Ring welding method for corrosion-resistant alloy lining composite pipe

A corrosion-resistant alloy and composite pipe technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc. Solve problems such as unfused welds, achieve high-quality and efficient welding, solve dead angles in the fusion zone, and achieve low welding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

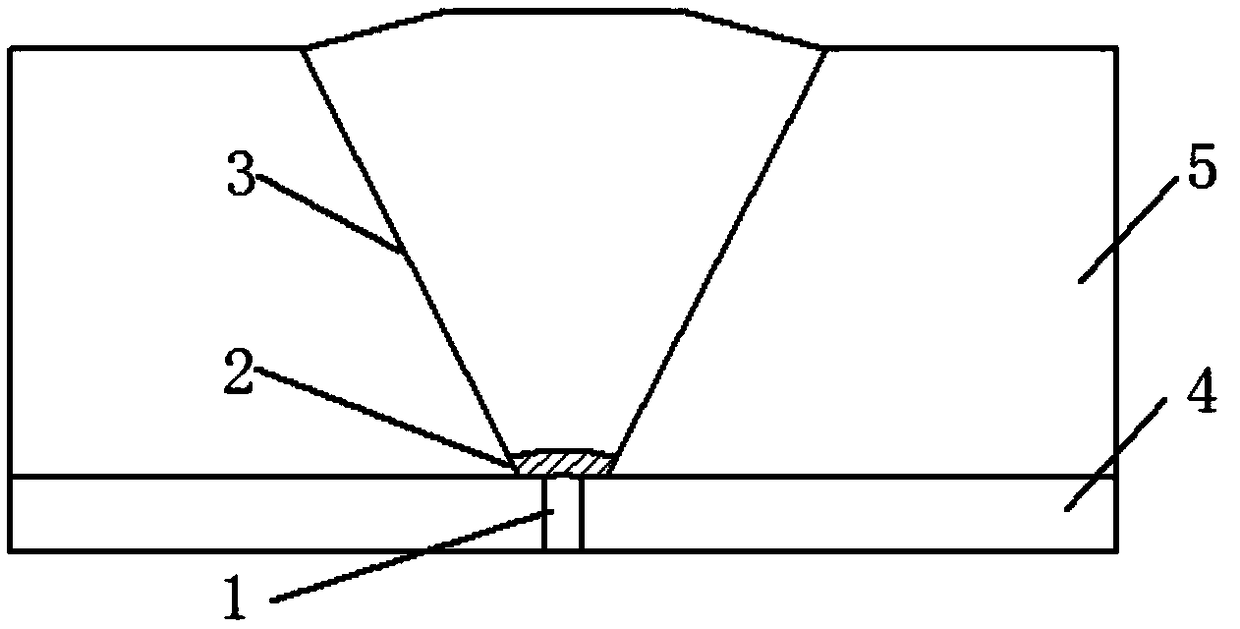

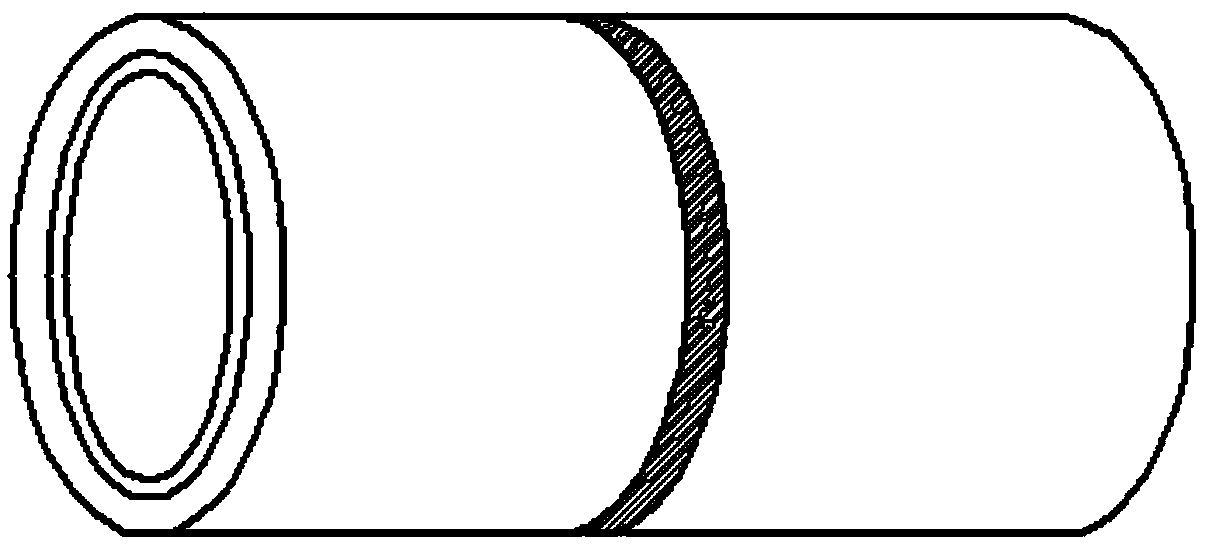

[0020] Take Φ430×(15+3)mm 304 / X65 hot-rolled bimetal composite pipe as an example for welding. First, expand the diameter of the pipe ends of the two pipe sections to ensure their roundness. The carbon steel side of the pipe end has a V-shaped groove, the height of the groove is 0.2mm greater than the thickness of the carbon steel layer, the width of the bottom is 4mm, and the groove angle is 60°. Use a stainless steel wire brush to clean the groove burr, and use acetone to clean the groove, especially the cladding groove. The pipe ends are butt-jointed with a counterpart, and the gap between the pipe ends is 0.5mm.

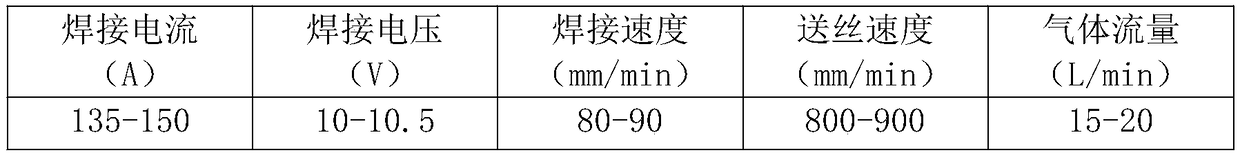

[0021] The corrosion-resistant alloy layer is welded from the carbon steel side by argon tungsten arc welding to form a cladding weld 1 . The welding of cladding layer 4 adopts double-layer single-pass welding, the first layer fills the cladding weld s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com