High-corrosion-resistance super-free-cutting soft magnetic ferrite stainless steel wire rod and preparation method thereof

A stainless steel plate, corrosion-resistant technology, applied in the direction of inductor/transformer/magnet manufacturing, magnetic objects, manufacturing tools, etc., can solve the problems of inability to achieve easy cutting effect, increase production difficulty, affect corrosion resistance, etc., and achieve soft magnetic properties. Excellent performance, improved machinability, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

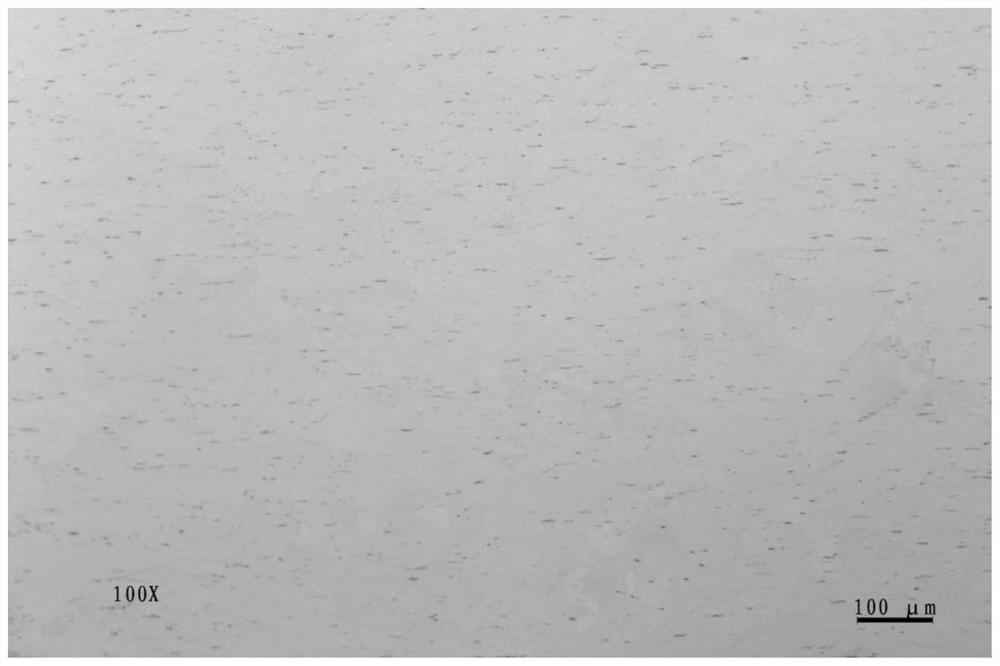

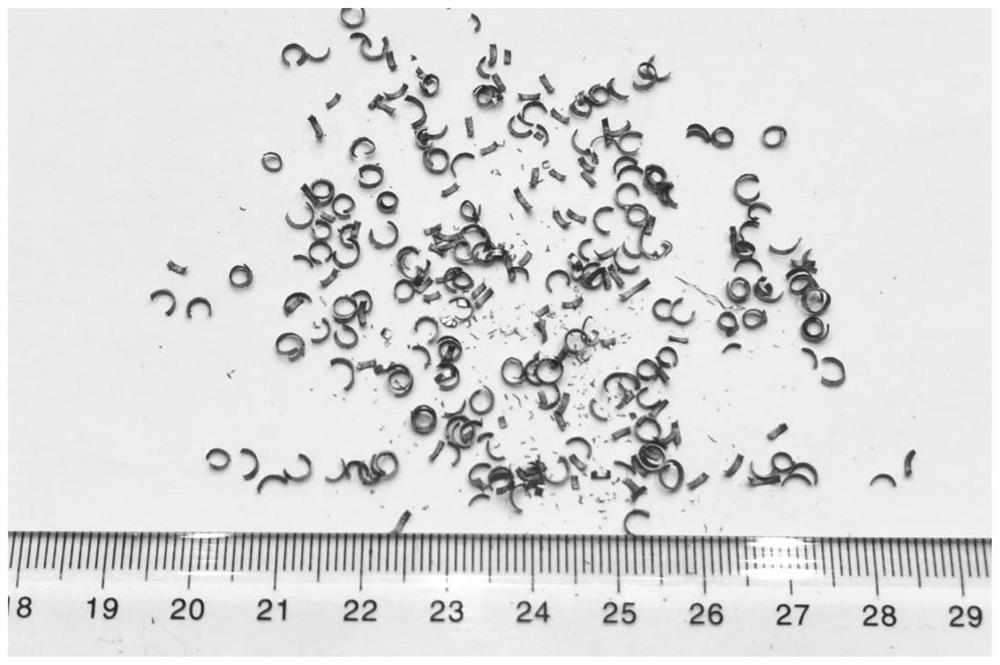

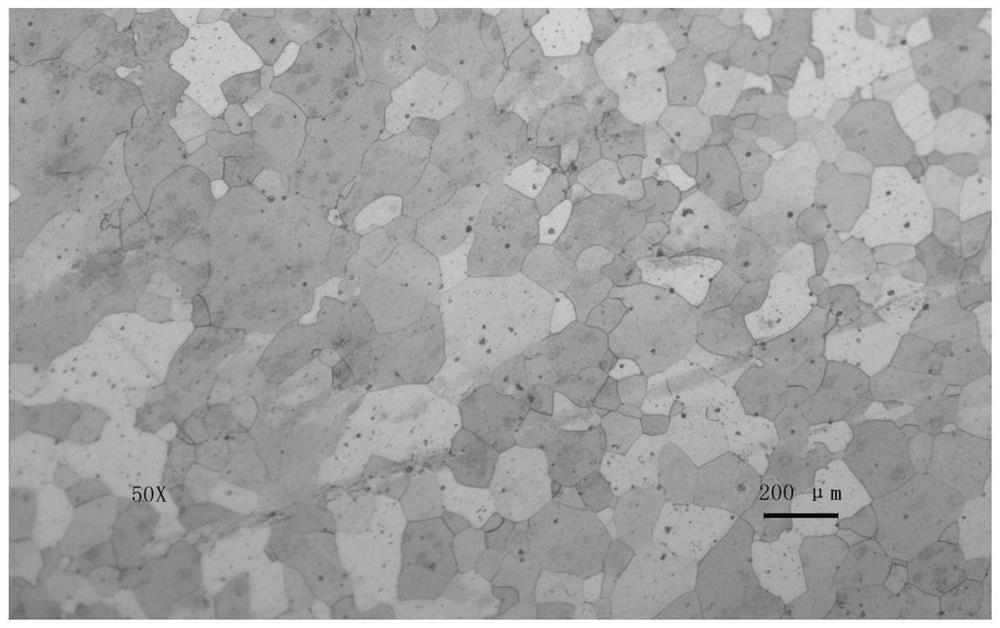

[0065] The high-corrosion-resistant and super-cuttable soft ferrite stainless steel wire rod in this embodiment is mainly composed of the corresponding components in Table 1, the balance of Fe and unavoidable impurities in terms of mass percentage.

[0066] The stainless steel wire rod is prepared by the following method: It should be noted that the percentages mentioned below are all mass percentages,

[0067](1) Electric arc furnace smelting: A 30t electric furnace is used for smelting, and waste high-chromium steel is fed into the electric arc furnace as a raw material for melting, and the P content is controlled to be 0.020% when tapping the steel, and the amount of molten steel to be tapped is 32t. (2) AOD furnace smelting: first add 1000Kg of lime, then add 300Kg of ferrochrome, then mix the crude steel into the AOD furnace; control the slag basicity R to 3.0 during the decarburization period, and the C content at the decarburization end point to 0.002%; add 950Kg Ferros...

Embodiment 2

[0069] The high-corrosion-resistant and super-cuttable soft ferrite stainless steel wire rod in this embodiment is mainly composed of the corresponding components in Table 1, the balance of Fe and unavoidable impurities in terms of mass percentage.

[0070] The stainless steel wire rod is prepared by the following method: It should be noted that the percentages mentioned below are all mass percentages,

[0071] (1) Electric arc furnace smelting: A 30t electric furnace is used for smelting, and waste high-chromium steel is melted in the electric arc furnace. The tapping P: 0.019% is controlled, and the amount of crude molten steel is 31t. (2) AOD furnace smelting: first add 1000Kg of lime, then add 280Kg of ferrochrome, then mix crude molten steel into the AOD furnace; control the slag basicity R at 3.3 during the decarburization period, and the C content at the decarburization end point is 0.001%; add 950Kg Ferrosilicon is reduced. After the reduction, 140Kg of ferrous sulfu...

Embodiment 3

[0073] The high-corrosion-resistant and super-cuttable soft ferrite stainless steel wire rod in this embodiment is mainly composed of the corresponding components in Table 1, the balance of Fe and unavoidable impurities in terms of mass percentage.

[0074] The stainless steel wire rod is prepared by the following method: It should be noted that the percentages mentioned below are all mass percentages,

[0075] (1) Electric arc furnace smelting: A 30t electric furnace is used for smelting, and scrap steel is melted in the electric arc furnace, which can be high chromium steel. (2) AOD furnace smelting: first add 1000Kg of lime, then add 260Kg of ferrochrome, then mix the crude steel into the AOD furnace; control the slag basicity R at 3.0 during the decarburization period, and the C content at the decarburization end point is 0.005%; add 960Kg Ferrosilicon is reduced. After reduction, add 138Kg of sulfur iron in two batches, add 69Kg in each batch, and stir for 8 minutes after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com