Pipeline repaired mouth anti-corrosive primer coating having high adhesive bonding ability with thermal contraction belt

An anti-corrosion primer and heat-shrinking technology, used in anti-corrosion coatings, pipeline anti-corrosion/anti-rust protection, pipeline protection, etc., can solve problems such as corrosion, easy leakage and water penetration, and achieve good storage stability, construction conditions, and curing. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

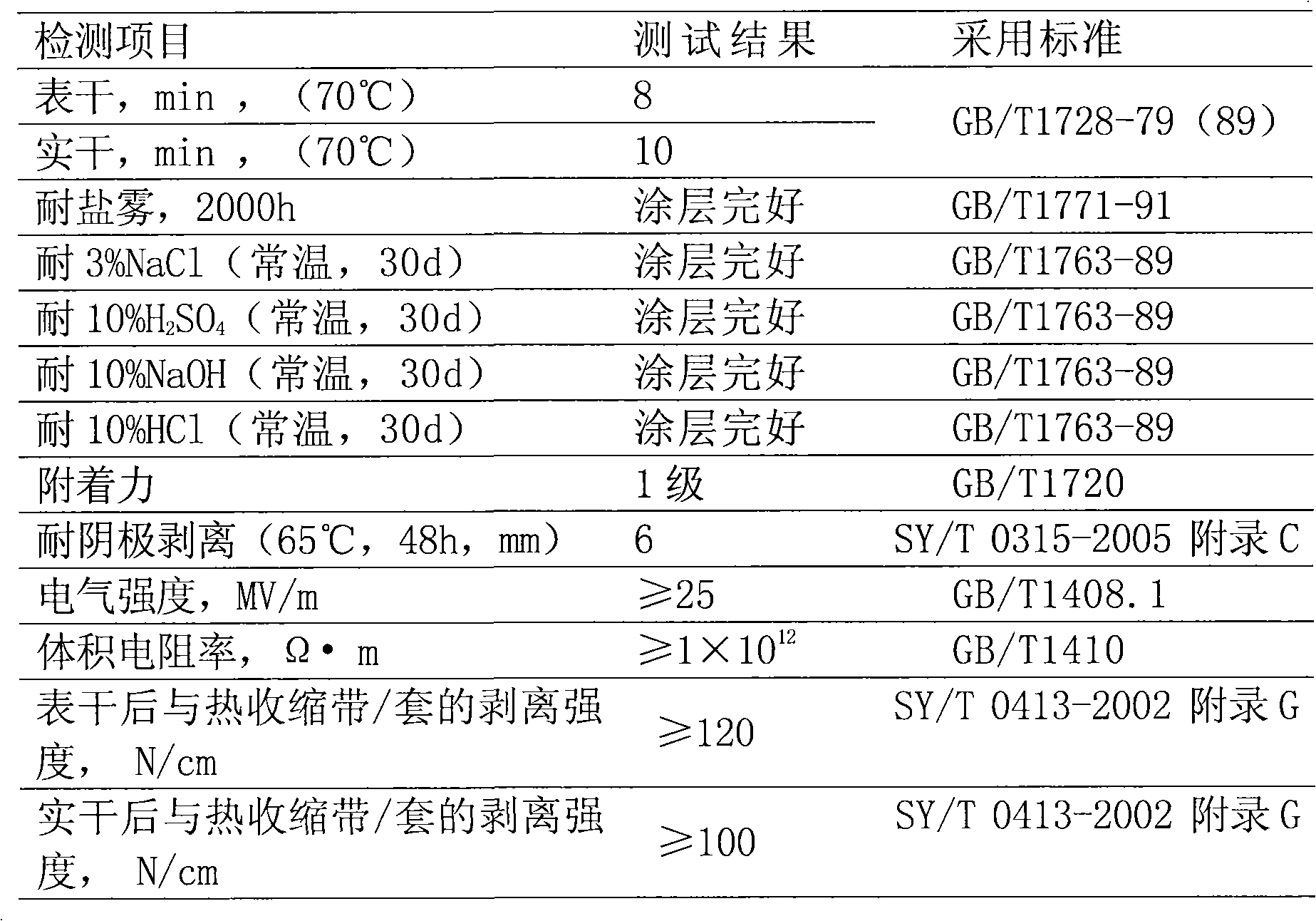

Embodiment 1

[0015] Embodiment 1: the preparation process of the pipeline joint anticorrosion primer coating with high bonding capacity with heat shrinkage:

[0016] ①Preparation of polyurethane modified epoxy resin: In a stainless steel reaction kettle, add 1 weight part of polyether polyol, heat to 80°C under stirring, add 0.0005 weight part of dibutyltin dilaurate, dropwise add 0.25 weight part of Isocyanate MDI-50, after reacting for 2 hours, add 2.1 parts by weight of bisphenol A epoxy resin in batches, continue stirring for 4 hours, stop stirring, and discharge to obtain polyurethane modified epoxy resin. The hydroxyl value of polyether polyol is 56, the functional group is 3, and the molecular weight is 5000.

[0017] ②Preparation of agent A: In a stainless steel bucket, add 1 part by weight of polyurethane modified epoxy resin, 0.15 parts by weight of neopentyl glycol diglycidyl ether, and 0.10 parts of polycarboxylic acid polymer (TEGO 610S ), 0.01 part of acrylate polymer (BYK-1...

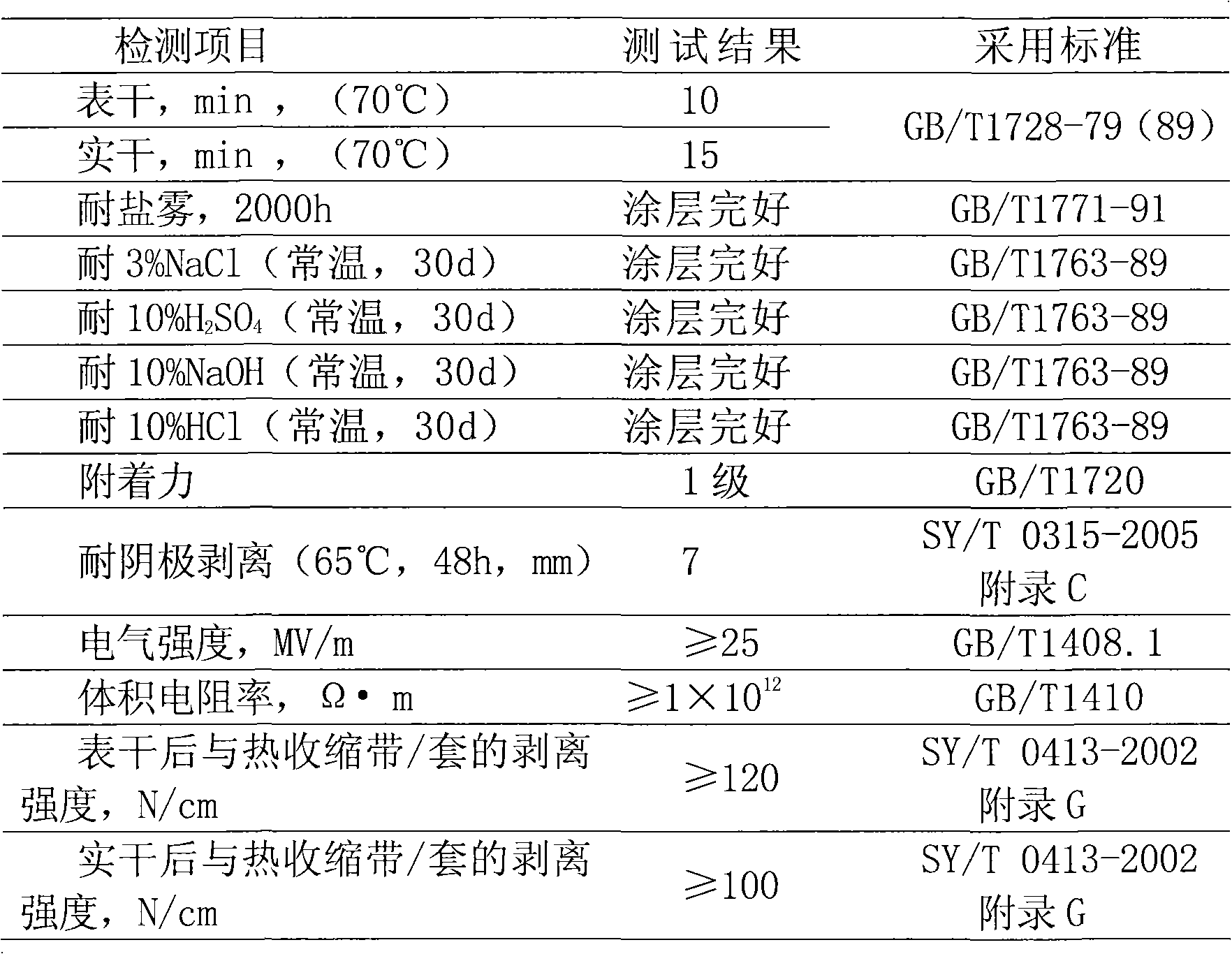

Embodiment 2

[0023] ①Preparation of polyurethane-modified epoxy resin: In a stainless steel reaction kettle, add 1 weight part of polyether polyol, heat to 80°C under stirring, drop 0.25 weight part of isocyanate MDI-50, add in batches after 4 hours of reaction 2.8 parts by weight of bisphenol F-type epoxy resin, continue to stir for 6 hours, stop stirring, and discharge to obtain polyurethane modified epoxy resin. The hydroxyl value of polyether polyol is between 50, the functional group is between 4, and the molecular weight is about 4000.

[0024] ②Preparation of Agent A: In a stainless steel bucket, add various components in sequence according to the component ratio of Example 1, stir at high speed for 0.25h, grind with a sand mill for 0.5h, and discharge to obtain Agent A in the coating;

[0025] ③Preparation of Agent B: Add 1 part by weight of modified alicyclic amine and 0.01 part by weight of polyamide wax in a stainless steel tank in sequence, and stir at high speed for 0.5 h to o...

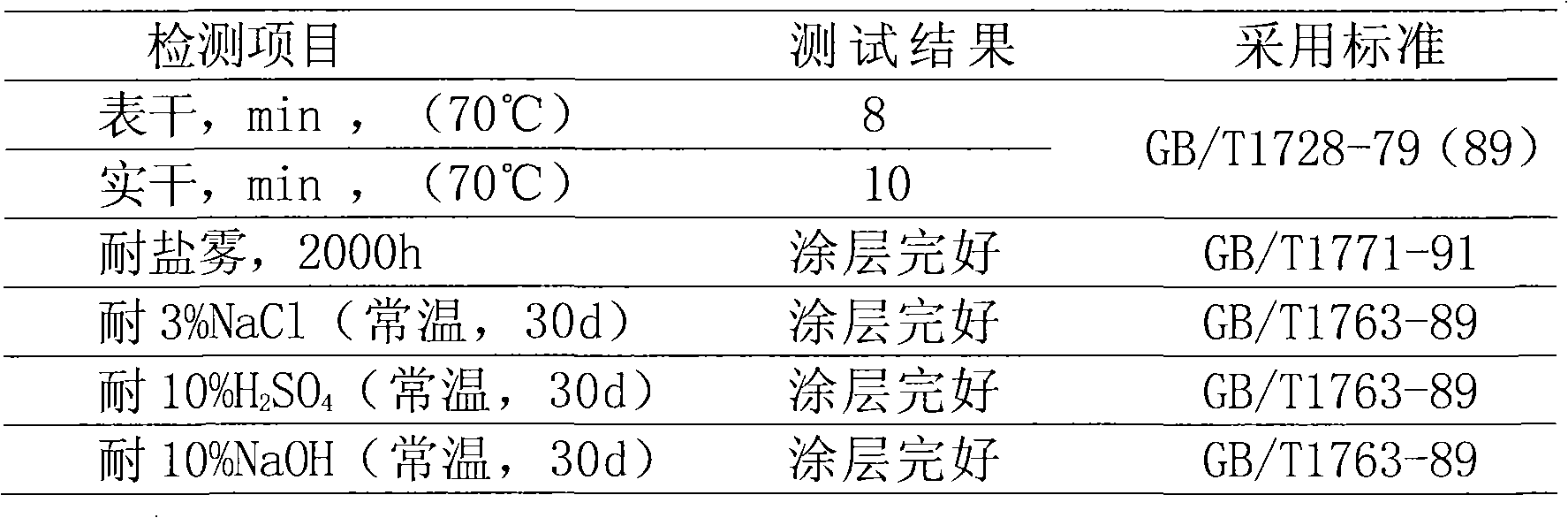

Embodiment 3

[0030] ①Preparation of polyurethane modified epoxy resin: In a stainless steel reaction kettle, add 1 weight part of polyether polyol, heat to 80°C under stirring, add 0.0005 weight part of dibutyltin dilaurate, dropwise add 0.25 weight part of Isocyanate MDI-50, after reacting for 2 hours, add 2.1 parts by weight of bisphenol AD epoxy resin in batches, continue stirring for 4 hours, stop stirring, and discharge to obtain polyurethane modified epoxy resin.

[0031] ② Preparation of Agent A: In a stainless steel bucket, add 1 part by weight of polyurethane modified epoxy resin, 0.20 part by weight of 2-diol diglycidyl ether, and 0.05 part of polycarboxylic acid polymer (TEGO 610S ), 0.01 part of acrylate polymer (BYK-110), 0.01 part of polysiloxane (BYK-080), 0.02 part of polyether siloxane copolymer (BYK-330), 0.015 part of urethane Ester polymer (TEGO 710), control the temperature at 30°C, mix and stir at high speed, add 0.02 parts by weight of fumed silica, 0.24 parts by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com