Method for obtaining expansion Alpha phase on surface of stainless steel

A technology of stainless steel and atmosphere, which is applied in the field of stainless steel surface modification treatment process, can solve the problems of reducing the corrosion resistance of martensitic stainless steel, and achieve the effects of high hardness, short production cycle and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

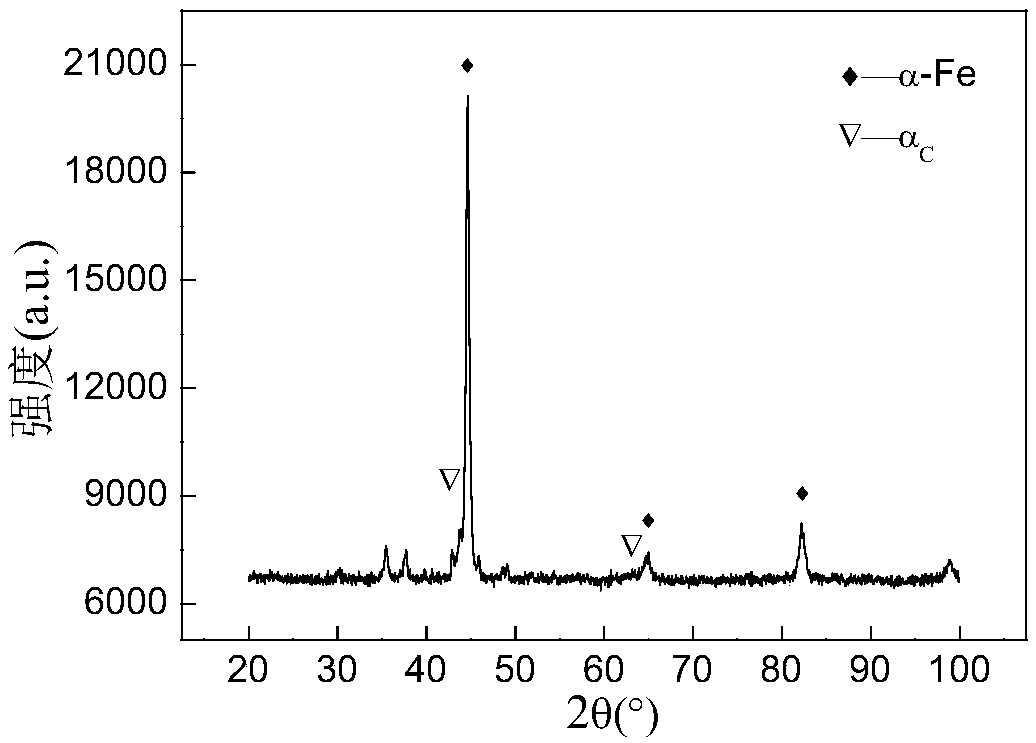

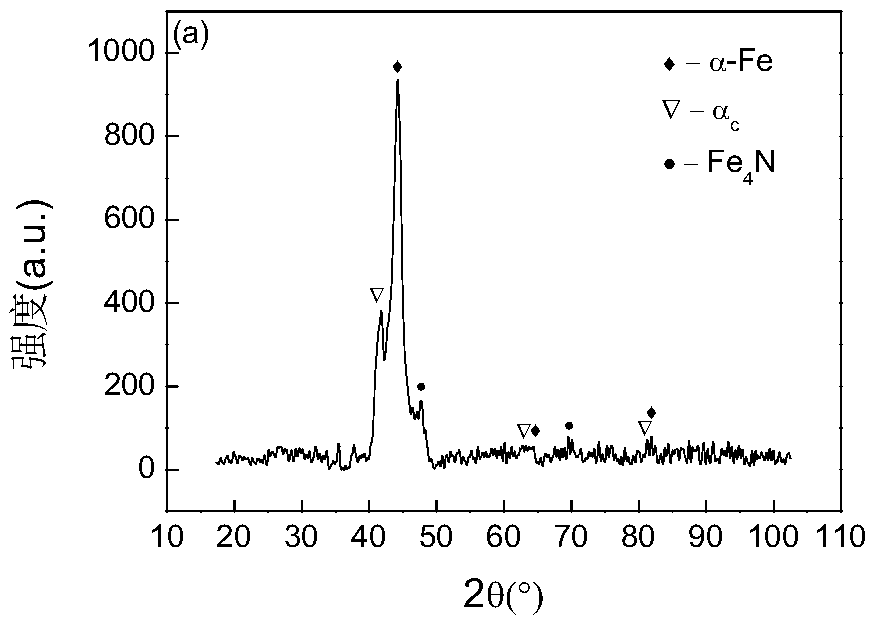

[0025] Specific embodiment one: a kind of process method that obtains homogeneous carbon-containing " expanding " α phase layer on the surface of 2Cr13 martensitic stainless steel, this process comprises the following steps: 1, 2Cr13 martensitic stainless steel is carried out solid solution treatment, make Homogenize the stainless steel structure; 2. Polish the surface oxide layer with 240#~800# SiC sandpaper on the surface of the stainless steel workpiece, and then perform ultrasonic cleaning on the stainless steel workpiece in ethanol, acetone and deionized water in sequence to remove oil and impurities on the surface of the workpiece, and dry 3. Put the stainless steel workpiece into the plasma multi-component co-infiltration furnace, evacuate to below 10Pa, feed a very small amount of dried hydrogen gas, start the glow and heat up, and perform plasma cleaning at the same time; 4. The temperature reaches 100 At ℃, acetone steam is introduced, the ratio of acetone and hydroge...

specific Embodiment approach 2

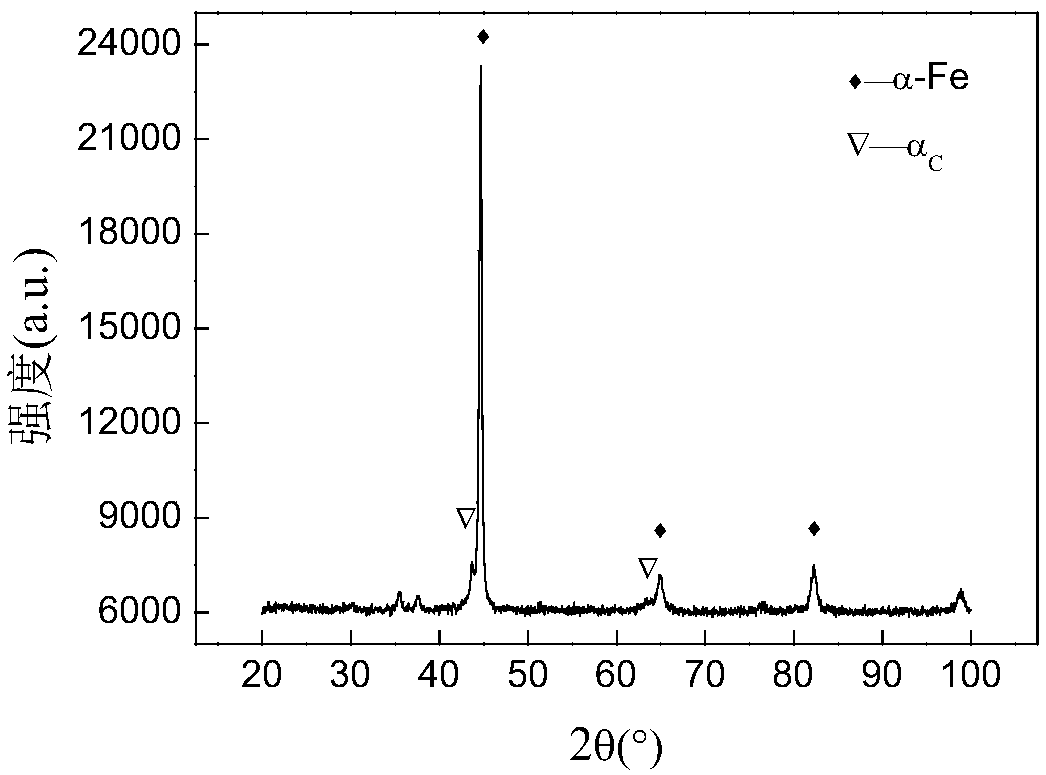

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the carburizing temperature in step 4 is 500° C. and the temperature is kept for 4 hours. Other steps and parameters are the same as those in Embodiment 1. By means of this embodiment a modified layer containing carbon "expanded" alpha phase is obtained.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the ratio of acetone and hydrogen introduced in step 4 is 2:4, and the pressure in the furnace is 300Pa. Other steps and parameters are the same as those in Embodiment 1. By means of this embodiment a modified layer containing carbon "expanded" alpha phase is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com