Metal product rustproof cleaning agent

A technology for metal products and cleaning agents, applied in the field of surface treatment of metal products, can solve the problems of great influence of rust prevention ability, rust prevention and corrosion resistance can not meet the needs of the industry, etc., to achieve easy high-pressure jet cleaning, good rust prevention The effect of strong cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of antirust cleaning agent for metal products of the present invention is made of following components:

[0024] Fatty amine polyoxyethylene ether 5kg, petroleum calcium sulfonate 4kg, N-methyl-2-pyrrolidone 4kg, sorbitan fatty acid ester (Span 20) 5kg, polyoxyethylene polyoxypropanol amine ether 1kg, Methyl siloxane 2kg, deionized water 15kg.

[0025] Preparation method: Weigh each component in the formula amount, heat to 60°C, and keep stirring until completely mixed.

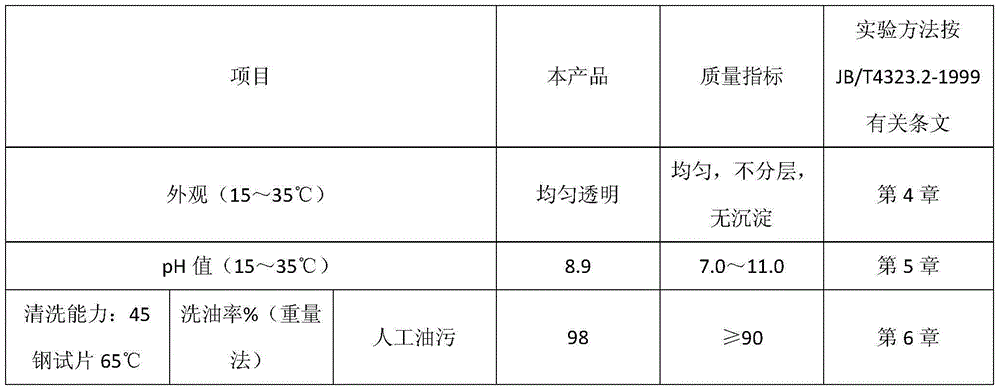

[0026] The properties of the antirust cleaning agent for metal products are shown in Table 1.

[0027] Table 1. Embodiment 1 prepares the performance parameter of antirust cleaning agent for metal products

[0028]

[0029]

Embodiment 2

[0031] A kind of antirust cleaning agent for metal products of the present invention is made of following components:

[0032] Fatty amine polyoxyethylene ether 7kg, petroleum calcium sulfonate 8kg, N-methyl-2-pyrrolidone 6kg, sorbitan fatty acid ester (Span 60) 7kg, polyoxyethylene polyoxypropanol amine ether 1kg, poly Methyl siloxane 3kg, deionized water 20kg.

[0033] Preparation method: Weigh each component in the formula amount, heat to 60°C, and keep stirring until completely mixed.

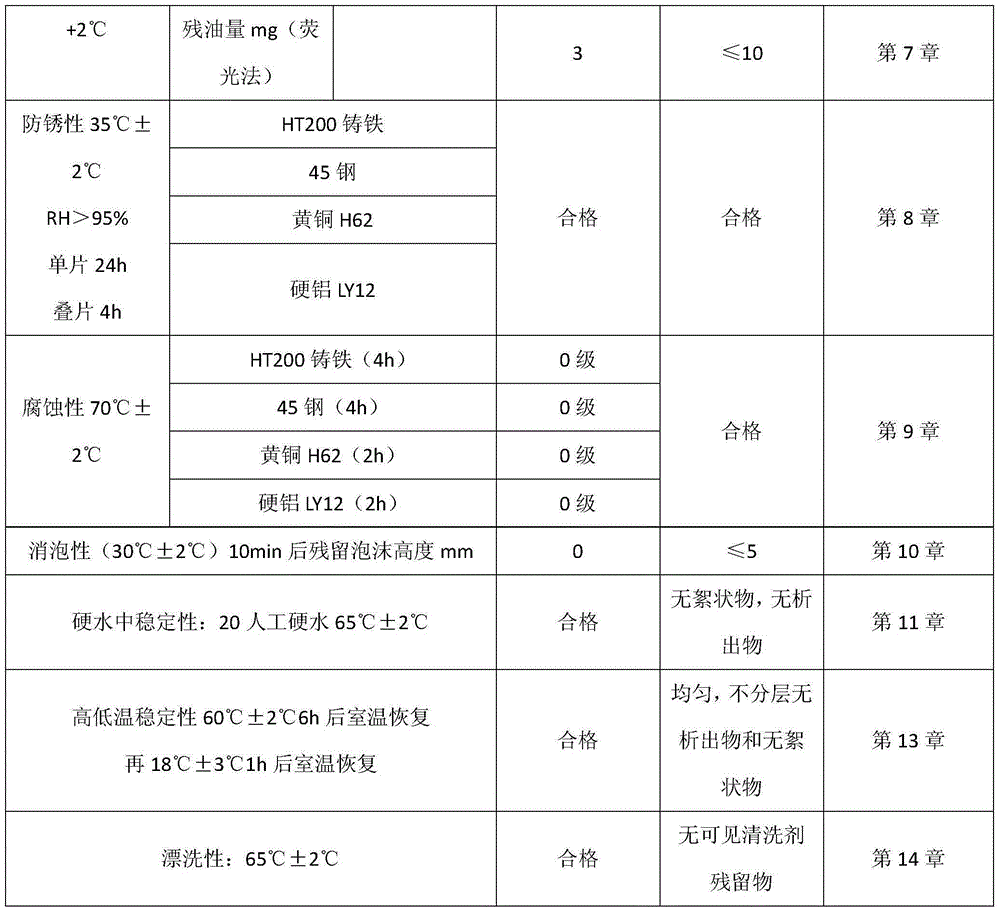

[0034] The properties of the antirust cleaning agent for metal products are shown in Table 2.

[0035] Table 2. Embodiment 2 prepares the performance parameter of antirust cleaning agent for metal products

[0036]

[0037]

Embodiment 3

[0039] A kind of antirust cleaning agent for metal products of the present invention is made of following components:

[0040] Fatty amine polyoxyethylene ether 6kg, petroleum calcium sulfonate 6kg, N-methyl-2-pyrrolidone 5kg, sorbitan fatty acid ester (Span 65) 6kg, polyoxyethylene polyoxypropanol amine ether 1kg, poly Methyl siloxane 2kg, deionized water 17kg.

[0041] Preparation method: Weigh each component in the formula amount, heat to 60°C, and keep stirring until completely mixed.

[0042] The properties of the antirust cleaning agent for metal products are shown in Table 3.

[0043] Table 3. Embodiment 3 prepares the performance parameter of antirust cleaning agent for metal products

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com