Aluminum surface anti-corrosion treatment method

A treatment method and anti-corrosion technology, which can be used in pre-treating surfaces, devices for coating liquids on surfaces, and metal material coating processes, etc., can solve problems such as high toxicity, difficult corrosion inhibition mechanism, and restricting the development of corrosion inhibitors, etc. To achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention are specifically described below.

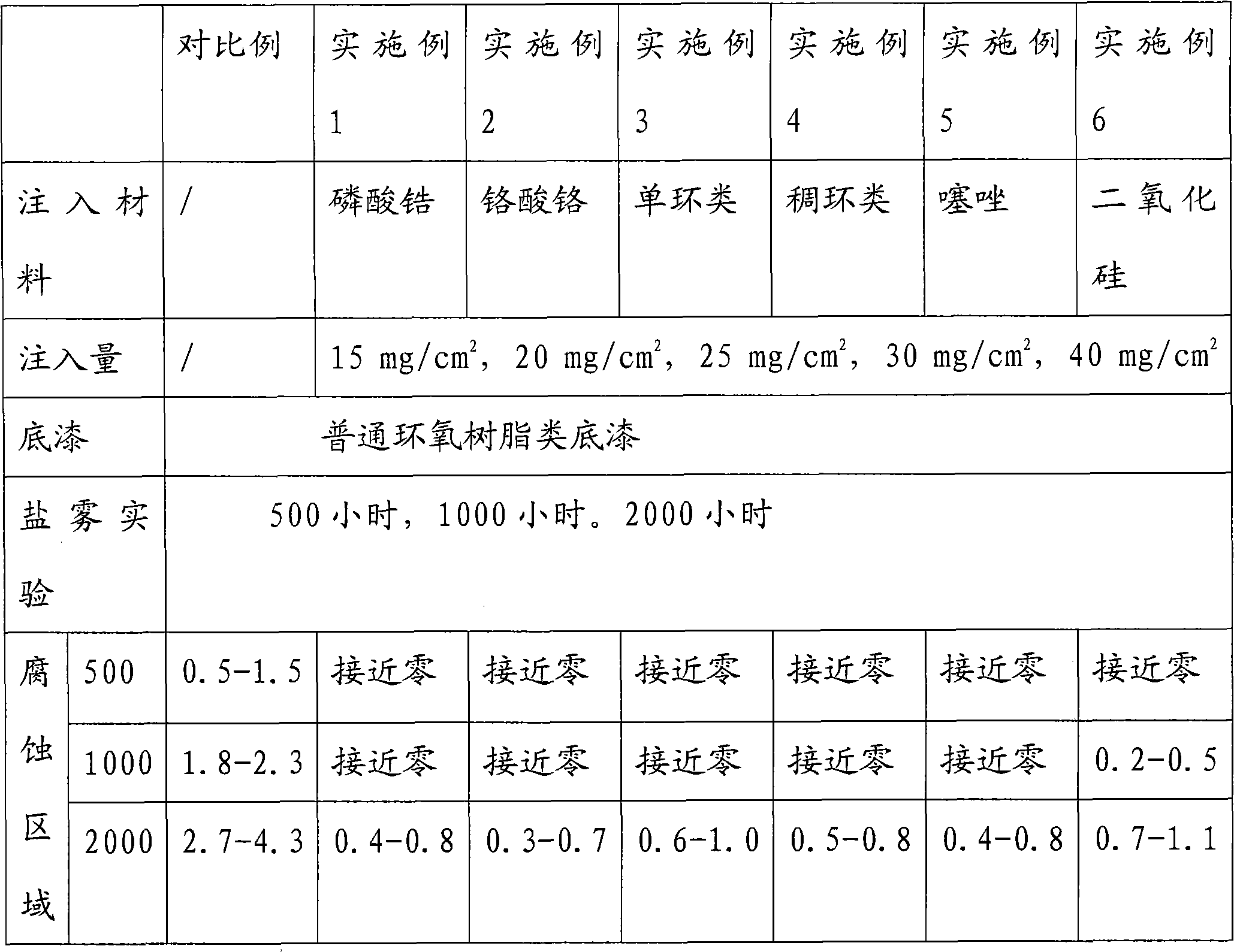

[0016] Firstly, take the metal aluminum plate, and you can also choose other types or shapes of aluminum materials according to the needs, clean the surface of the aluminum materials, and select amorphous substances for ion implantation, the amorphous substances include organic compounds, or Inorganic oxides. The amorphous substance includes one or a combination of zirconium phosphate, chromium chromate, monocyclic, condensed ring, sulfur-containing heterocyclic compounds, silicon dioxide and sodium fluorosilicate. The amorphous substances selected in Examples 1-6 of the present invention are only single-component amorphous substances, see Table 1 for details. However, due to the toxicity of chromium chromate, it is usually not used.

[0017] The ion implantation energy of the present invention is on the order of 45-80KeV; the specific implantation energy is selected according to the purpose of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com