High-performance water-based heavy anti-corrosion paint and preparation method thereof

A heavy-duty, high-performance technology, used in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve problems such as poor thick coating, poor water and chemical resistance, and cannot be used in corrosive environments, to meet the requirements of lightweight coatings. The effect of improving the adhesion, enhancing the adhesion and improving the resistance to salt spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

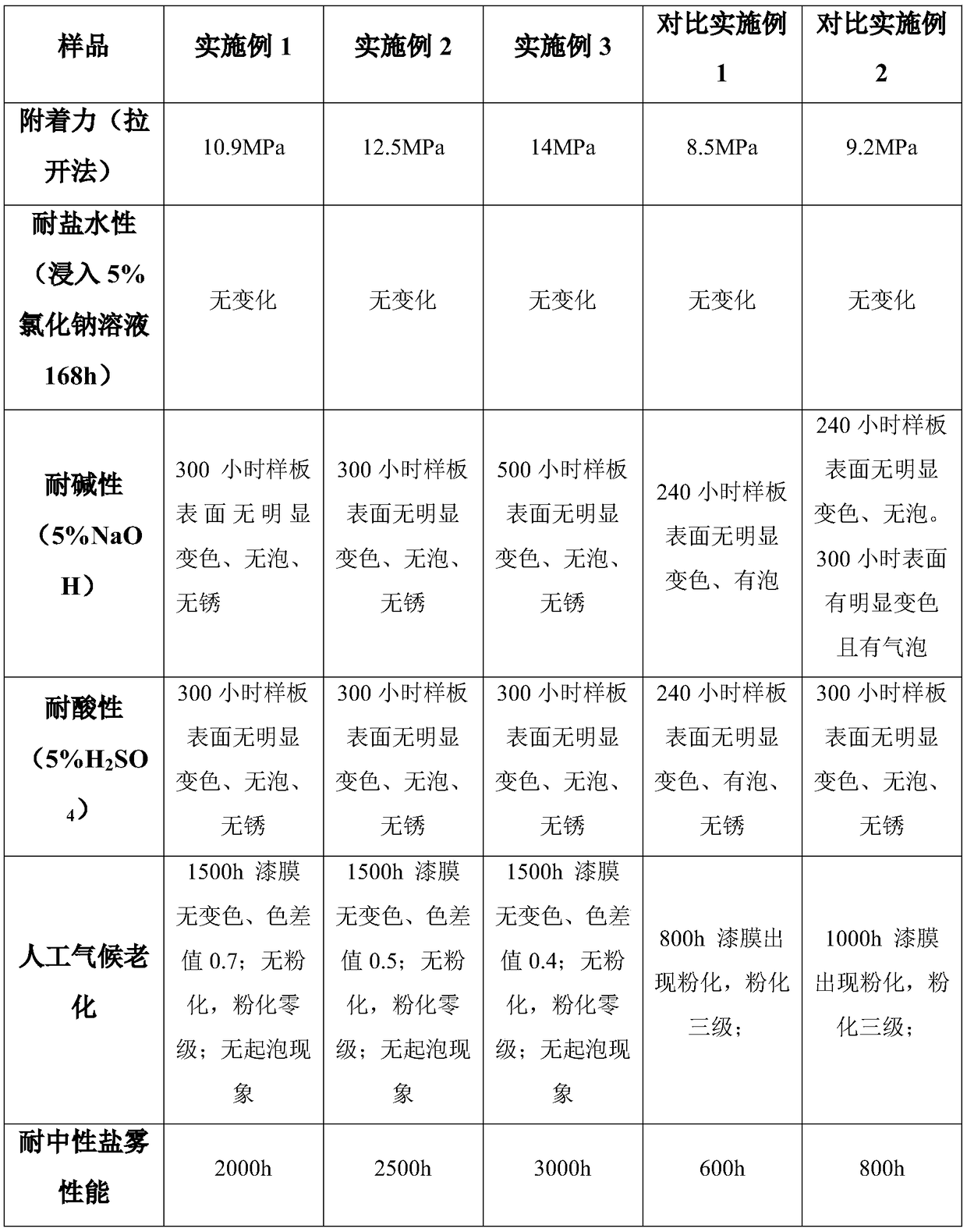

Examples

Embodiment 1

[0027] Preparation of water-based heavy-duty anti-corrosion paint

[0028] (1) Preparation of waterborne epoxy zinc-rich primer

[0029] Weigh 10 parts respectively to get the solid content to be 80wt%, the water-based polyamide curing agent that the active hydrogen equivalent is 306, 8 parts of cosolvent (ethylene glycol ethyl ether), 3 parts of rheology modifier (organic bentonite) and 80 parts of particle size For 1000-mesh zinc powder, first add water-based polyamide curing agent and co-solvent (ethylene glycol ether) into the paint mixing tank with cooling device, stir and mix until the water-based polyamide curing agent is fully dissolved, and then stir Add the rheological additive (organic bentonite) and stir at the speed of 1000r / min for 12min at the same time, and finally add zinc powder and continue to stir at the speed of 2000r / min for 25min until the fineness≤20μm, then stop the dispersion, according to the product index Adjust the viscosity to the specified requi...

Embodiment 2

[0039] Preparation of water-based heavy-duty anti-corrosion paint

[0040] (1) Preparation of waterborne epoxy zinc-rich primer

[0041] Weighing 12 parts respectively to get the solid content as 80wt%, the water-based polyamide curing agent whose active hydrogen equivalent is 306, 15 parts of cosolvent (ethylene glycol butyl ether), 4.5 parts of rheological modifier (attapulgite) and 70 parts Zinc powder with a particle size of 500 mesh, first add water-based polyamide curing agent and cosolvent (ethylene glycol butyl ether) into the paint mixing tank with cooling device, stir and mix until the water-based polyamide curing agent is fully dissolved, Then add the rheology additive (attapulgite) while stirring again and stir at the speed of 1000r / min for 10min at the same time, finally add zinc powder and continue stirring at the speed of 2000r / min for 30min until the fineness≤20μm, then stop the dispersion. According to the index of the product, the viscosity is adjusted to th...

Embodiment 3

[0051] Preparation of water-based heavy-duty anti-corrosion paint

[0052] (1) Preparation of waterborne epoxy zinc-rich primer

[0053] Weighing 15 parts respectively to get the solid content as 80wt%, active hydrogen equivalent of 306 water-based polyamide curing agent, 12 parts of cosolvent (ethylene glycol ethyl ether), 6 parts of rheology modifier (fumed silica) and 60 parts Zinc powder with a particle size of 800 meshes, first add a water-based polyamide curing agent and a cosolvent (ethylene glycol ether) into a paint mixing tank with a cooling device, stir and mix until the water-based polyamide curing agent is fully dissolved, and then In the case of re-stirring, add a rheological additive (fumed silica) and stir at a speed of 1000r / min for 15min at the same time, and finally add zinc powder and continue stirring at a speed of 2000r / min for 20min until the fineness≤20μm, then stop the dispersion. According to the index of the product, the viscosity is adjusted to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com