Corrosion-resistant weather-resistant high-storage-performance polyester resin for powder coating

A technology of polyester resin and powder coating, which is applied in the field of polyester resin for powder coating, powder coating and coating, which can solve the problems of poor corrosion resistance, complex formula, attention to corrosion resistance, etc., and achieve excellent corrosion resistance , strong key energy, and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides the preparation method of above-mentioned polyester resin simultaneously, and the steps are as follows:

[0033] (1) Add the formulated amount of neopentyl glycol, ethylene glycol, fluorine-containing glycol, and optional isosorbide into a three-necked flask equipped with a stirring and reflux condenser, mix and stir and heat at 100-140°C melt;

[0034] (2) Continue to raise the temperature to 150-180°C, add the formulated amount of terephthalic acid, fluorine-containing dicarboxylic acid and catalyst, pass nitrogen gas and raise the temperature to 180-190°C to start the esterification reaction and produce esterified water to distill out, and then gradually Raise the temperature to 22-250°C, react for 5-10 hours until 95% of the esterification water is discharged, and the acid value reaches 12-15mgKOH / g;

[0035] (3) Then cool down to 200-210°C, add the formula amount of isophthalic acid, and then continue to gradually raise the temperatu...

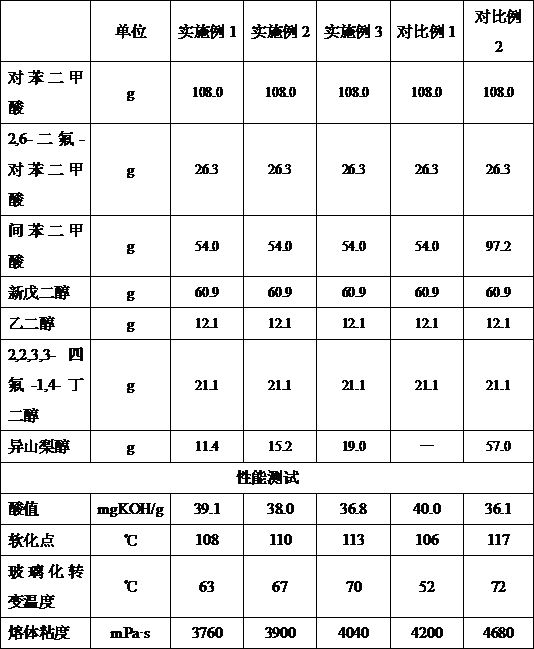

Embodiment 1

[0041] A polyester resin for powder coatings with corrosion resistance, weather resistance and high storage performance. 54.0g, neopentyl glycol 60.9g, ethylene glycol 12.1g, 2,2,3,3-tetrafluoro-1,4-butanediol 21.1g, isosorbide 11.4g; the catalyst is tetrabutyl titanate 0.02mol.

[0042] The preparation method step of polyester resin is as follows:

[0043] (1) Add the prescribed amount of neopentyl glycol, ethylene glycol, 2,2,3,3-tetrafluoro-1,4-butanediol, and isosorbide into a three-necked flask equipped with a stirring and reflux condenser , mixed and stirred and heated and melted at 130°C;

[0044] (2) Continue to raise the temperature to 170°C, add the formulated amount of terephthalic acid, 2,6-difluoro-terephthalic acid and tetrabutyl titanate catalyst, and raise the temperature to 180°C with nitrogen gas to start the esterification reaction and generate ester Distill off the water, then gradually raise the temperature to 240°C, react for 5-10 hours until 95% of th...

Embodiment 2

[0047] A polyester resin for powder coatings with corrosion resistance, weather resistance and high storage performance. 54.0g, neopentyl glycol 60.9g, ethylene glycol 12.1g, 2,2,3,3-tetrafluoro-1,4-butanediol 21.1g, isosorbide 15.2g; the catalyst is tetrabutyl titanate 0.02mol.

[0048] The preparation method step of polyester resin is as follows:

[0049] (1) Add the prescribed amount of neopentyl glycol, ethylene glycol, 2,2,3,3-tetrafluoro-1,4-butanediol, and isosorbide into a three-necked flask equipped with a stirring and reflux condenser , mixed and stirred and heated and melted at 130°C;

[0050] (2) Continue to raise the temperature to 170°C, add the formulated amount of terephthalic acid, 2,6-difluoro-terephthalic acid and tetrabutyl titanate catalyst, and raise the temperature to 180°C with nitrogen gas to start the esterification reaction and generate ester Distill off the water, then gradually raise the temperature to 240°C, react for 5-10 hours until 95% of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com