Preparation method of low-weightlessness sintered NdFeB magnet

A magnet, magnetron sputtering technology, applied in the manufacture of permanent magnets, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of reduced magnetism, low content of rare earth elements, and high cost, and achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

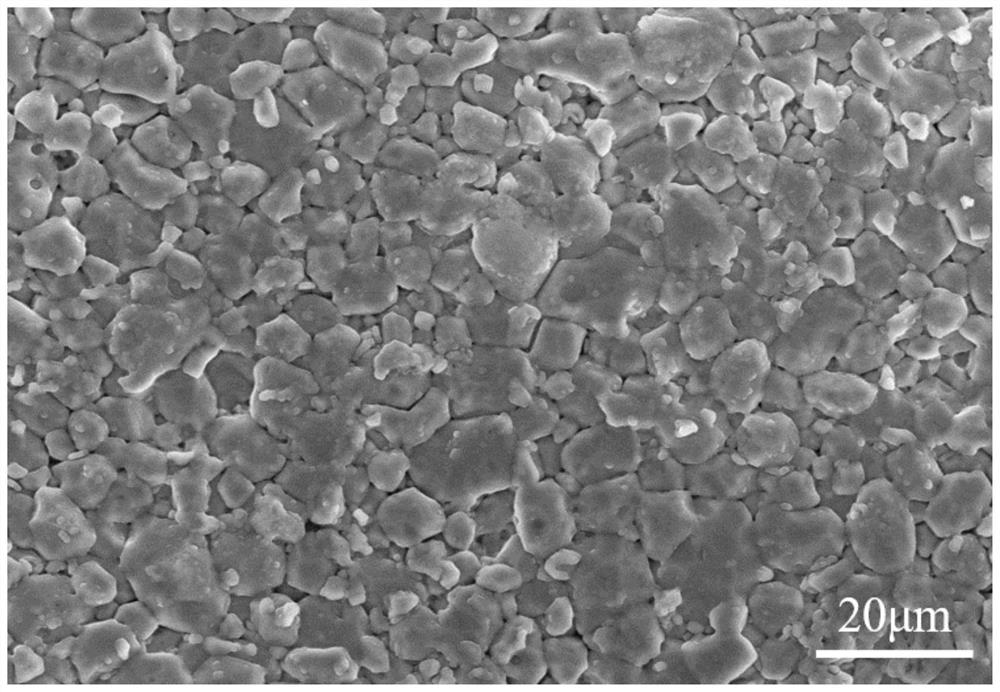

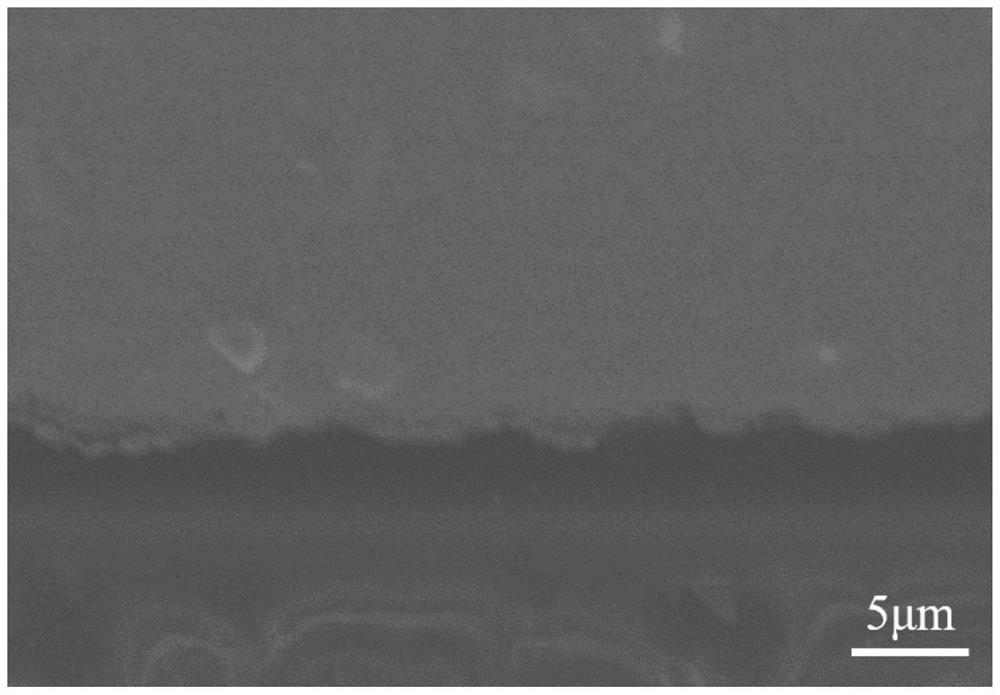

[0025] A method for preparing a low-weight-loss sintered NdFeB magnet. A low-weight-loss sintered NdFeB magnet with high corrosion resistance is obtained by depositing a coating film on the sintered NdFeB magnet by magnetron sputtering, and then performing diffusion heat treatment, which specifically includes the following steps:

[0026] S1. Magnet pre-treatment: The sintered NdFeB magnet in the demagnetized state is washed with 3wt.% sodium hydroxide solution to remove oil for 3 minutes, then pickled with 3vol% nitric acid for 20 seconds, and then ultrasonically cleaned with absolute ethanol for 5 minutes to remove surface dirt, repeated Rinse 3 times and dry naturally to obtain a pretreated sintered NdFeB magnet ready for use.

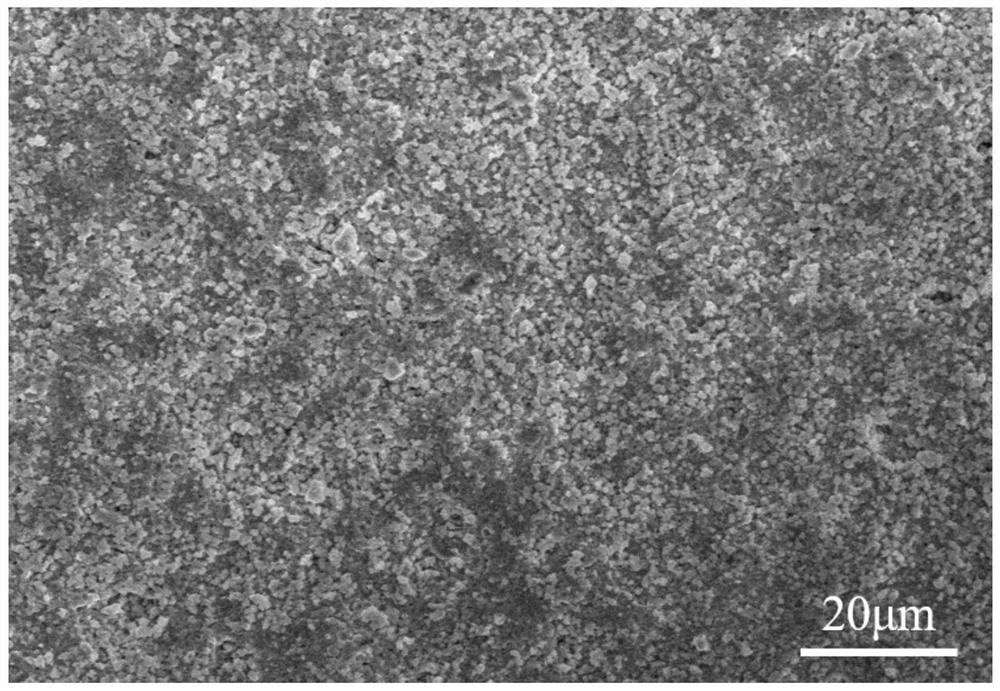

[0027] S2, magnetron sputtering deposition coating: on the surface of the sintered NdFeB magnet after pretreatment, select 99.99% high-purity target material (size is ), and use the radio frequency magnetron sputtering method to coat a silicon film...

Embodiment 2

[0032] The preparation method of this embodiment is the same as that of Embodiment 1, except that the sputtering time in step S2 is 1 h.

[0033] After testing, according to the above steps, the weight loss of high corrosion resistance and low weight loss sintered NdFeB magnet is 0.18mg / cm 2 , its own corrosion resistance is obviously better than that of the comparative example.

Embodiment 3

[0035] The preparation method of this example is the same as that of Example 1, except that the holding time in step S3 is 4 hours.

[0036] After testing, according to the above steps, the weight loss of sintered NdFeB magnet with high corrosion resistance and low weight loss is 0.09mg / cm 2 , its own corrosion resistance is obviously better than that of the comparative example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com