Austenitic stainless steel nitriding treatment system and method based on hollow cathode ion source

A technology of austenitic stainless steel and hollow cathode, which is applied in coating, metal material coating process, solid-state diffusion coating, etc., can solve the problem of low nitriding rate of too long, so as to improve nitriding efficiency and accelerate diffusion rate , Improving the effect of nitriding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 450

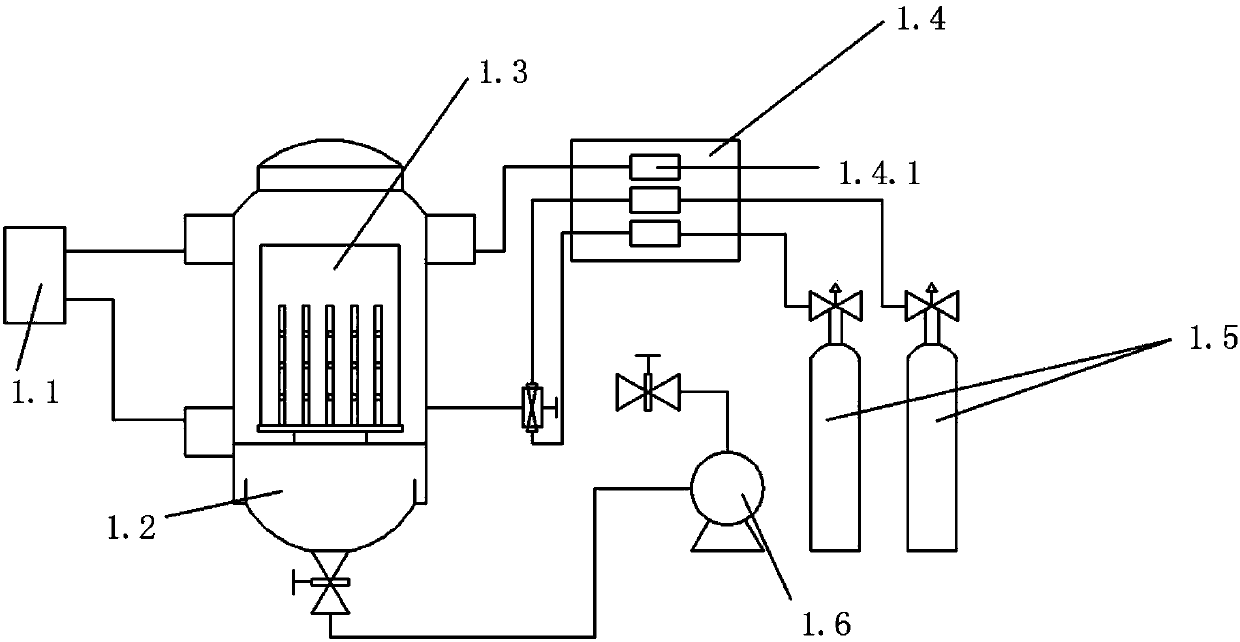

[0030] 2) Put multiple parts into the vacuum nitriding furnace between the two metal plates where the hollow cathode device is installed, connect it to the cathode of the power supply, cover the furnace cover, turn on the air pump to vacuum the nitriding furnace, and pass cooling water; Evacuate to 5-15Pa (10Pa in this embodiment, you can see the value from the pressure indicator, pressure, temperature, voltage, current and gas flow, etc. can be displayed on the computer of the control system), adjust the working voltage (700-900V) and duty cycle (70%-80%), then open the ammonia cylinder, adjust the flow meter to maintain the air pressure at 400-450Pa (450Pa in this embodiment);

[0031] 3) Raise the temperature of the parts in the vacuum nitriding furnace, adjust the current and pressure (control the pressure by adjusting the flow meter on the ammonia cylinder, and ensure the stable discharge of the hollow cathode, the temperature rise rate is 15-25 degrees / min, the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com