Application of aromatic polyamide material in waterborne coating filling agent

A technology of aromatic polyamide and water-based paint, applied in the direction of coating, etc., can solve the problem of no aromatic polyamide, etc., and achieve the effect of less mass fraction, good dispersion stability and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Add zirconia beads with a diameter of 5 mm into the grinding jar, and then add 1,3,5-benzenetricarboxylic acid chloride and 1,4-p-phenylenediamine. Grind with a ball mill for 10 minutes at a speed of 600 rpm; and control the molar ratio of the acid chloride to the primary amine to be 0.99:1.0 to obtain the product, and the mass ratio of the aromatic polyamide compound in the product is 80%.

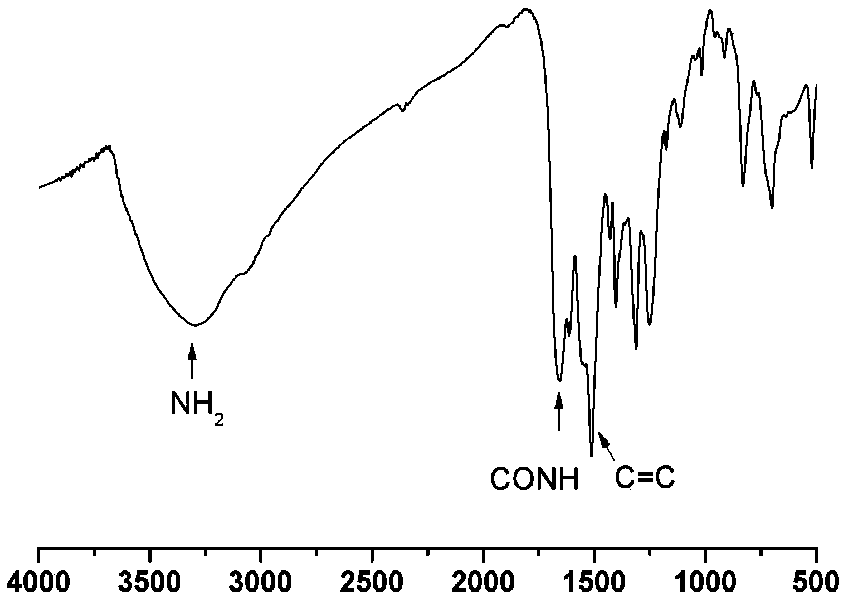

[0039] Such as figure 1 The microscopic morphology of the product shown, the scale bar in the figure is 100 μm, the aromatic polyamide of the product has a lamellar structure, the side length is less than 20-30 μm, and the size dispersion is small. figure 2 It is the Fourier infrared spectrogram of the product after drying, at a wave number of 3300cm -1 The absorption peak at is attributed to the absorption peak of the amine group, at a wave number of 1650cm -1 The absorption peak at is due to the C=O in the amide group, at a wave number of 1510cm -1 The absorption peak at i...

Embodiment 2

[0046] 1) Add zirconia beads with a diameter of 5 mm into the grinding jar, and then add 1,3,5-benzenetricarboxylic acid chloride and 4,4'-diaminodiphenylmethane. Grinding with a ball mill for 3 minutes at a speed of 900 rpm; and controlling the molar ratio of the acid chloride to the primary amine to be 0.5:1.0 to obtain the product, and the mass ratio of the aromatic polyamide compound in the product is 82%.

[0047] 2) The product was first neutralized with 15 mL of 5% sodium hydroxide aqueous solution, and then separated by a centrifuge. The obtained solid product was first washed with absolute ethanol until the supernatant was colorless, and then washed with deionized water until the water phase was neutral. Then, the product was dispersed in the solvent N,N-dimethylacetamide (prepared to a concentration of 2 mg / mL) for use.

[0048] 3) Take the above dispersion and mix it with water-based paint (0.15% added to the aromatic polyamide layered material). After the paint fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com