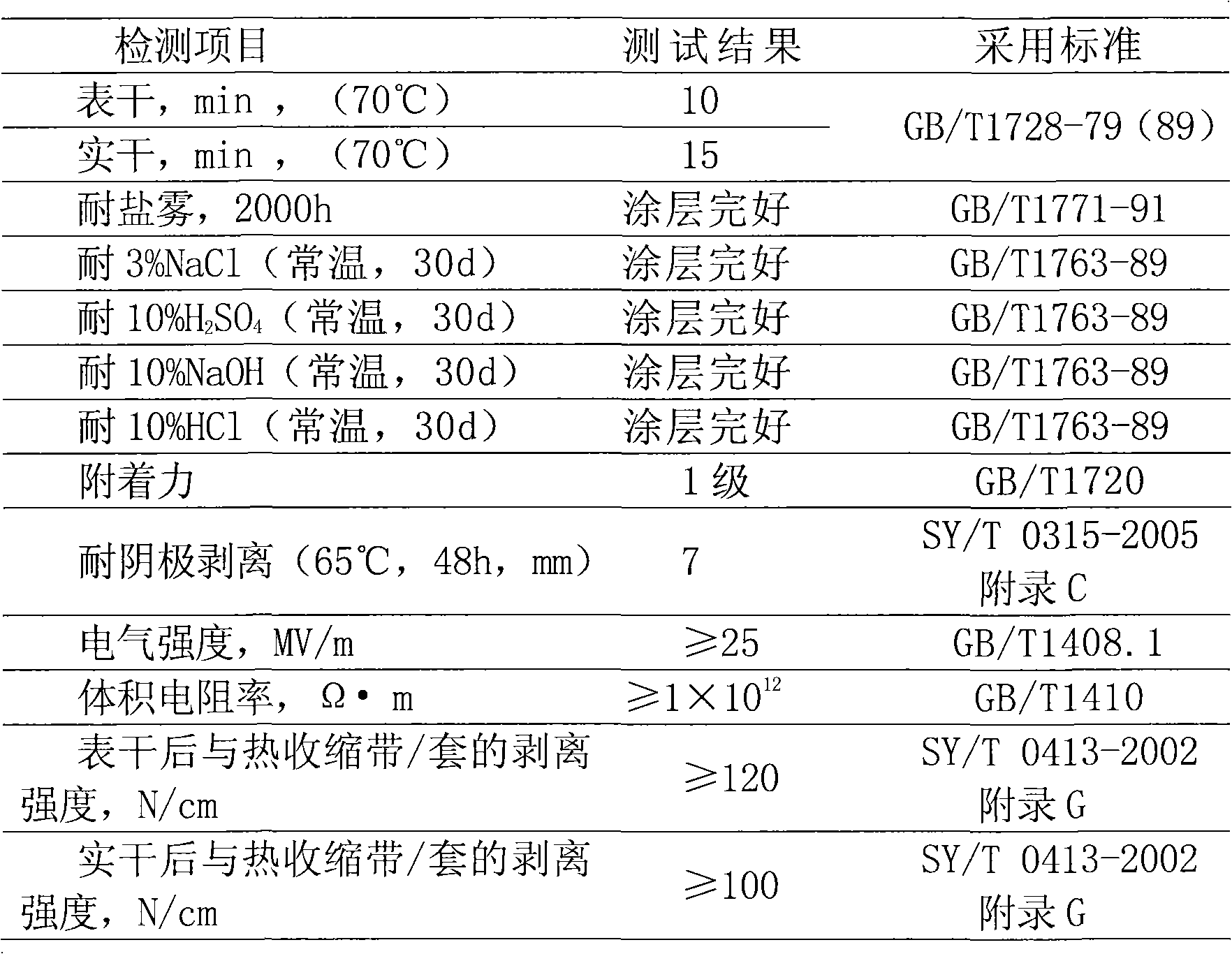

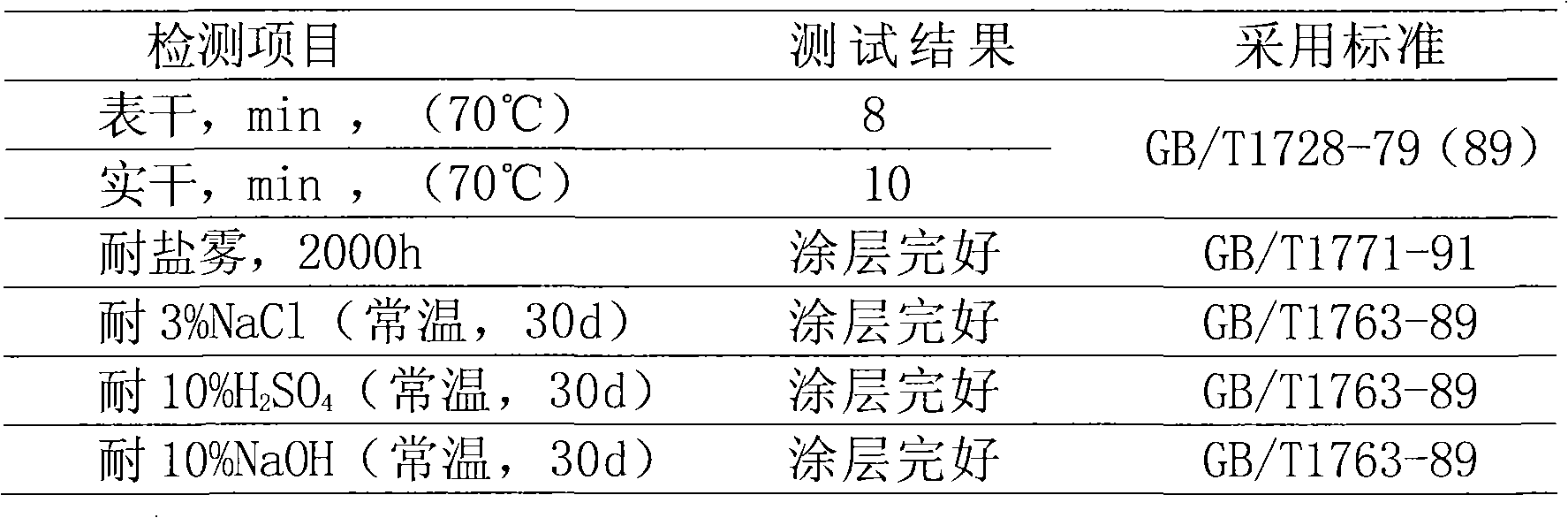

Pipeline joint coating anticorrosion primer paint with high adhesive bonding capability to a thermal contraction belt is applied to the pipeline paint technical field. The primer paint consists of an agent A and an agent B, wherein the agent A comprises the following compositions of polyurethane modified epoxy resin, neopentylene glycol diglycid ether, a polyocarboxy acid polymer, an acrylic ester polymer, a polysiloxane, a polyether siloxane copolymer, a carbamate polymer, a gas phase silicone dioxide, precipitated barium sulphate, mica powder, quartz powder and chromium oxide green, and the agent B comprises the following compositions of modified aliphatic ring amine and polyamide wax. The primer paint has the advantages that: the primer paint has higher adhesive bonding capacity to the thermal contraction belt with one-shot paint film thickness of more than 200 mu m and high curing speed, thereby greatly shortening a construction cycle. The paint film meets the joint coating anticorrosion requirements with resistance to corrosion. The primer paint is safe and environmentally friendly without a solvent and with good storage stability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

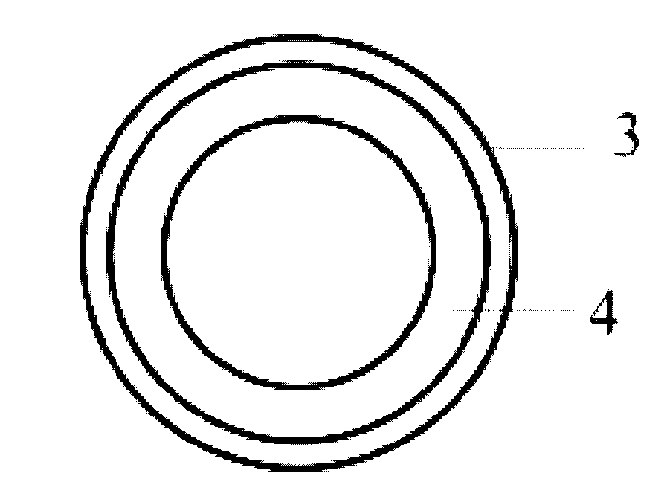

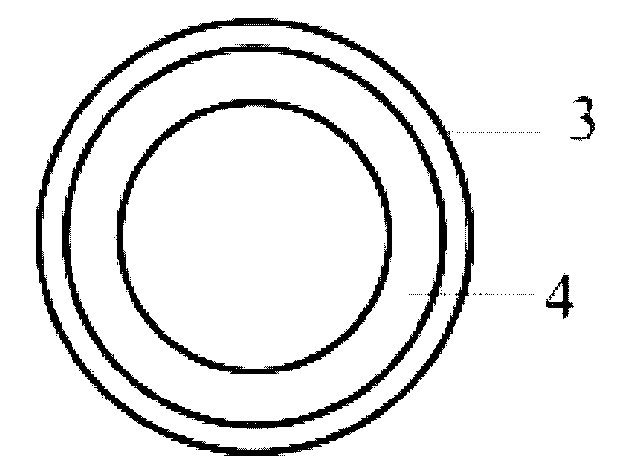

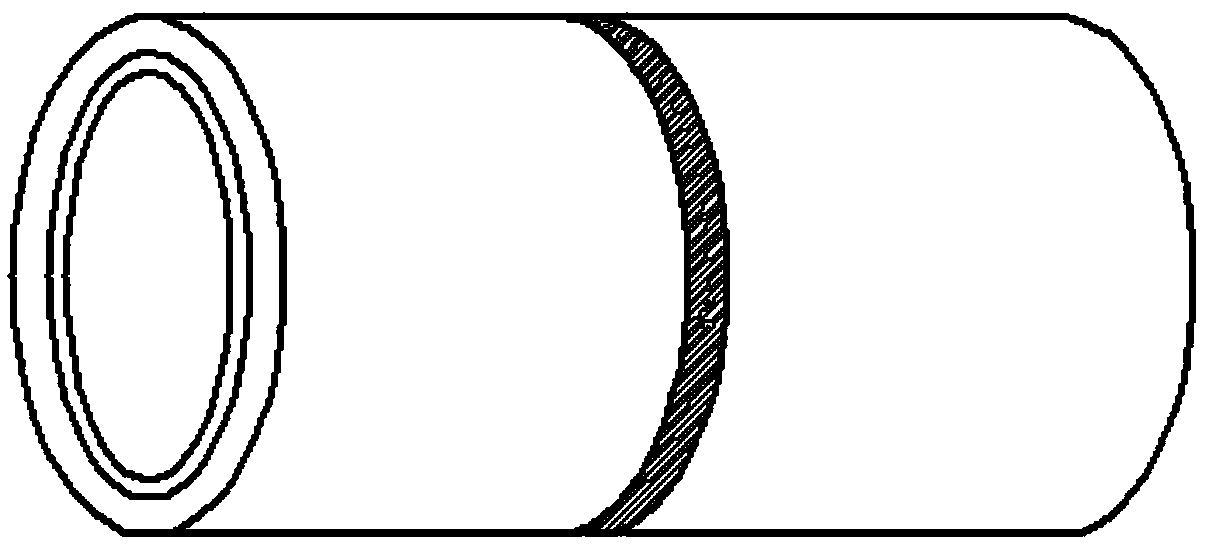

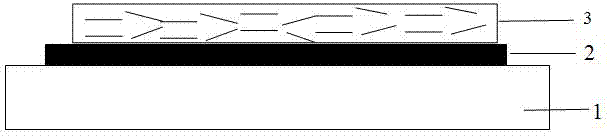

Porous composite filter tube and preparation method thereof

The invention discloses a porous composite filter tube. The filter tube comprises a tube-shaped structural layer with the thickness of 2-10mm, wherein the surface of the structural layer is provided with a functional layer with the thickness of 50-200mu m, the aperture of the structural layer is 20-150mu m, and the aperture ratio of the structural layer to the functional layer is 2.5-5. The invention also discloses a preparation method of the porous composite filter tube and the method comprises the following steps: weighting composite layer powder and carrier to prepare suspension liquid, adopting fluidization technology to distribute air and stir, then adopting heterogeneous atomization technology to ensure that the suspension liquid to perform atomization deposition or be coated on the outer surface of the matrix of porous material, sintering at 600-1400 DEG C under vacuum or hydrogen atmosphere, and keeping temperature for 1-3 hours to prepare the porous composite filter tube. The invention increases the filtration precision and permeation flux of the filtering element, overcomes the defects of ceramic porous materials and metal porous materials prepared by conventional sintering, has high strength and good filterability and breathability, has corrosion resistance, oxidation resistance and high temperature resistant, and is not easy to break.

Owner:WESTERN BAODE TECH CO LTD

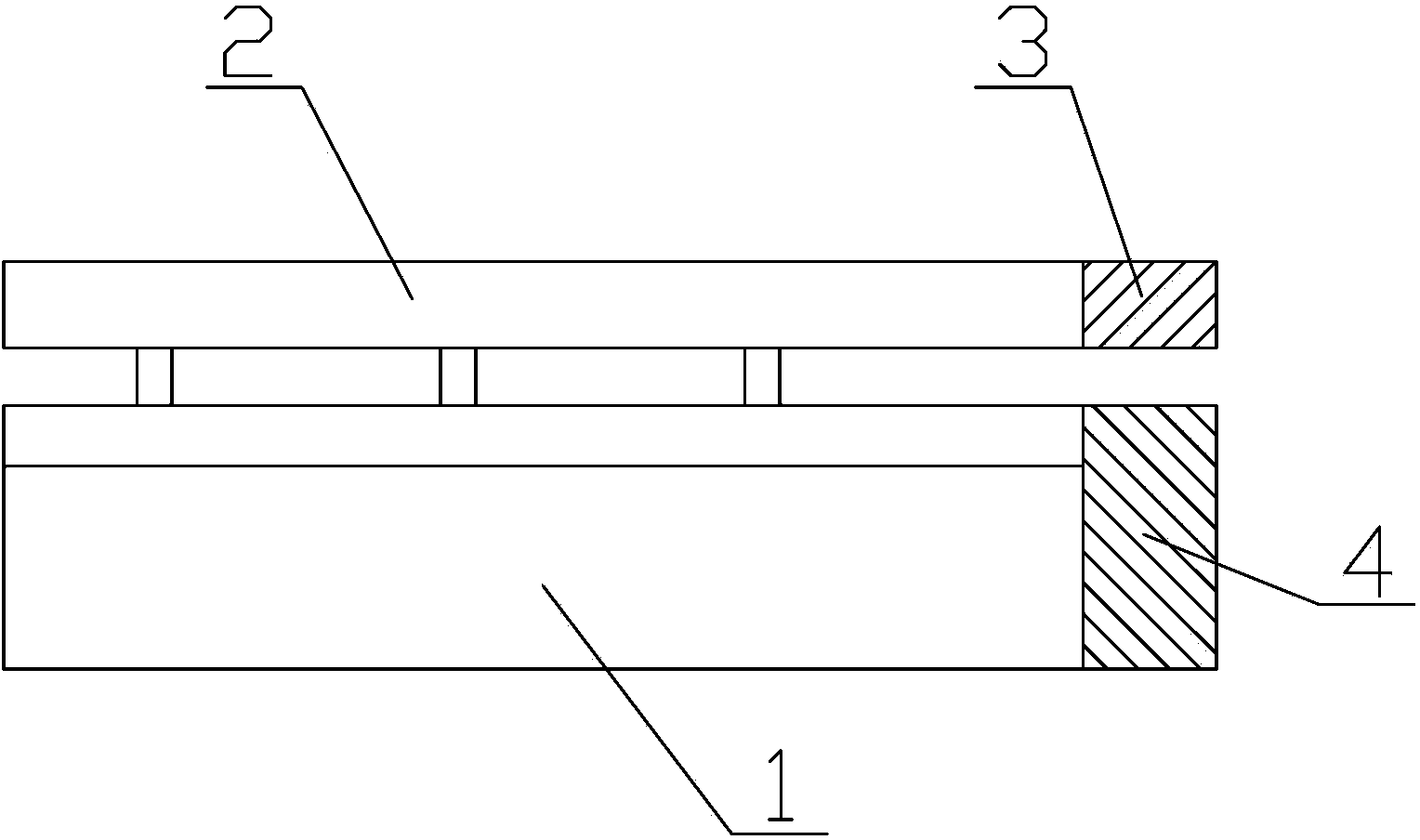

Method for controlling detonator zone during explosion cladding of multilayer thick zirconium/titanium/steel composite plate

ActiveCN103639585AEffective size controlSolve the big problemWelding/soldering/cutting articlesMetal working apparatusDetonatorTitanium

The invention discloses a method for controlling a detonator zone during the explosion cladding of a multilayer thick zirconium / titanium / steel composite plate. The method comprises the following steps: (1), welding a steel block to one side of a titanium / steel composite plate, and welding a titanium block to one side of a multilayer zirconium plate; (2), assembling the titanium / steel composite plate with the multilayer zirconium plate, ensuring that the titanium block is aligned with the steel block, then arranging an explosive on the surface of the multilayer zirconium plate, and mounting a satchel charge on the titanium block for explosion cladding so as to obtain the multilayer thick zirconium / titanium / steel composite plate. The method is easy in operation and convenient to implement, can effectively control the size of the detonator zone during cladding of the multilayer thick zirconium / titanium / steel composite plate, and thus solve the problem that a detonator zone is overlarge when a detonator is directly mounted on the surface of the multilayer zirconium plate. Besides, the detonator zone can be removed completely during the subsequent cutting of the multilayer thick zirconium / titanium / steel composite plate, and the size and the corrosion resisting property of the finished zirconium steel composite plate cannot be affected. The multilayer thick zirconium / titanium / steel composite plate prepared through the method can completely meet the requirements of subsequent large equipment.

Owner:XIAN TIANLI CLAD METAL MATERIALS

Waterborne epoxy graphene zinc anticorrosive coating and preparation method and application thereof

InactiveCN109762446AIncrease the conductive pathIncrease profitAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention discloses a waterborne epoxy graphene zinc anticorrosive coating. The waterborne epoxy graphene zinc anticorrosive coating comprises a first component and a second component, wherein thefirst component is prepared from the following components in parts by weight: 5-10 parts of a waterborne epoxy resin curing agent, 0.5-1 part of a dispersant, 1-3 parts of an anti-settling agent, 1-3parts of a coalescing agent, 10-15 parts of body pigment, 42-65 parts of zinc powder and 4.5-5 parts of graphene dispersion slurry. The second component is prepared from the following components in parts by weight: 30-40 parts of aqueous epoxy emulsion, 1-2 parts of an anti-flash rust agent, 5-15 parts of water and 0.2-0.8 part of a defoaming agent. The waterborne epoxy graphene zinc anticorrosive coating has high utilization rate of zinc powder and is easy to prepare, and the formed coating has excellent comprehensive properties, such as good compactness, excellent cathodic protection performance and shielding performance, anticorrosive performance is remarkably improved, and the waterborne epoxy graphene zinc anticorrosive coating has wide application prospects in the field of marine equipment anticorrosion.

Owner:宁波中科银亿新材料有限公司 +1

Fused zinc corrosion resistant intermetallic compound Ti-Al-Nb alloy

The invention provides an intermetallic compound-Ti-Al-Nb alloy comprising the following constituents: Al 40-60%, ú¼ Nb 5-20%, W 0.1-2%, B 0.05-2%, Y 0.05-2%, and balancing Ti, the ratio is calculated by atom percent.

Owner:UNIV OF SCI & TECH BEIJING

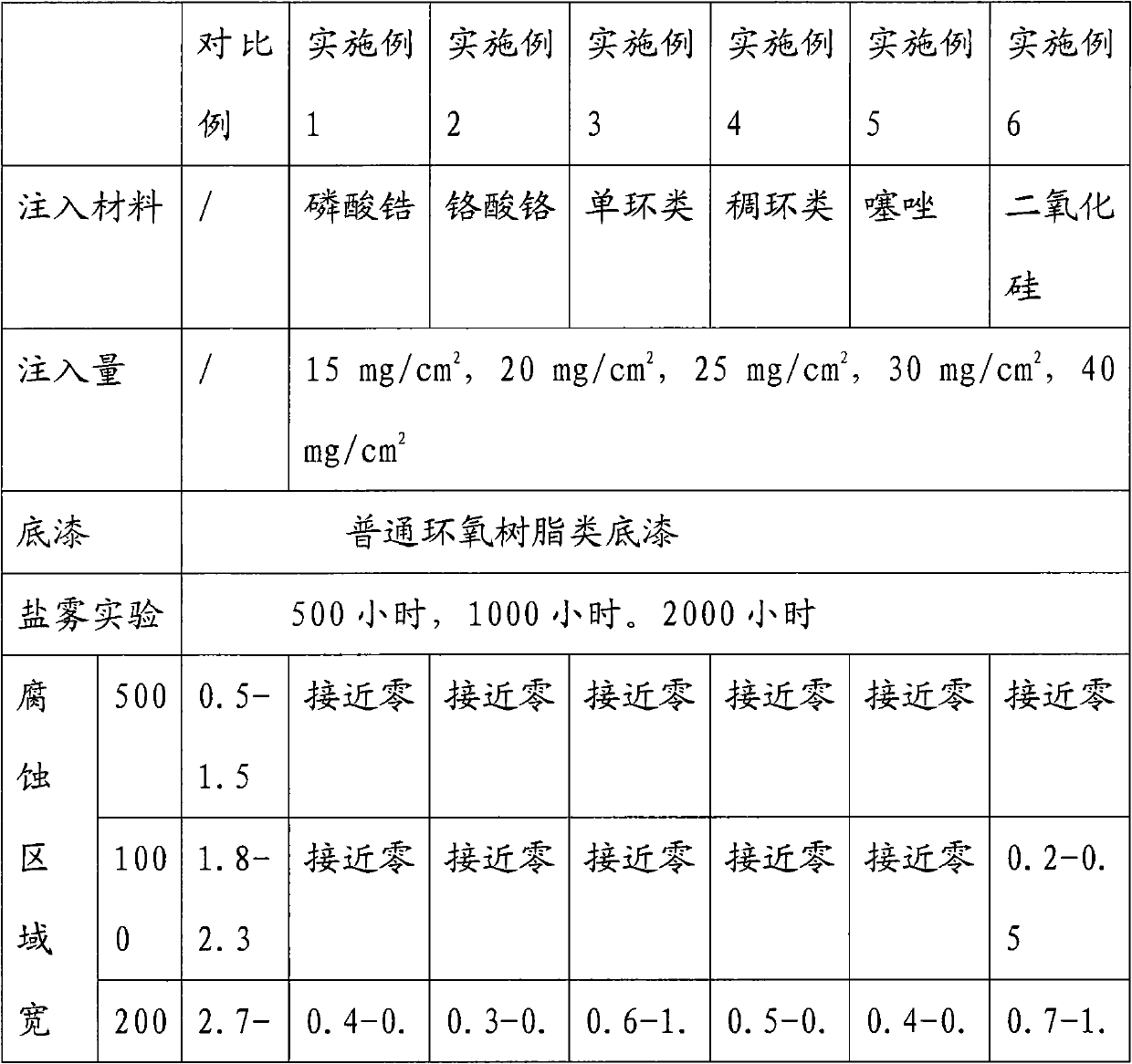

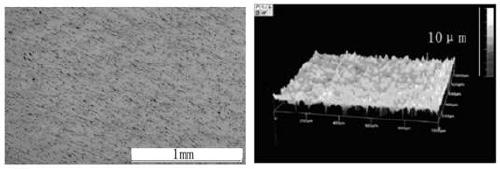

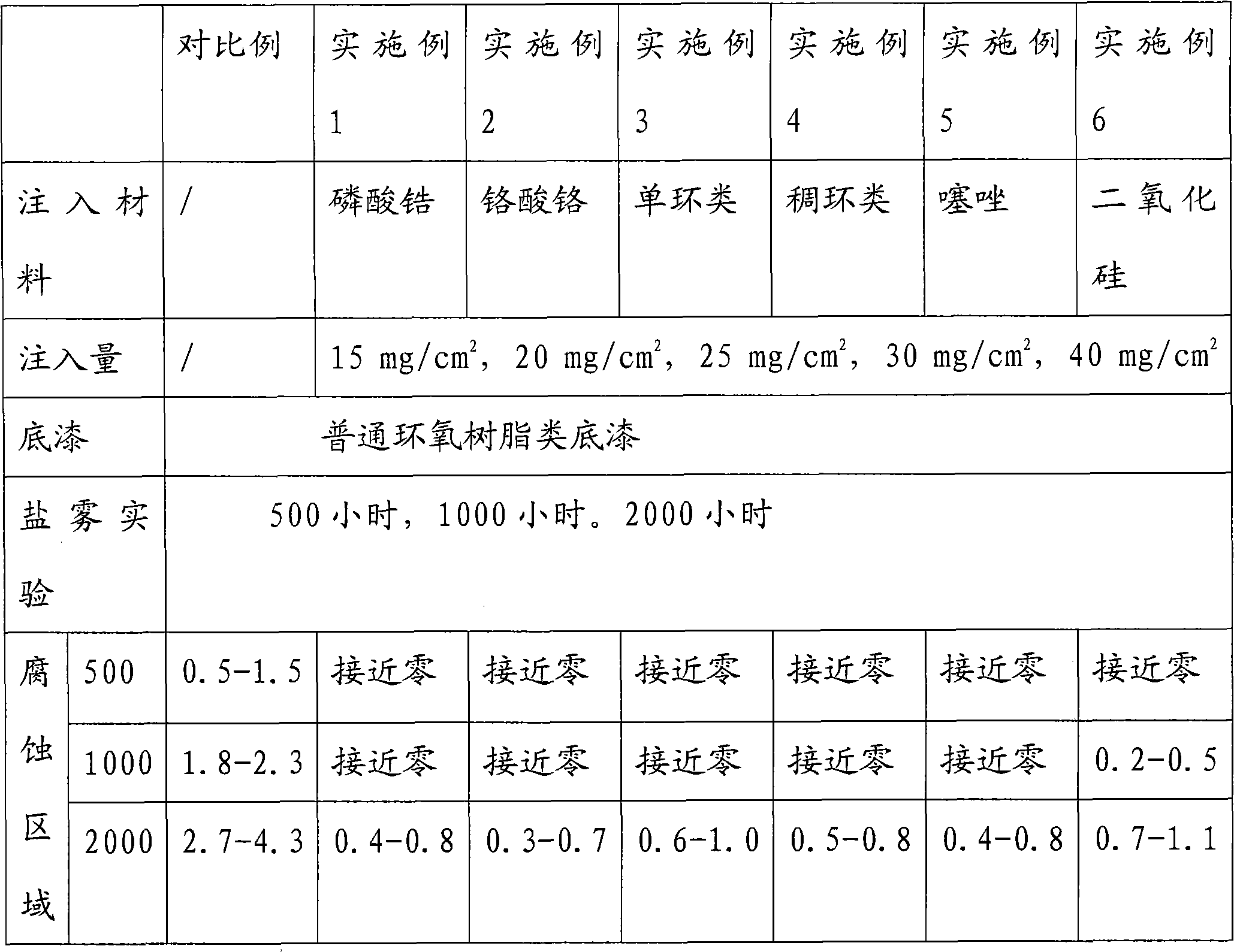

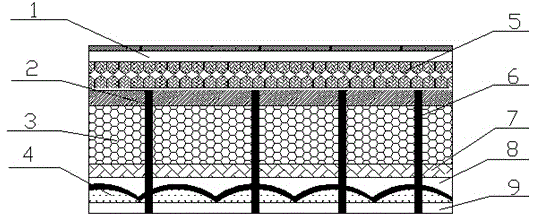

Anti-corrosion treatment method for surface of metal aluminum

InactiveCN102888604ADoes not affect generationDoes not affect corrosion resistancePretreated surfacesSuperimposed coating processAluminiumSimple Organic Compounds

The invention relates to an anti-corrosion treatment method for surface of metal aluminum. The anti-corrosion treatment method comprises the following steps of firstly implanting amorphous substances into the surface of the metal aluminum by utilizing an ion implantation manner to form an insoluble co-complexing layer; and secondly preparing a metal oxidation layer on the surface of the metal aluminum, undercoating the metal oxidation layer, wherein the amorphous substances comprises organic compounds or inorganic oxides.

Owner:虞伟财

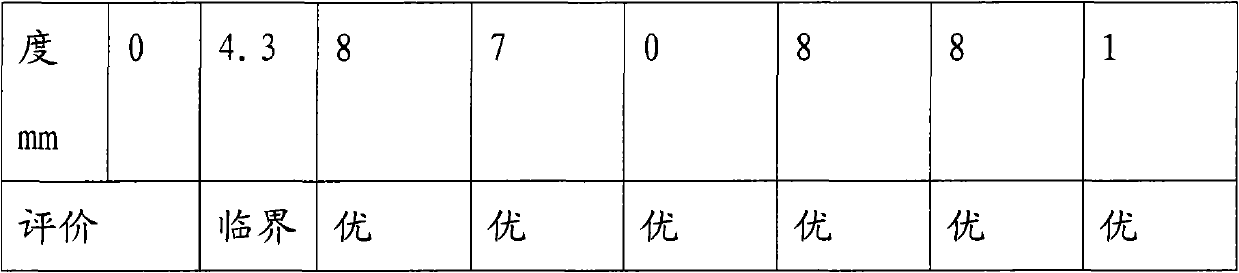

High-performance water-based heavy anti-corrosion paint and preparation method thereof

InactiveCN108690465AEasy to prepareRaw materials are easy to getAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedEpoxy

The invention relates to high-performance water-based heavy anti-corrosion paint and a preparation method thereof, and belongs to the technical field of water-based anti-corrosion paint. The water-based heavy anti-corrosion paint comprises water-based epoxy zinc rich primer, water-based epoxy graphene-modified intermediate paint and water-based polyurethane finishing paint, wherein an intermediatecoating uses the water-based epoxy graphene-modified intermediate paint; properties, such as an extra-large specific surface area, good barrier property, high chemical stability and good electrical conductivity, of graphene are utilized, so the overall performance of the anti-corrosion compound coating is greatly improved, for example, an adhesive force of the coating to a base material is reinforced, the abrasive resistance and the anti-corrosion property of the paint are improved, and the coating has the characteristics of environmental protection and safety, and no secondary pollution andthe like. Three types of the paint are compounded for using, a thickness of a paint film can be greatly reduced under the precondition without affecting the anti-corrosion property, and the requirements of lightweight coating are satisfied. The preparation method of the water-based heavy anti-corrosion paint is simple, and suitable for industrial production, and raw materials are easily obtained.

Owner:重庆绿涂腾科技有限公司

Plasma composite plating and seeping method for abrasive-proof nickel base surface alloy layer

InactiveCN101008084AHigh hardnessImprove abrasion resistanceSolid state diffusion coatingSuperimposed coating processCorrosion resistantMetallurgy

The invention relates to a process of preparing plasma composite depositing wear-resisting nickle- base surface alloy layer, belonging to field of surface composite wear- resisting gradient material preparation. It comprises preparation of nanometer oxidant particle composite coating layer, special granular variety selection and process of producing biglow multicomponent depositing nickle- base alloy on said coating layer. The invention is characterized in that the added nanometer oxidant is nonconductor, so it will not influence the corrosion resistant property of nickle- base alloy, and the rigidity of alloy layer is dramatically increased which is favourable for increasing corrosion resistant performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Manufacturing method of aluminum alloy coated plates

InactiveCN103790317AHigh transparencyHigh glossCovering/liningsLamination ancillary operationsAcoustic absorptionThermal insulation

The invention relates to a manufacturing method of building plates, in particular to a manufacturing method of aluminum alloy coated plates. The building plates are resistant to corrosion and weather proof, prevent dew dropping, and have certain insulation performance. The manufacturing method includes the steps of selecting materials, preprocessing surfaces of plates, drying, coating with glue, laminating, drying, hot-pressing, and checking for storage. The product manufactured by the method has good fire resistance; detections show that the product is approved by the level B-1 of fire rating for national building materials, is fully environment friendly and pollution free, also passes environmental certification, and has the advantages of long service life, environment friendliness, fire proofing, dew prevention, corrosion resistance, acoustic absorption, light absorption, thermal insulation, high transparency, high glossiness, low haze, excellent UV barrier property, laser security, and bright decoration.

Owner:WUXI XINDAZHONG STEEL SHEET

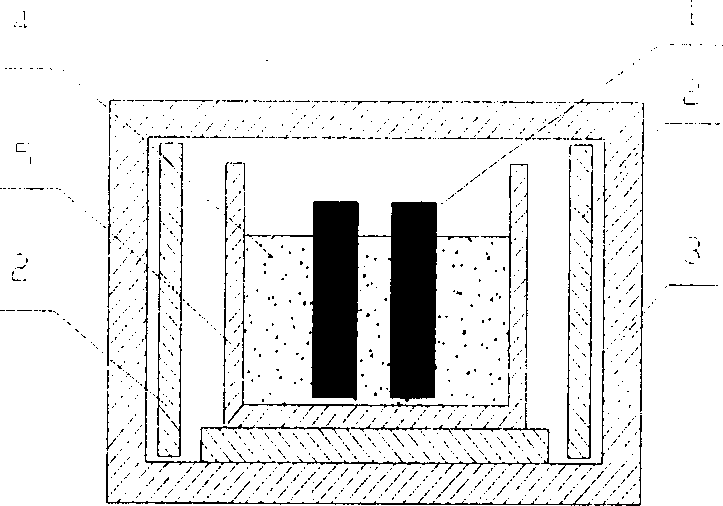

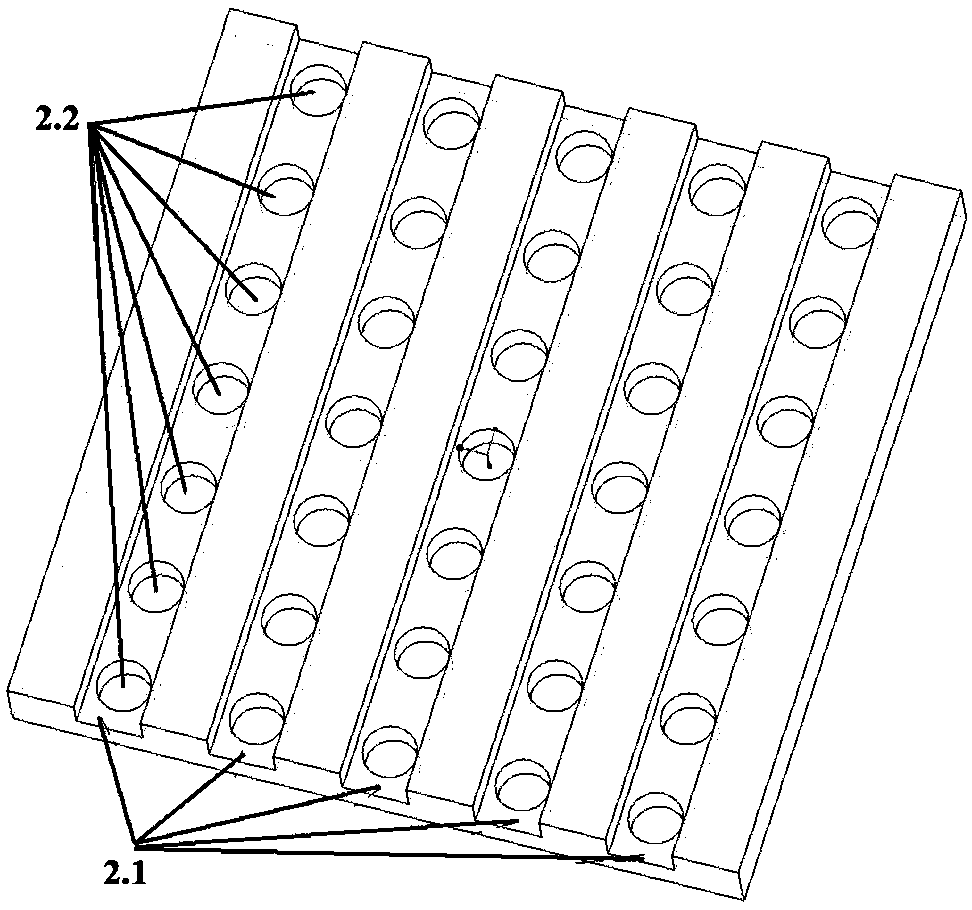

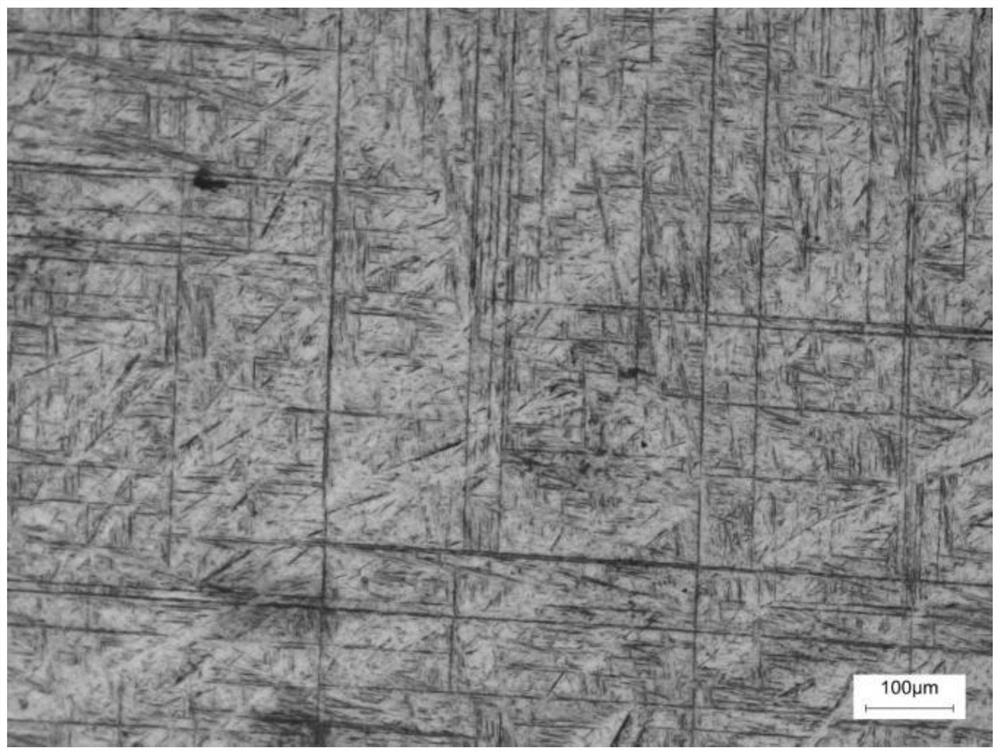

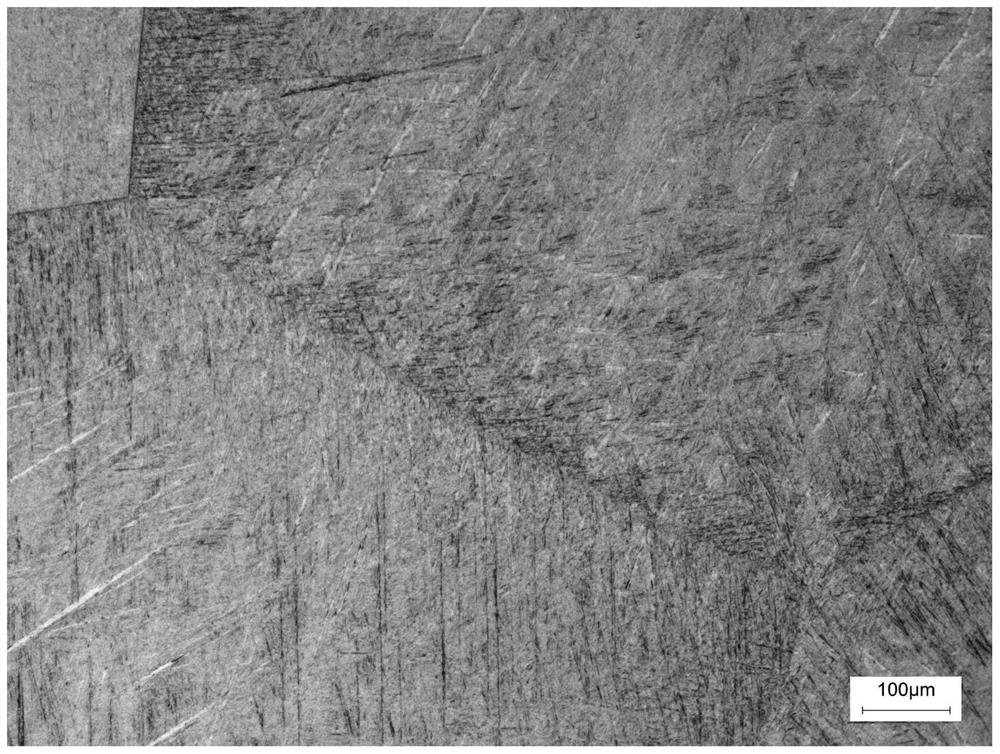

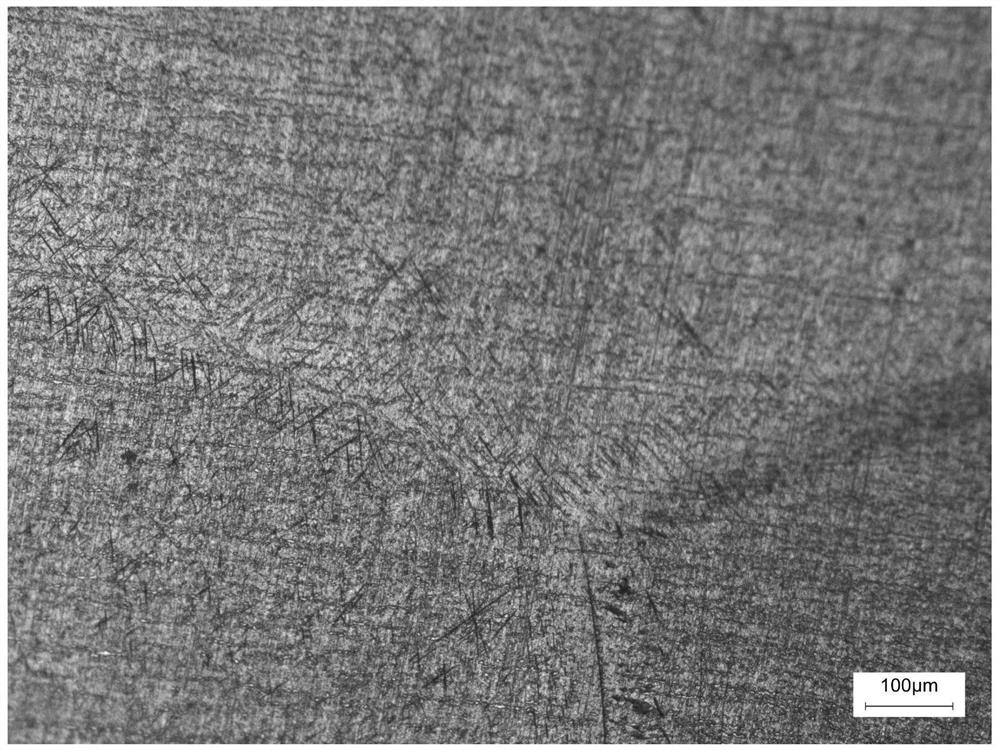

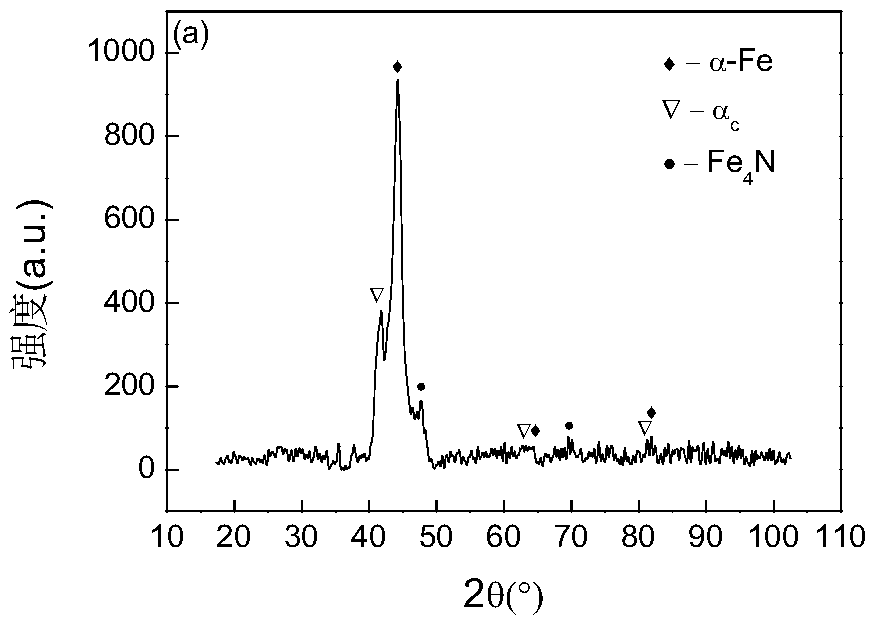

Austenitic stainless steel nitriding treatment system and method based on hollow cathode ion source

ActiveCN107620031AIncrease the areaIncrease ionization rateSolid state diffusion coatingHardnessPlasma concentration

The invention relates to an austenitic stainless steel nitriding treatment system and method based on a hollow cathode ion source and belongs to the technical field of austenitic stainless steel nitriding treatment. The system comprises a power source system, a vacuum nitriding furnace, a hollow cathode device placed in the furnace, a gas extracting system, a gas supply system, a measuring and controlling system, a connection pipeline and a valve; the structure of the hollow cathode device in the vacuum nitriding furnace is composed of a plurality of metal plates arranged in the furnace in parallel; each metal plate is provided with a plurality of long strip grooves arranged at intervals; and through holes arranged at intervals are formed in each groove. According to the method, after a plurality of parts are cleaned, are placed between every two metal plates of the hollow cathode device installed in the vacuum nitriding furnace and are subjected to nitriding treatment, temperature rises to 500-550 DEG C, the heat preserving time is 0.5 h to 1.5 h, then cooling is performed, and the parts are taken out. By means of the austenitic stainless steel nitriding treatment system and method based on the hollow cathode ion source, the gas ionizing rate is increased, the plasma concentration is increased, the surface hardness and the abrasion resistance of austenitic stainless steel canbe improved, the corrosion resistant performance of the austenitic stainless steel is not affected, and the nitriding efficiency is improved.

Owner:TSINGHUA UNIV

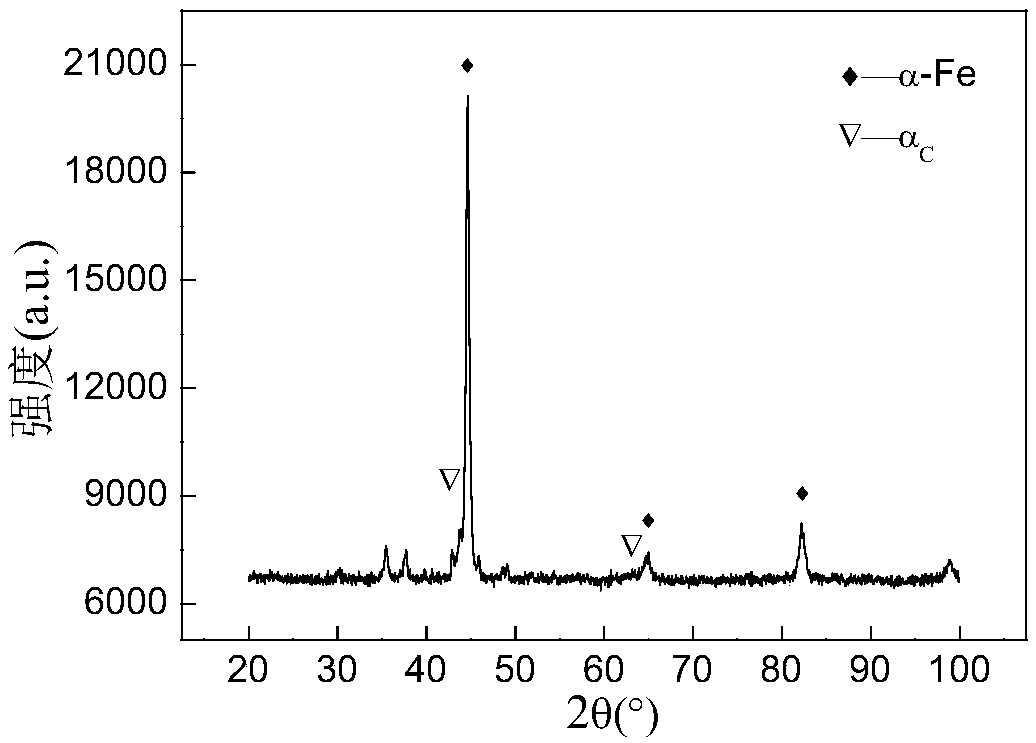

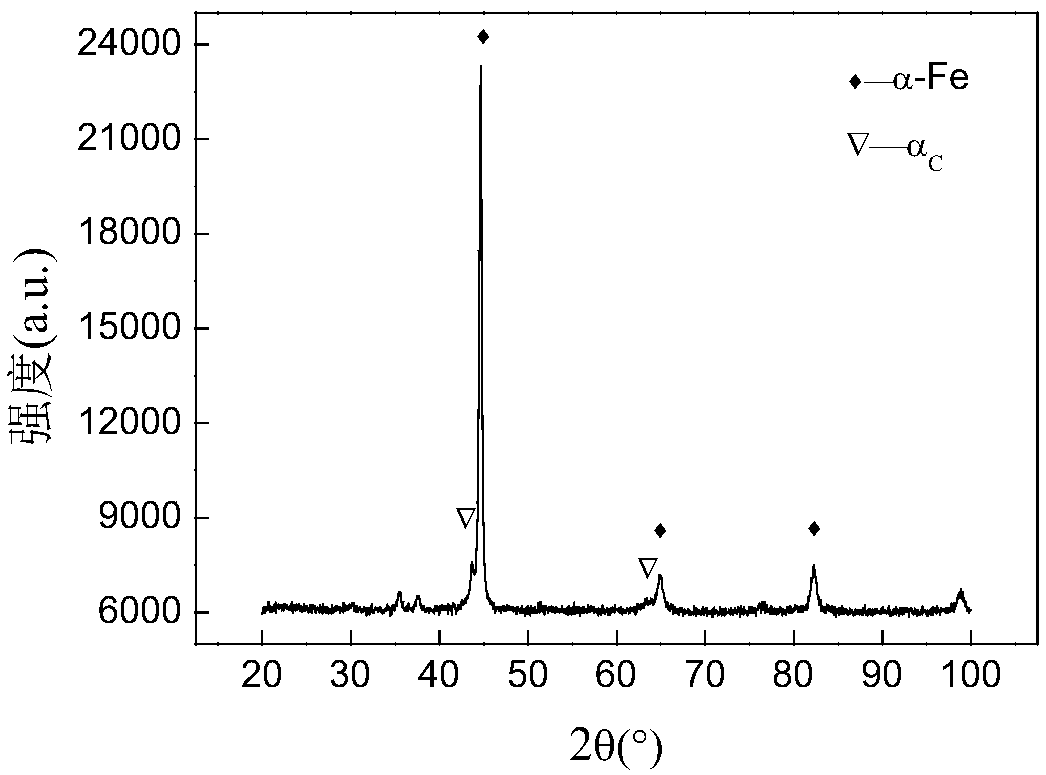

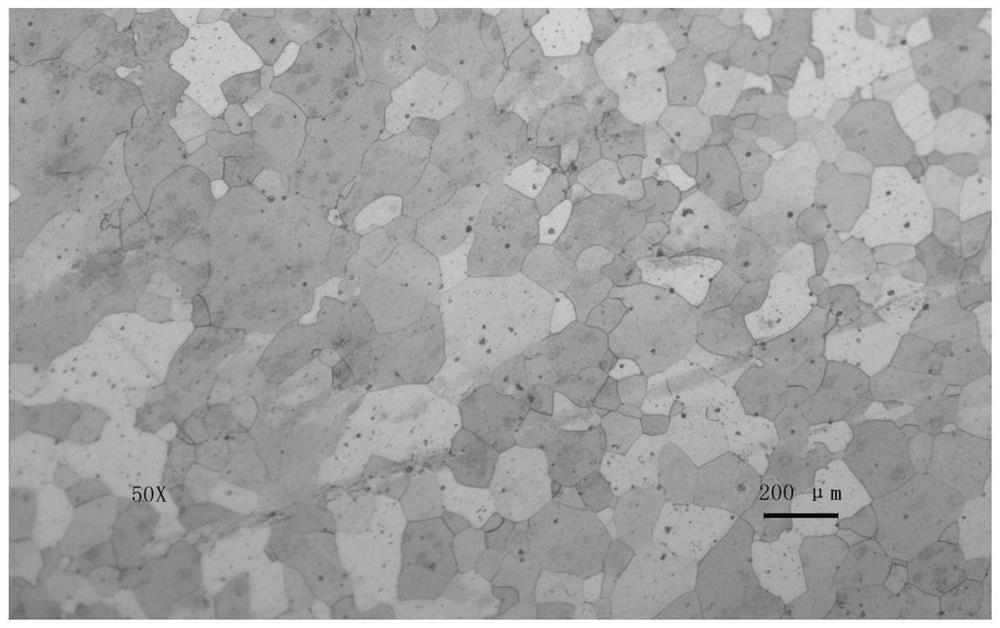

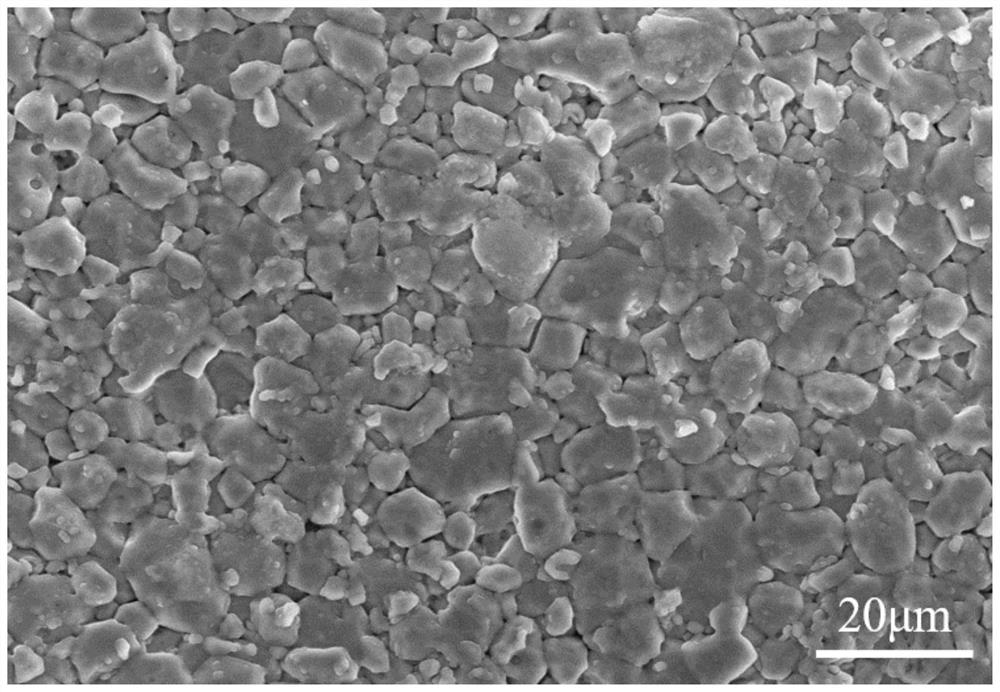

High-strength high-toughness corrosion-resistant zirconium-titanium-vanadium alloy and preparation method thereof

InactiveCN112226647ADoes not affect corrosion resistanceImprove mechanical propertiesTitaniumUltimate tensile strength

The invention relates to a high-strength high-toughness corrosion-resistant zirconium-titanium-vanadium alloy and a preparation method thereof. The alloy is a zirconium-titanium-vanadium alloy, and the atomic ratios of the three elements are as follows: 45-49 at% of Zr, 45-49 at% of Ti, 2-10 at% of V and the balance of inevitable impurities. The zirconium-titanium-vanadium ternary alloy with the vanadium element content being 6-10 at% shows good plasticity and yield strength, the zirconium-titanium-vanadium ternary alloy with the vanadium element content being 2-4 at% has high microhardness and yield strength, and besides, the zirconium-titanium-vanadium ternary alloy further has the characteristics of being simple in production process, good in corrosion resistance and the like.

Owner:HEBEI UNIV OF TECH

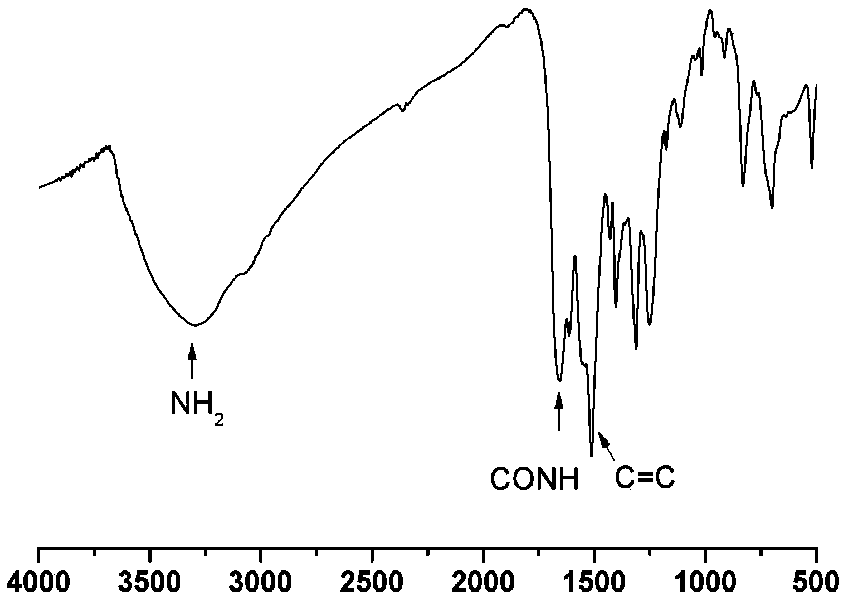

Application of aromatic polyamide material in waterborne coating filling agent

The invention provides application of an aromatic polyamide material in a waterborne coating filling agent and belongs to the technical field of waterborne coating. Meanwhile, the invention provides an application method of the aromatic polyamide material to the waterborne coating filling agent; the prepared aromatic polyamide material is prepared into an aromatic polyamide material dispersion solution; then the aromatic polyamide material dispersion solution is mixed with waterborne coating. An experiment proves that after the coating prepared by taking the aromatic polyamide material as thewaterborne coating water-resisting filling agent is constructed, the water-resisting performance of an obtained coating layer is obviously improved, and original color and transparency of the coatingare not influenced.

Owner:YANTAI UNIV

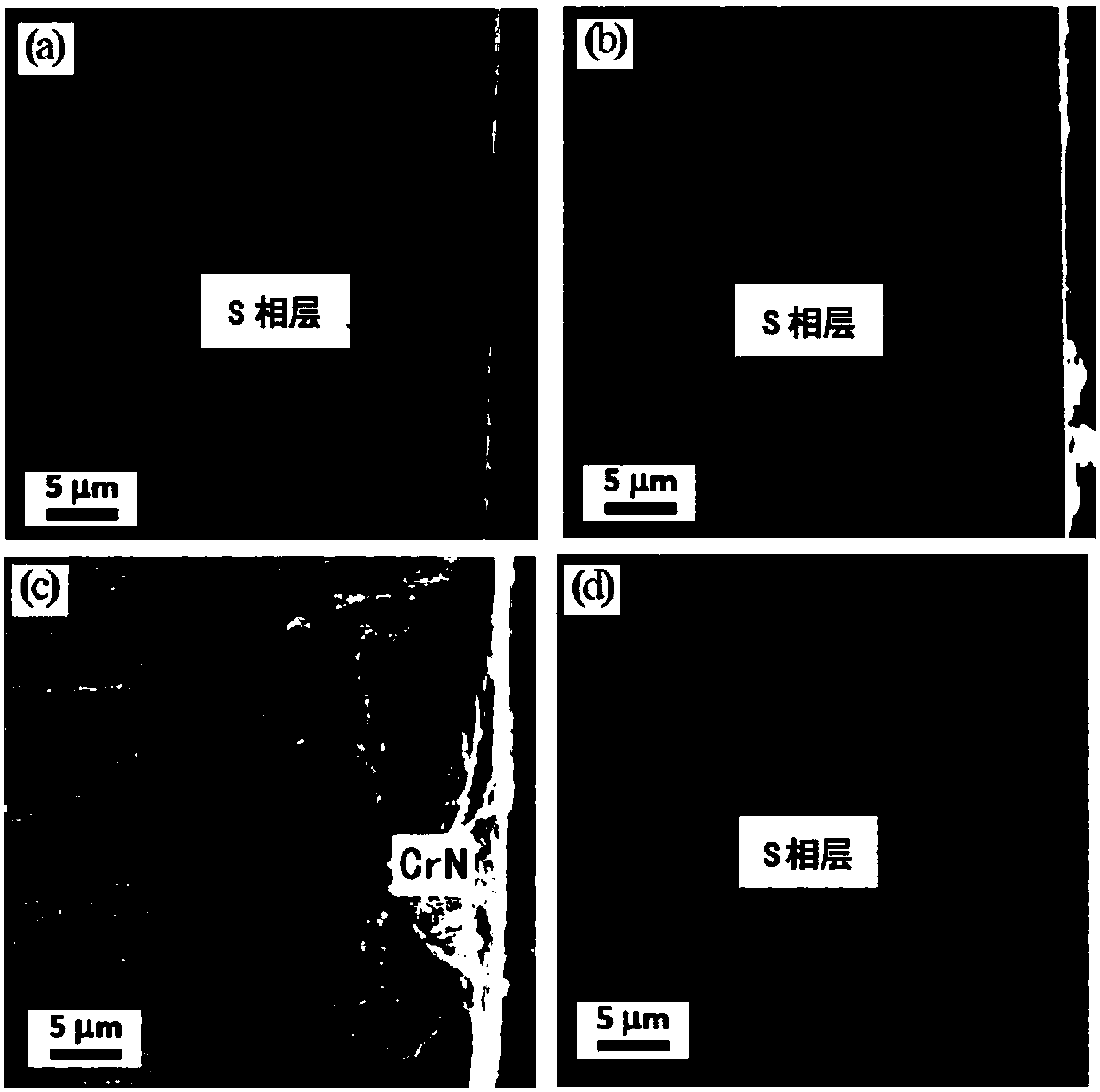

Method for obtaining expansion Alpha phase on surface of stainless steel

InactiveCN107841706ADoes not affect corrosion resistanceHigh hardnessSolid state diffusion coatingVacuum pumpingHydrogen

The invention provides a method for obtaining the expansion Alpha phase on the surface of stainless steel. The method includes the steps that a pretreated stainless steel material is put into a plasmamulti-element penetration furnace, vacuum pumping is conducted to 10Pa or below, hydrogen is connected in and luminance build-up temperature rising is carried out; after the temperature reaches 200-250 DEG C, a nitrogen-containing atmosphere or a carbon-containing atmosphere or a nitrogen-carbon-containing atmosphere is connected in, the volume ratio of the nitrogen-containing atmosphere or the carbon-containing atmosphere or the nitrogen-carbon-containing atmosphere to nitrogen is adjusted, the furnace pressure is made to be 200-1000Pa, timing begins when the temperature is 300-500 DEG C, and the air exhaust state is maintained during the period; and after heat preservation lasts for 1-16h, hydrogen is stopped from being connected in, the nitrogen-containing atmosphere or the carbon-containing atmosphere or the nitrogen-carbon-containing atmosphere is stopped from being connected in after the temperature is lower than 200 DEG C, furnace cooling is conducted below 40 DEG C and furnacedischarging is performed. A modified layer with the nitrogen-carbon-containing 'expansion' Alpha phase is obtained on the surface of the stainless steel treated by the technological method, the hardness and abrasive resistance of the surface of the stainless steel treated through the method are improved obviously, and the corrosion resistance of the stainless steel cannot be influenced.

Owner:HARBIN ENG UNIV

Manufacturing method of hot-dip galvanized coated plates

InactiveCN103790309AExtended service lifeEnvironmentally friendlyLamination ancillary operationsCovering/liningsAcoustic absorptionThermal insulation

The invention relates to a manufacturing method of building plates, in particular to a manufacturing method of hot-dip galvanized coated plates. The building plates are resistant to corrosion and weather, prevent dropping of dews, and have certain thermal insulating property. The manufacturing method includes the steps of selecting materials, preprocessing the surfaces, drying, coating with glue, laminating, drying, hot-pressing, and checking for storage. Products manufactured by method are well fireproof; detections show that the products are approved by the level B-1 of national building materials fire rating, are fully environment friendly and free of pollution, also pass environmental certification, and have the effects of long service life, environment friendliness, fire proofing, dew prevention, corrosion resistance, acoustic absorption, light absorption, thermal insulation, high transparency, high glossiness, low haze, excellent UV barrier property, laser security, and bright decoration.

Owner:WUXI XINDAZHONG STEEL SHEET

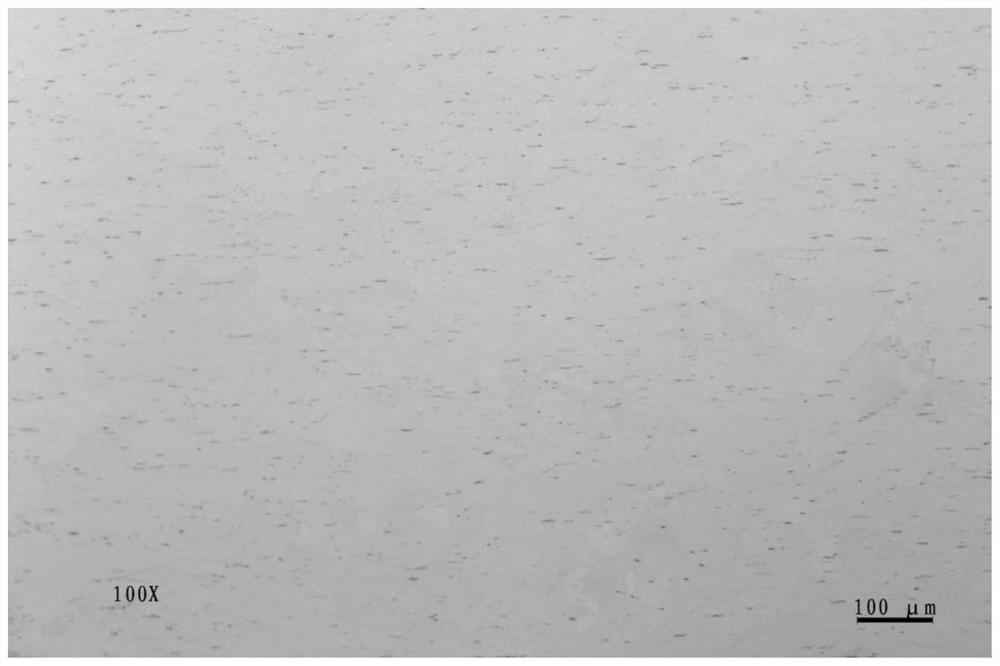

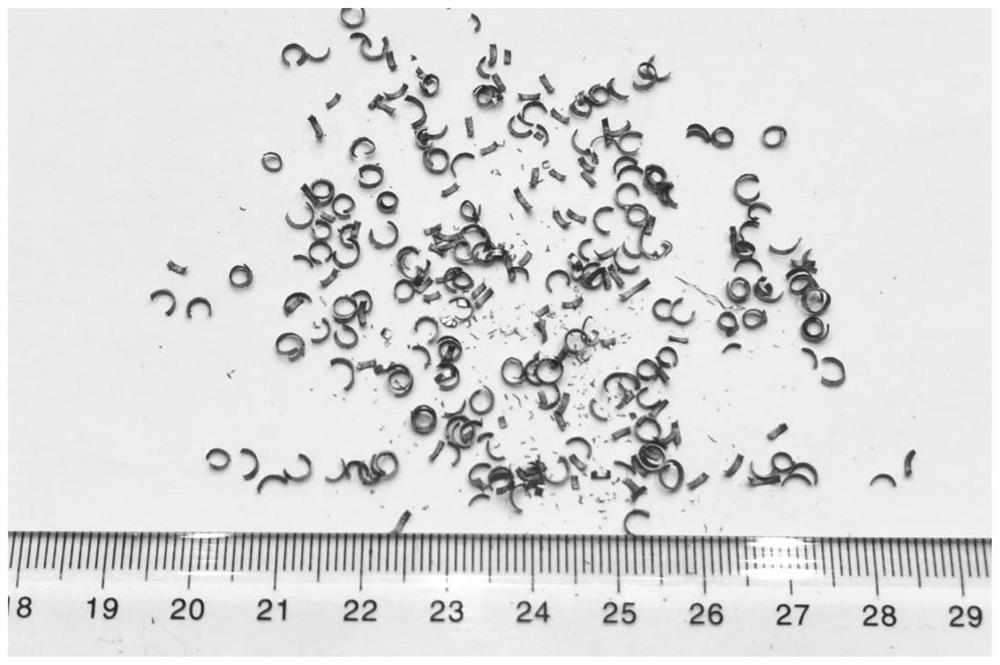

High-corrosion-resistance super-free-cutting soft magnetic ferrite stainless steel wire rod and preparation method thereof

ActiveCN113462984AEvenly distributedImprove cutting performanceFurnace typesInductances/transformers/magnets manufactureElectric arc furnaceSS - Stainless steel

The invention relates to the technical field of metal smelting, in particular to a high-corrosion-resistance super-free-cutting soft magnetic ferrite stainless steel wire rod. The wire rod is characterized by being prepared from the components including, by mass, 0.05%-0.15% of S, 1.0%-2.0% of Si, 0.1%-0.4% of Cu, 17.0%-19.0% of Cr, 1.0%-2.0% of Mo, 0.2%-0.4% of Nb, 0.005%-0.015% of Te, less than or equal to 0.03% of C, less than or equal to 0.03% of N, less than or equal to 0.03% of P, less than or equal to 0.8% of Mn, less than or equal to 0.4% of Ni and the balance Fe and other impurities. The invention further relates to a preparation method of the stainless steel wire rod. The preparation method comprises the steps that raw materials are sequentially subjected to electric arc furnace smelting, AOD furnace smelting, LF ladle refining, continuous casting, continuous casting billet heating, rolling, solid solution and acid pickling, and finally, the stainless steel wire rod finished product is obtained. Through component optimization, tellurium alloying and production process technology control, the high-corrosion-resistance super-free-cutting soft magnetic stainless steel wire rod is manufactured, and the soft magnetic stainless steel wire rod also has excellent machining performance and soft magnetic performance at the same time. The total yield of the produced soft magnetic stainless steel wire rod is larger than or equal to 95%, and the production cost is low.

Owner:浙江青山钢铁有限公司

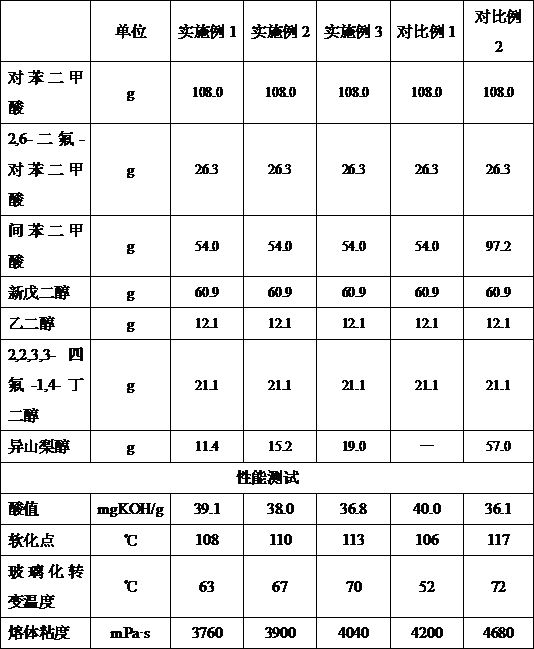

Corrosion-resistant weather-resistant high-storage-performance polyester resin for powder coating

ActiveCN112961334AKey can be strongGood corrosion resistanceGeneral water supply conservationAnti-corrosive paintsComposite materialWeather resistance

The invention relates to the technical field of powder coatings, in particular to polyester resin for a powder coating with corrosion resistance, weather resistance and high storage performance, the powder coating and a coating. The polyester resin is prepared from, by weight, 90-125 parts of terephthalic acid, 22-30 parts of fluorine-containing dicarboxylic acid, 46-60 parts of isophthalic acid, 50-70 parts of neopentyl glycol, 10-14 parts of ethylene glycol, 18-24 parts of fluorine-containing dihydric alcohol; through reasonable matching of the components, the glass transition temperature of the polyester resin is improved, and the polyester resin has excellent corrosion resistance and weather resistance.

Owner:SHANDONG SHANGHE POWER TECH

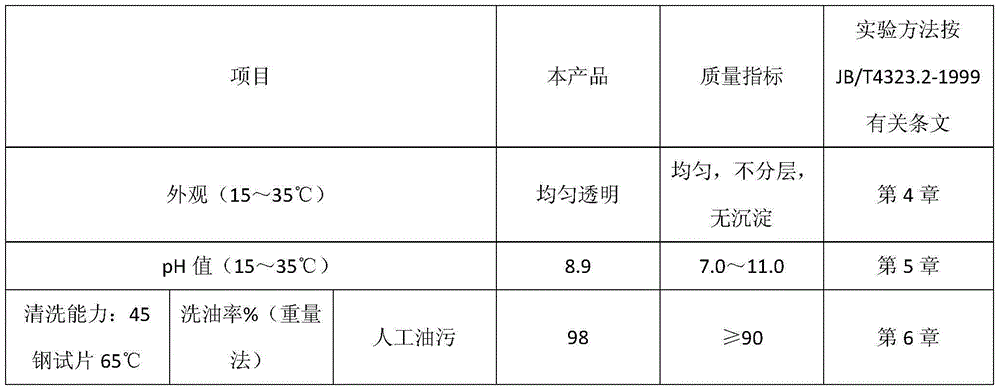

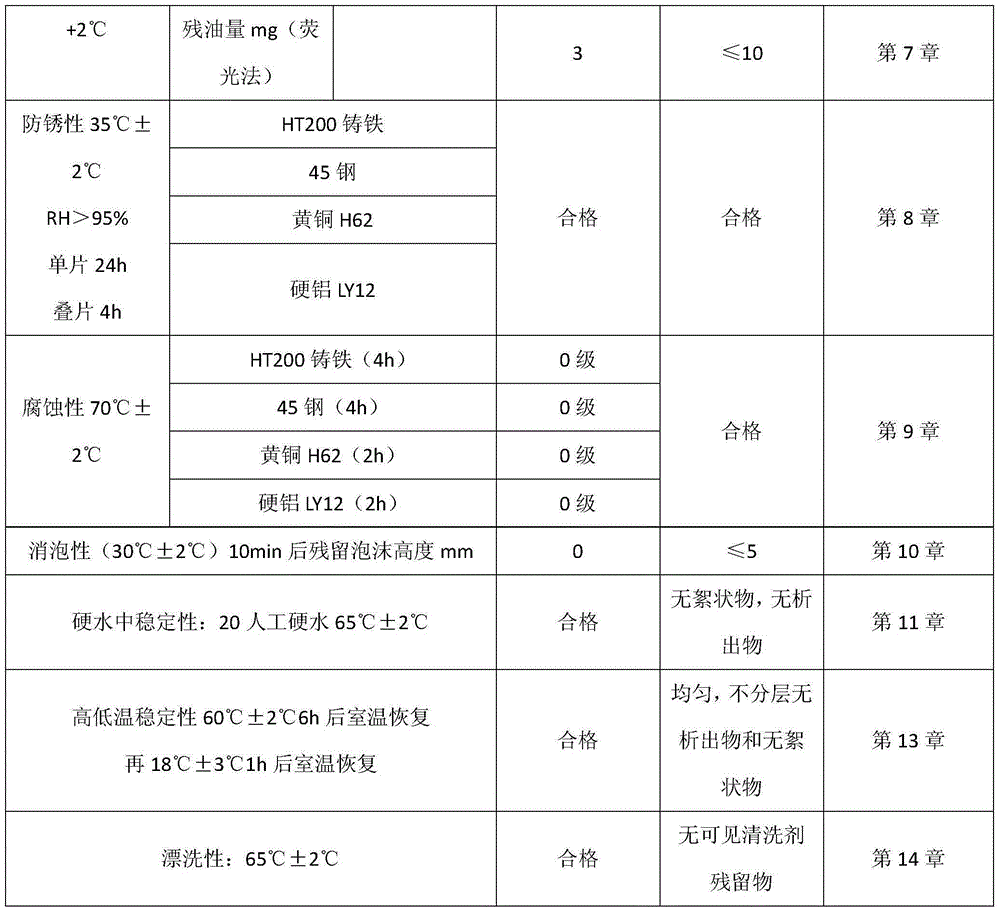

Metal product rustproof cleaning agent

The invention discloses a metal product rustproof cleaning agent, and belongs to the technical field of surface treatment of metal products. The metal product rustproof cleaning agent is prepared by the following components in parts by weight: 5-7 parts of fatty amine polyoxyethylene ether, 4-8 parts of petroleum calcium sulfonate, 4-6 parts of N-nethyl-2-pyrrolidone, 5-7 parts of sorbitol anhydride aliphatic ester, 3-4 parts of defoaming agent, and 15-20 parts of de-ionized water. The metal product rustproof cleaning agent is strong in cleaning capacity, can guarantee better rust preventability under the condition of high humidity, cannot influence the corrosion resistance under the condition of high temperature, and is low in product foam, quick in foam removal, convenient for high-pressure spraying cleaning, safe, harmless and free of environmental pollution. The rustproof cleaning agent is long in rustproof time; and the rustproof time reaches above 180 days.

Owner:GUANGDONG MEIYAN JIXIANG IND INVESTMENT

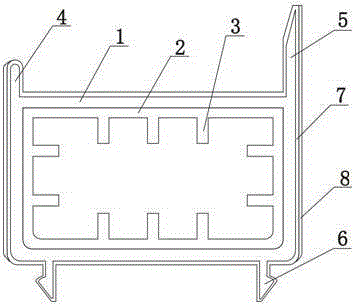

High-strength plastics-steel door and window profile

InactiveCN106555536AHigh strengthImprove the decorative effectWindow/door framesWing framesHeat resistanceEngineering

The invention discloses a high-strength plastics-steel door and window profile which comprises a rectangular hollow profile body, a reinforcing frame, metal nickel layers and decorative layers. The profile body sleeves the reinforcing frame. Reinforcing ribs are arranged on the inner wall of the reinforcing frame. The reinforcing ribs are vertical to the reinforcing frame. A short plate and a long plate are arranged on both end parts of the top of the profile body respectively, wherein the short plate and the long plate are vertical to the profile body. The bottom of the profile body is provided with a buckle rib with a hook. The metal nickel layers are coated on the outer surfaces of the profile body, the short plate, the long plate and the buckle rib. The decorative layers are arranged on both sides of each metal nickel layer. The high-strength plastics-steel door and window profile provided by the invention has the advantages of simple structure, low processing cost, high production efficiency, heat resistance, abrasion resistance, corrosion resistance, long service life and high strength.

Owner:CHONGQING YUANHUA DOORS & WINDOWS

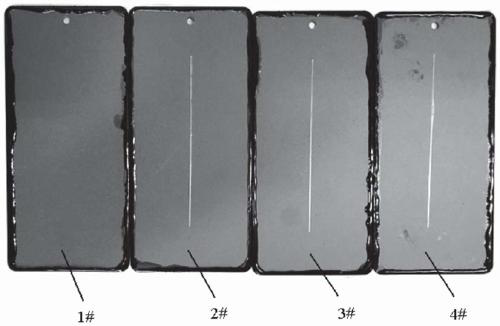

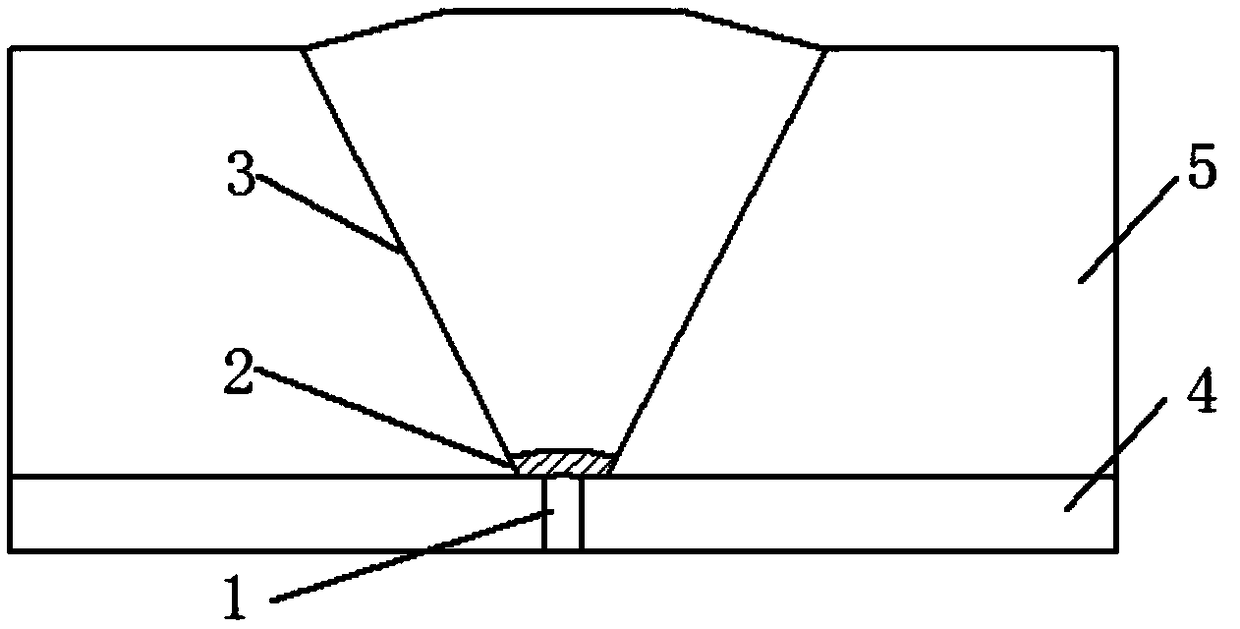

Ring welding method for corrosion-resistant alloy lining composite pipe

InactiveCN108890076ALittle thermal impactDoes not affect corrosion resistanceArc welding apparatusIsolation effectCorrosion resistant alloy

The invention discloses a circumferential welding method for corrosion-resistant alloy-lined composite pipe, which comprises the following steps: (1) cutting a V-shaped groove at the end of the composite pipe to be welded, butting the V-shaped groove at the end of the composite pipe to be welded with a butt joint, wherein the end-to-end gap of the pipe is 0-1.5mm; (2) welding the corrosion-resistant alloy layer by TIG welding to form a cladding weld; (3) Cold spraying is adopted to form the weld seam of the transition layer, the height of the transition layer is not lower than the bimetallic joint surface of the composite pipe, and the thickness of the weld seam of the transition layer is controlled at 0.2-3mm; 4) that base lay is welded by mel electrode gas shielded welding or manual arcwelding to form a base lay weld; As that transition lay adopts the cold spray technology, the metal is sprayed on the surface of the corrosion-resistant alloy and then solidified rapidly, thereby effectively solving the problems that a large amount of coat alloy elements generated by the traditional transition layer welding are punched, mixed and diffused to the transition layer, thereby generating a high-hardness phase and cracks easy to occur in subsequent welding, and playing a better isolation effect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

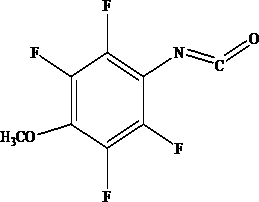

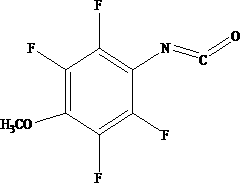

Epoxy anti-corrosion and anti-fog coating and preparation method thereof

InactiveCN111534196AGood anti-fog performanceDoes not affect corrosion resistanceAnti-corrosive paintsPowdery paintsPolymer scienceFirming agent

The invention belongs to the technical field of coating, and discloses epoxy anti-corrosion and anti-fog coating and a preparation method thereof. The epoxy anti-corrosion and anti-fog coating comprises epoxy resin, hydroxyl-terminated polydimethylsiloxane, acrylic acid modified alkyd resin, gemini quaternary ammonium salt, a fluorophenyl isocyanate curing agent, polyethylene wax, a filler, an antifoaming agent and a leveling agent. The epoxy resin, the hydroxyl-terminated polydimethylsiloxane, the acrylic acid modified alkyd resin and the fluorophenyl isocyanate curing agent in the coating are combined for use; the anti-fogging property of the coating is improved, the corrosion resistance of the coating is not influenced, and furthermore, the anti-fogging and anti-corrosion properties ofthe coating are further improved by the gemini quaternary ammonium salt, the polyethylene wax and the filler consisting of graphite, nano aluminum oxide and a nano silicon dioxide-graphene composite.

Owner:广东睿智环保科技股份有限公司

Graphene nonstick paint

ActiveCN103214897BGood construction performanceImprove performanceCoatingsPolymer scienceHigh energy

The invention discloses a graphene nonstick paint, and aims to solve the problem of high energy consumption caused by weak thermal conductivity of an existing nonstick paint. The invention employs graphene to modify a nonstick paint, and the addition of the graphene accounts for 0.1-5wt% of the nonstick paint. The graphene nonstick paint provided by the invention can substantially improve heat conduction effect of a nonstick coating, save energy and reduce consumption, without influencing other indexes of the coating, such as viscosity, adhesive force, heat resistance, friction resistance and corrosion resistance.

Owner:NINGBO MORSH NEW MATERIALS

Preparation method of low-weightlessness sintered NdFeB magnet

ActiveCN112992521ADoes not affect corrosion resistanceImprove corrosion resistanceMagnetic materialsPermanent magnet manufactureSputter depositionGrain boundary

The invention discloses a preparation method of a low-weightlessness sintered NdFeB magnet. The low-weightlessness sintered NdFeB magnet with high corrosion resistance is obtained by performing magnetron sputtering deposition coating on the sintered NdFeB magnet and then performing diffusion heat treatment. According to the preparation method of the low-weightlessness sintered NdFeB magnet, regulation and control of the grain boundary of the surface layer of the sintered NdFeB magnet can be achieved, and corrosion resistance of the sintered NdFeB magnet is improved on the basis that the overall corrosion resistance is not affected.

Owner:HEFEI UNIV OF TECH +1

Stainless steel material

The invention provides a stainless steel material, belonging to the technical field of metallic material, and comprising the following components in percentage by weight: 0.06-0.09% of C, less than or equal to 0.6% of Si, 1.10-1.40% of Mn, less than or equal to 0.040% of P, less than or equal to 0.010% of S, 18.00-19.00% of Cr, 8.00-8.50% of Ni, 0.70-1.20% of Cu, less than 0.5% of Mo, 0.07-0.12% of N and the balance of Fe. Compared with the prior art, the stainless steel material provided by the invention improves the fatigue resistance and the corrosion resistance, reduces abrasion on a die to a certain degree, improves the product quality, and reduces the production cost.

Owner:SHANDONG TENGDA STAINLESS STEEL PRODS

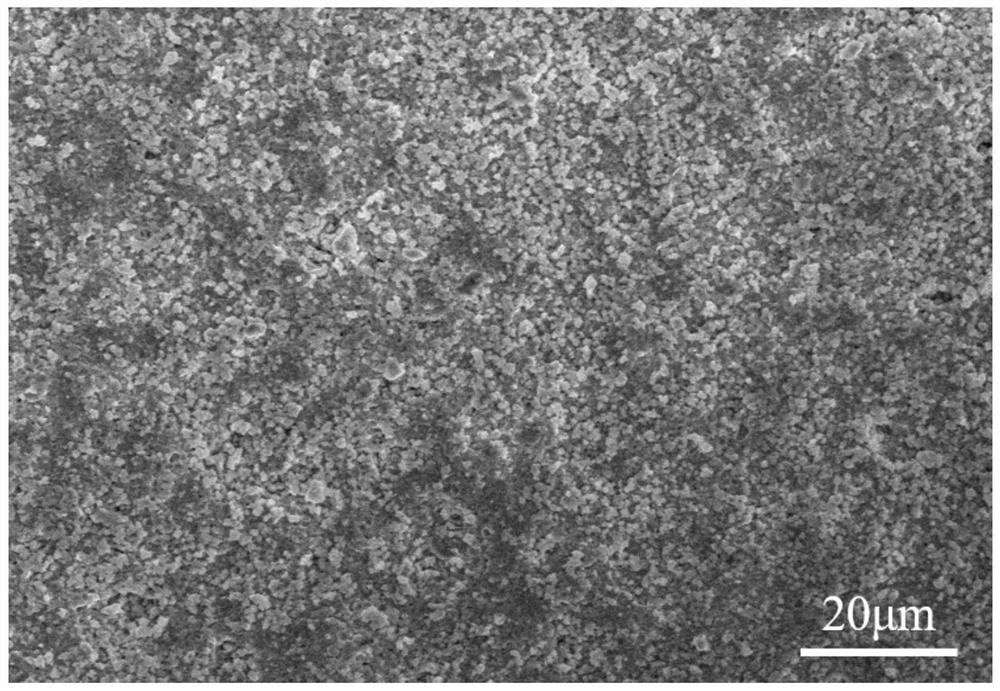

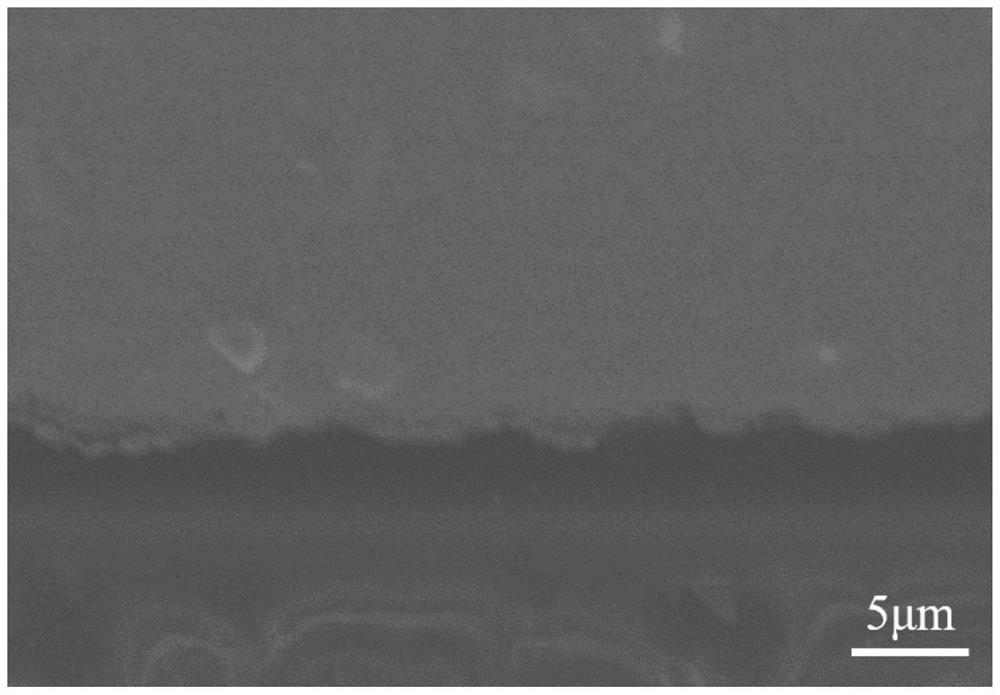

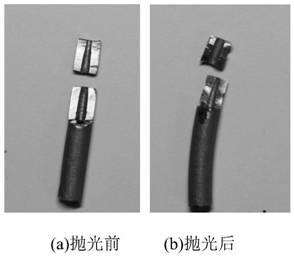

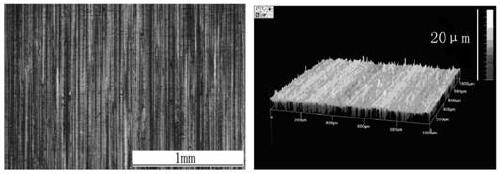

Chemical polishing device and method for inner surface of 3D printing high-temperature alloy pipeline

The invention relates to a chemical polishing device and method for an inner surface of a 3D printing high-temperature alloy pipeline, and belongs to the technical field of inner surface treatment of3D printing metals. In the chemical polishing device, the 3D printing high-temperature alloy pipeline and an acid-proof hose are positioned in a constant-temperature control tank and outside an acid liquid tank; the acid liquid tank is positioned in the constant-temperature control tank; the 3D printing high-temperature alloy pipeline communicates through an acid-proof rigid tube through the acid-proof hose; one end of the acid-proof rigid tube communicates with an acid-proof circulating pump; the other end of the acid-proof rigid tube communicates with a high-temperature alloy chemical polishing agent in the acid liquid tank; and an acid-proof valve and an acid-proof flowmeter are arranged on the acid-proof rigid tube. The chemical polishing method is achieved through the chemical polishing device and comprises the steps that the 3D printing high-temperature alloy pipeline is subjected to heat preservation for 10 min at the temperature of 50 DEG C to 60 DEG C, the chemical polishing agent is introduced into the pipeline at the flow velocity of 400 ml / min, and polishing is carried out for 20 min at the temperature of 50 DEG C to 60 DEG C. According to the chemical polishing deviceand the chemical polishing method, operation is simple, automatic circulating polishing can be achieved, flow velocity of the chemical polishing agent can be effectively controlled to be steady and uniform, the inner surface is flat after polishing, and the removing amount is uniform.

Owner:BEIJING POWER MACHINERY INST

Manufacturing method for hotly-rolled steel film coated sheet material

InactiveCN103786388AExtended service lifeEnvironmentally friendlyCovering/liningsLaminationAdhesiveUltraviolet lights

The invention relates to a manufacturing method for a building sheet material which has corrosion-resisting and weather-resisting performances, can prevent dew from dripping off and has a certain heat-preservation performance, and particularly relates to a manufacturing method for a hotly-rolled steel film coated sheet material. The manufacturing method comprises the following steps: selecting materials, pre-treating a sheet surface, carrying out drying treatment, coating an adhesive, coating a film, carrying out a drying procedure, hotly pressing, checking and storing. According to the method, an obtained product has a very good fireproof performance; as being detected, the hotly-rolled steel film coated sheet material obtains the national building material fireproof B-1-grade authentication, is completely environmentally-friendly and has no pollution; the hotly-rolled steel film coated sheet material also obtains the environment-friendly authentication, has the long service life, is environmentally-friendly, has the fireproof, anti-dewing and corrosion-resisting effects, and has the effects of sound absorption, light absorption, heat preservation, high transparency, high glossiness, low haze, excellent ultraviolet light barrier property, laser anti-counterfeiting property and bright decoration effect.

Owner:WUXI XINDAZHONG STEEL SHEET

Production method for electrogalvanizing laminated boards

InactiveCN103790308AExtended service lifeEnvironmentally friendlyCovering/liningsLamination ancillary operationsFireproofingUltraviolet lights

The invention relates to a production method for anti-corrosive, weather-proof and dew-dripping preventive building boards with a certain heat insulation performance, in particular to a production method for electrogalvanizing laminated boards. The production method includes the steps of material selecting, board surface pre-processing, drying treatment, adhesive coating, laminating, drying, hot pressing, inspecting and storing. Products produced by the production method have good fireproofing performance, pass the national building material fireproofing grade certification B-1 according to tests, is completely environment friendly and pollution-free, pass the environmental protection certification, and have the advantages of long service life, environment protection, fireproofing, condensation and corrosion resistance, sound and light absorption, heat insulation, high transparency, high glossiness, low haze, excellent ultraviolet-light isolation property, laser anti-fake property and bright decorative effect.

Owner:WUXI XINDAZHONG STEEL SHEET

Aluminum surface anti-corrosion treatment method

InactiveCN102978620ADoes not affect generationDoes not affect corrosion resistancePretreated surfacesSuperimposed coating processSimple Organic CompoundsAluminum metal

The present invention relates to an aluminum surface anti-corrosion treatment method, which comprises the following steps: injecting an amorphous material on the aluminum metal surface by using an ion injection manner to form an insoluble co-complex layer, then forming a metal oxidation layer on the metal surface, and coating a prime coat on the metal oxidation layer, wherein the amorphous material comprises an organic compound or an inorganic oxide.

Owner:吴雅萍

Heat-resistant aluminum alloy profile

InactiveCN104859226AImprove insulation effectEffective barrierWood layered productsMetal layered productsSilicon alloyShock resistance

The invention discloses a heat-resistant aluminum alloy profile which comprises an aluminum alloy plate, wherein a foam polyurethane layer, an anti-seismic layer and a wood-wool layer are sequentially arranged on the outer side of the aluminum alloy plate; a foam panel layer, a fireproof layer and a titanium-silicon alloy layer are sequentially arranged on the inner side of the aluminum alloy layer; a plurality of fireproof bags which are tightly connected with one another are arranged in the fireproof layer; a transparent protective film is arranged on the surface of the wood-wool layer; a plurality of nylon strips are arranged in the foam polyurethane layer, the aluminum alloy plate, the foam panel layer, the fireproof layer and the titanium-silicon alloy layer in the longitudinal direction. By virtue of a multi-layer structure design, the fire resistance, the high-temperature resistance, the anti-corrosion property, the sound and heat insulation properties, the shock resistance and the damp-proof effect are obviously improved; the service life is relatively long; the application range is relatively wide.

Owner:MAANSHAN XINJIA MACHINERY MFG

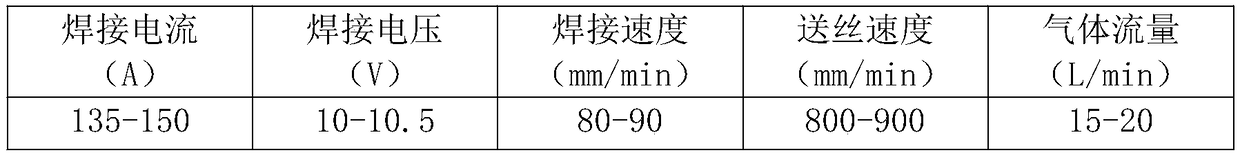

Technology for welding steel containing molybdenum

InactiveCN104985295AAvoid pollutionDoes not affect corrosion resistanceArc welding apparatusMechanical propertyMetal

The invention discloses a technology for welding steel containing molybdenum. The elements of the steel containing molybdenum include, by mass, smaller than or equal to 0.02% of C, smaller than or equal to 1.30% of Si, smaller than or equal to 1.80% of Mn, smaller than or equal to 0.0305% of P, smaller than or equal to 0.01% of S, 12.0-15.0% of Ni, 13.0-18.0% of Cr, 1.0-2.5% of Mo and the balance Fe. The technology includes the following steps that firstly, a welding material is selected; secondly, a groove is machined; thirdly, weld preheating is conducted; fourthly, argon arc welding bottoming is conducted; and fifthly, argon arc welding capping is conducted. The technology has the beneficial effects that the welding technology of argon arc welding bottoming and argon arc welding capping is adopted, contamination of the welding material to the steel during welding is avoided; little heat input is selected as much as possible during welding; low welding currents and high welding speeds are adopted under the premise that the welding quality is ensured, and therefore the corrosion-resistance performance of the steel is not affected, and the mechanical property of parent metal cannot be changed.

Owner:LIUZHOU JINMAO MACHINERY

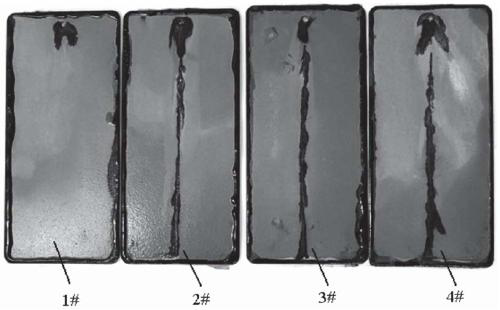

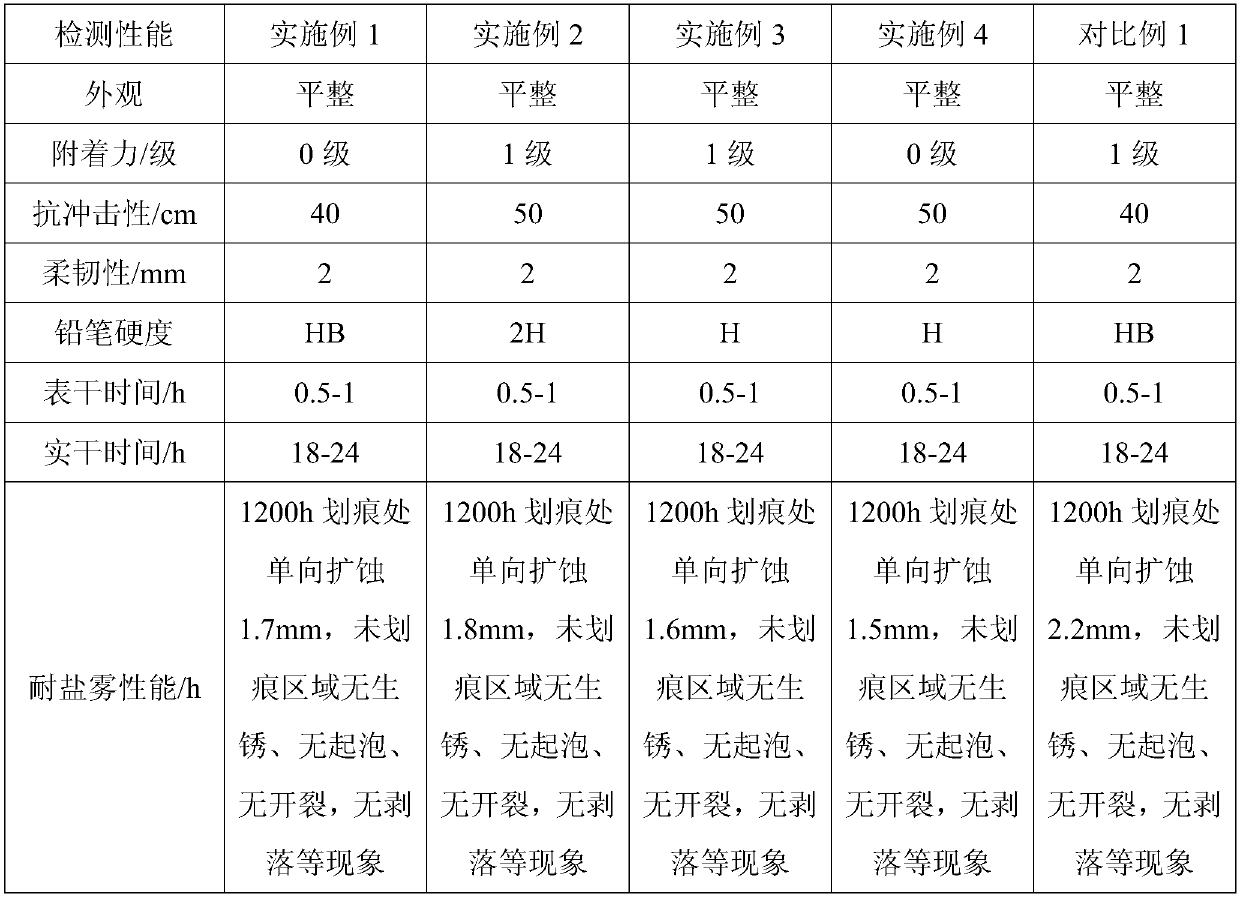

Fiber and/or scale enhanced self-repairing anticorrosive coating material, preparation method and application thereof

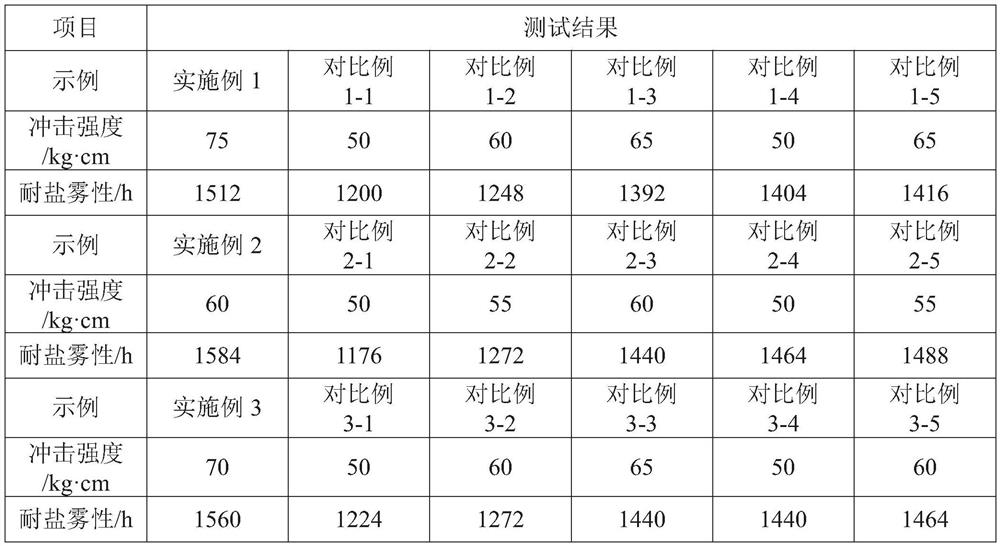

ActiveCN113278318AWith cushioning enhancementNo impact on impact resistanceAnti-corrosive paintsEpoxy resin coatingsFiberDefoaming Agents

The invention discloses a fiber and / or scale enhanced self-repairing anticorrosive coating material, a preparation method and application thereof. The fiber and / or scale reinforced self-repairing anticorrosive coating material comprises the following components in parts by weight: 40-70 parts of a matrix resin, 0.1-0.5 part of scale micro-powder graphite, 5-10 parts of ground calcium carbonate, 10-20 parts of a pigment filler, 3-5 parts of a coupling agent, 1-5 parts of a self-repairing microcapsule component A, 1-5 parts of a self-repairing microcapsule B, 3-8 parts of microcapsule chemical fiber and / or scales, 0.5-1.5 parts of a dispersing agent, 0.1-0.5 part of a flatting agent, 0.1-0.5 part of a defoaming agent, 0.5-1.5 parts of an anti-sagging agent and 12-24 parts of a first solvent. The fiber and / or scale enhanced self-repairing anticorrosive coating material prepared by the invention has good impact resistance and self-repairing performance; and the preparation method is simple, large-scale preparation is easy, the coating can be widely applied to the surfaces of matrixes impacted by water waves or in dynamic working environments in rivers, lakes and seas, and the service life of the coating is prolonged.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com