Method for preparing uranium tetrafluoride by fluorinating U3O8 or UO3 at high temperature

A technology of uranium tetrafluoride and UO3, which is applied in the direction of uranium fluoride and uranium halide, can solve the problems of long reaction time, large reaction activation energy, and low electrolysis efficiency, so as to reduce the requirements for reaction equipment, simplify the reaction equipment, and reduce the The effect of preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

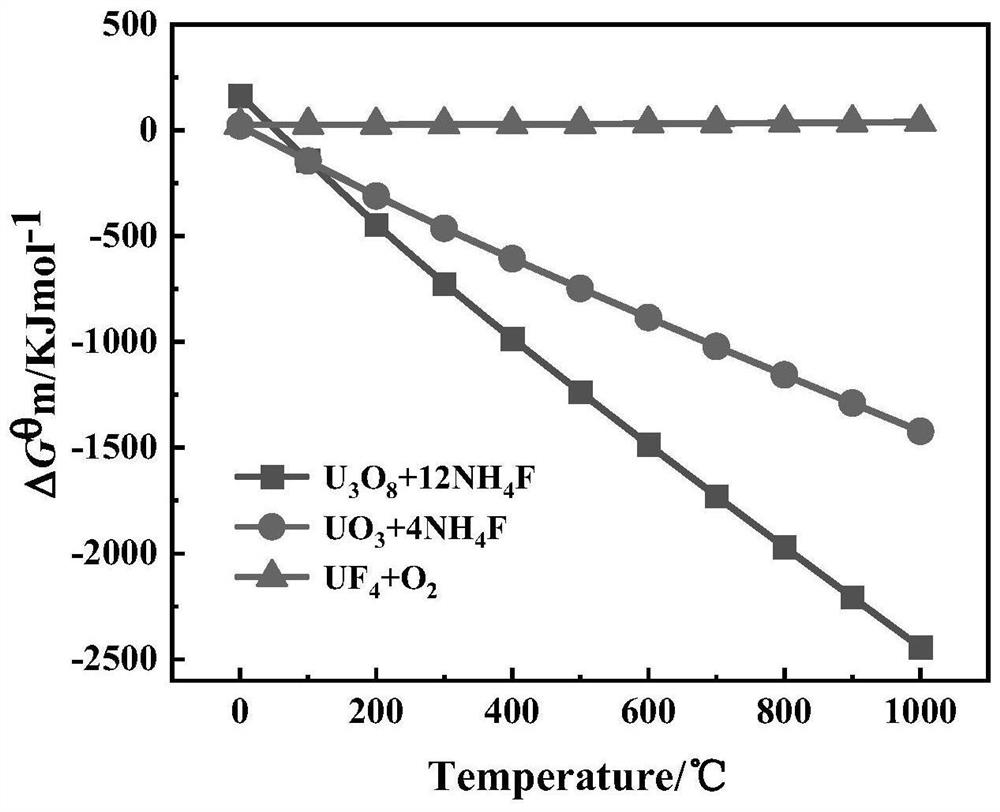

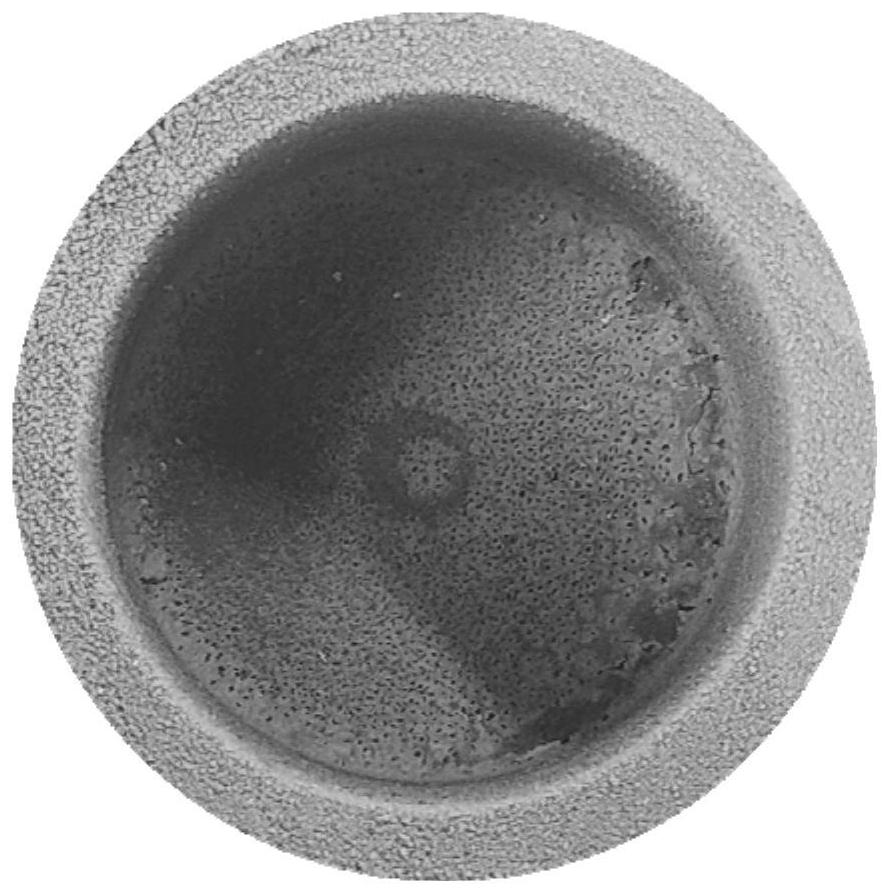

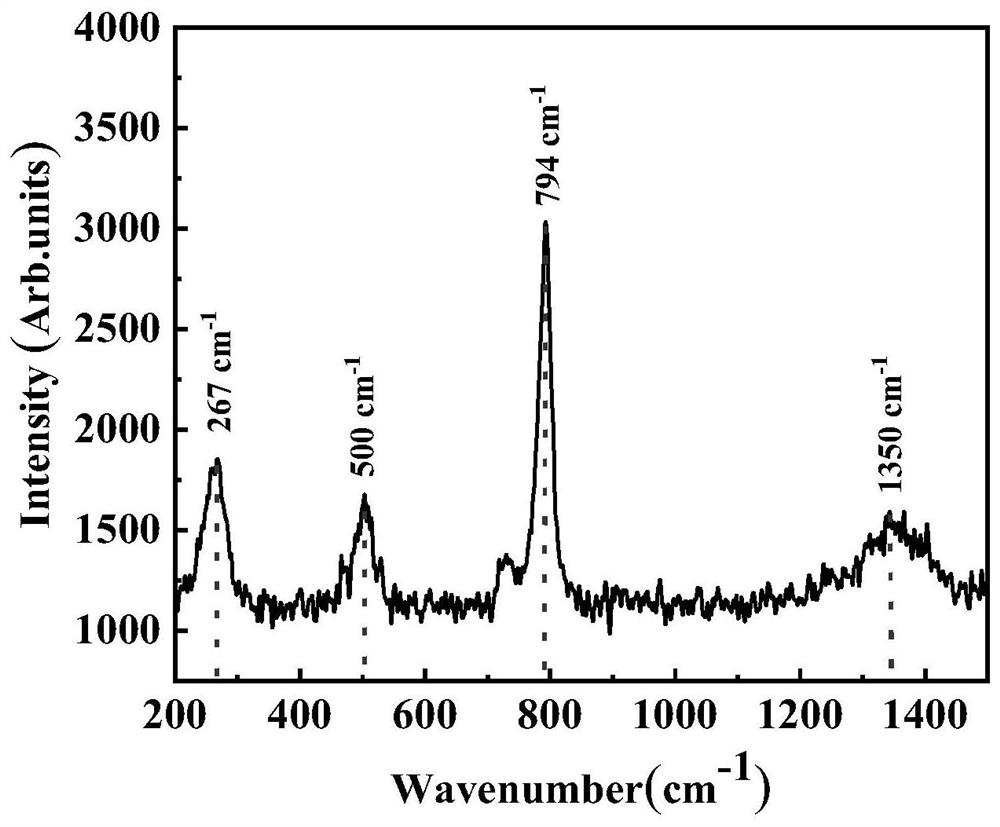

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. u 3 o 8 or UO 3 , NH 4 F and KF are placed in a mortar at a ratio of 1:30 or 50:3, mixed thoroughly and evenly, and then placed in a graphite crucible. The temperature is programmed to 450°C, and the intermediate product UO is rapidly generated 2 f 2 , so the controlling step of the reaction rate of the overall reaction mainly depends on UO 2 f 2 recovery rate. Due to the participation of gas in the rate-controlling step of the reaction, in ordinary fluorination reaction devices, the gas is easy to diffuse out of the device, resulting in a small amount of gas participating in the reduction, which is not conducive to UO 2 f 2 Therefore, it has been improved on the common fluorination r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com